Patents

Literature

42results about How to "Fast and accurate alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

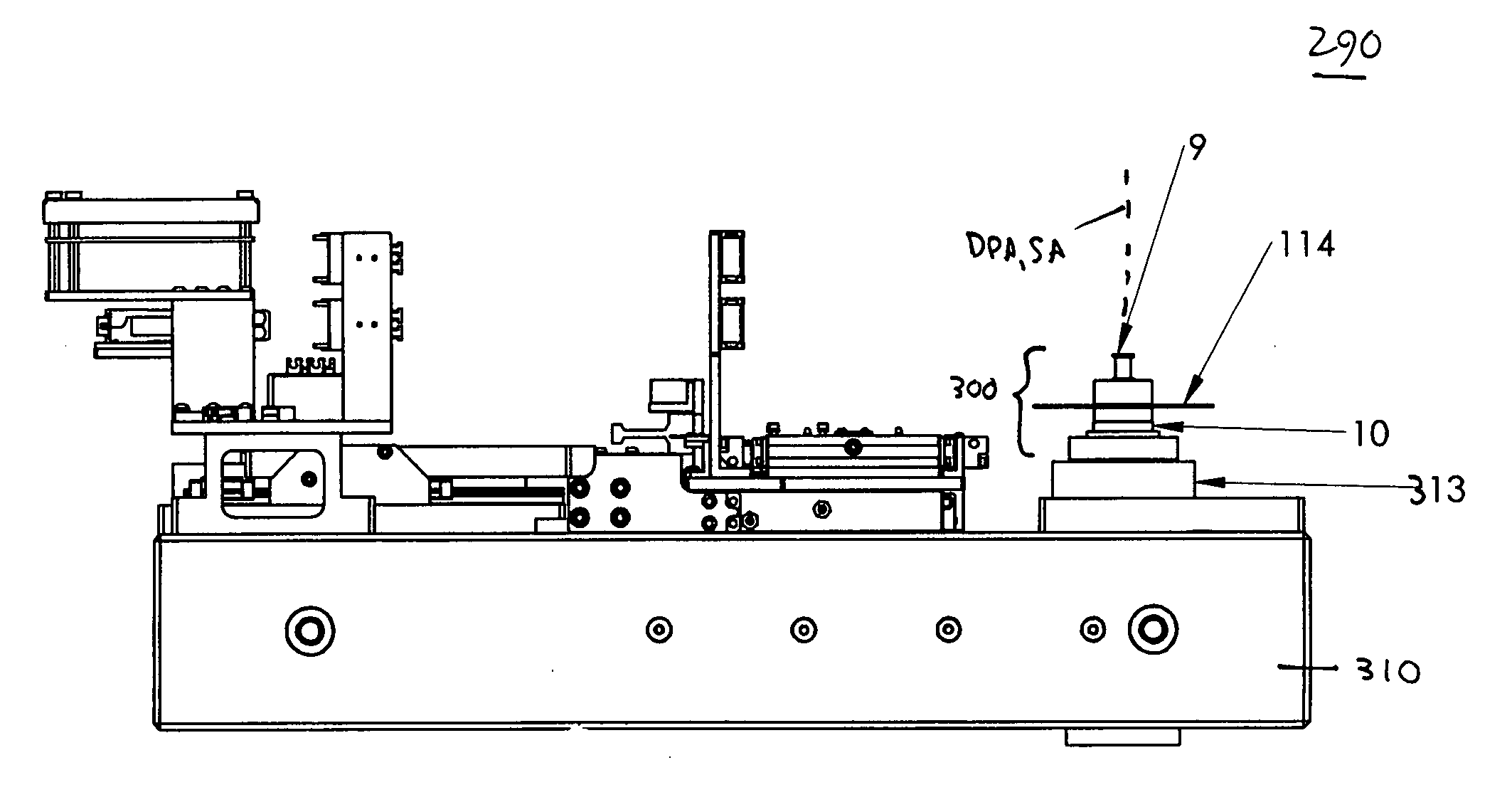

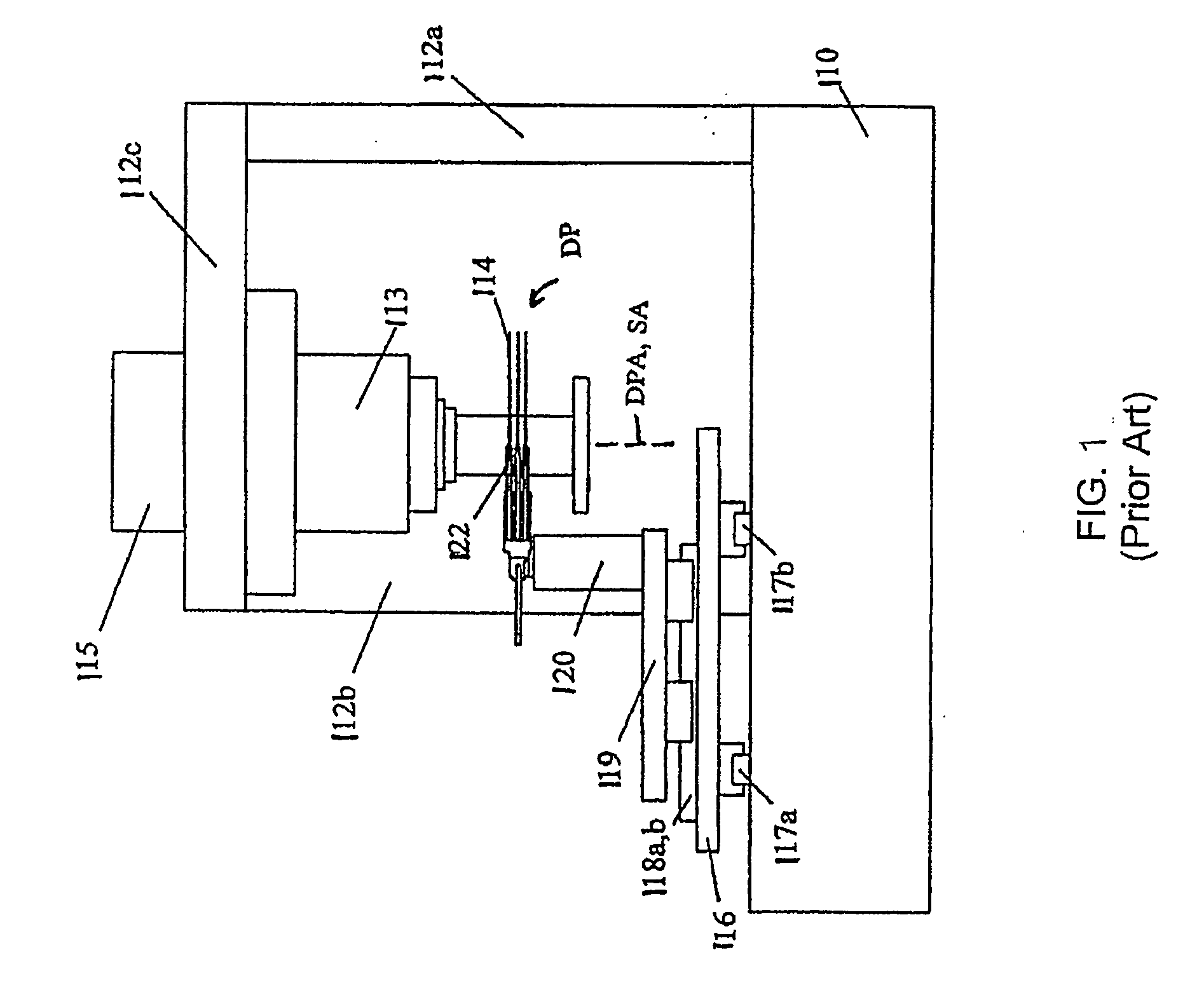

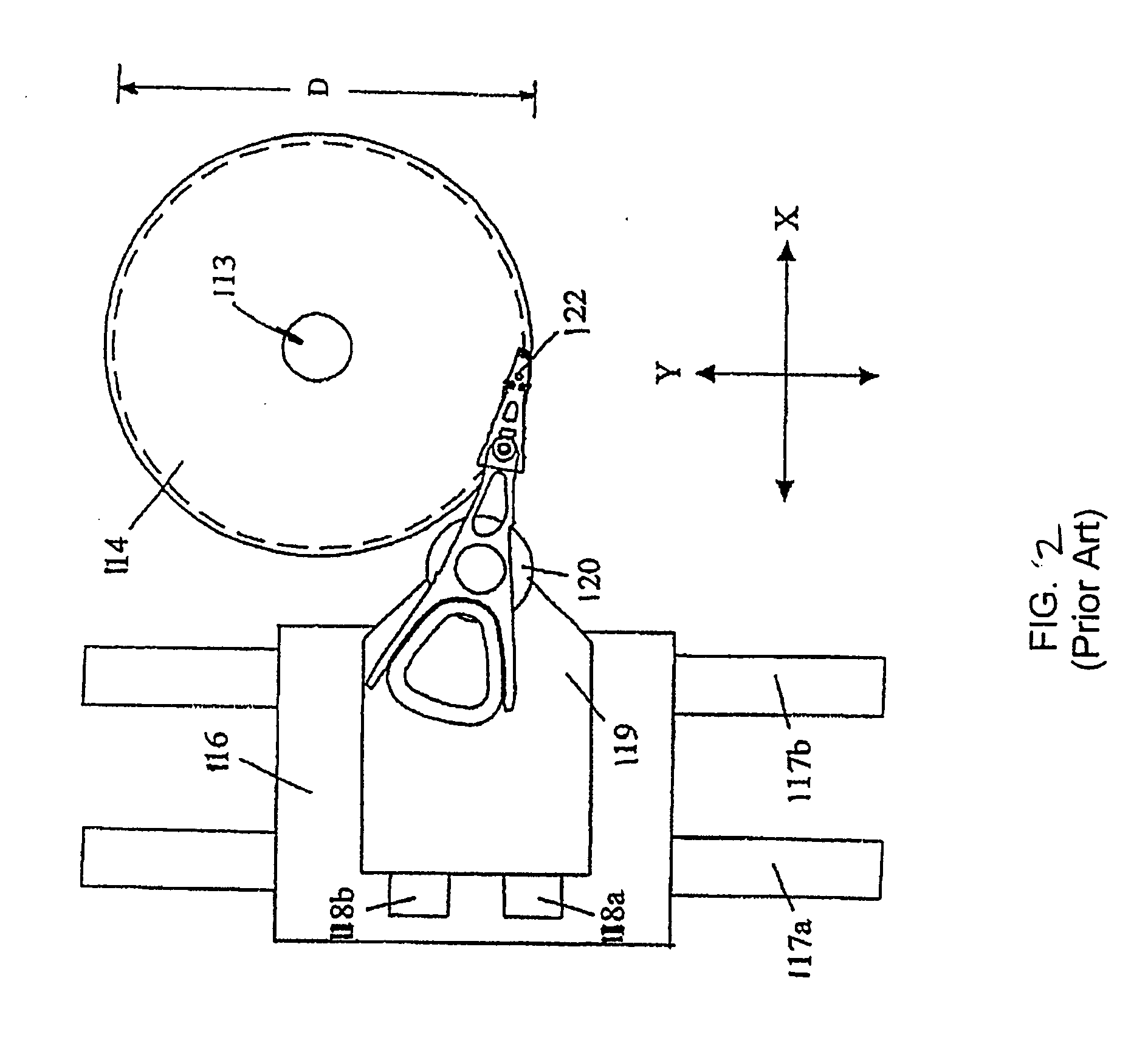

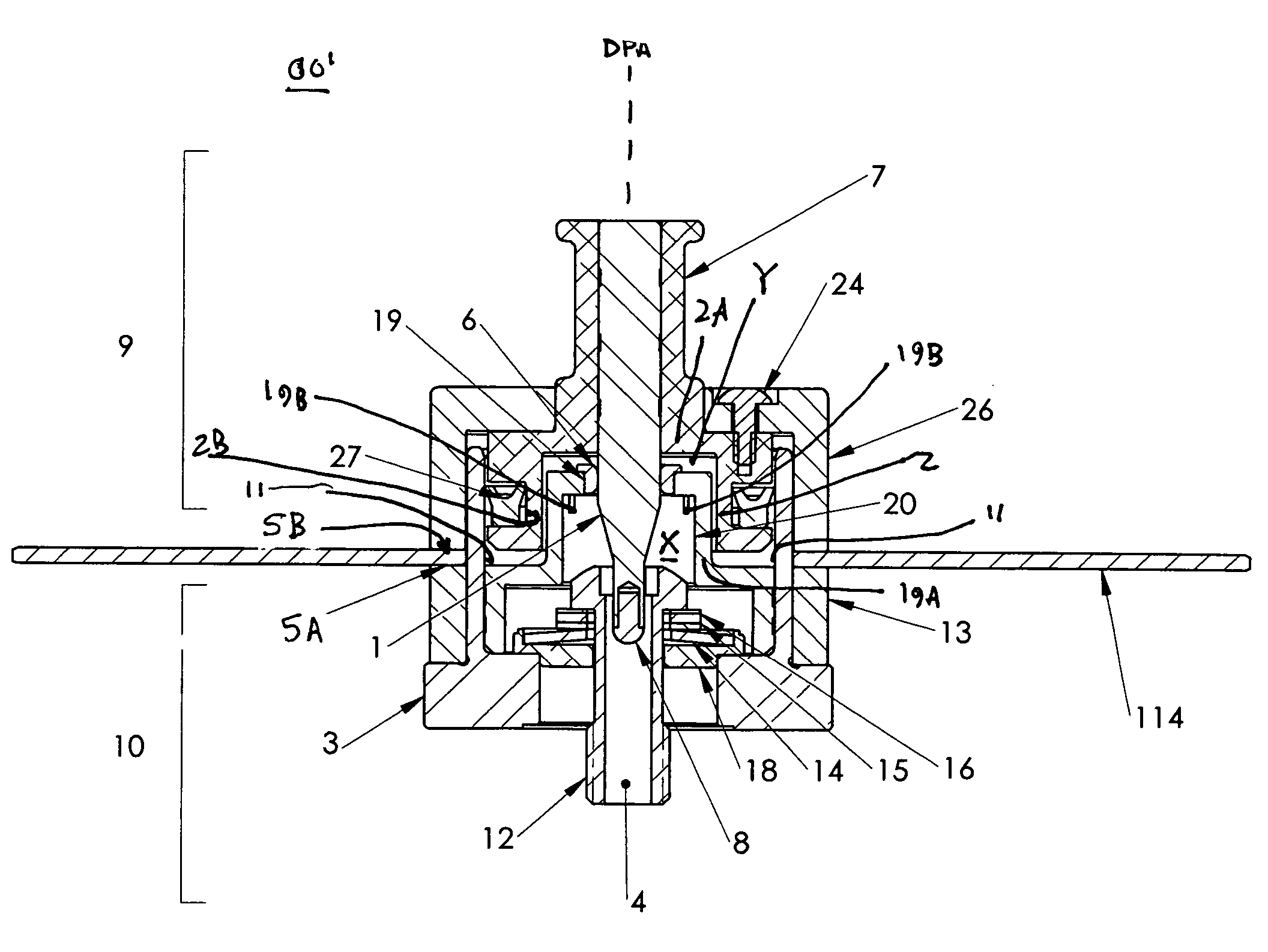

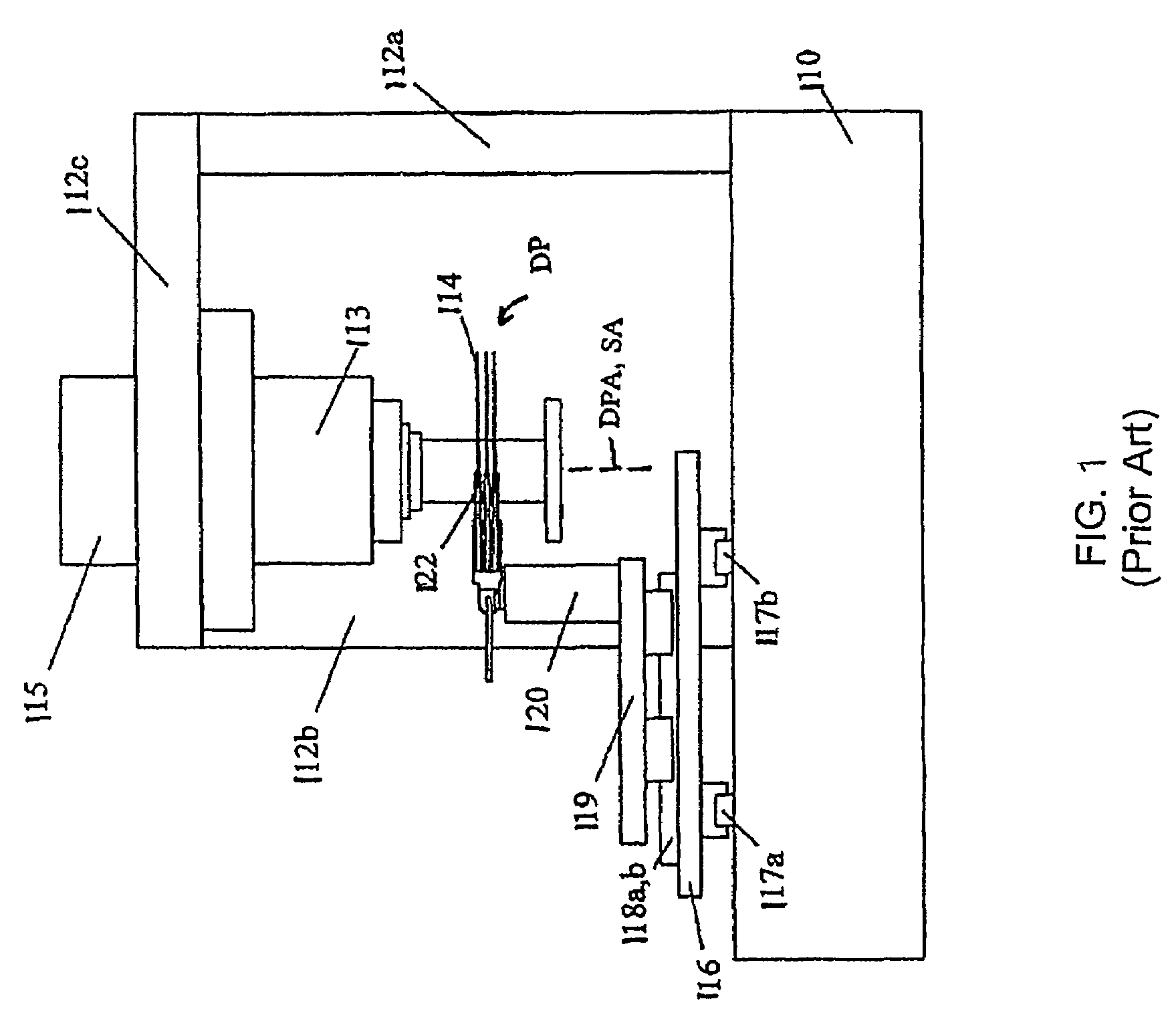

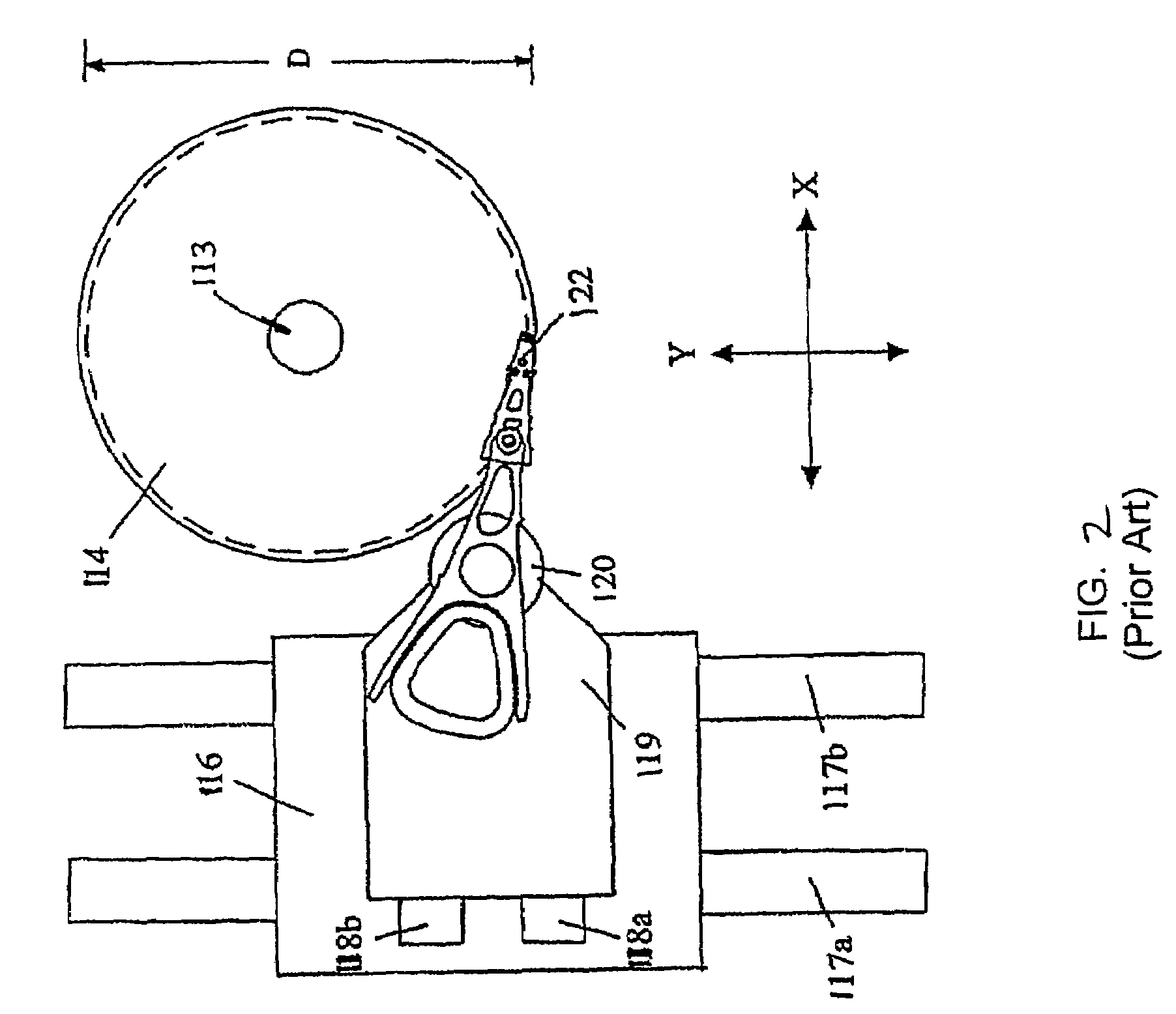

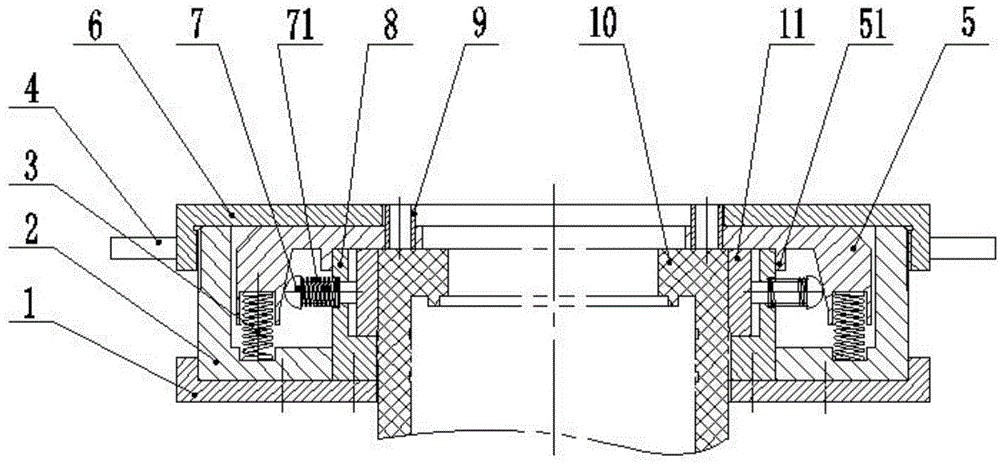

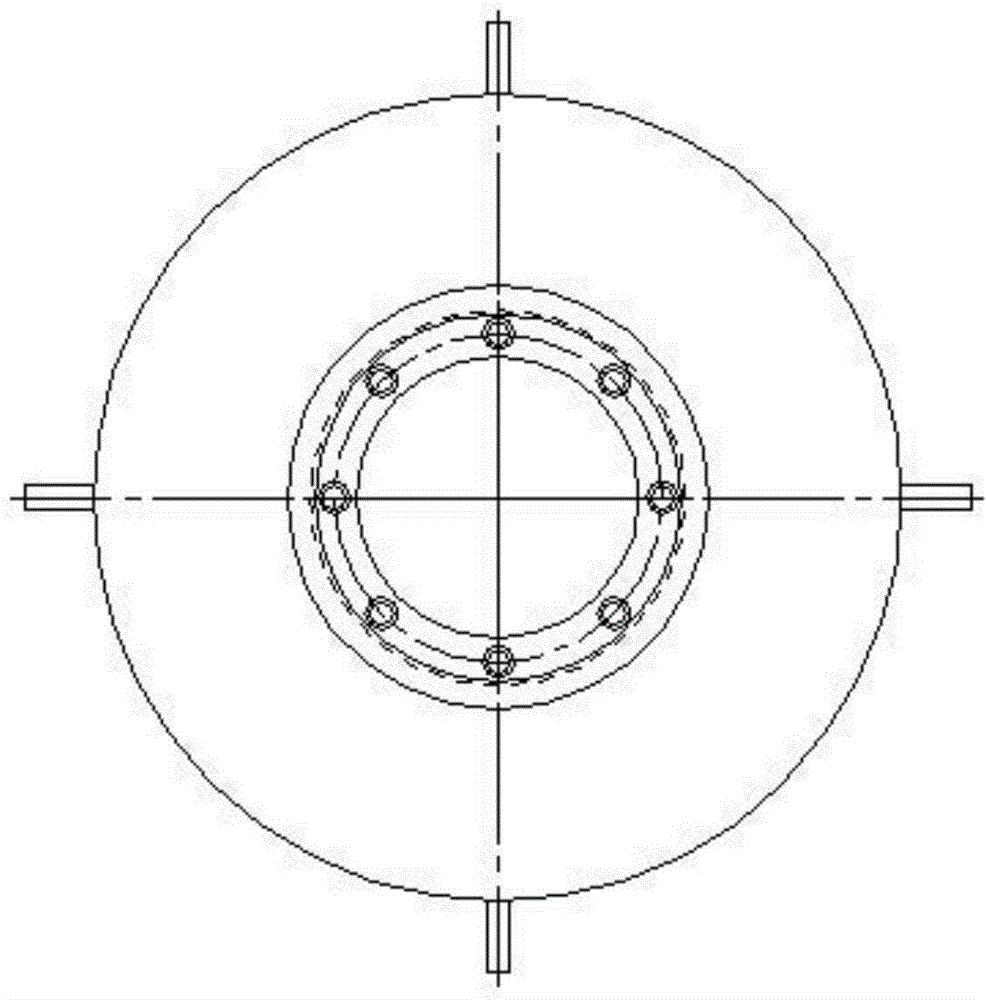

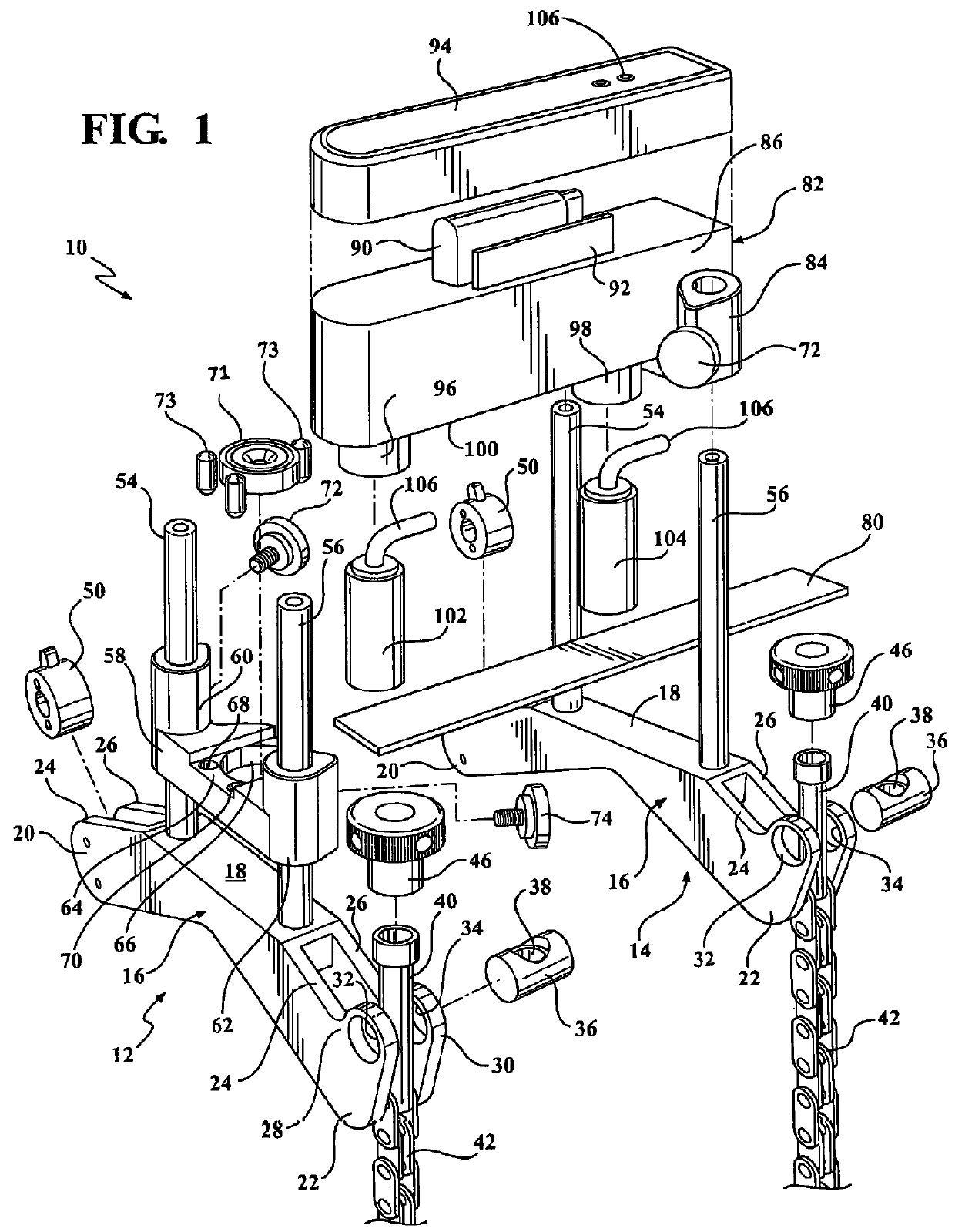

Vacuum chuck spinstand for testing magnetic heads and disks

InactiveUS20070018640A1Quickly and accurately centerQuickly removeMagnetic property measurementsRecord information storagePistonMagnetic disks

A spinstand having a vacuum chuck clamping mechanism for securing magnetic discs includes a cap (9) and a base (10). A disk-to-be-clamped is held between the cap (9) and the base (10). Vacuum, applied through a port (4) in a mounting screw (12) of the base, provides the clamping force. The vacuum is held constant using a circumferential seal (27) on a piston (2) of the cap, which extends into a cylindrical countering bushing (3) extending from the base. In one form, the cap (9) is centered about a spin axis (SA) extending through the base (10), using a hardened pin (1) extending from the cap and a locating bushing (19) affixed to the base. When the cap (9) is inserted into the base (10), the pin (1) prevents a piston (2) in the cap from contacting the inside walls / sealing surface (11) of the centering bushing (3) of the base. To remove the cap, positive air pressure is applied to the air passage (4), collapsing the seal (27), and forcing the cap (9) out of the base (10) without causing wear on the seal (27) or the sealing surface (11) of the centering bushing (3).

