Device for locking traveler of tyre builder

A tire building machine and locking device technology, applied to tires, other household appliances, household appliances, etc., can solve the problems of inconsistent stretching of the bladder, affecting the symmetry and balance of the tire, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

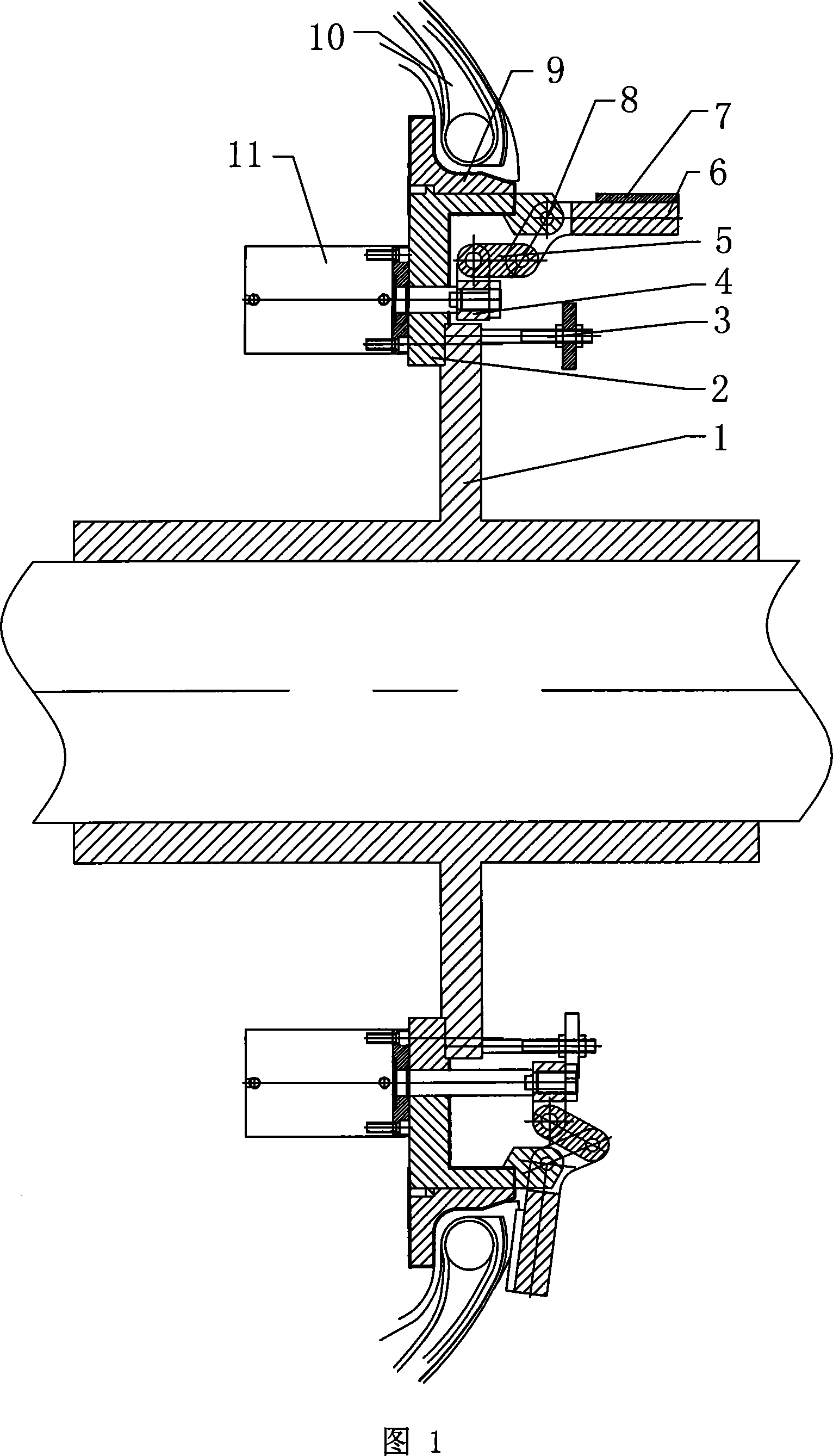

[0016] The embodiment of the traveler locking device of the tire building machine of the present invention is shown in Figure 1. The sliding flange sleeve 1 is installed on the main shaft of the shaping drum of the second section of the tire building machine, and is driven and fixedly connected with the inner shaft screw of the main shaft. The outer positioning table of the flange sleeve 1 is fixedly connected with the inner positioning table of the annular connecting sleeve 2. The outer circumference of the connecting sleeve is evenly fixed with 4 driving cylinders 11, and the connecting sleeve 2 has a through hole matching the driving cylinder 12. The piston rod passes through the hole of the connecting sleeve 2, and is respectively fixed to a push plate 4 inside the connecting sleeve 2. The outer edge of the connecting sleeve 2 is fixed to the easily removable positioning chuck 9, and the stop of the positioning chuck 9 Towards the center of the shaping drum; 4 connecting rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com