Owner:GUZIK TECHN ENTERPRISES

Vacuum chuck spinstand for testing magnetic heads and disks

InactiveUS7295002B2Easy to removeFast and accurate alignmentRecord information storageMagnetic property measurementsEngineeringSpin axis

A spinstand having a vacuum chuck clamping mechanism for securing magnetic discs includes a cap (9) and a base (10). A disk-to-be-clamped is held between the cap (9) and the base (10). Vacuum, applied through a port (4) in a mounting screw (12) of the base, provides the clamping force. The vacuum is held constant using a circumferential seal (27) on a piston (2) of the cap, which extends into a cylindrical countering bushing (3) extending from the base. In one form, the cap (9) is centered about a spin axis (SA) extending through the base (10), using a hardened pin (1) extending from the cap and a locating bushing (19) affixed to the base. When the cap (9) is inserted into the base (10), the pin (1) prevents a piston (2) in the cap from contacting the inside walls / sealing surface (11) of the centering bushing (3) of the base. To remove the cap, positive air pressure is applied to the air passage (4), collapsing the seal (27), and forcing the cap (9) out of the base (10) without causing wear on the seal (27) or the sealing surface (11) of the centering bushing (3).

Owner:GUZIK TECHN ENTERPRISES

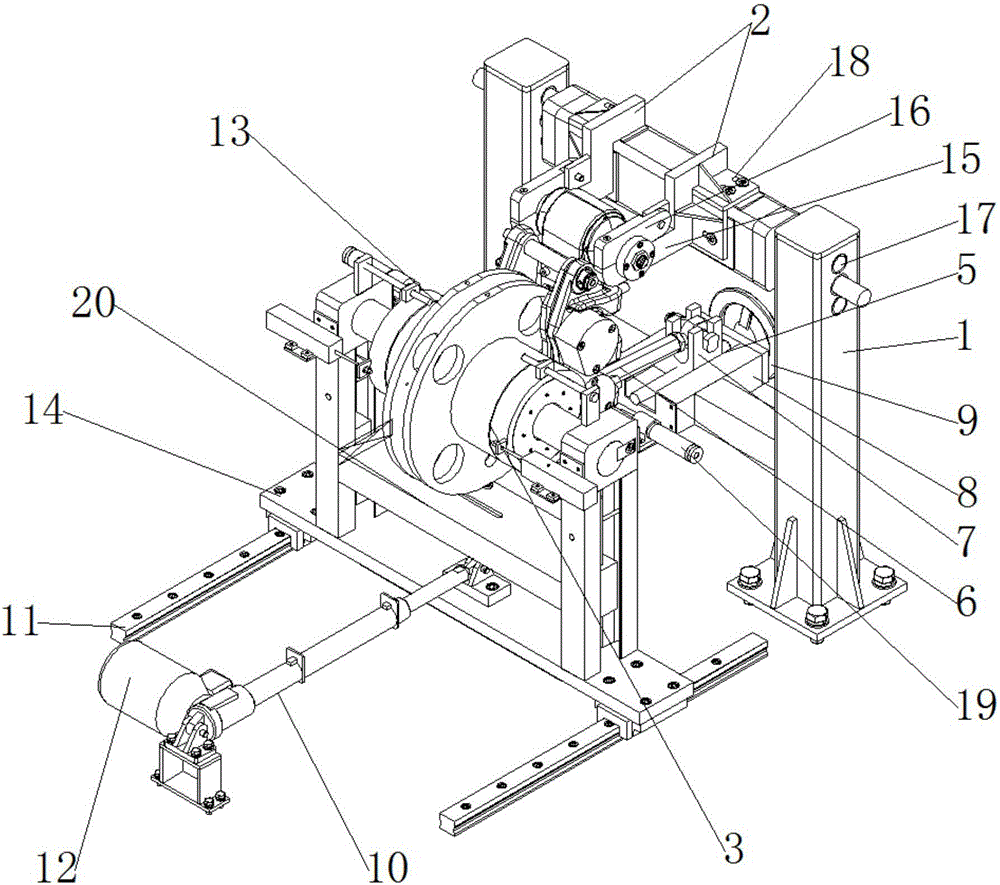

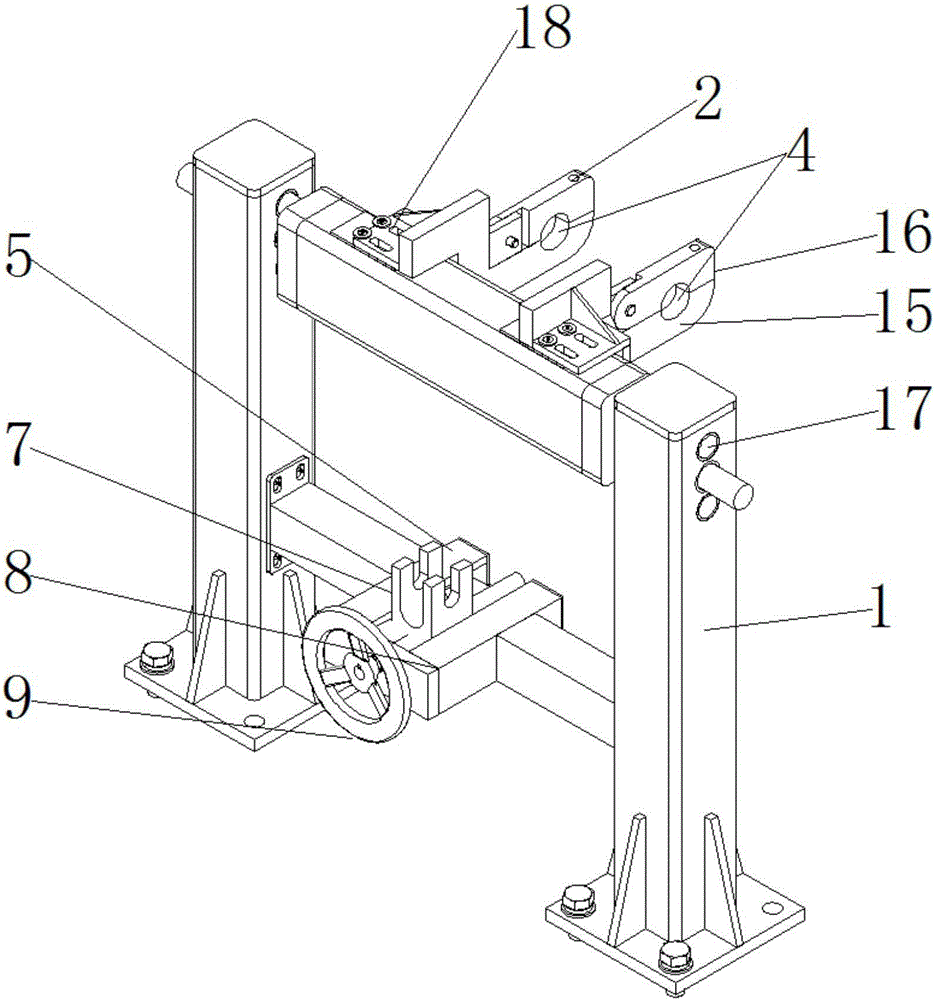

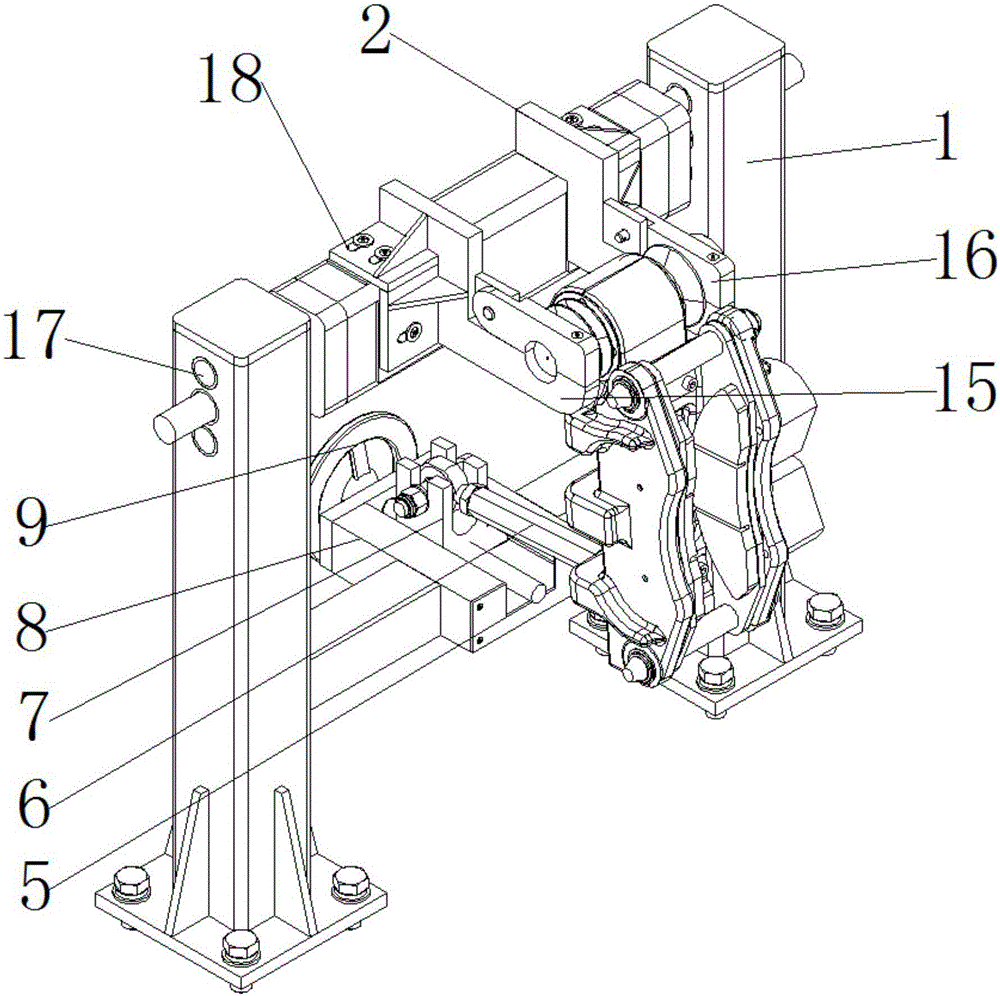

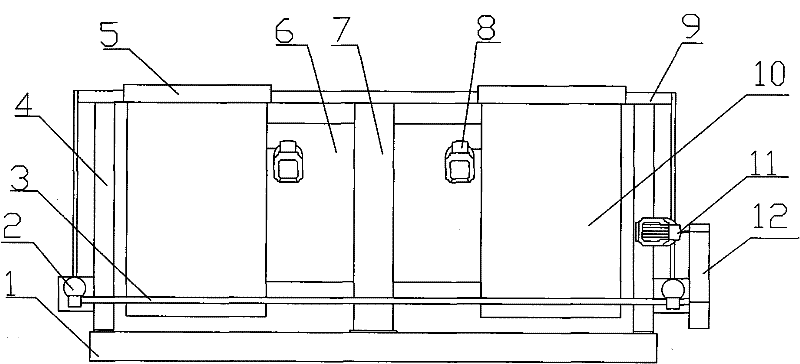

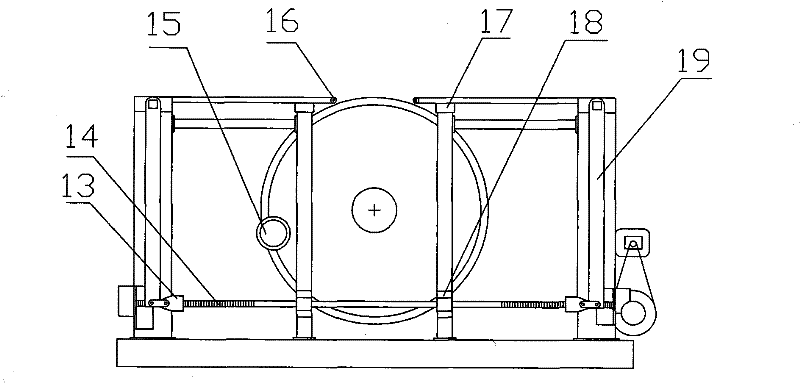

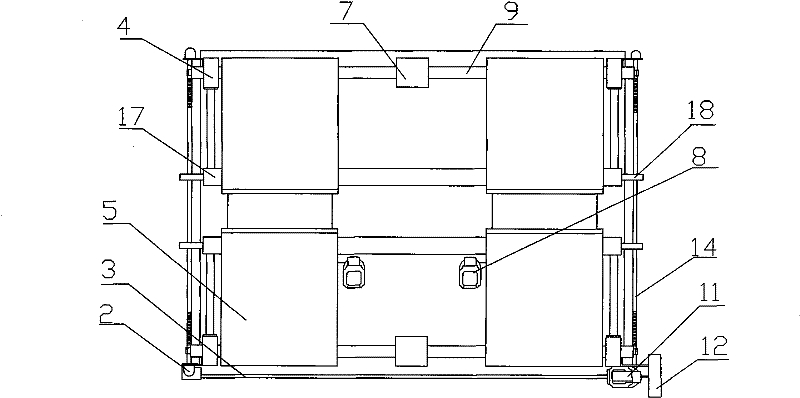

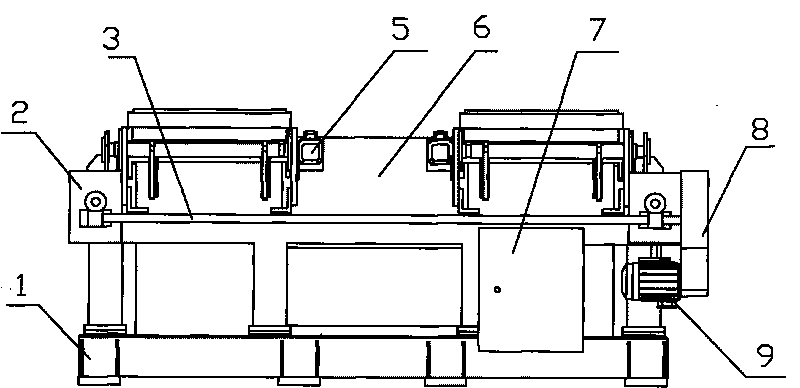

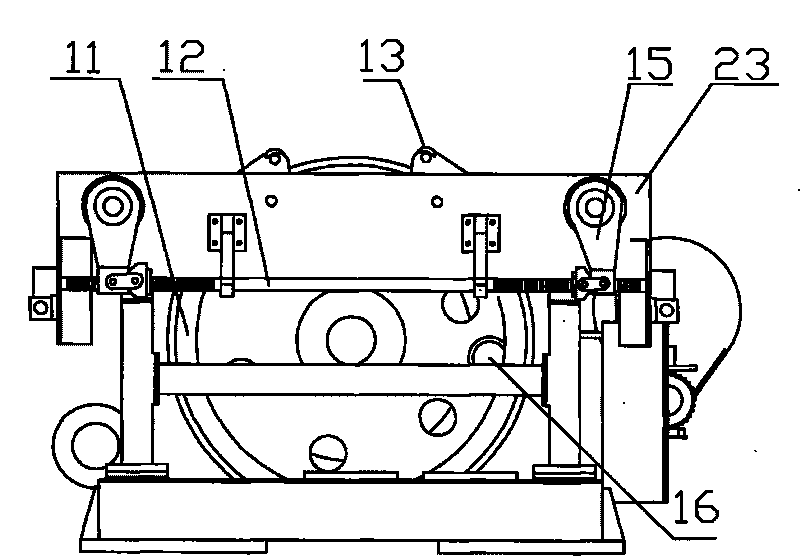

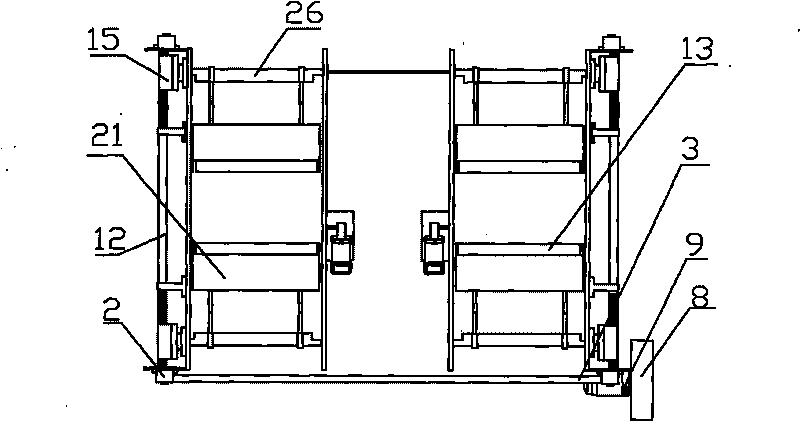

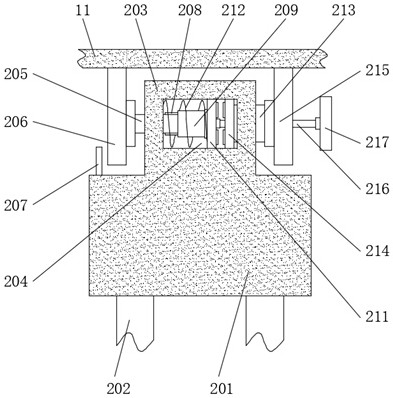

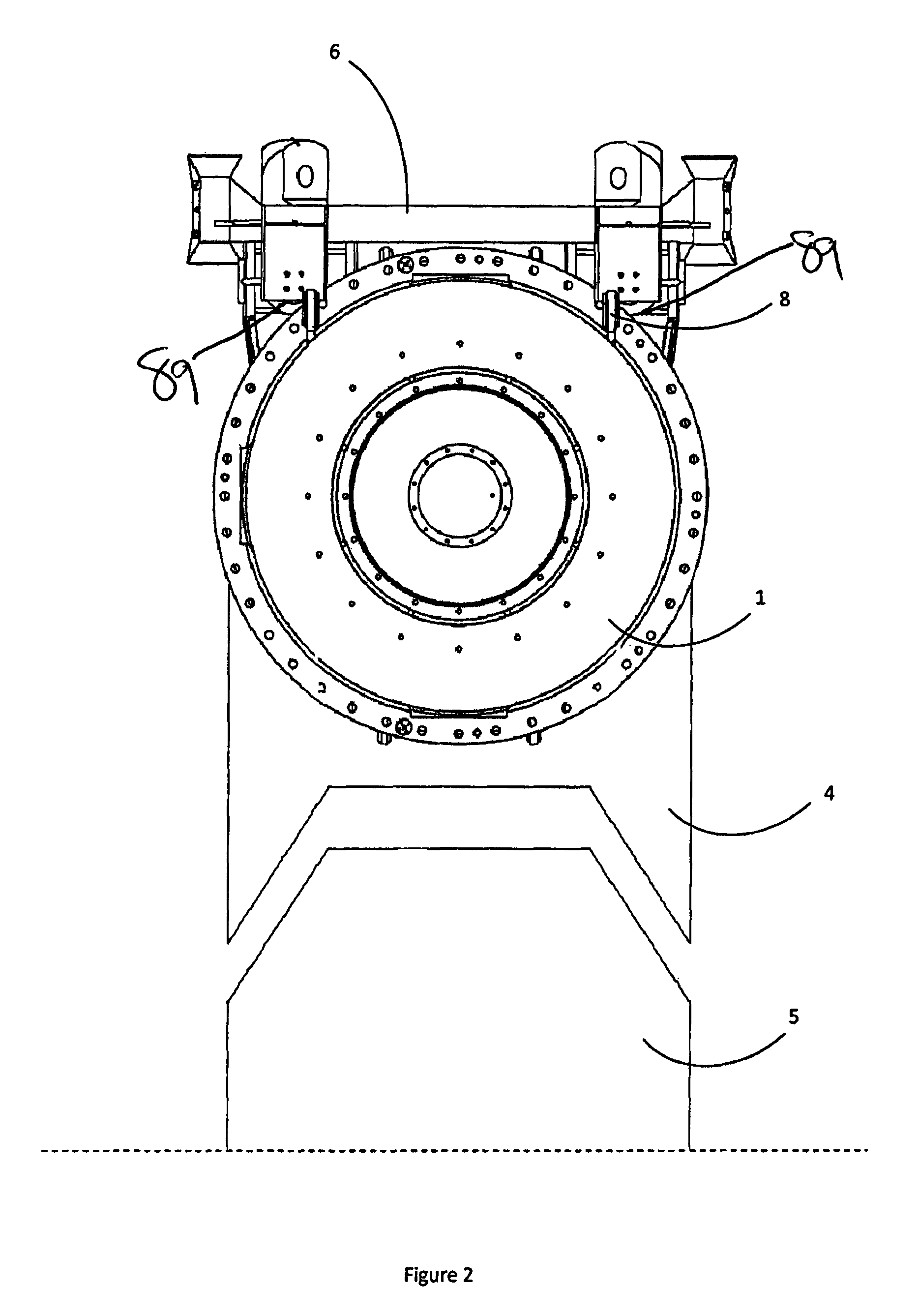

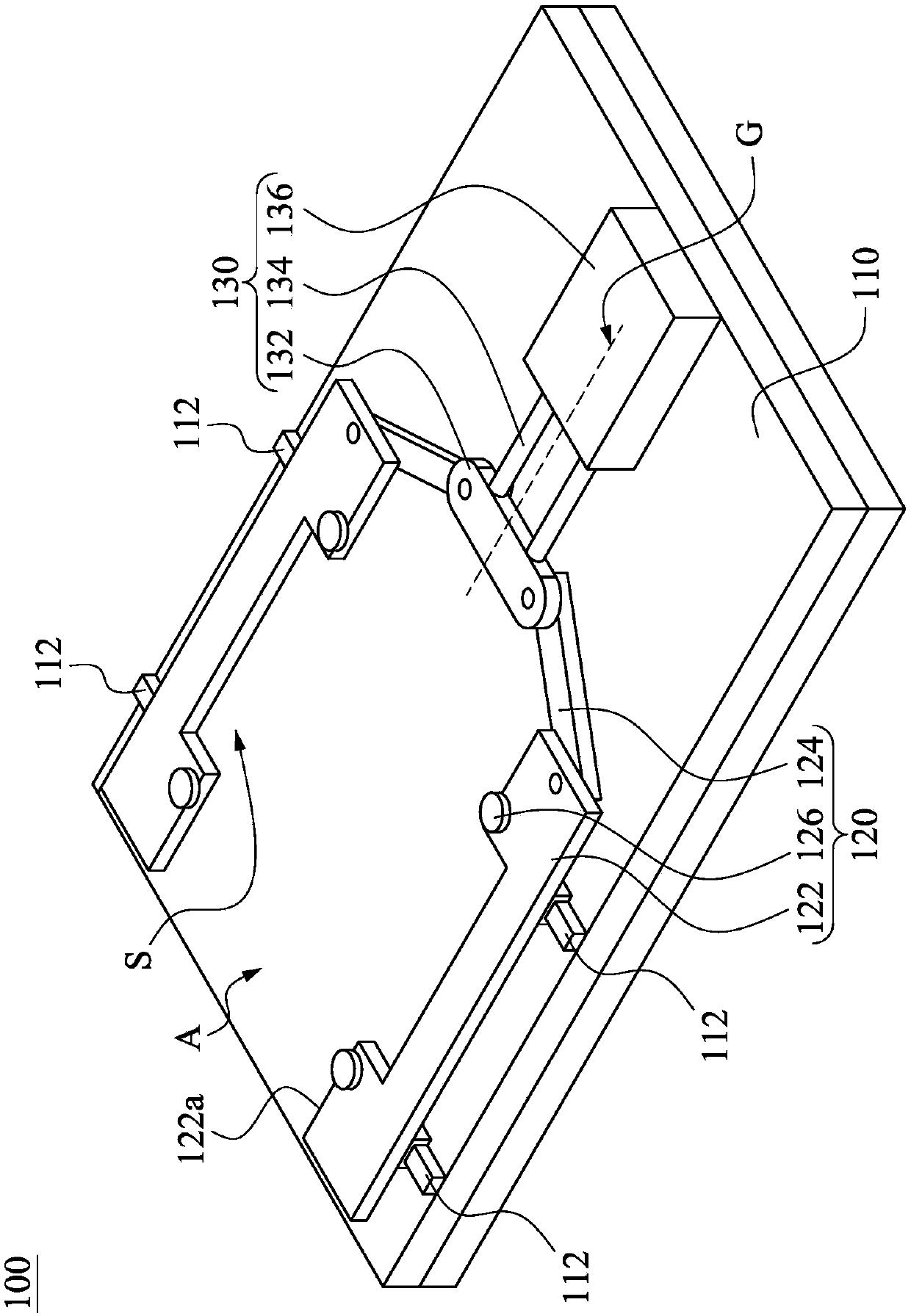

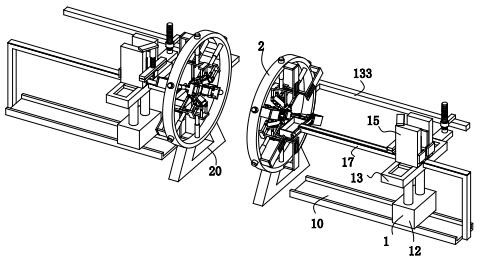

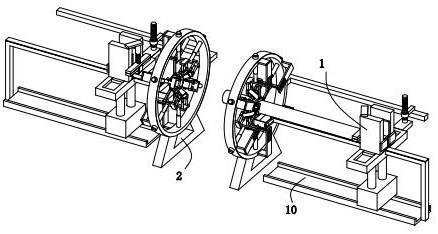

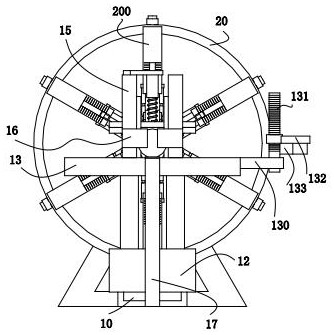

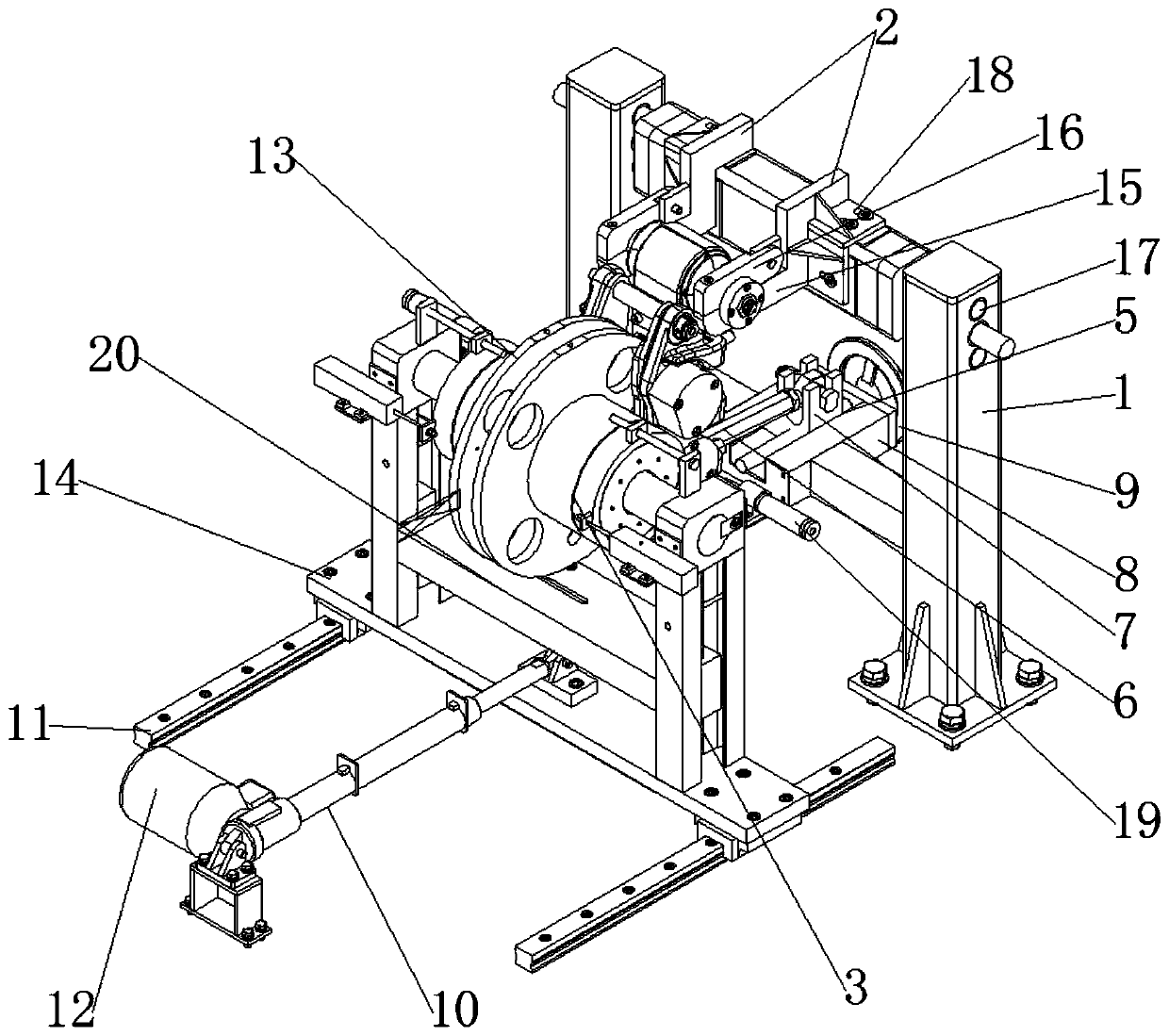

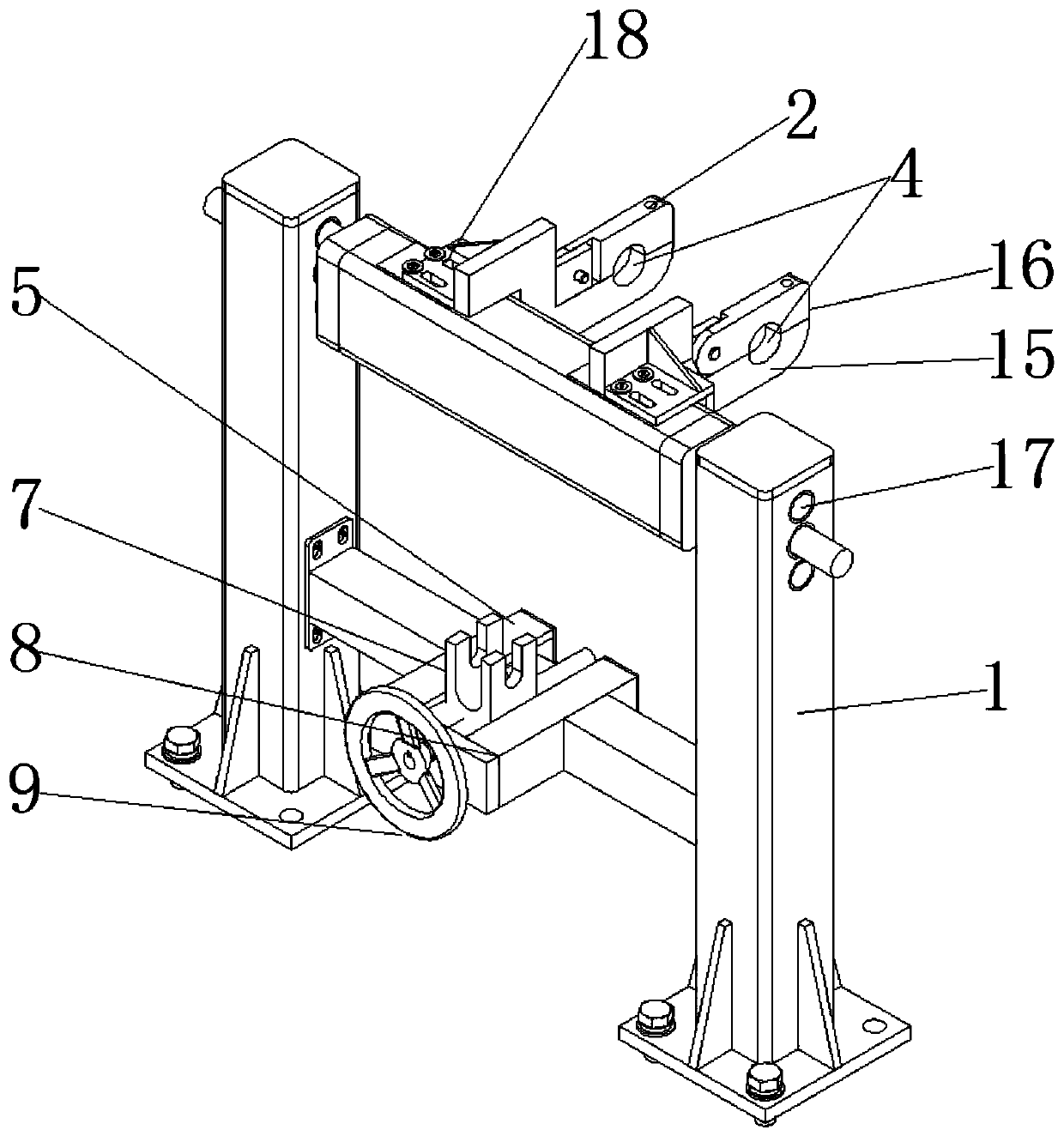

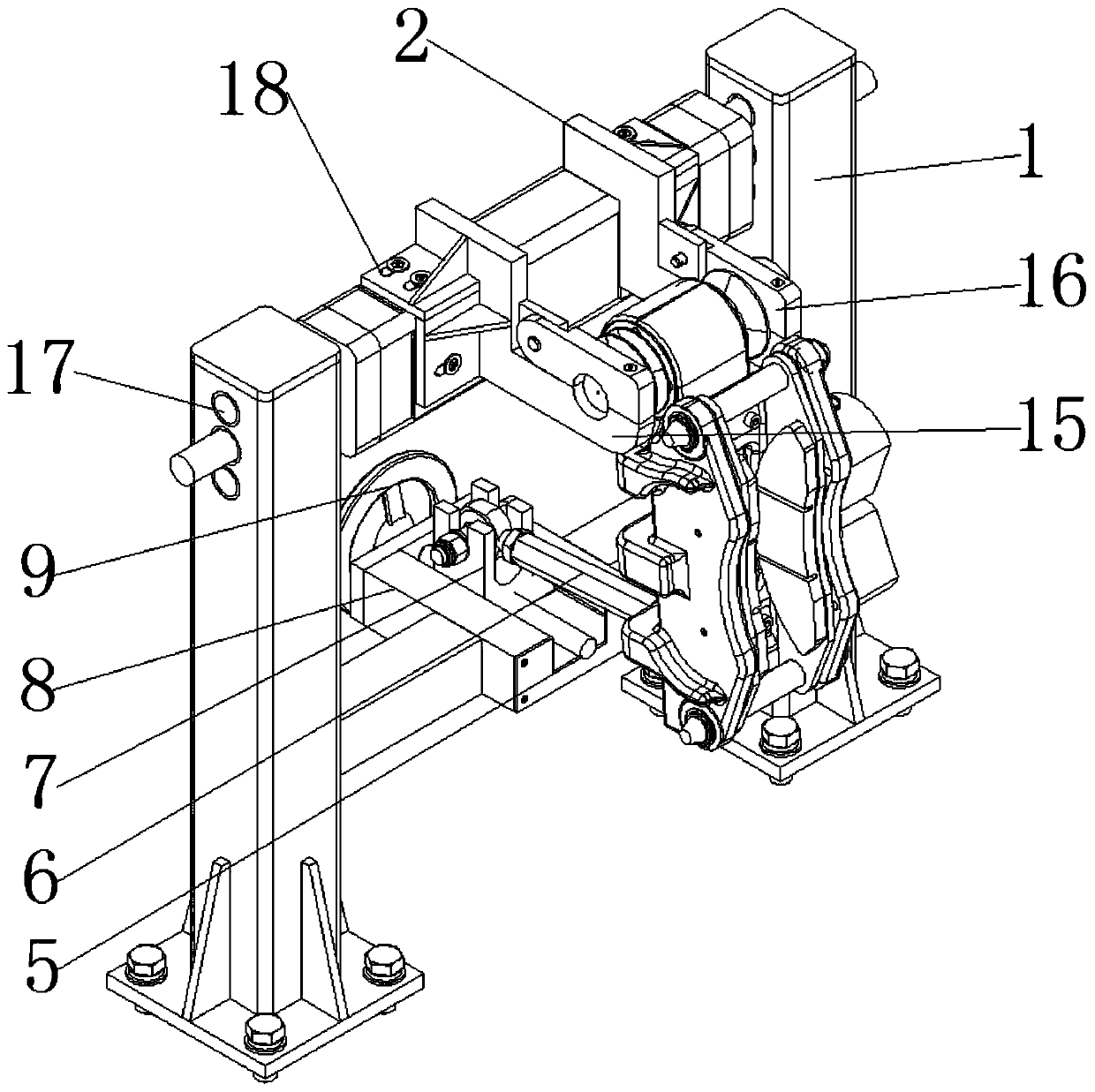

Brake clamp testbed

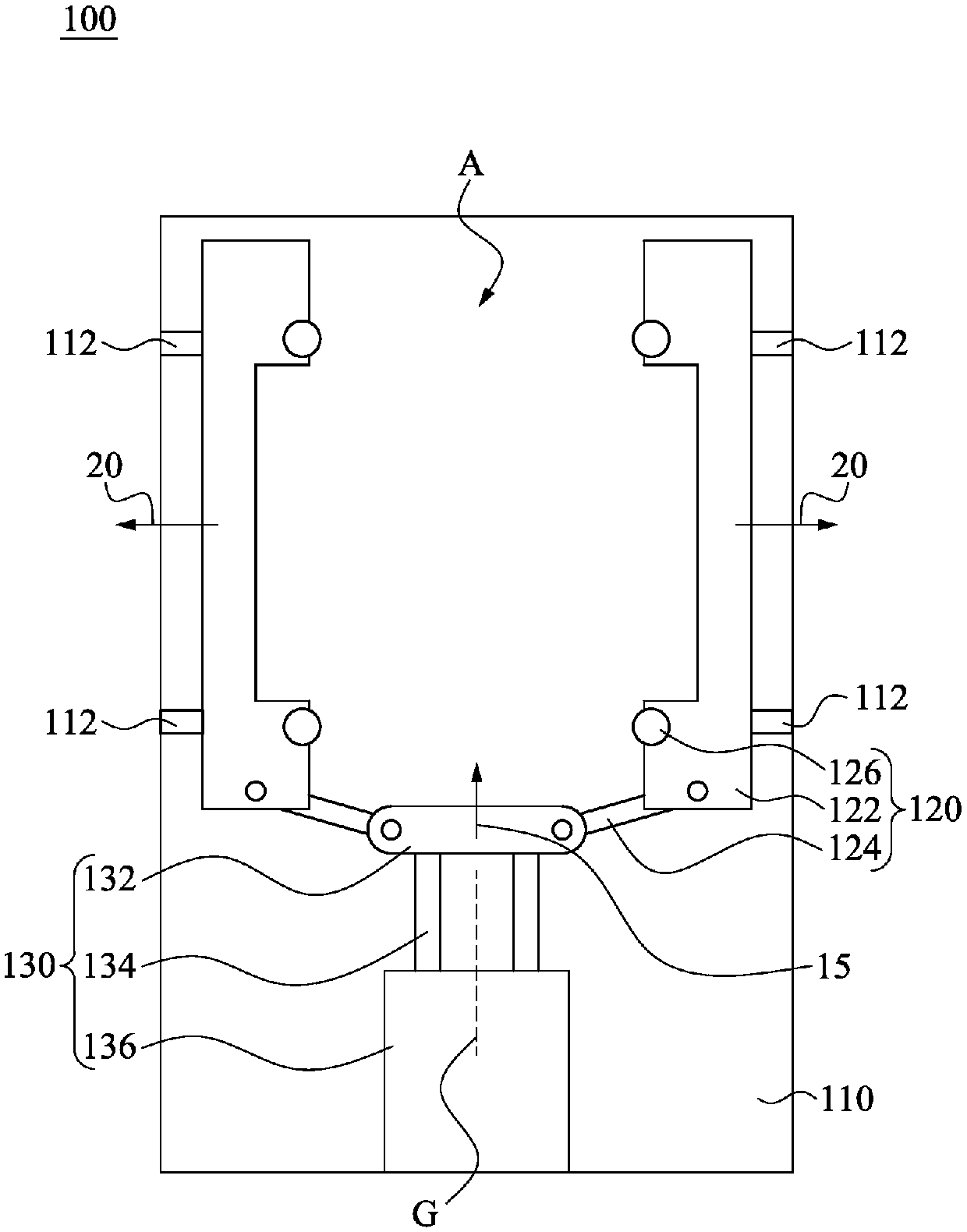

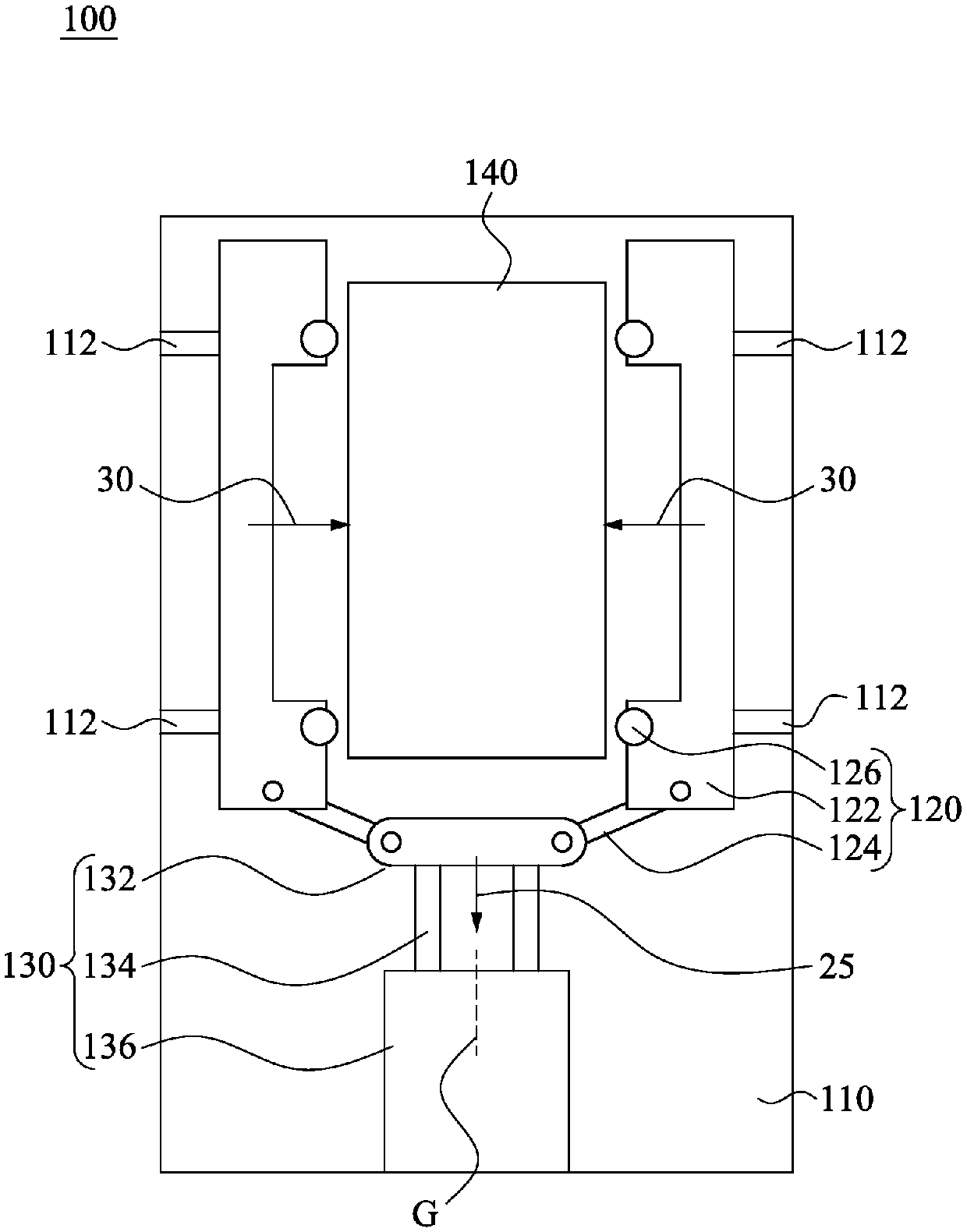

ActiveCN106680000ARealize hoistingImprove assembly efficiencyMachine part testingRailway vehicle testingReciprocating motionEngineering

The invention provides a brake clamp testbed. The brake clamp testbed comprises a support capable of fixing a brake clamp, and a rotary disc unit capable of linearly reciprocating in the direction vertical to the support. Two limiting units capable of hoisting the brake clamp are installed on the top of the support, first through holes capable of being connected with the two ends, in the clamping direction, of the brake clamp in a sleeving mode are formed in the limiting units, and the support is provided with a first driving unit capable of driving the brake clamp to rotate around the axes of the first through holes. The rotary disc unit comprises a rotary disc with the two side faces capable of being clamped by the brake clamp at the same time, and a second sliding base capable of supporting the two sides of the rotary disc. The second sliding base is connected with a second driving unit capable of driving the second sliding base to linearly move. The test result is accurate, and the assembly efficiency of the brake clamp is high.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Electric power measuring machine automatically centering automobile chassis

ActiveCN101750176AReduce workloadExtended service lifeWork measurementTorque measurementElectric machineElectric power system

The invention discloses an electric power measuring machine automatically centering automobile chassis, which comprises a machine frame, wherein the middle of the machine frame is fixedly provided with a supporting shell, the middle of the which is provided with a double-shaft motor, the two output shafts of the double-shaft motor are respectively provided with a rolling drum, each of the rolling drums is provided with a centering mechanism, the centering mechanisms of the two rolling drums are arranged in the manner of bilateral symmetry, and each centering mechanism comprises a screw rod arranged vertical to the rolling drums and rotationally connected to the machine frame, and lifting mechanisms symmetrically arranged on the front and rear sides of the rolling drums. The invention uses the automatic centering mechanisms so that the vehicle is quickly and correctly centered, greatly reduces the workload of testers, saves the preparation time of tests, saves lots of miniature parts compared with the prior centering mechanism, and has simple and practical structure. A bearing mechanism driven continuously is arranged between the end part of the double-shaft motor and the rolling drum corresponding to the bearing mechanism so as to enhance the correctness of the tests and prolong the service life of the power measuring machine.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

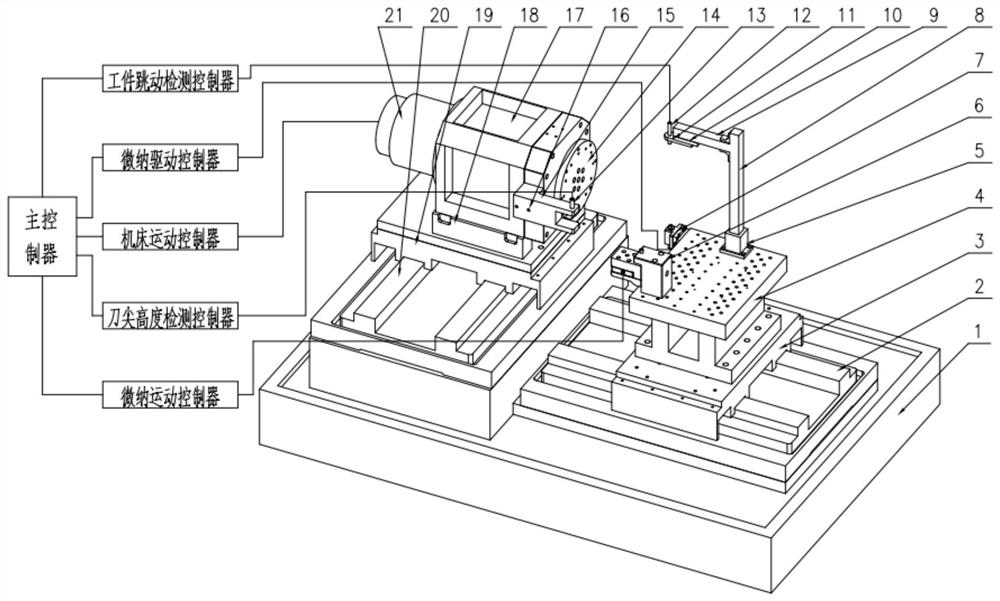

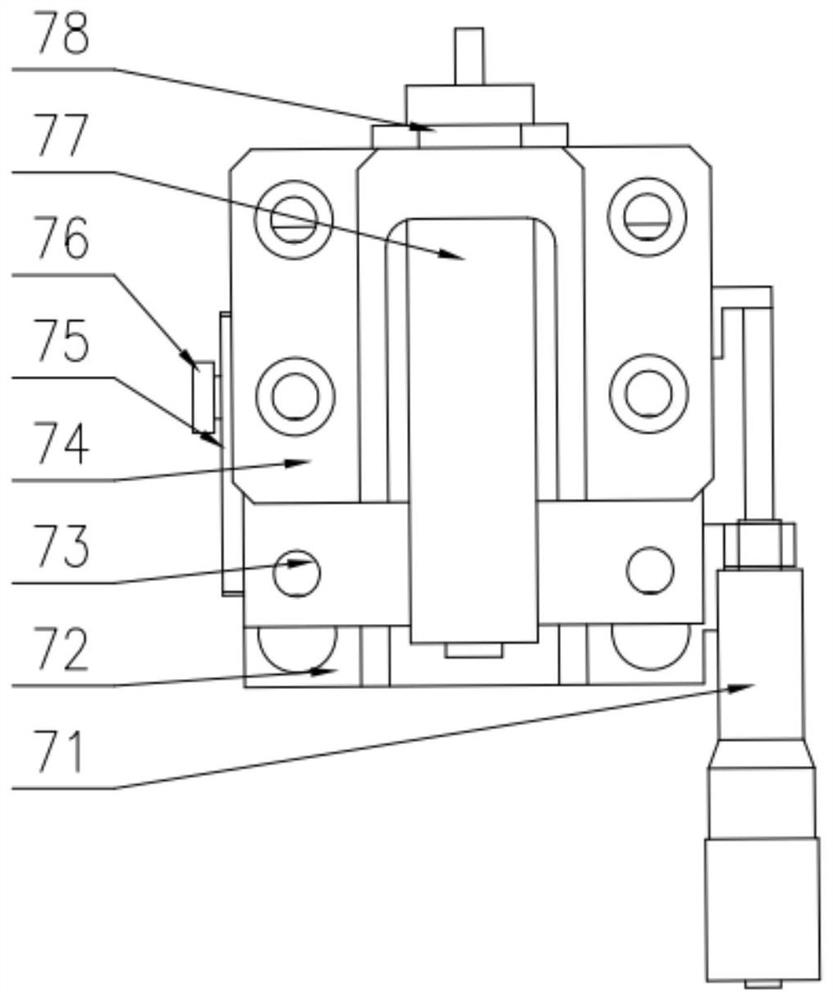

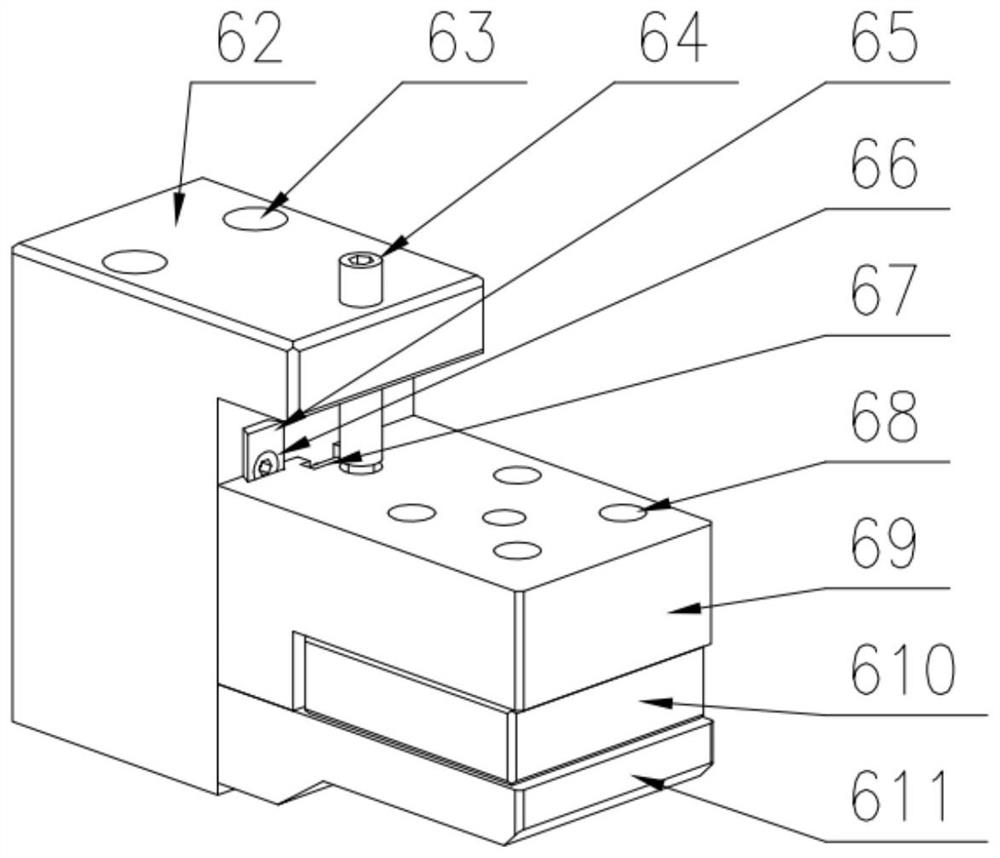

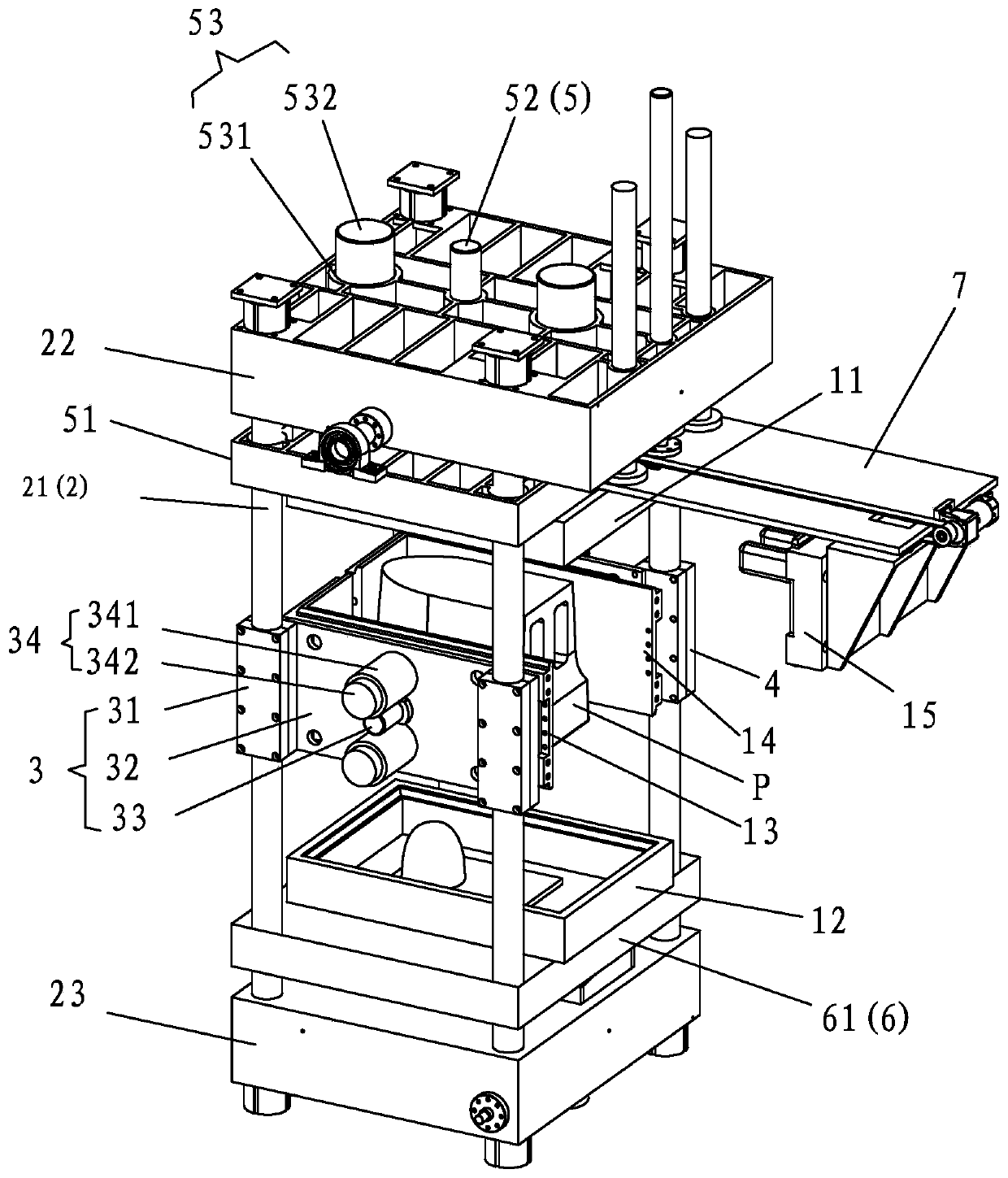

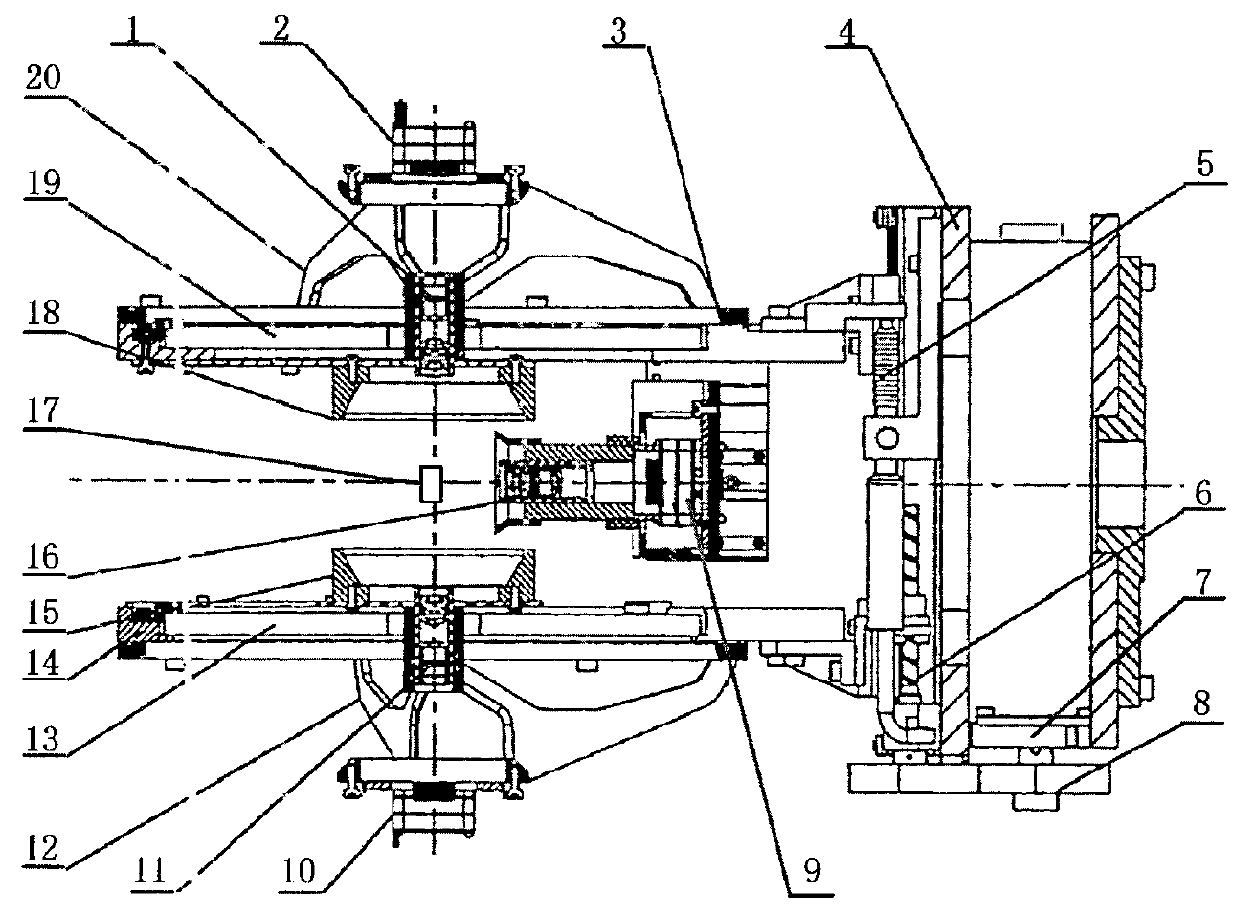

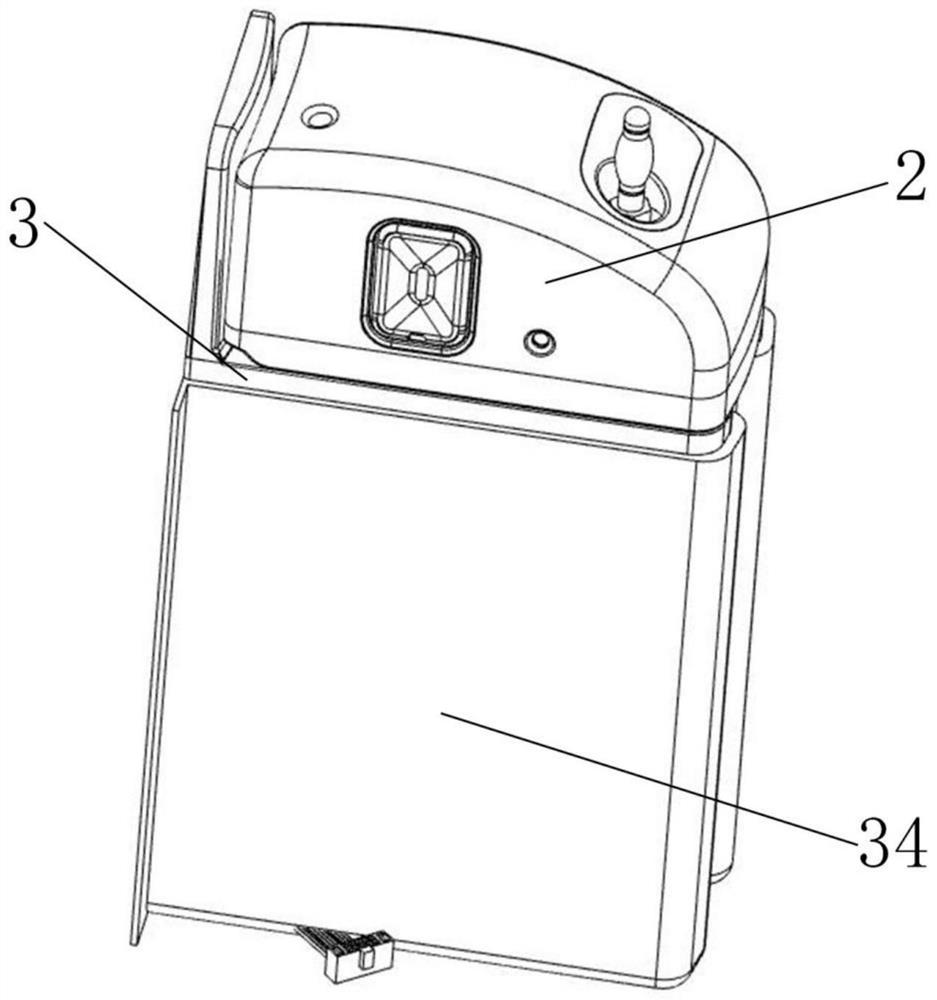

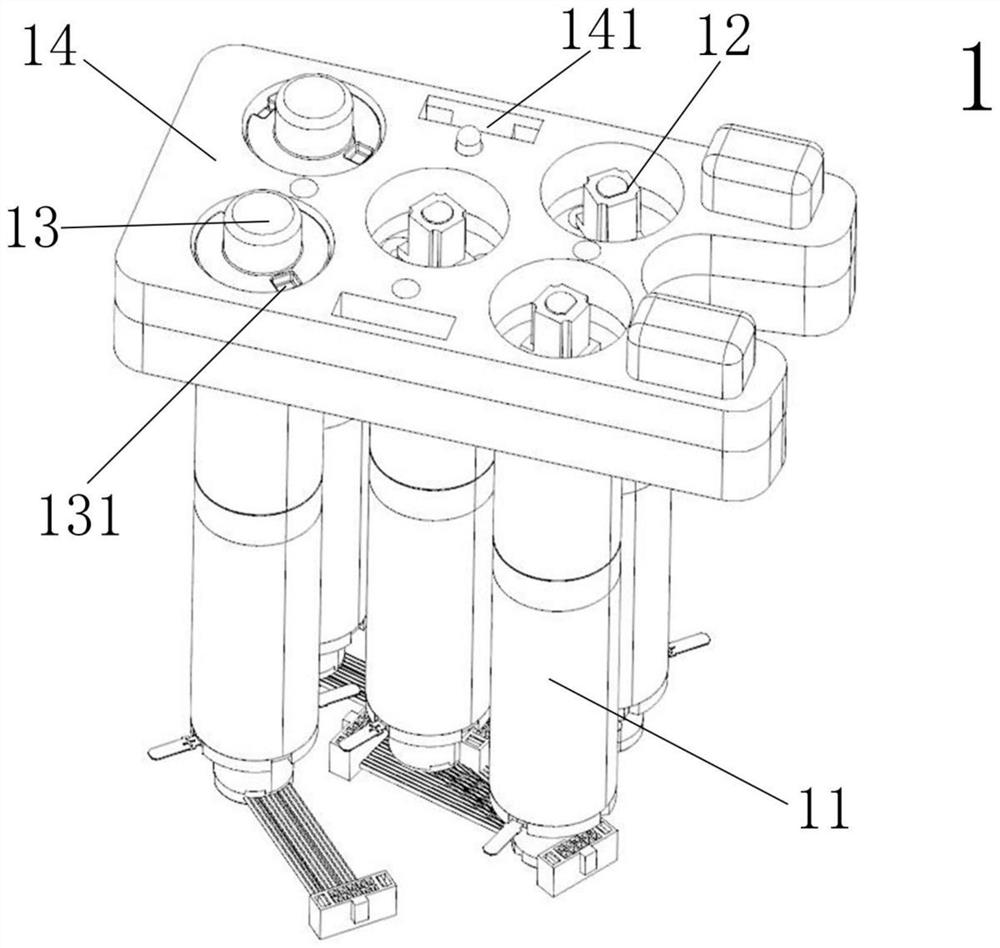

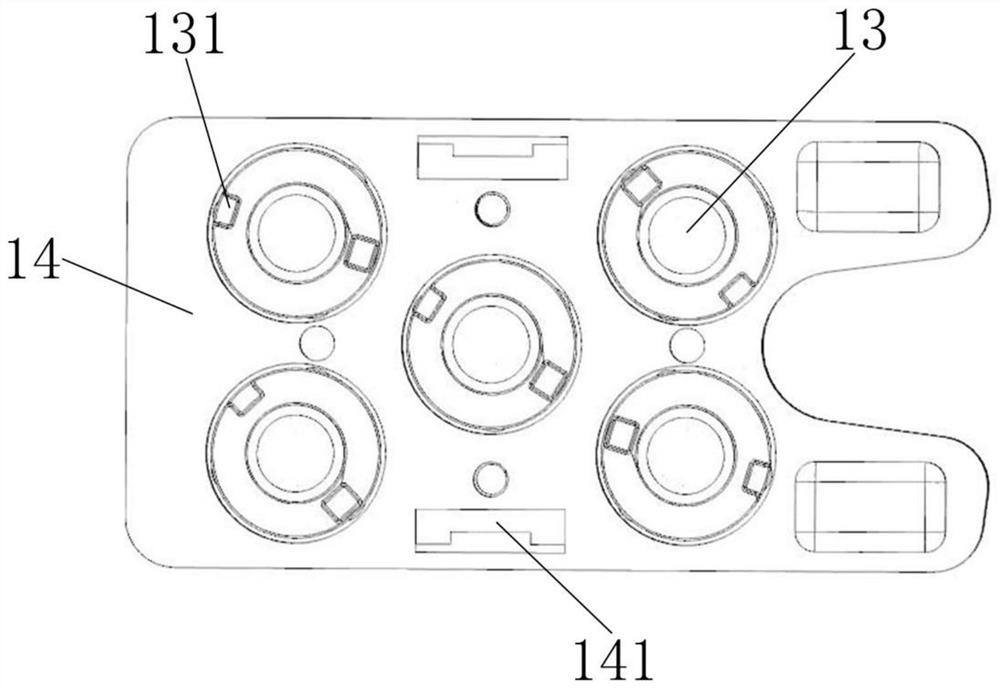

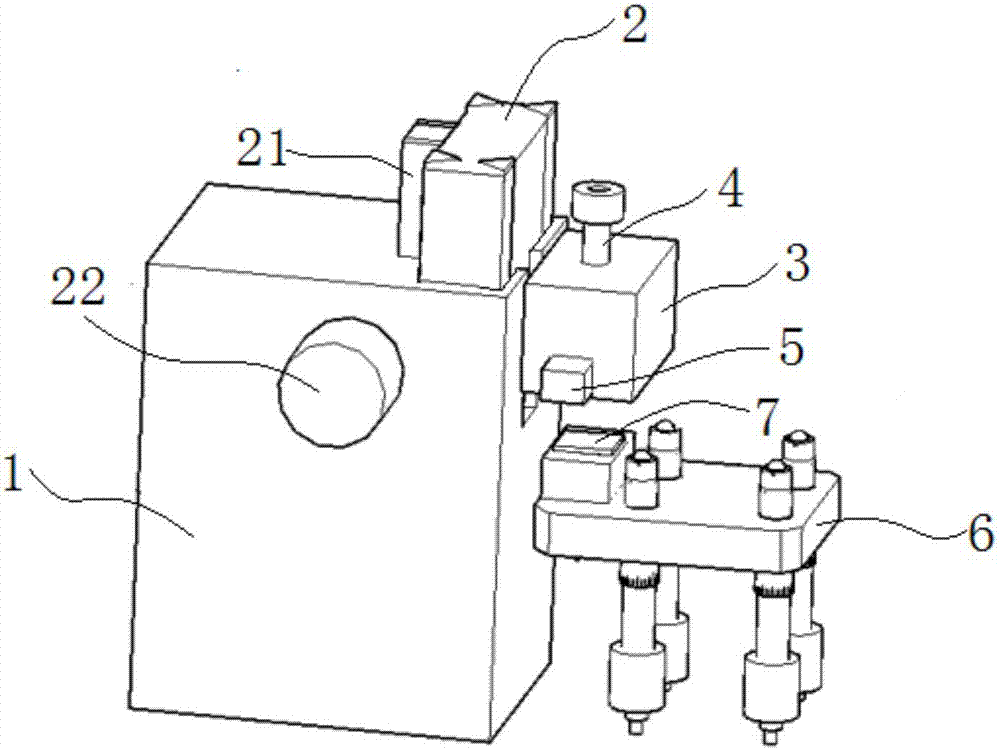

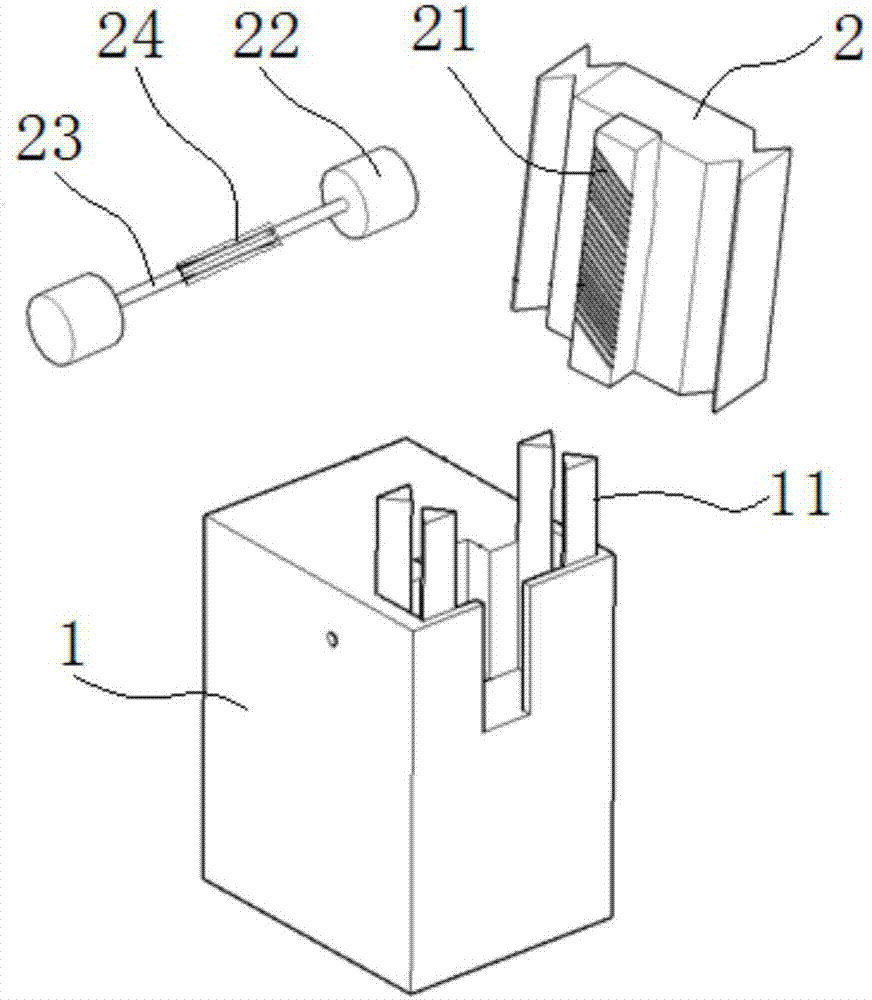

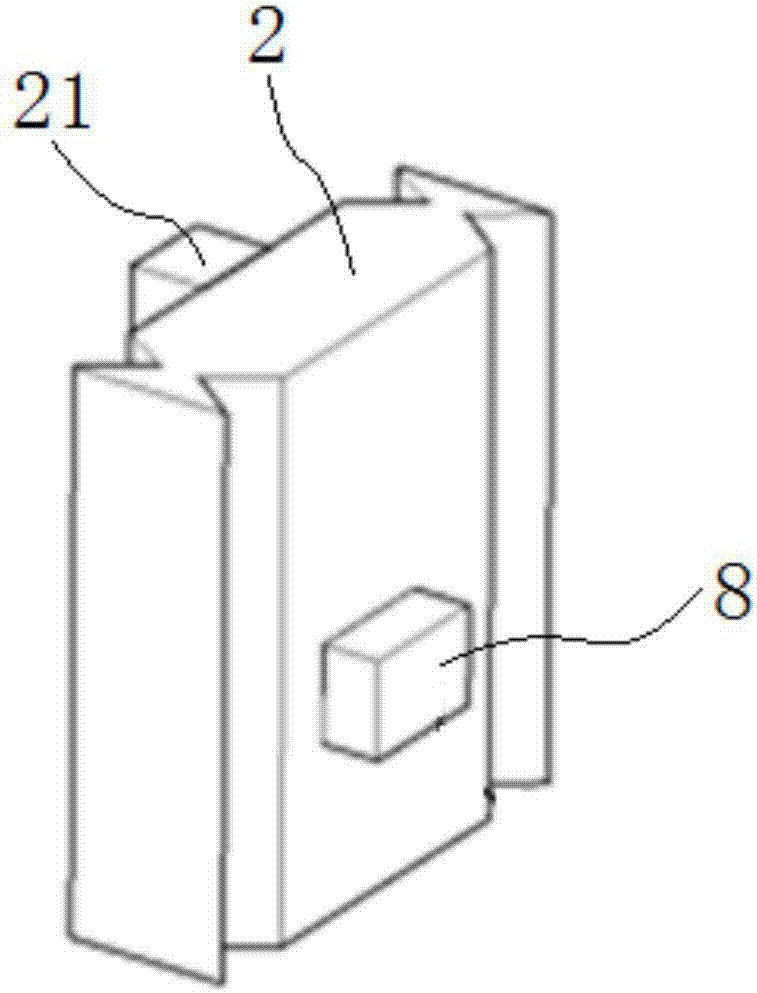

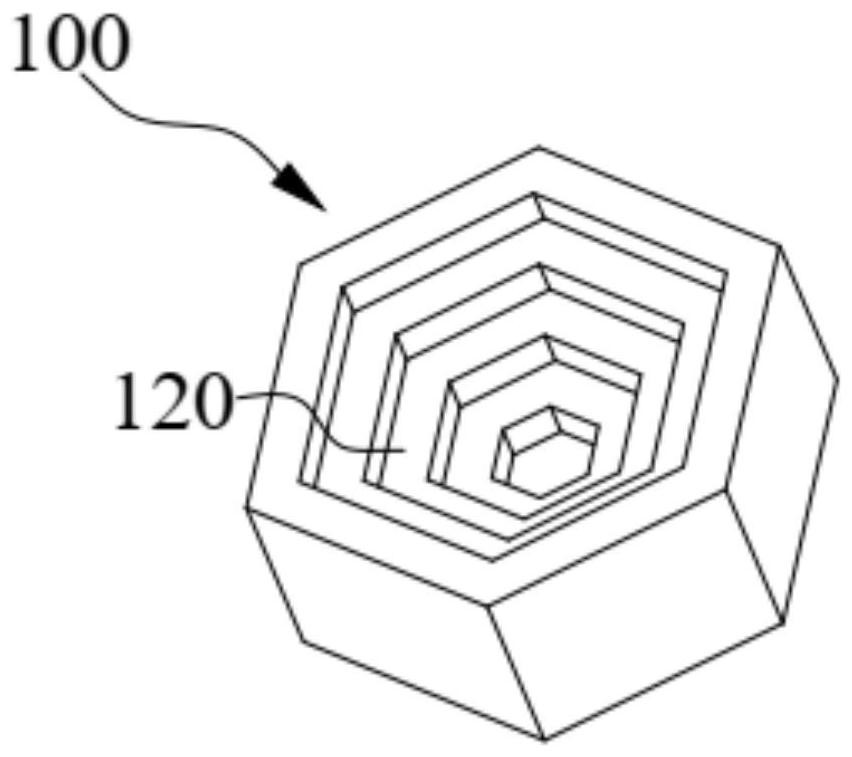

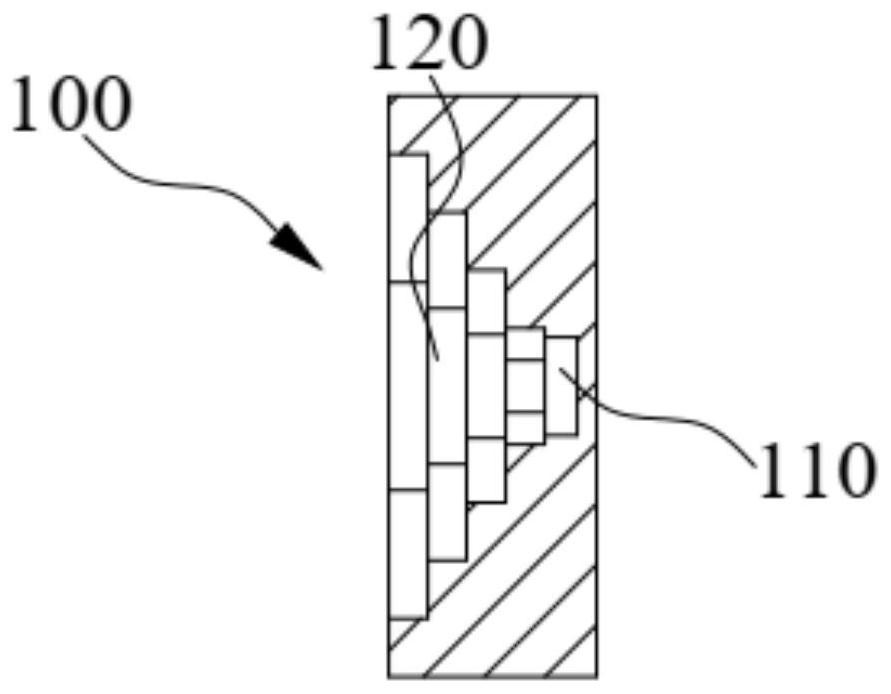

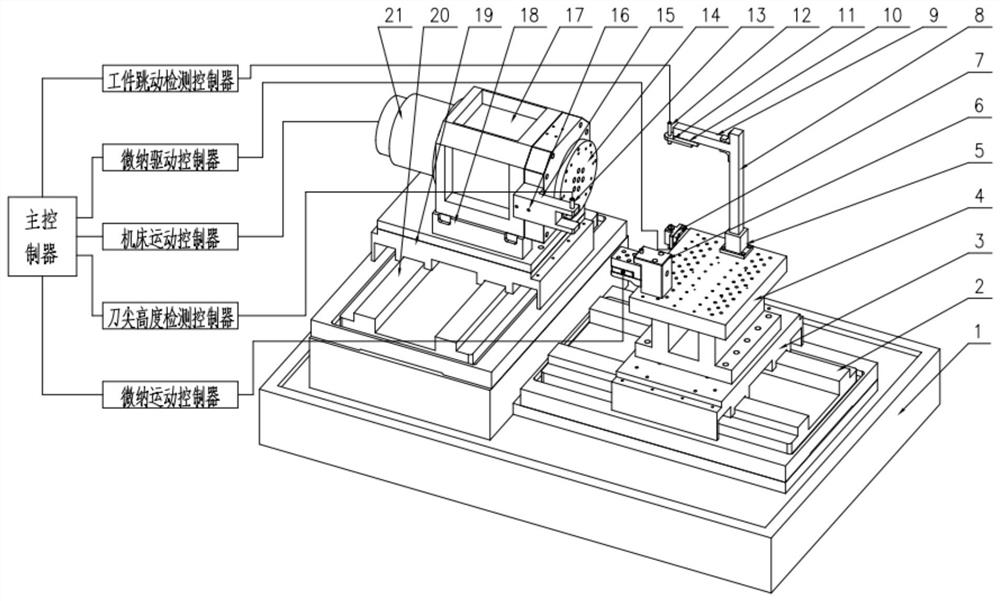

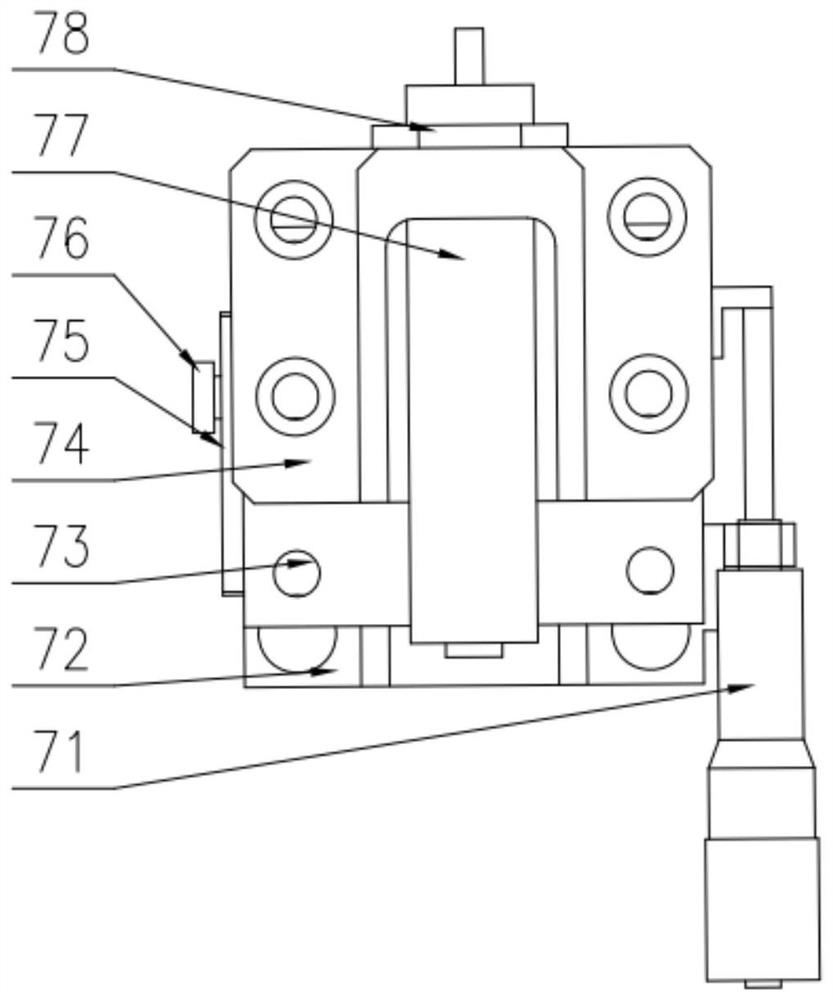

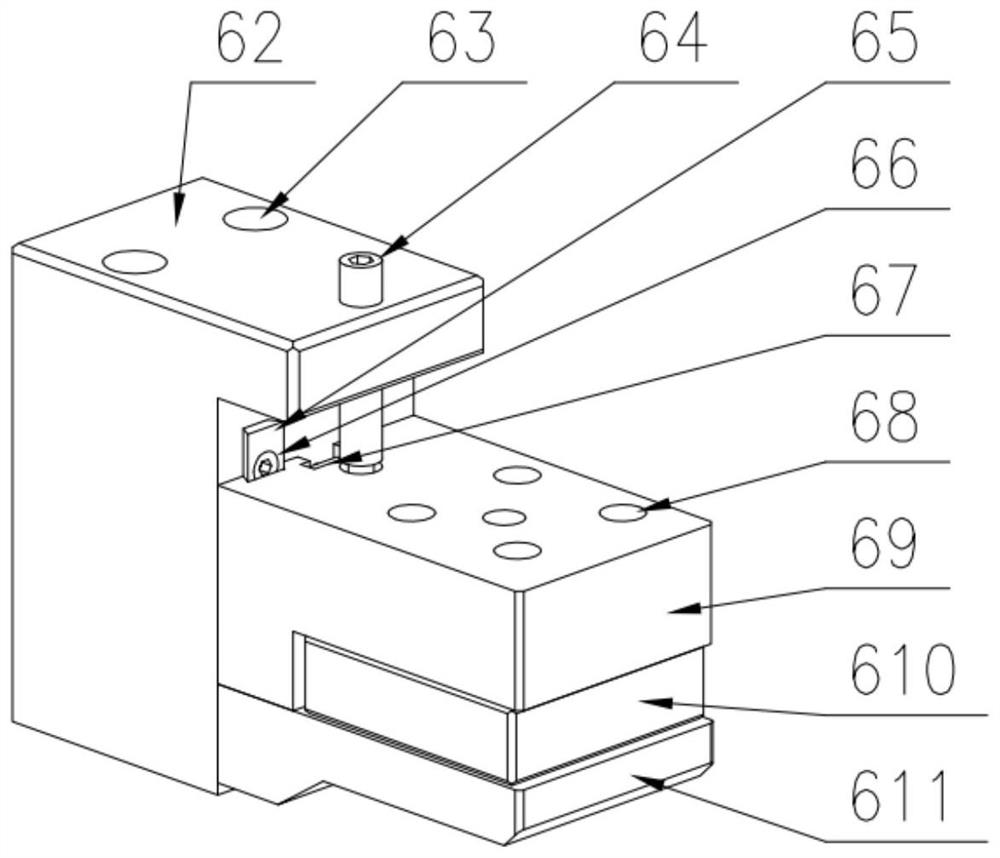

Wall thickness error precision control machining device and method for rotating shell parts

ActiveCN111716147AThe wall thickness error satisfiesControl Profile AccuracyAutomatic control devicesGrinding feed controlMicro nanoKinematic controller

The invention provides a wall thickness error precision control machining device and method for rotating shell parts, and belongs to the field of precision / ultra-precision machining. The machining device comprises a main controller, a workpiece runout precision detection device, a workpiece position precision adjustment device, a tool tip height precision detection device, a tool tip height precision adjustment device and an auxiliary structure. The workpiece runout precision detection device is used for precisely detecting runout of parts. The workpiece position precision adjustment device isused to achieve accurate and fast alignment of workpieces. The tool tip height precision detection device comprises a tool tip height detection controller and a tool tip height detection sensor, andis used for precisely checking tool tip heights. The tool tip height precision adjustment device comprises a micro-nano motion controller, a tool holder base, a dovetail guide rail, upper and lower tool rest blocks, and a micro-nano lifting platform. The tool tip height precision adjustment device is used to adjust the tool tip height at micro-nano precision. The machining device and method are simple. The machining device can meet the machining requirements of high profile precision and low wall thickness error of rotary parts, and automation is easy to realize.

Owner:DALIAN UNIV OF TECH

Centrally-mounted motorcar chassis electricity dynamometer

ActiveCN101762350AReduce workloadExtended service lifeWork measurementTorque measurementElectricityEngineering

The invention discloses a centrally-mounted motorcar chassis electricity dynamometer which comprises a lifting mechanism. The lifting mechanism comprises a screw connected with a screw rod, and the screw is connected with a rocker by a link I; the upper end of the rocker is fixedly connected with a lateral horizontal shaft, and the lateral horizontal shaft can be installed on a stander in a rotatable mode and is fixedly connected with a side link which extends toward the middle lower part of the dynamometer; the lower end of the side link is articulated with one end of a link II, and the other end of the link II is articulated with a top plate; both sides of the top plate are respectively provided with a convex block, and the convex block is matched with a rail of the stander; the rail arches upwards to form an arch for guiding the lifting of the top plate; and the free end of the top plate is provided with a supporting roller. The invention can center motorcars accurately and quickly by adopting an automatic centering mechanism, thereby reducing the workload of testing personnel, saving test preparation time and omitting lots of small-sized parts and components, so that the structure is simple and practical.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

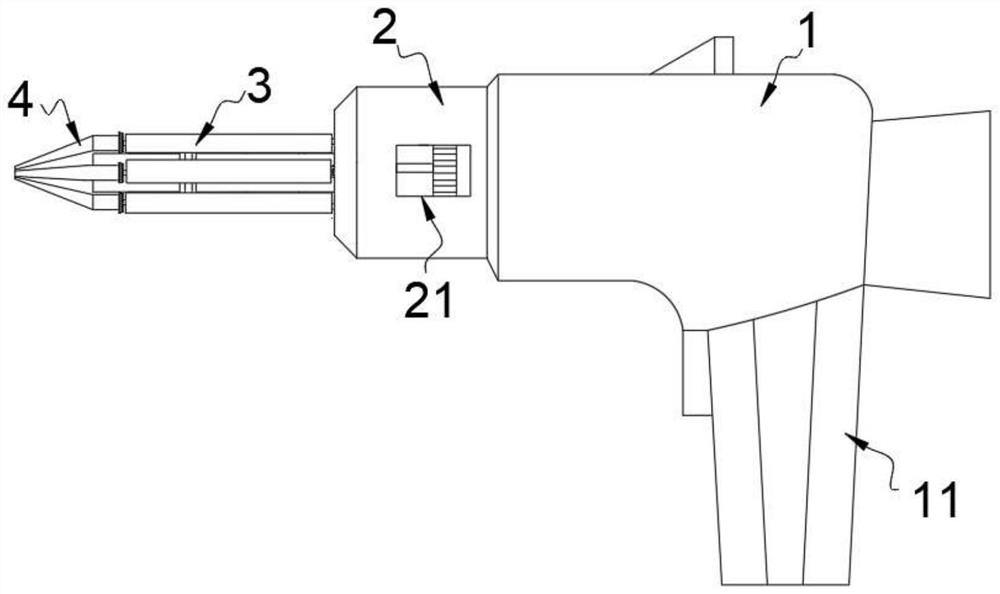

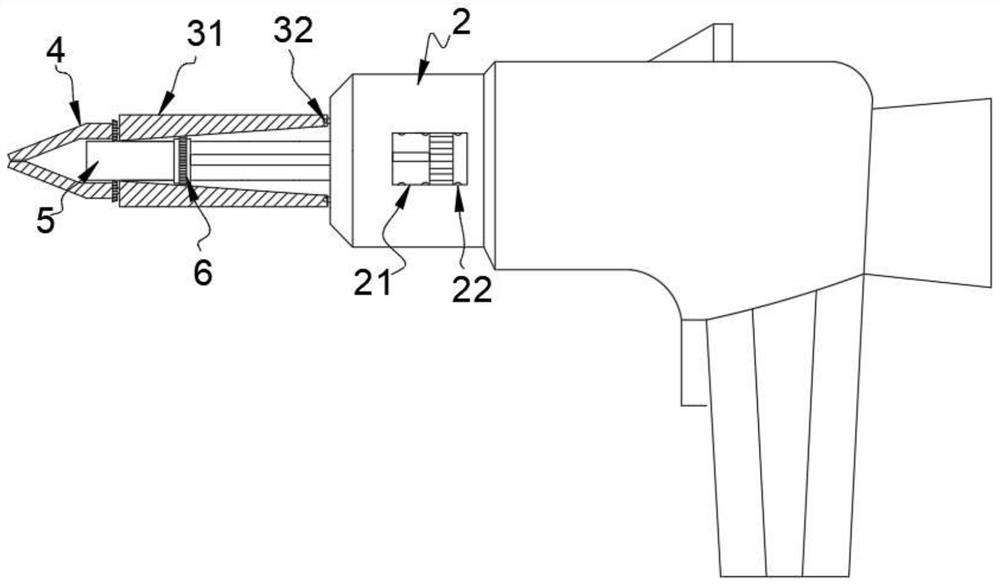

End face drilling tool

InactiveCN104057323AReduce adverse effectsFast and accurate alignmentPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses an end face drilling tool for a hydraulic cylinder sleeve, and belongs to the technical field of machining. The drilling tool comprises a lower cover plate and an upper cover plate, which are arranged in a way that openings of the upper and lower cover plates are opposite to each other, wherein a threaded sleeve, an inner positioning sleeve and a die sleeve are arranged between the upper and lower cover plates; the open end of the threaded sleeve is in threaded connection with the upper cover plate, and a center hole is machined in the bottom surface of the threaded sleeve; the lower end of the inner positioning sleeve is nested in the center hole in the bottom of the threaded sleeve; the inner positioning sleeve and the bottom of the threaded sleeve are connected with the lower cover plate respectively; each of the inner positioning sleeve and the lower cover plate is provided with a center hole; the inner wall of the die sleeve has a conical surface structure, and is arranged between the upper cover plate and the inner positioning sleeve in an upturning way; one-to-one corresponding spring mounting grooves are machined in the end face of the die sleeve and the bottom surface of the threaded sleeve respectively; resetting springs are arranged in the mounting grooves. According to the technical scheme, the die sleeve is matched with a ball pushrod structure for elastic alignment, so that adverse effects of overall dimension fluctuation on a drilling position can be eliminated, and an effect of rapid and accurate alignment is achieved.

Owner:ZUNYI CHANGJIA MACHINERY MFG CO LTD

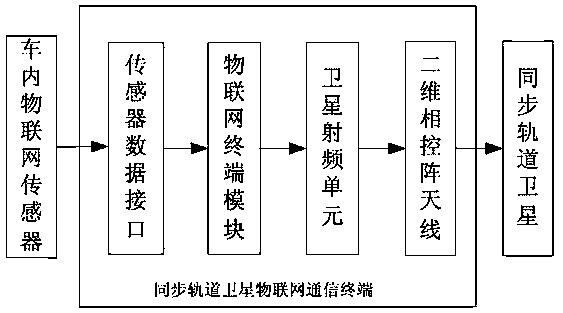

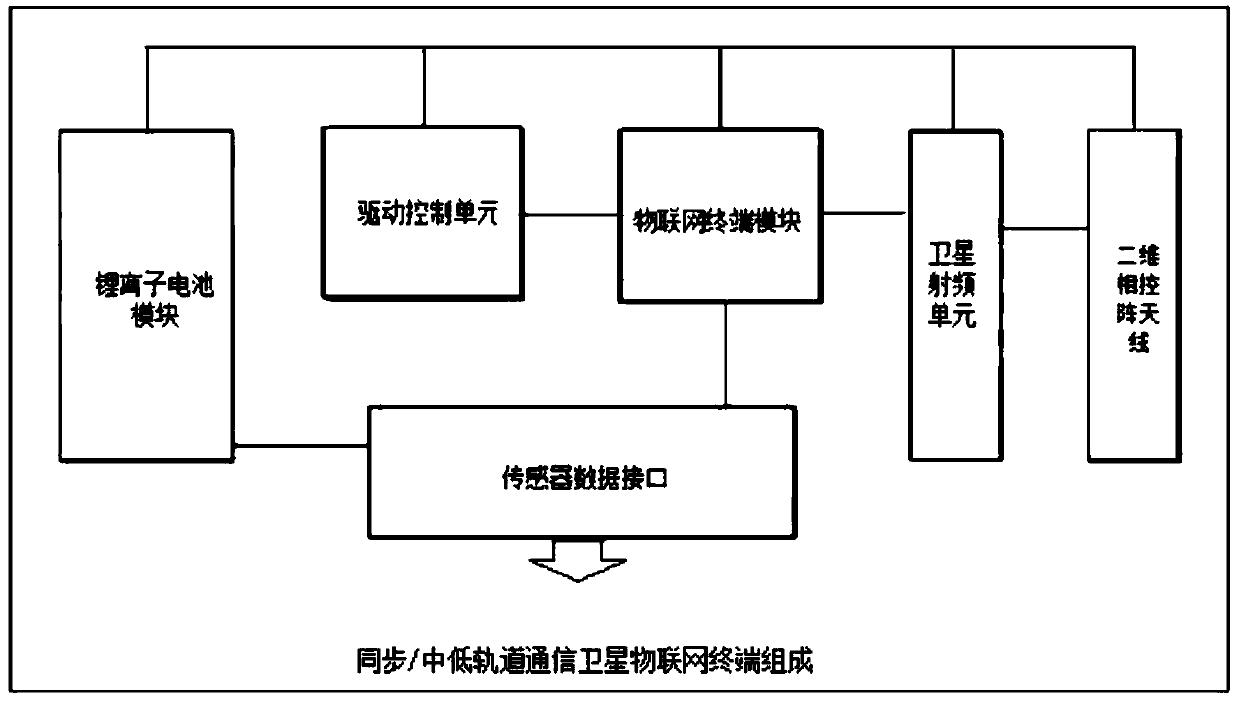

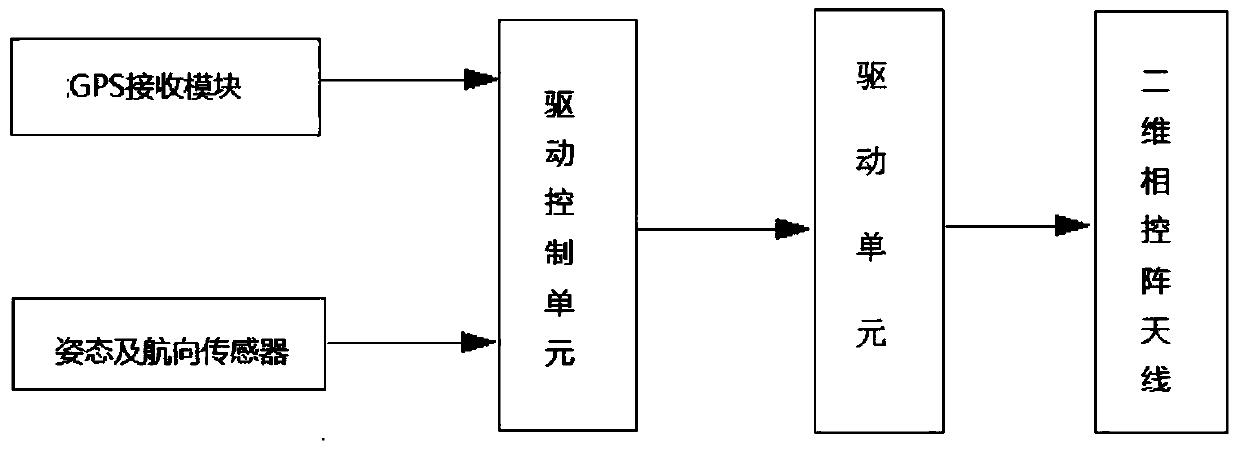

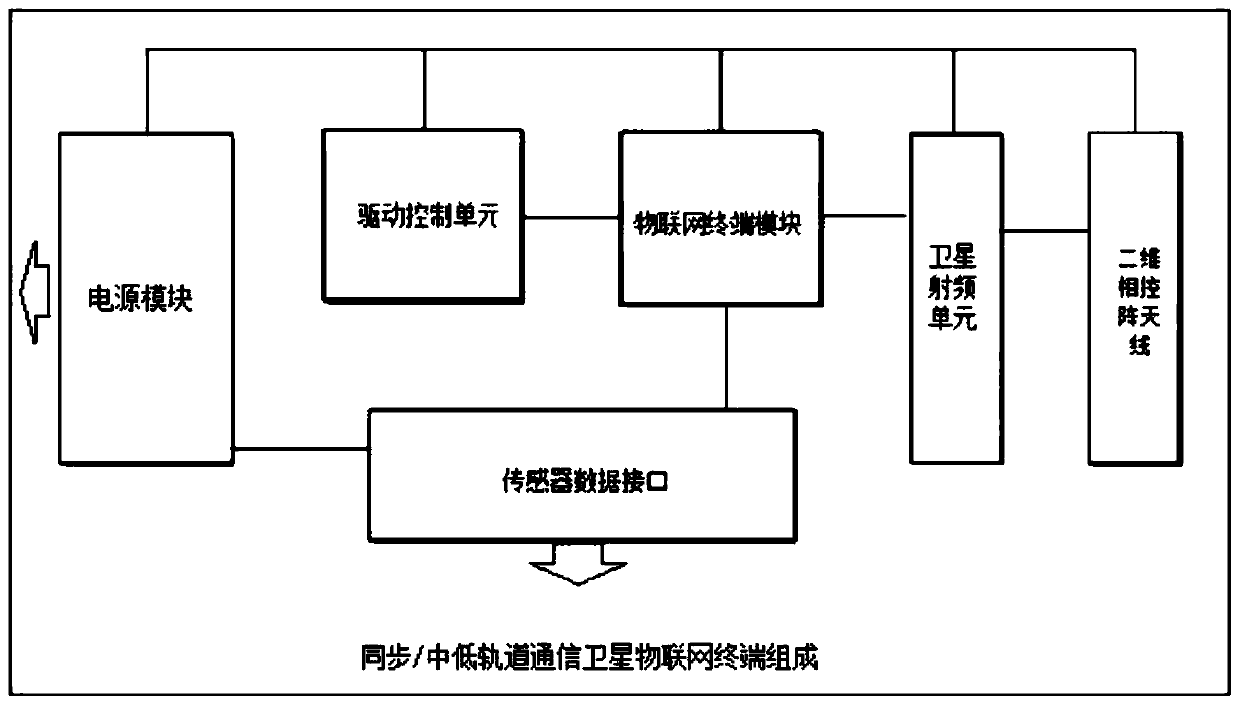

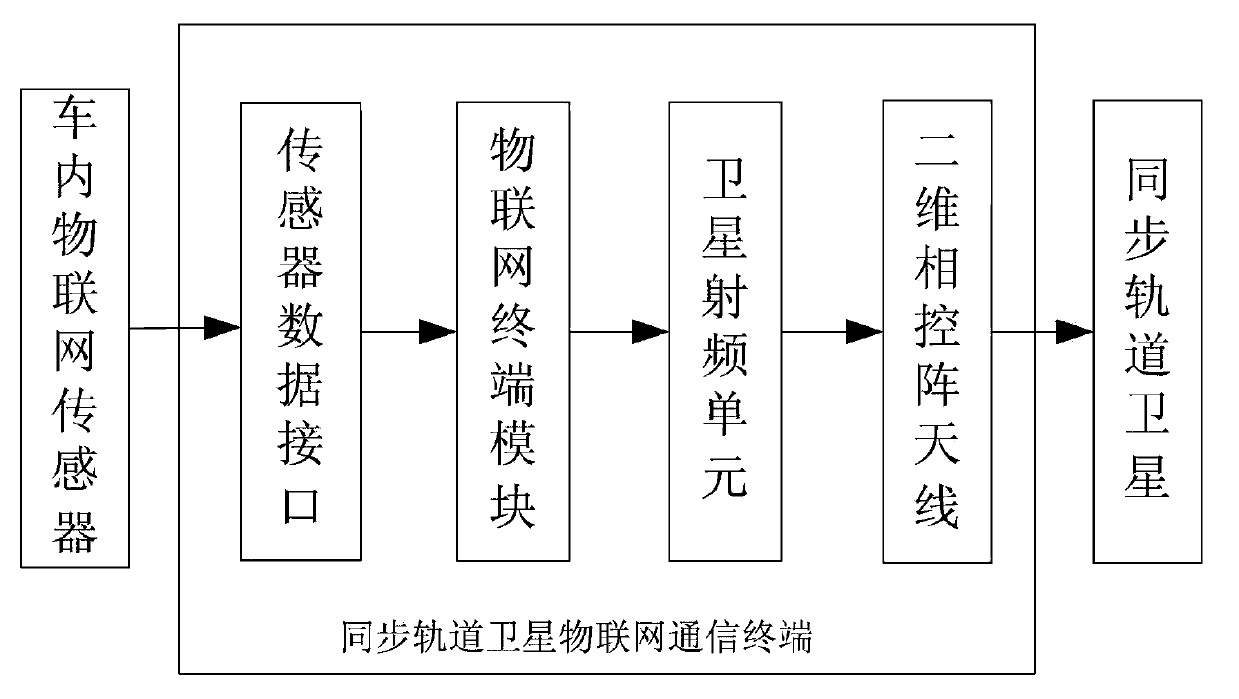

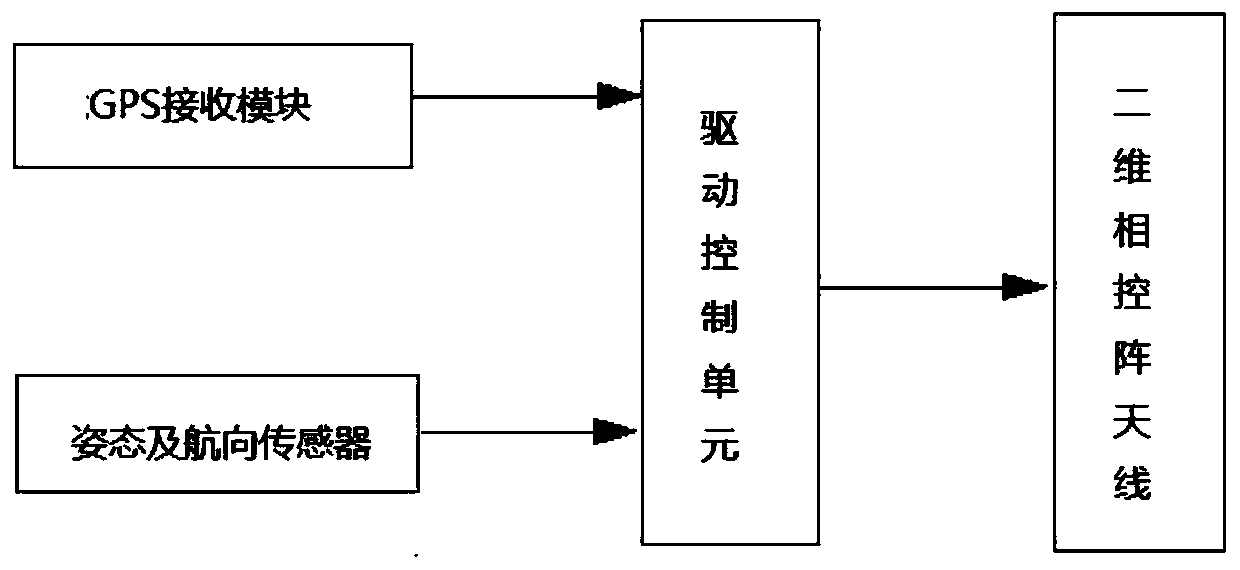

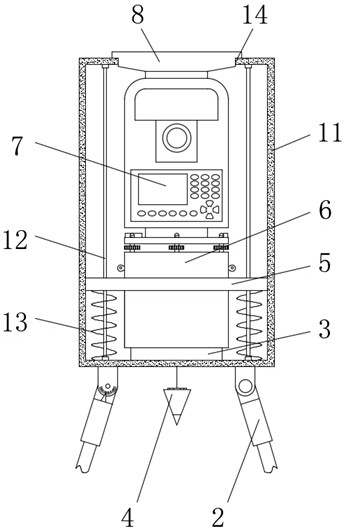

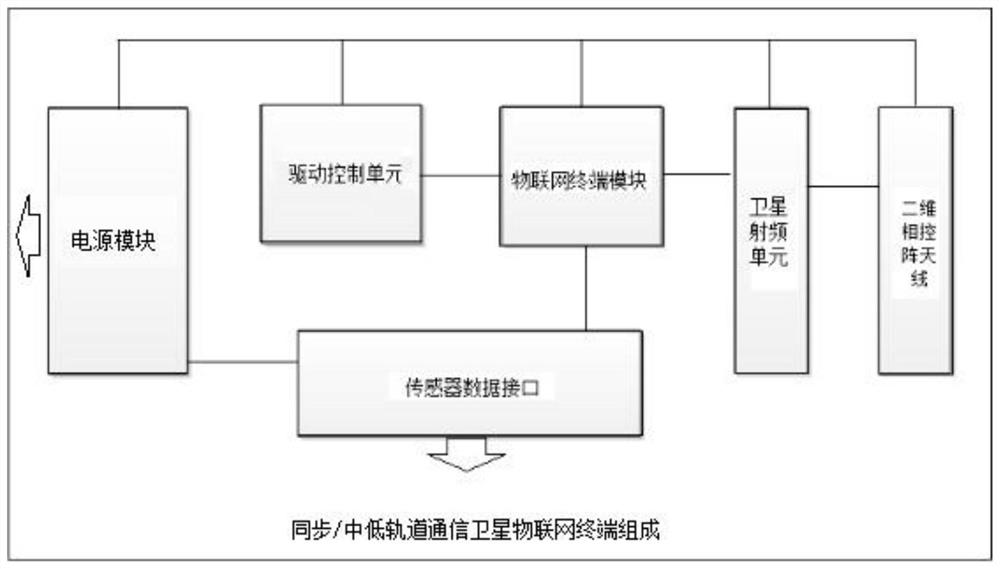

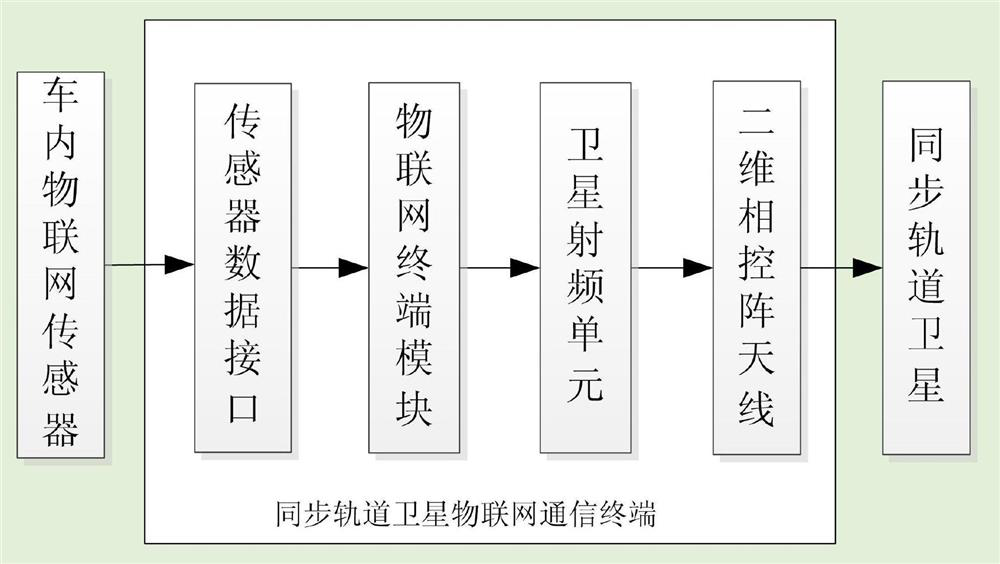

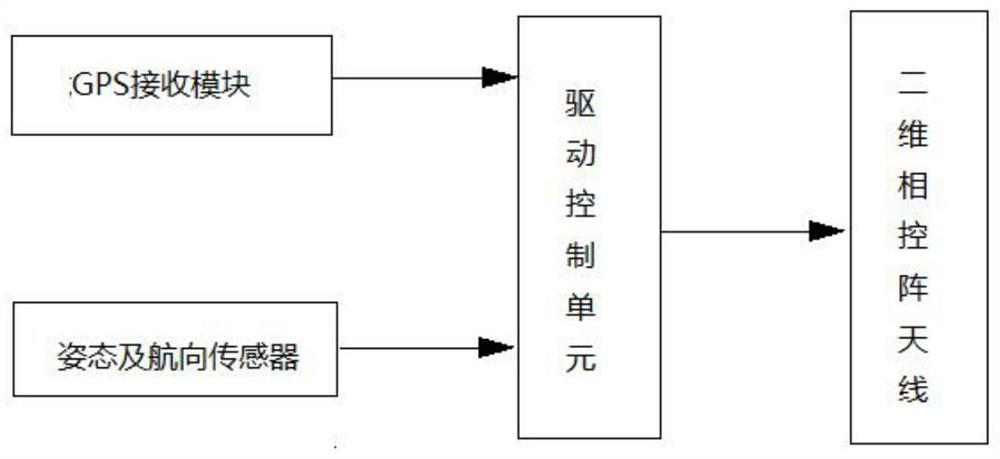

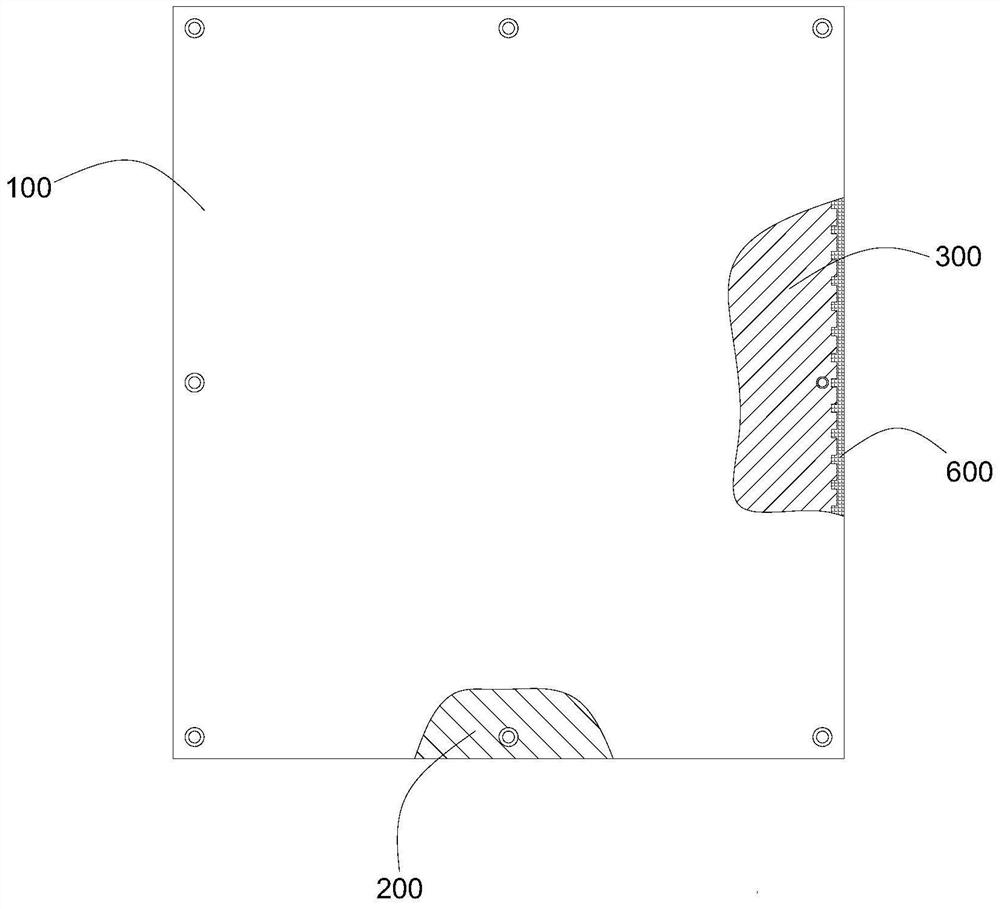

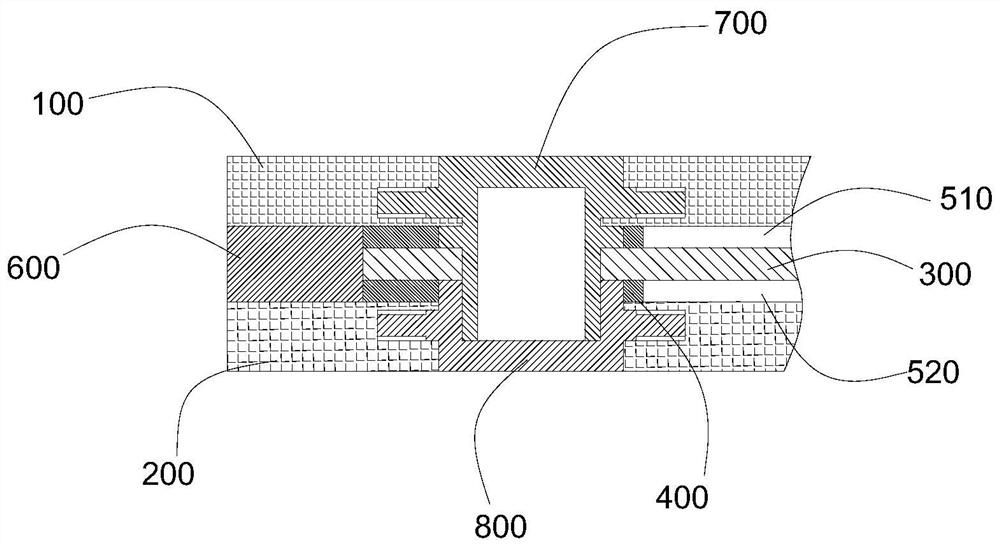

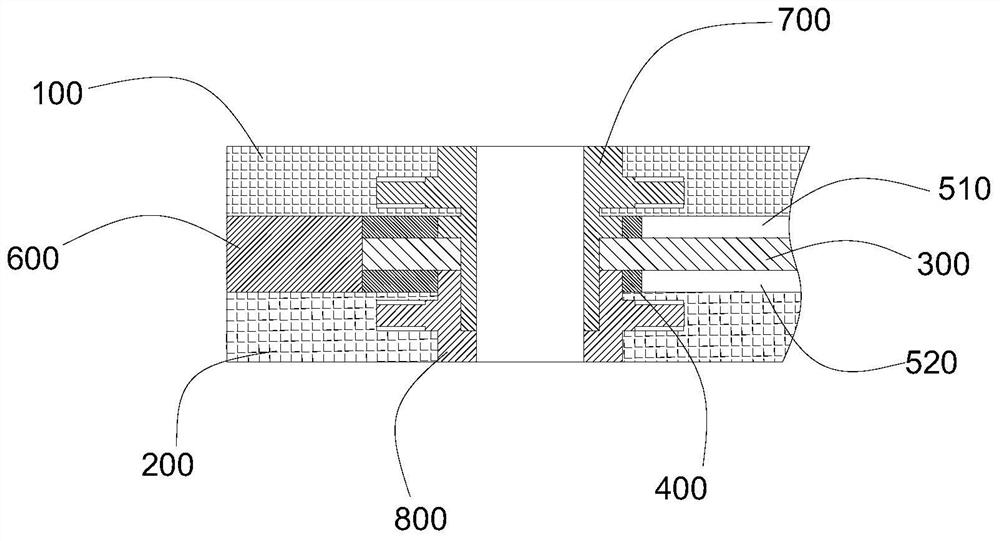

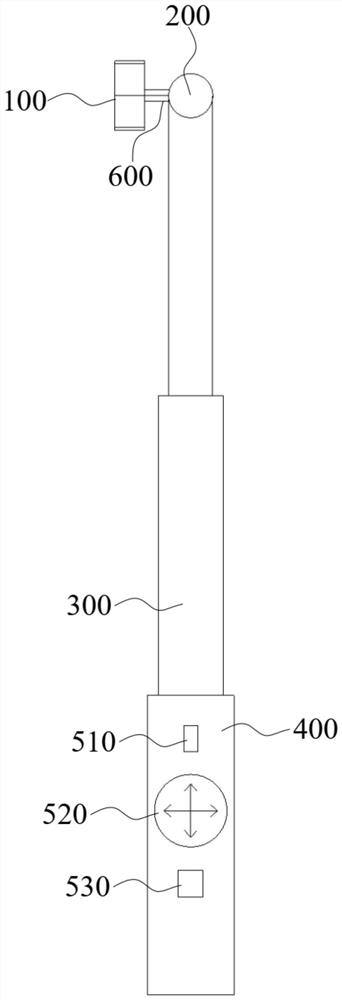

Vehicle-mounted Internet of Things terminal and information transmission method thereof

ActiveCN110337089ALow profileEasy to installParticular environment based servicesNetwork topologiesInformation processingSatellite radio

The invention discloses a vehicle-mounted Internet of Things terminal and an information transmission method, and belongs to the technical field of Internet of Things. The vehicle-mounted Internet ofThings terminal is fixed on a vehicle and moves to a designated place or performs mobile patrol along with the vehicle; the vehicle-mounted Internet of Things terminal receives data transmitted by thesensor and transmits the data to the satellite radio frequency unit for frequency conversion, the two-dimensional phased array antenna sends the information after frequency conversion to the synchronous or medium-low orbit communication satellite, and the synchronous or medium-low orbit communication satellite sends the information to the ground information processing station. the beneficial effects of the invention are that the method achieves the IOT communication of synchronous or medium-low orbit satellites through one terminal, and solves a problem that a conventional IOT is short in transmission distance and cannot achieve the information collection of cross-region coverage through the long-distance coverage of the satellites; and the satellite can be accurately and quickly alignedin the stationary and running process of the vehicle, and real-time communication of information is completed.

Owner:天宸星通(深圳)科技有限公司

Airborne Internet of Things terminal and information transmission method

ActiveCN110445530AMiniaturizationLow profileActive radio relay systemsSatellite radioInformation transmission

The invention discloses an airborne Internet of Things terminal and an information transmission method, and belongs to the technical field of Internet of Things. An airborne Internet of Things terminal is installed in an unmanned aerial vehicle or a general aircraft to receive data transmitted by an airborne sensor and transmit the data to a satellite radio frequency unit to realize frequency conversion, so that a synchronous or medium-low orbit communication satellite can receive a signal through a transmitting behavior of a two-dimensional phased array antenna. The beneficial effects of theinvention are that the method achieves the IOT communication of synchronous or medium-low orbit satellites through one terminal, and solves a problem that a conventional IOT is short in transmission distance and cannot achieve the information collection of cross-region coverage through the long-distance coverage of the satellites; and the satellite can be accurately and quickly aligned in the static and high-speed operation of the aircraft, and the real-time communication of information is completed.

Owner:天宸星通(深圳)科技有限公司

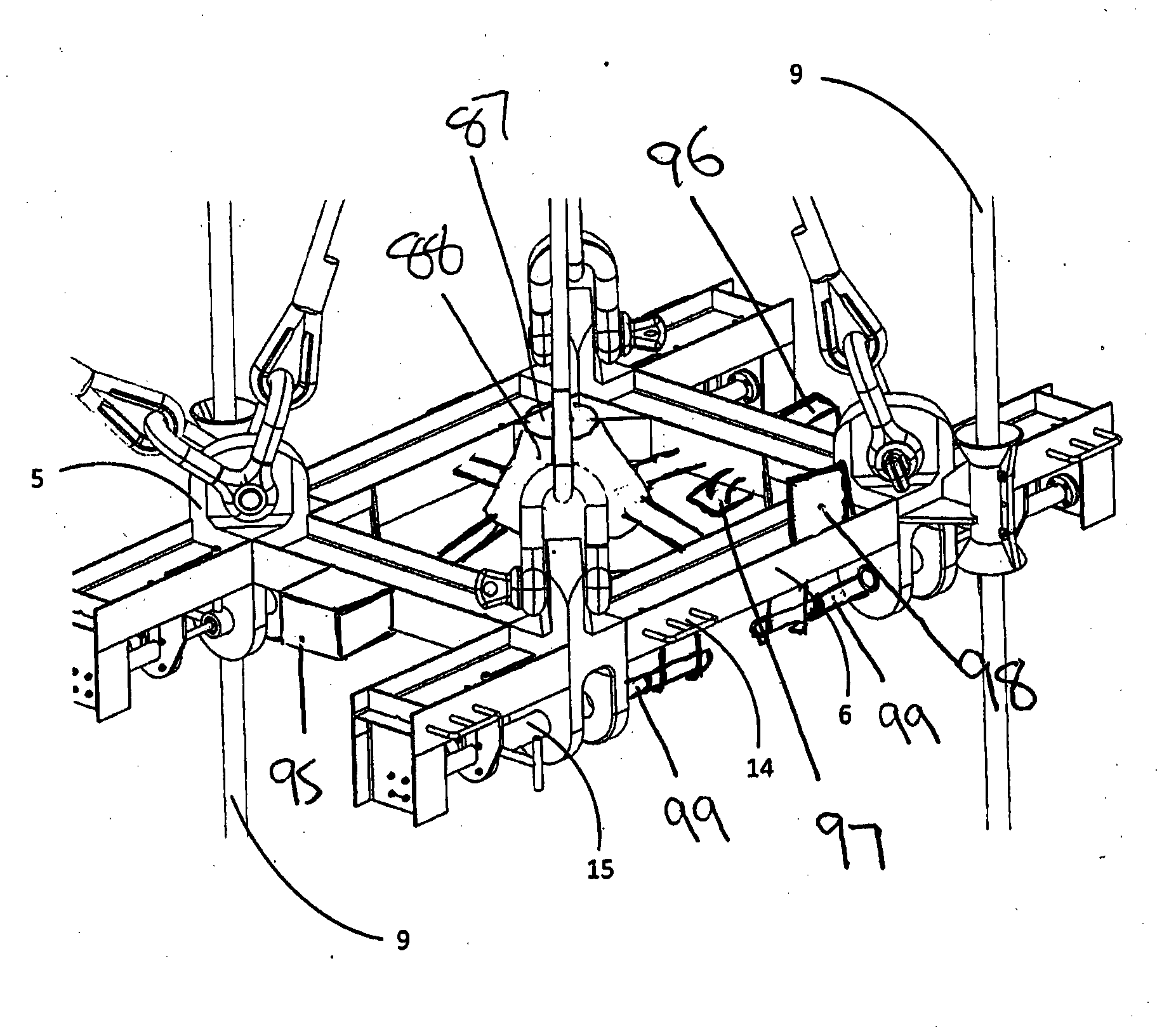

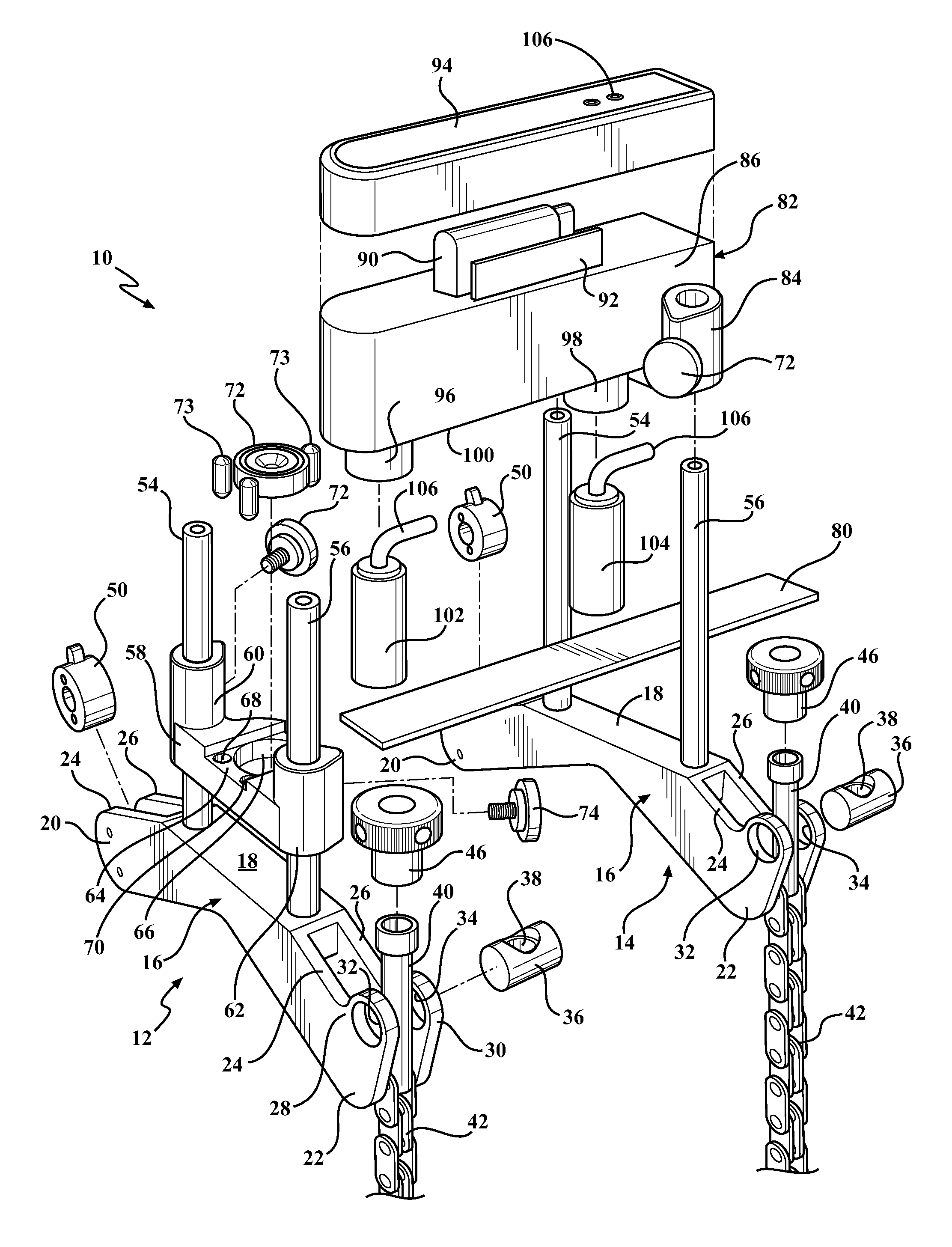

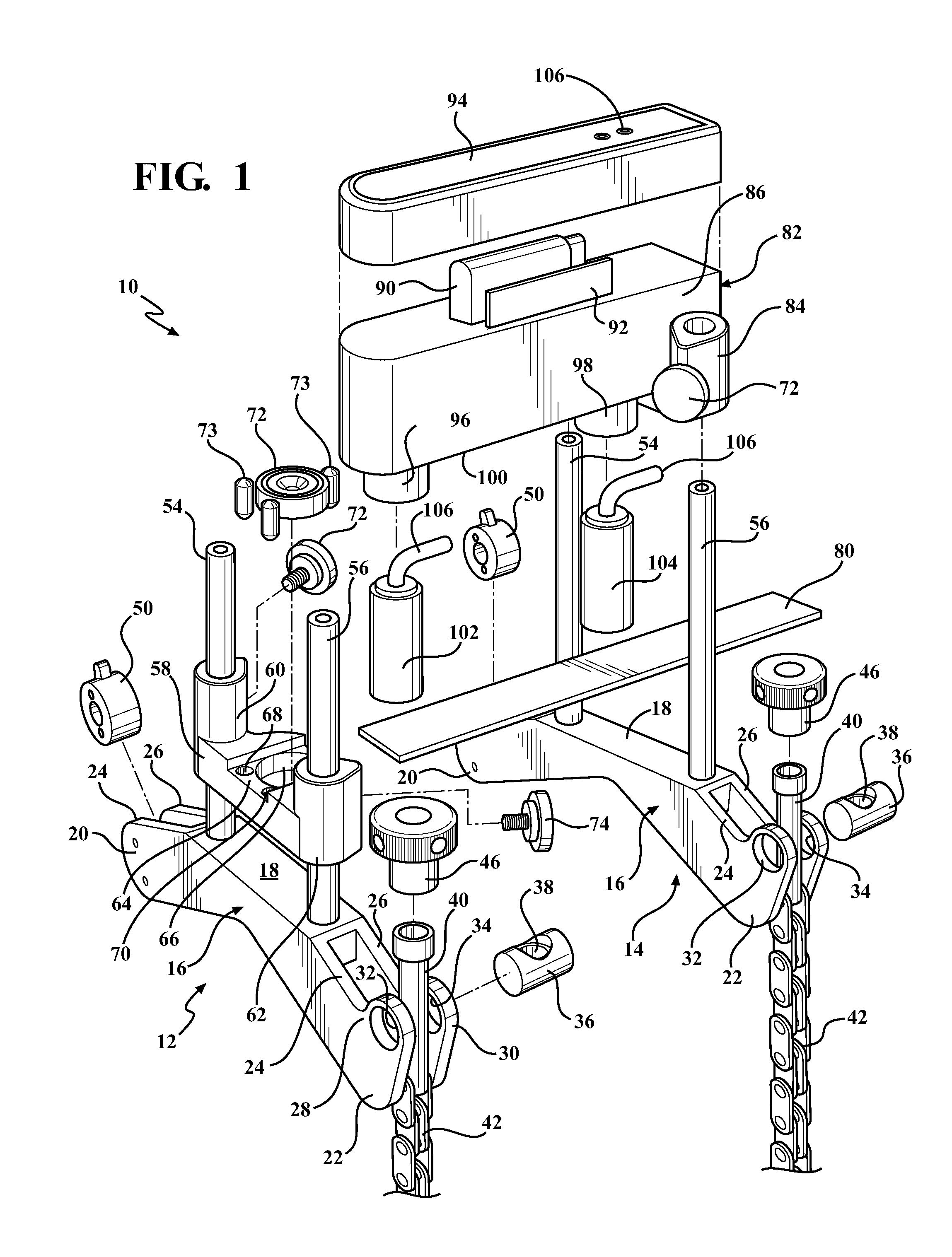

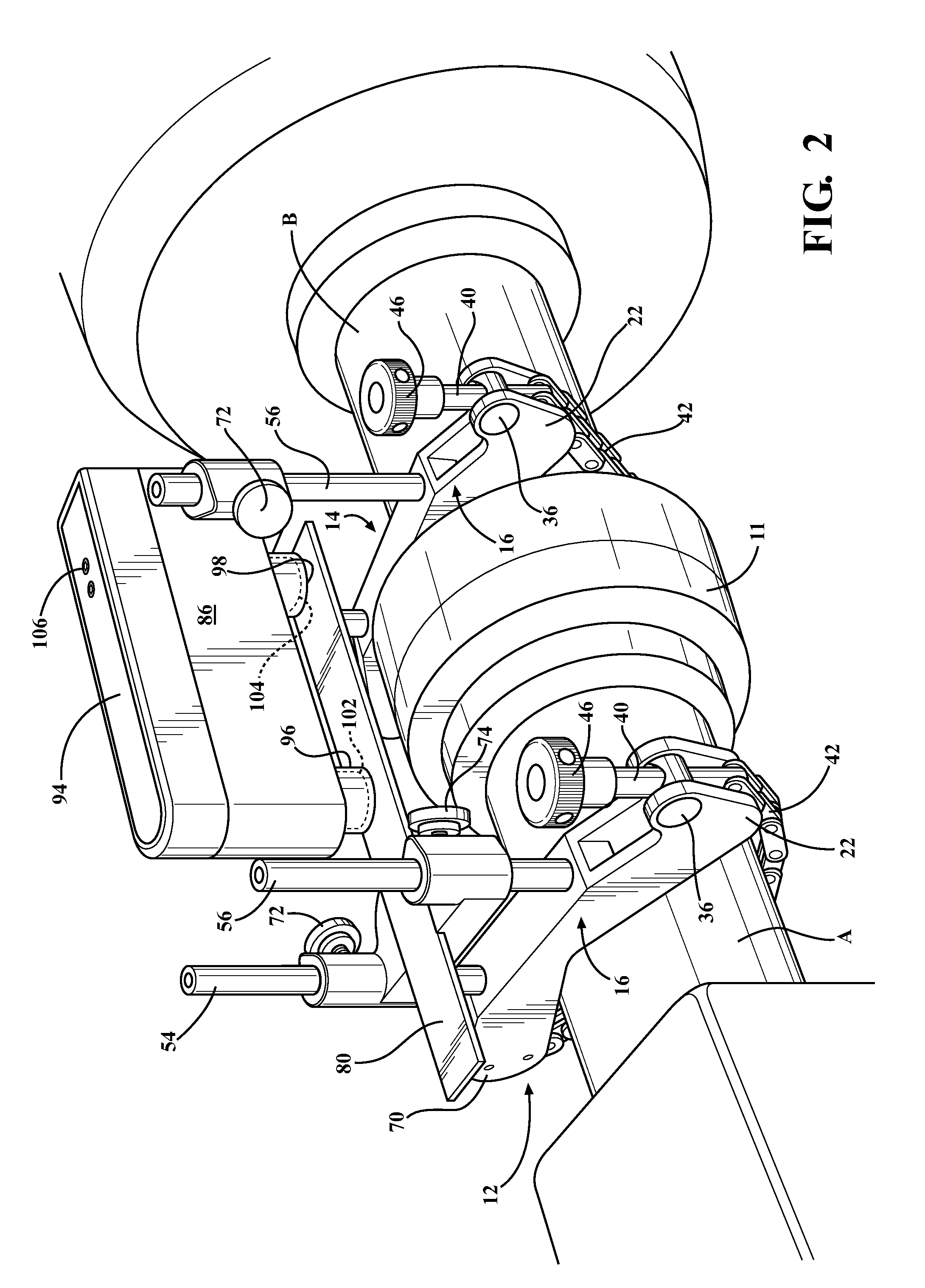

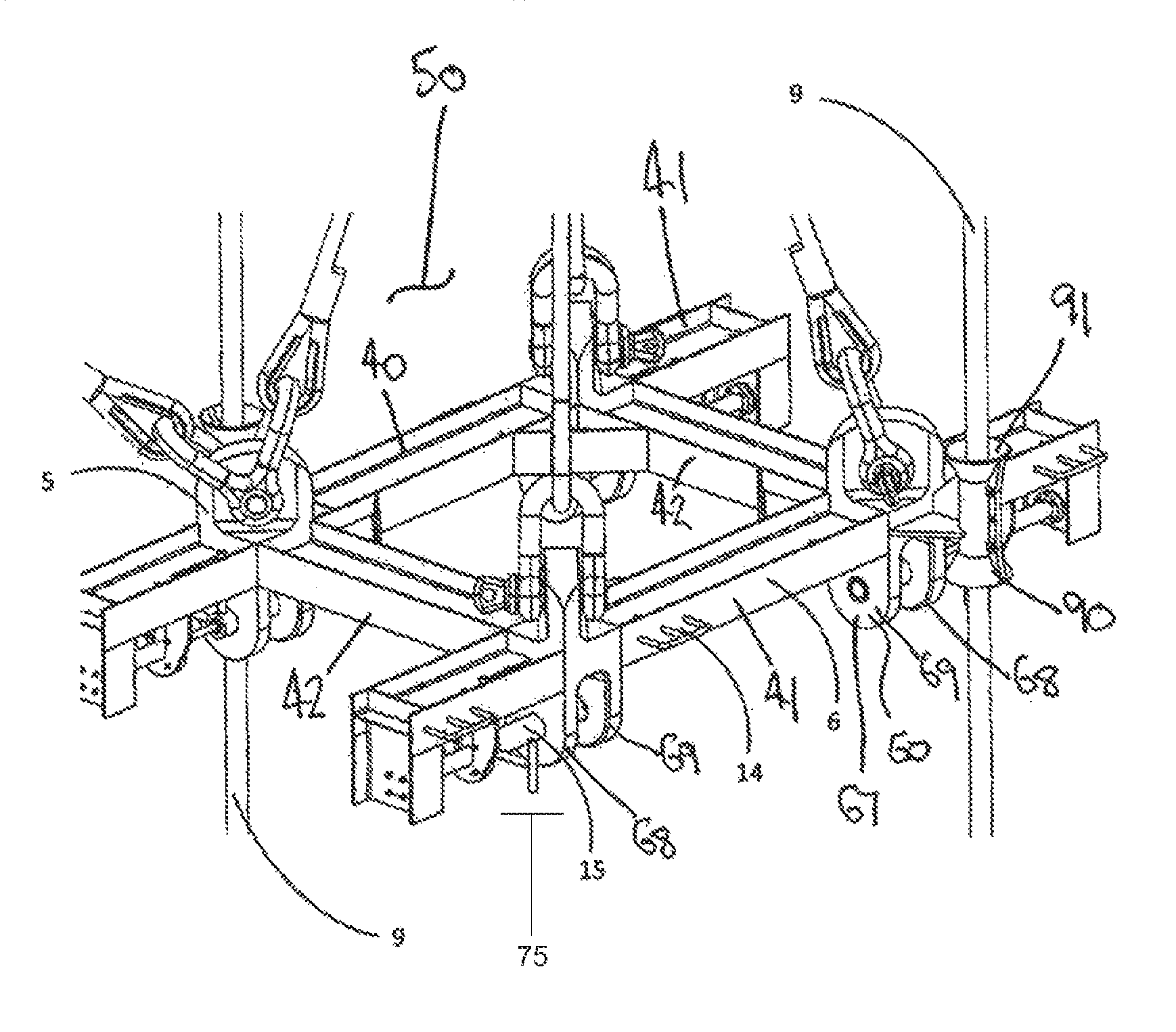

Alignment apparatus and method

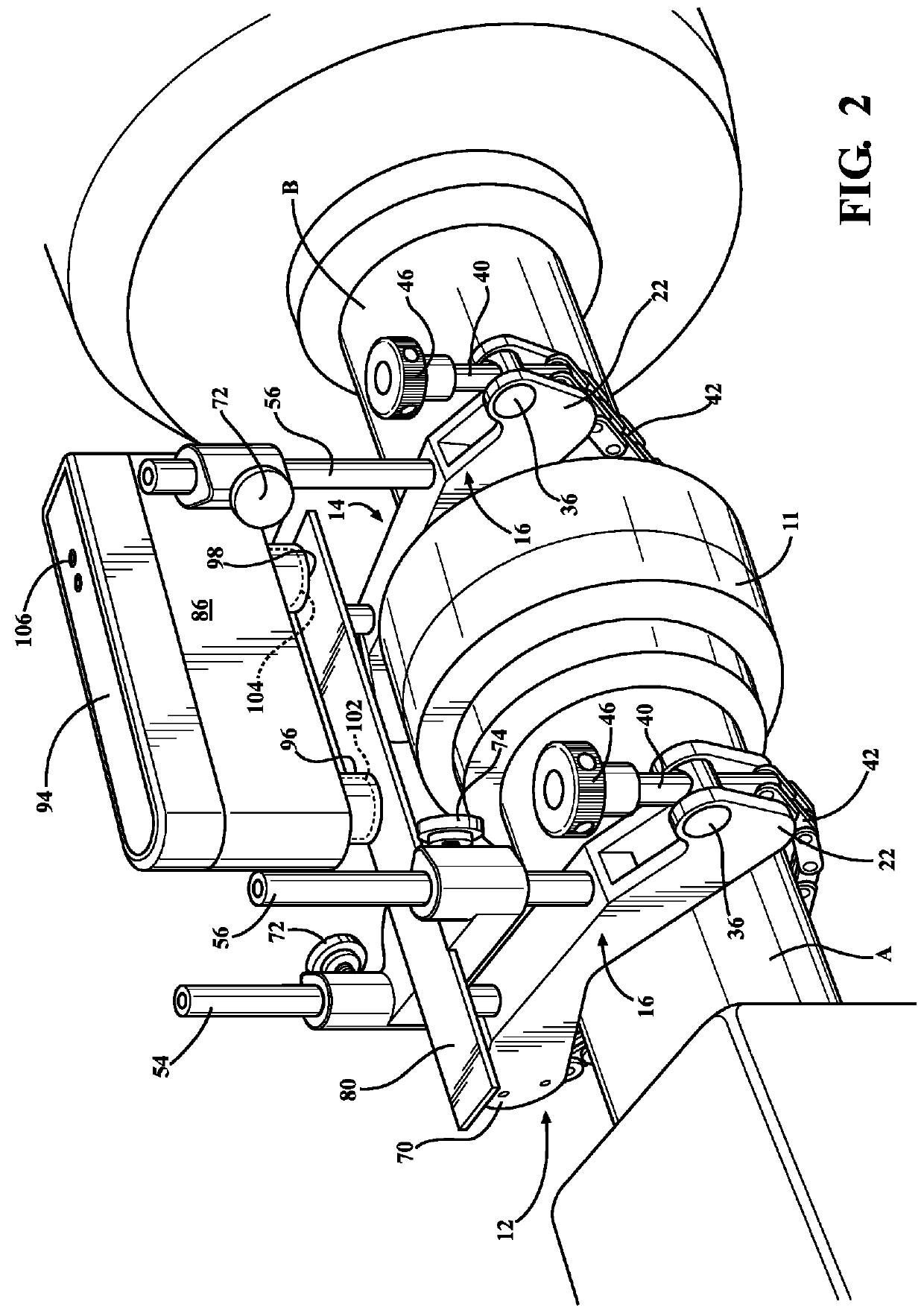

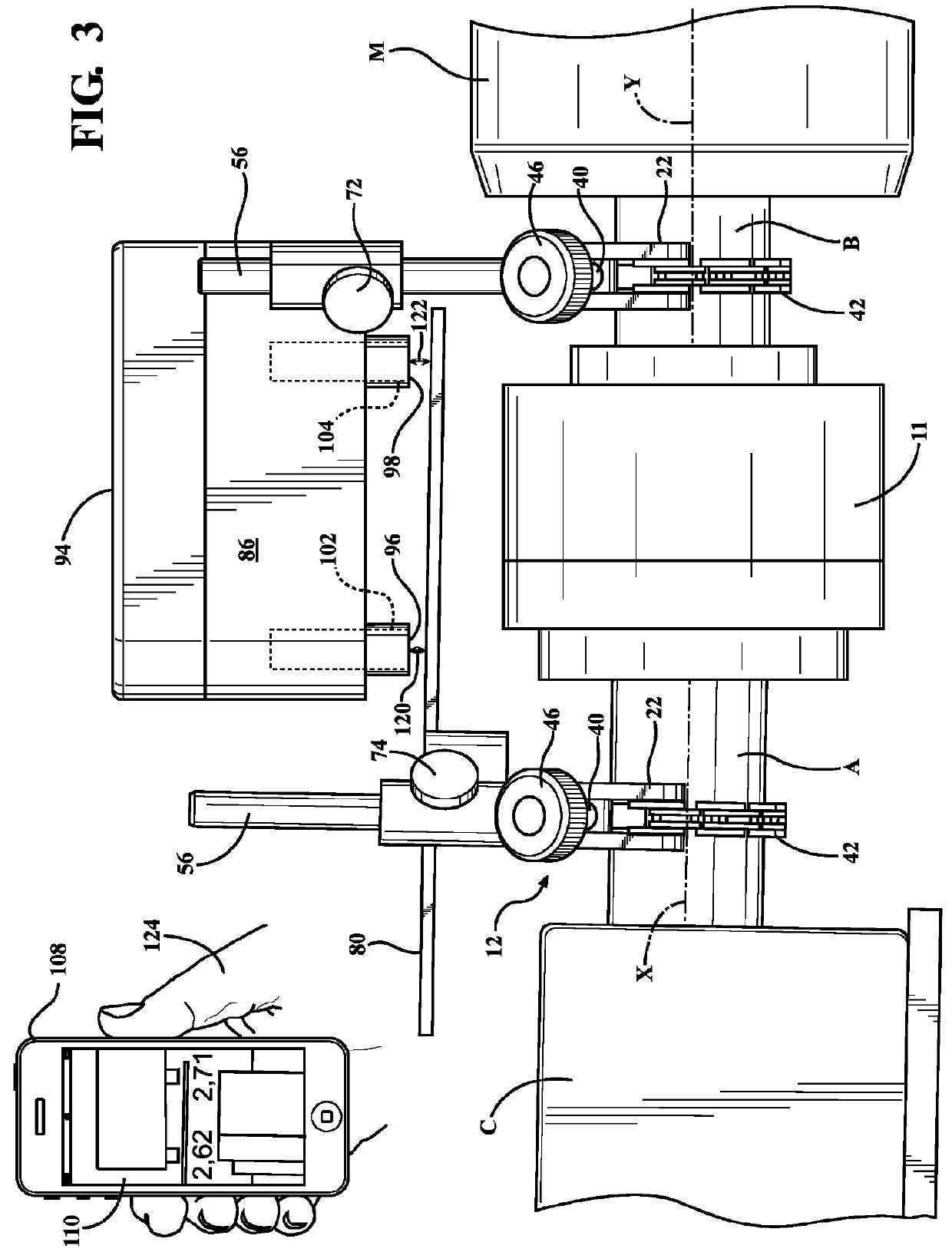

ActiveUS9964394B2Precise positioningFast and accurate alignmentAngles/taper measurementsUsing electrical meansMobile deviceElectrical and Electronics engineering

An alignment apparatus (the tool) of the present invention includes a pair of bracket devices for rigidly holding shafts. As the shafts are secured to the bracket devices with chains, sensors of one of the bracket devices are exposed to an extension beam of the other bracket device thereby defining gaps or distances between the extension beam and the sensors. If offset is determined between the distances because one shaft is misaligned relative the other shaft, the sensors send signal to a mobile device, thereby informing a user about misalignment between the shafts.

Owner:AB SKF

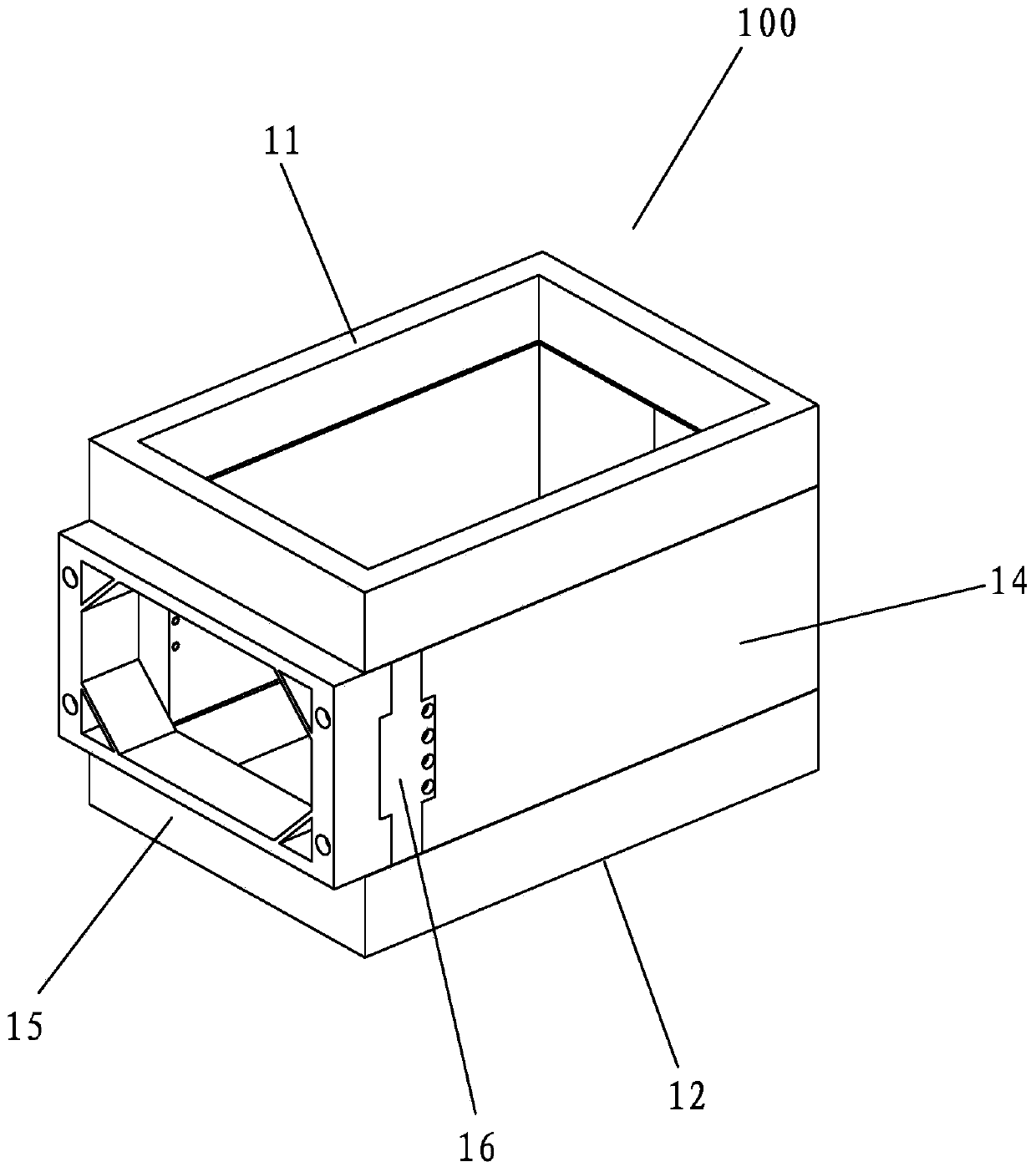

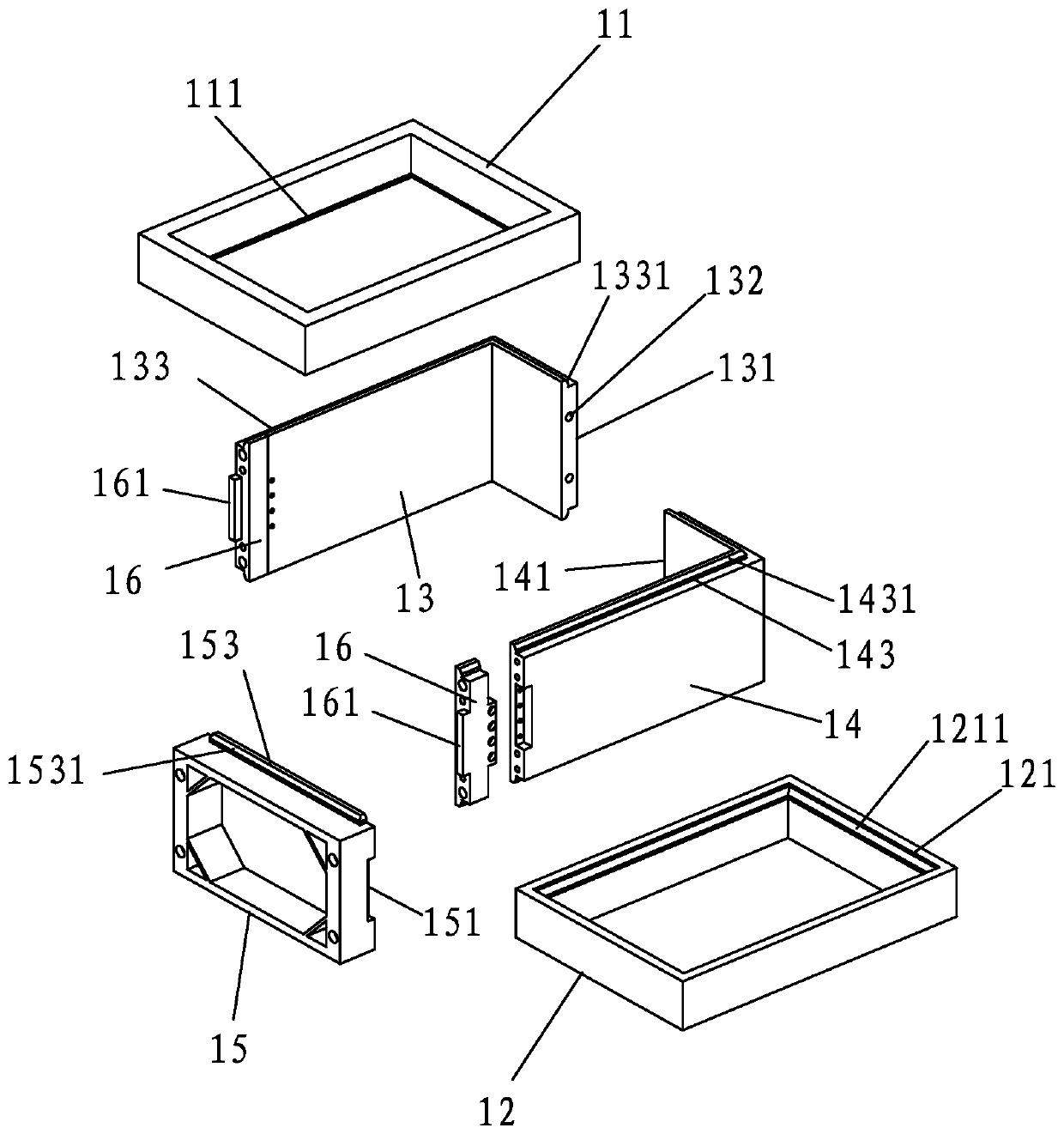

Grouting closestool mold capable of achieving precise and rapid mold closing and opening

PendingCN109940736ANovel structural designFast and accurate alignmentDischarging arrangementAuxillary shaping apparatusButt jointAgricultural engineering

The invention discloses a grouting closestool mold capable of achieving precise and rapid mold closing and opening. The grouting closestool mold comprises a mold body. The mold body is provided with an upper cover plate, a lower cover plate, a rear side plate, a left side plate and a right side plate. The left side plate and the right side plate are each of an L-shaped structure. The left side plate and the right side plate achieve left-and-right mold closing in a manner that one sides are in butt joint, and a movable connecting mechanism used for mold closing and alignment is arranged on thebutt-joint sides. The rear side plate is spliced between the left side plate and the right side plate so as to form a square structure, and lateral limiting structures beneficial to alignment and moldclosing are arranged between the rear side plate and the left side plate and between the rear side plate and the right side plate. The upper cover plate and the lower cover plate are arranged on thetop face and the bottom face of the square structure in a covering manner, and covering and limiting structures beneficial to alignment and mold closing are arranged on corresponding covered cooperation portions. The mold is flexible and exquisite in structural design, good in mold opening and closing operability, high in efficiency, low in product defect rate and excellent in quality, and operation is precise and rapid.

Owner:林铭兰

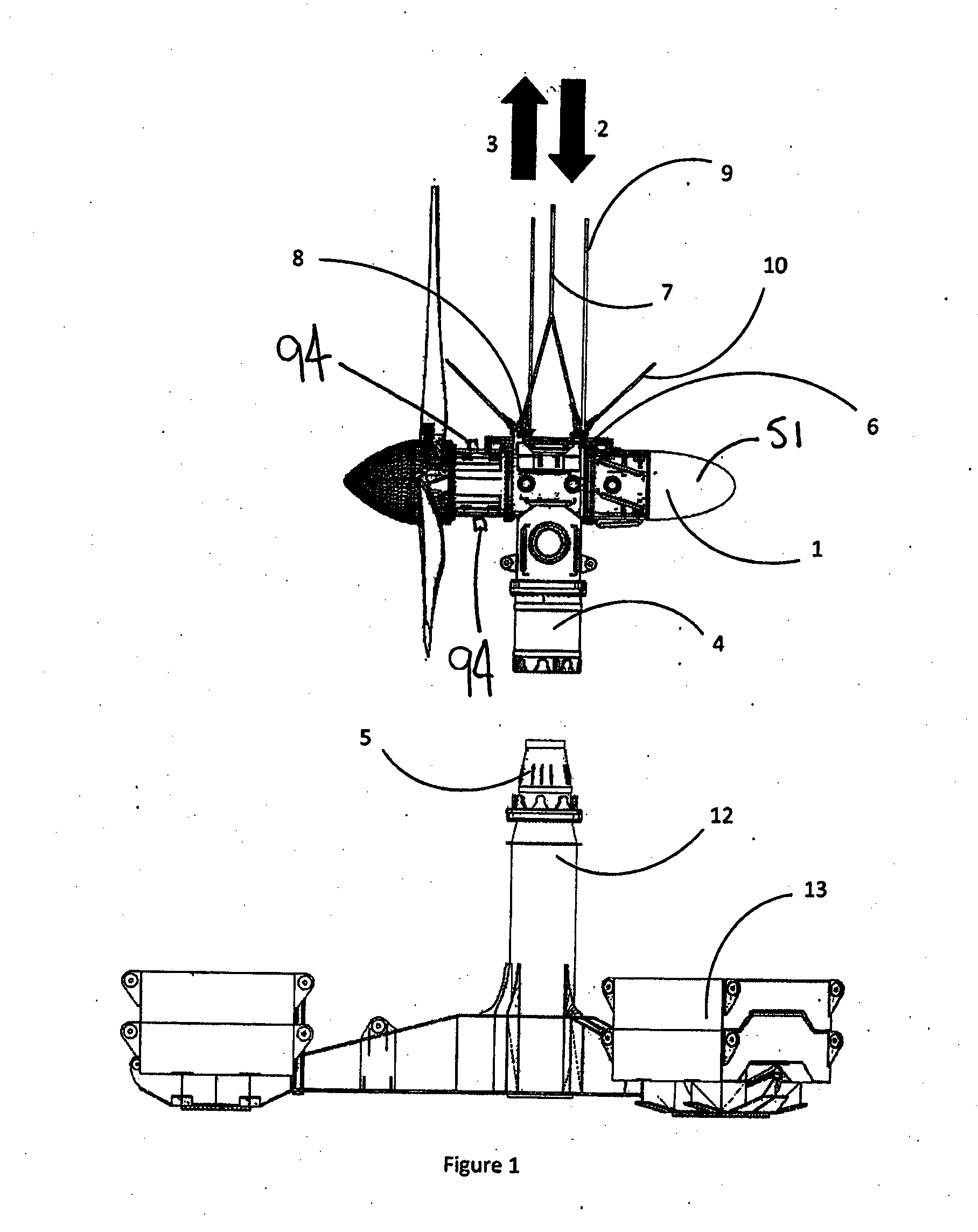

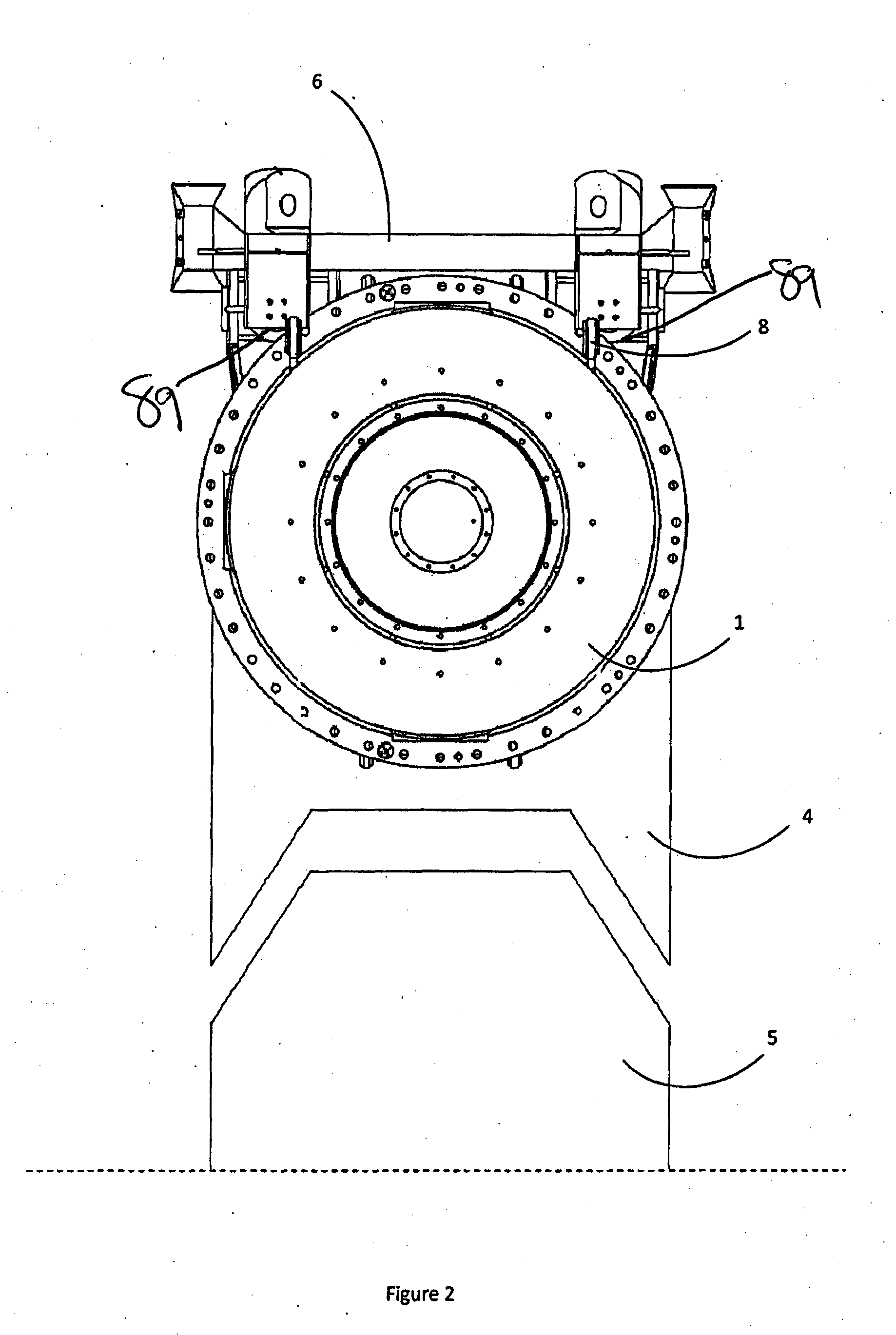

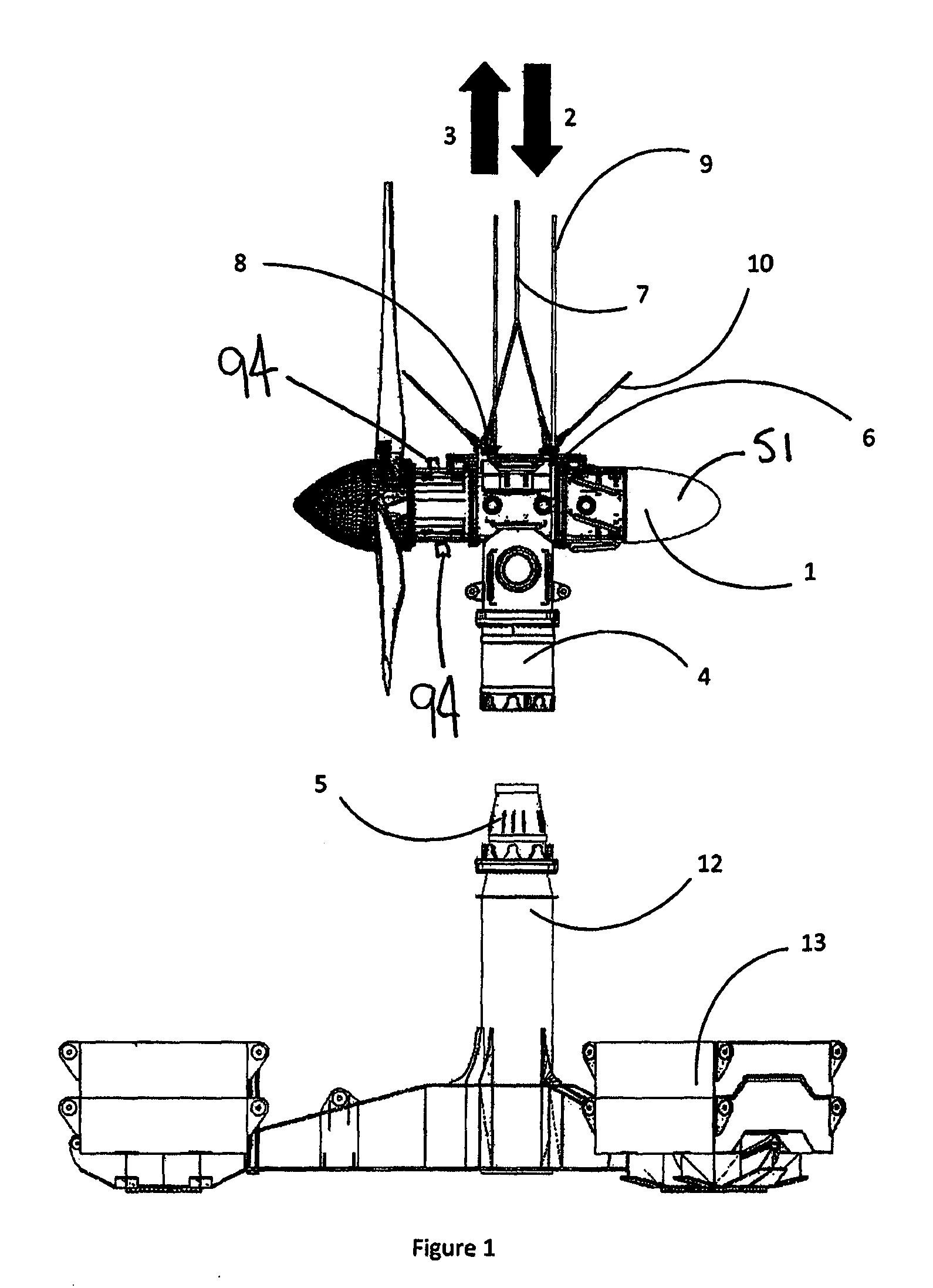

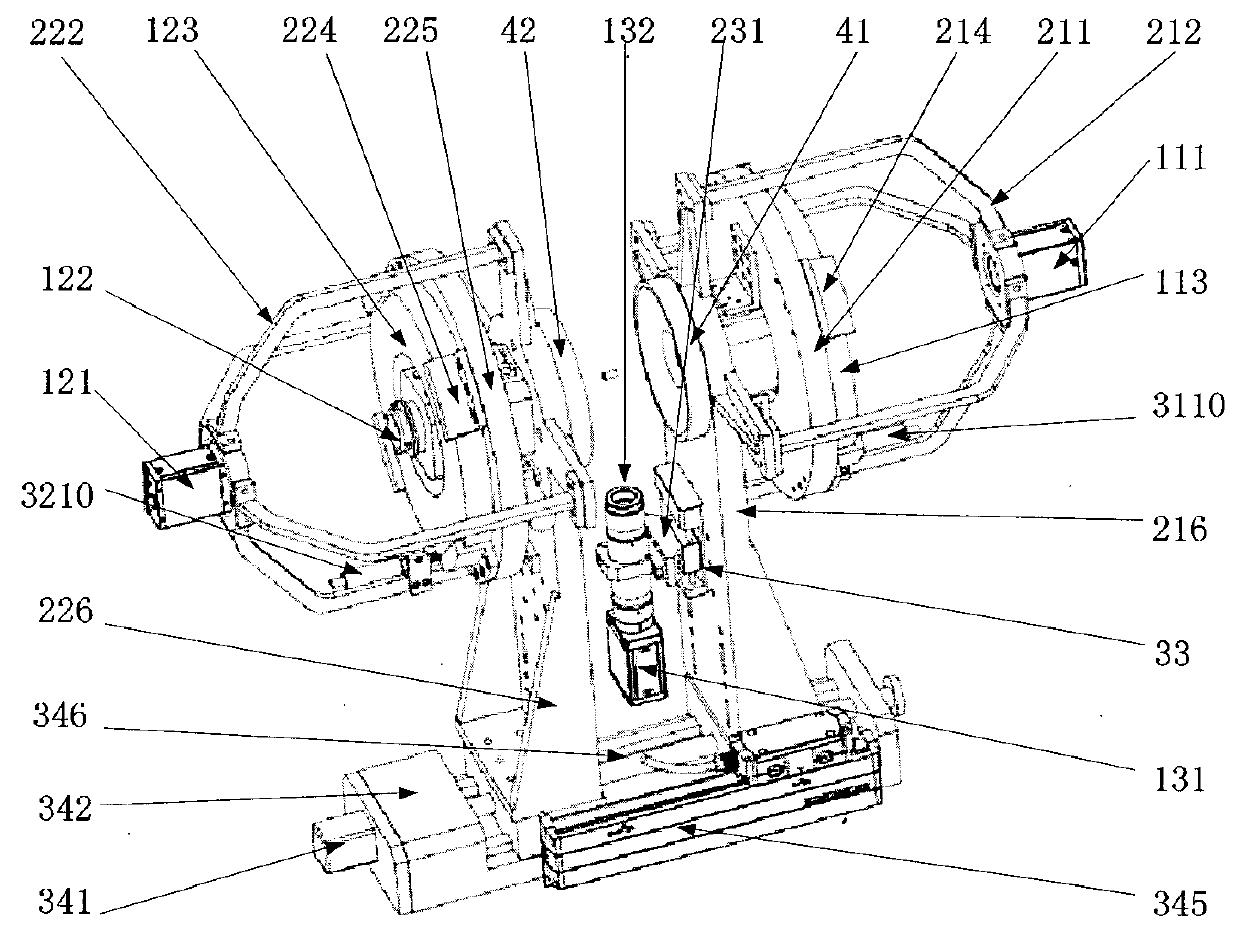

Deployment apparatus and method of deploying an underwater power generator

ActiveUS20140138973A1Precise positioningHelp positioningEngine manufacturePump componentsMarine engineeringUnderwater

A deployment apparatus is described. The deployment apparatus is for deploying an underwater power generator having a power generating main body from a deployment vessel disposed on the surface of a body of water onto a pylon disposed on the bed of the body of water and the deployment apparatus includes: a frame including one or more connectors disposed on a base region of the frame, the connectors for releasable connection to catches disposed on an upper region of the power generating main body, the connectors being remotely operable between a connected position in which the connectors are engaged with the catches and a disconnected position in which the connectors are disengaged from the catches; and one or more cameras disposed on the frame for providing visual guidance to the vessel of the position of the underwater power generator relative to the pylon. A method for deployment of the underwater power generator is also described.

Owner:ATLANTIS RESOURCES CORP PTE LTD

Alignment apparatus and method

ActiveUS20160363432A1Quick implementationEasy alignmentAngles/taper measurementsUsing electrical meansMobile deviceElectrical and Electronics engineering

An alignment apparatus (the tool) of the present invention includes a pair of bracket devices for rigidly holding shafts. As the shafts are secured to the bracket devices with chains, sensors of one of the bracket devices are exposed to an extension beam of the other bracket device thereby defining gaps or distances between the extension beam and the sensors. If offset is determined between the distances because one shaft is misaligned relative the other shaft, the sensors send signal to a mobile device, thereby informing a user about misalignment between the shafts.

Owner:AB SKF

On-site surveying and mapping device for construction project cost

ActiveCN110486585BEasy to fixEasy to disassembleSurveying instrumentsStands/trestlesStructural engineeringMechanical engineering

Owner:北京住总第六开发建设有限公司 +1

Deployment apparatus and method of deploying an underwater power generator

ActiveUS9073733B2Help positioningFacilitates extension and retractionEngine manufacturePump componentsUnderwaterMarine engineering

A deployment apparatus is described. The deployment apparatus is for deploying an underwater power generator having a power generating main body from a deployment vessel disposed on the surface of a body of water onto a pylon disposed on the bed of the body of water and the deployment apparatus includes: a frame including one or more connectors disposed on a base region of the frame, the connectors for releasable connection to catches disposed on an upper region of the power generating main body, the connectors being remotely operable between a connected position in which the connectors are engaged with the catches and a disconnected position in which the connectors are disengaged from the catches; and one or more cameras disposed on the frame for providing visual guidance to the vessel of the position of the underwater power generator relative to the pylon. A method for deployment of the underwater power generator is also described.

Owner:ATLANTIS RESOURCES CORP PTE LTD

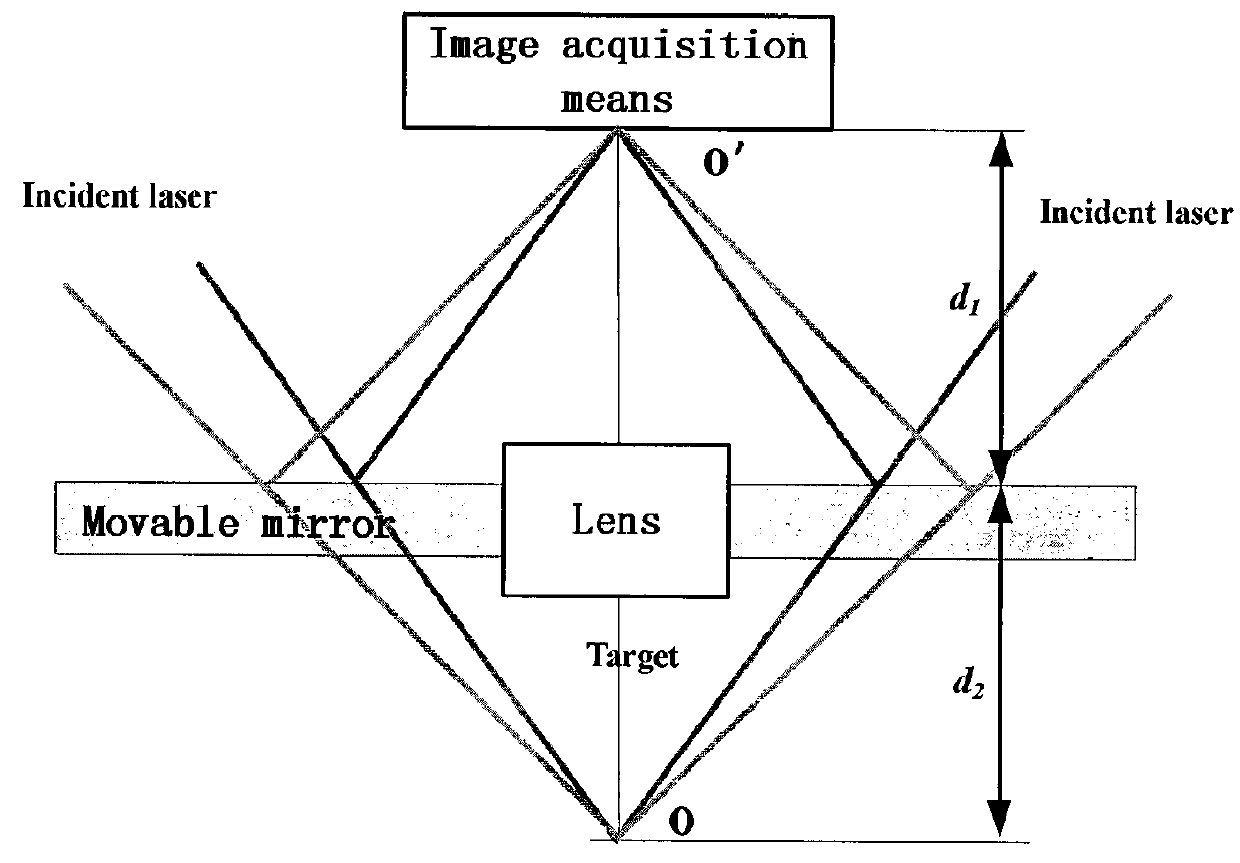

Laser alignment device with a movable mirror, laser-target alignment sensor with movable mirrors and laser alignment method

InactiveUS9360650B2Fast and accurate alignmentImprove accuracyColor television detailsClosed circuit television systemsLinear motionLaser target

A laser alignment device with at least one movable mirror, a laser-target alignment sensor with movable mirrors and a laser alignment method are disclosed. The laser alignment device with the movable mirror comprises an image acquisition means for collecting incident lasers, a moveable mirror for reflecting the lasers to the image acquisition means and is operable to move linearly with respect to the image acquisition means, and a lens for forming an image of a target in the image acquisition means. The present disclosure achieves linear motion of the movable mirror with high accuracy in a small range, which in turn achieves fast and accurate alignment of the laser. It solves the problem of laser spots overlapping, reduces alignment time and improves shooting accuracy.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

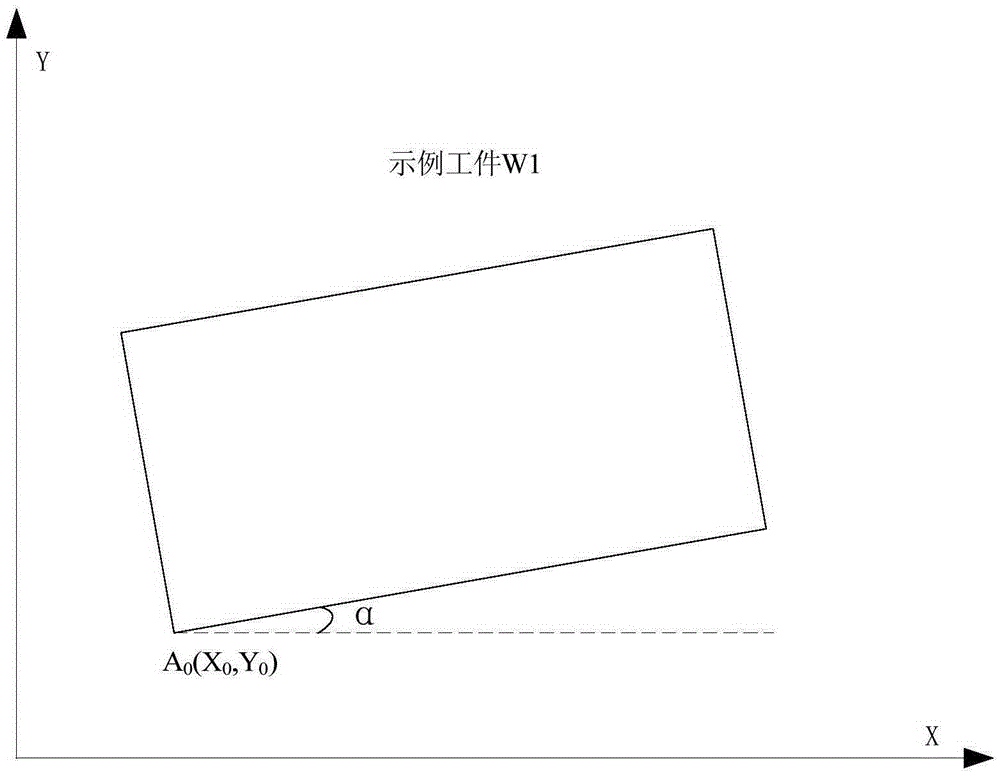

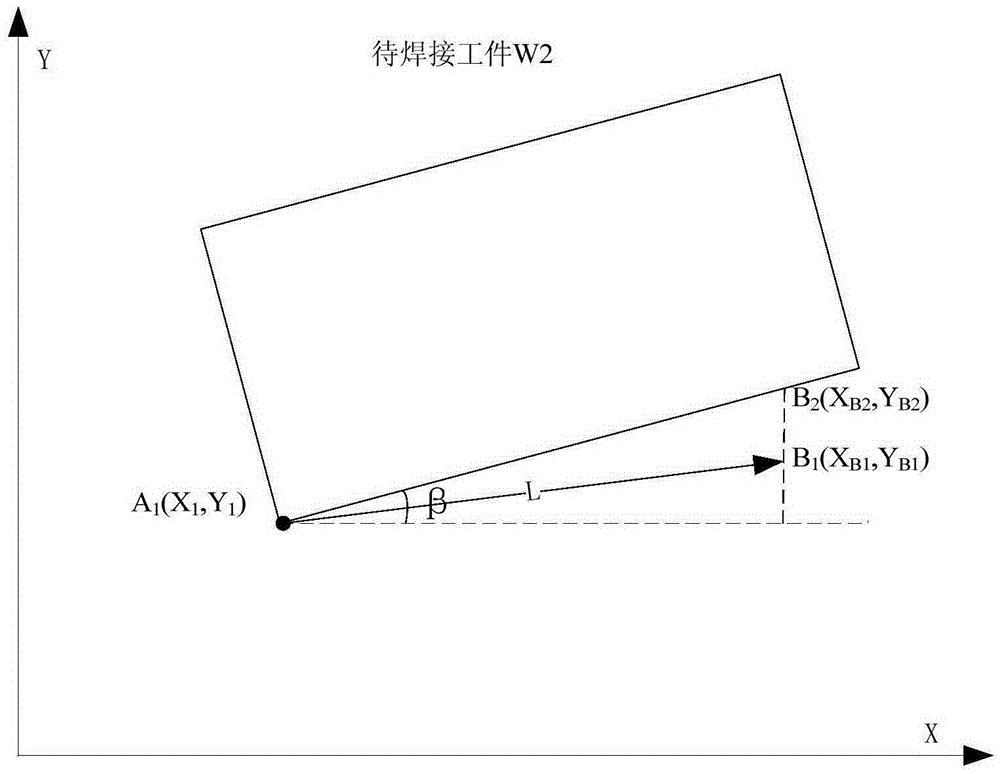

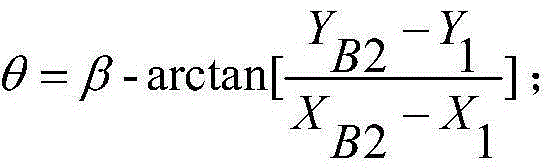

Laser welding alignment method for microwave assembly

ActiveCN105414778AFast and accurate alignmentSimple and fast operationLaser beam welding apparatusMicrowaveEngineering

The invention discloses a laser welding alignment method for a microwave assembly. The laser welding alignment method includes the following steps that firstly, a standard welding position for a workpiece to be welded is preset on a welding platform, a standard welding track is generated according to the standard welding position, and the standard welding position comprises a standard welding initial position A0 and a standard deviation angle alpha of the workpiece; secondly, the workpiece to be welded is placed at any position of the welding platform; thirdly, the actual welding initial position A1 and the actual deviation angle beta of the workpiece to be welded are obtained through an XYZ welding assembly to be compared with those of the standard welding position, and an actual welding track is generated according to the comparison result and the standard welding track; and fourthly, the workpiece to be welded is welded according to the actual welding track. The laser welding alignment method for the microwave assembly has the beneficial effects of being easy and convenient to operate, precise in alignment, high in welding efficiency and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Positioning clamp

InactiveCN111113293AFast and accurate alignmentUseful for finding the midlineWork holdersClassical mechanicsMechanical engineering

Owner:MINGSHUO COMP (SUZHOU) CO LTD +1

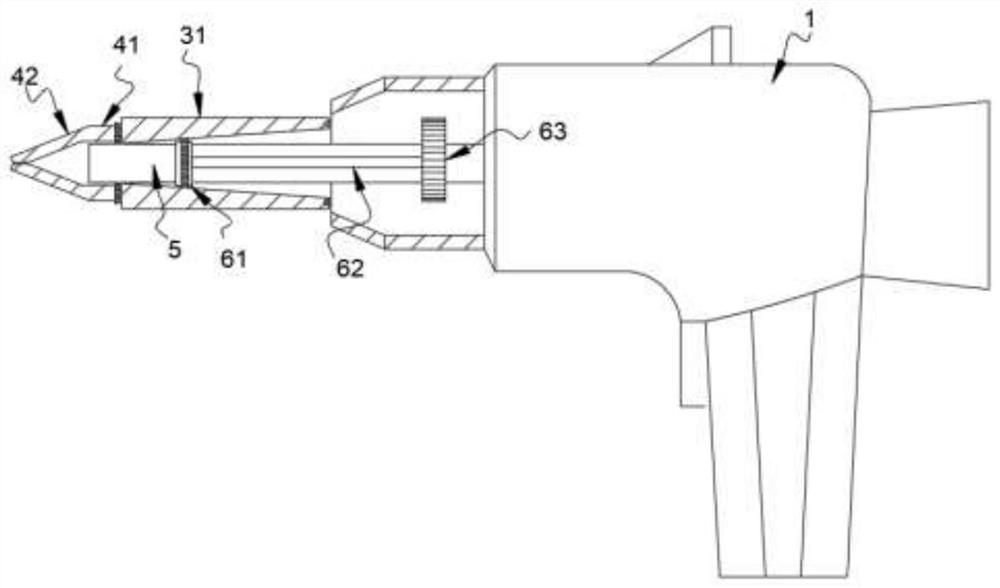

Instrument component assembly detection mechanism, detection method and instrument component thereof

ActiveCN114224404AAvoid surgical risksFast and accurate alignmentSurgeryStructural associationComputer hardwareElectric machinery

The invention discloses an instrument component assembly detection mechanism, an assembly detection method and an instrument component thereof, the instrument component assembly detection mechanism comprises an adapter used for connecting an instrument base and a driving base of the instrument component, and the adapter is movably provided with an adapter which is in butt joint with the driving base and the instrument base; a matching piece is arranged between the adapter piece and the adapter, and the matching piece limits rotation of the adapter piece when the adapter piece and the instrument base are not in butt joint successfully. Flexible soft limiting is adopted, the initial position of the adapter is determined, and the initial position of the adapter is set according to the relative position of the zero position of the motor, so that alignment can be completed only by small-angle rotation under the condition that the alignment position is known, and the whole alignment process is faster and more accurate.

Owner:NANJING TUODAO MEDICAL TECHNOLOGY CO LTD

Device for butted splicing of annular support grid and section sample for transmission electron microscope

ActiveCN107014652AReduce pollutionEasy to adjustPreparing sample for investigationEngineeringElectron microscope

The invention discloses a device for butted splicing of an annular support grid and a section sample for a transmission electron microscope. The device comprises a lifting pedestal, a lifting body, a butted splicing table, a butted splicing column, a slide block and a retaining pin, wherein the lifting body is arranged on the lifting pedestal and is driven by a lifting mechanism to life; the butted splicing table is arranged on the lifting body and is locked on the lifting body through a locking mechanism; a longitudinally distributed column hole is formed in the butted splicing table, and an upper step is arranged on the upper portion of the column hole; a lower step is arranged on the lower end of the butted splicing column, the lower portion of the butted splicing column is movably sleeved in the column hole, and a spring clamped between the lower step and the upper step sleeves on the butted splicing column; the slide block is arranged in the bottom of the butted splicing table in a sliding manner; and the retaining pin is fixed on the slide block which can pushes the retaining pin to the lower end of the column hole. According to the device disclosed by the invention, the distance and dispense volume of dispensing points on the annular support grid can be regulated conveniently, and the annular support grid with the dispensing points is quickly and precisely centered and adhered to the section sample on a grinding machine.

Owner:GUANGXI UNIV

Full-automatic stacking system for large cement component steam curing kiln and control method of system

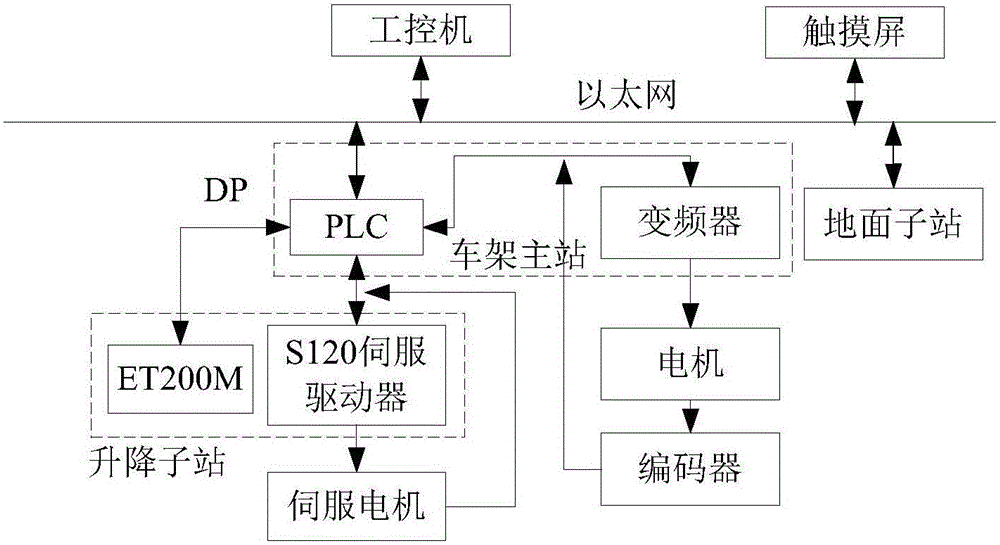

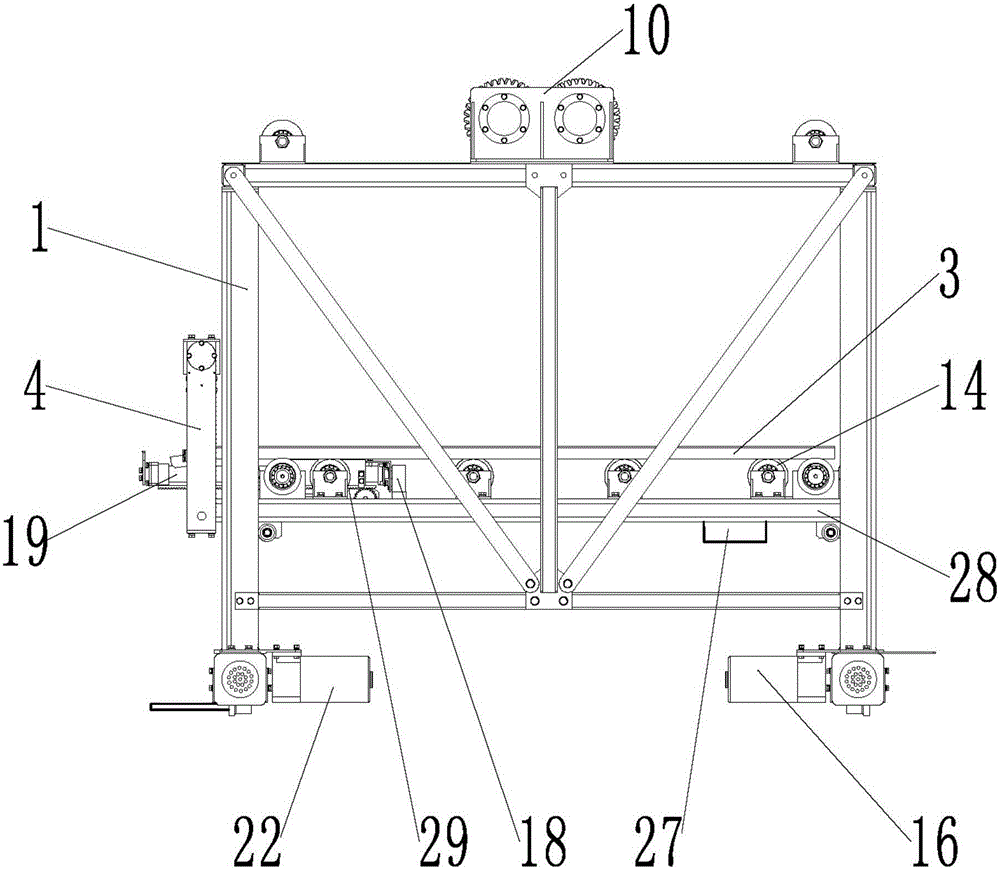

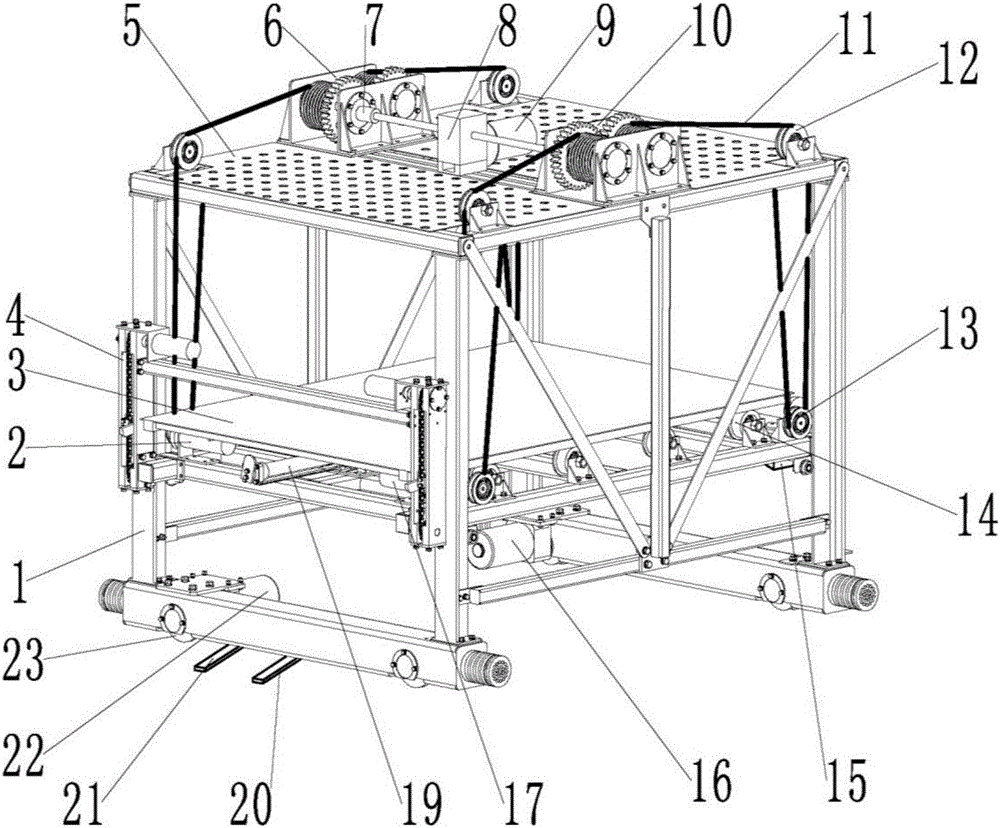

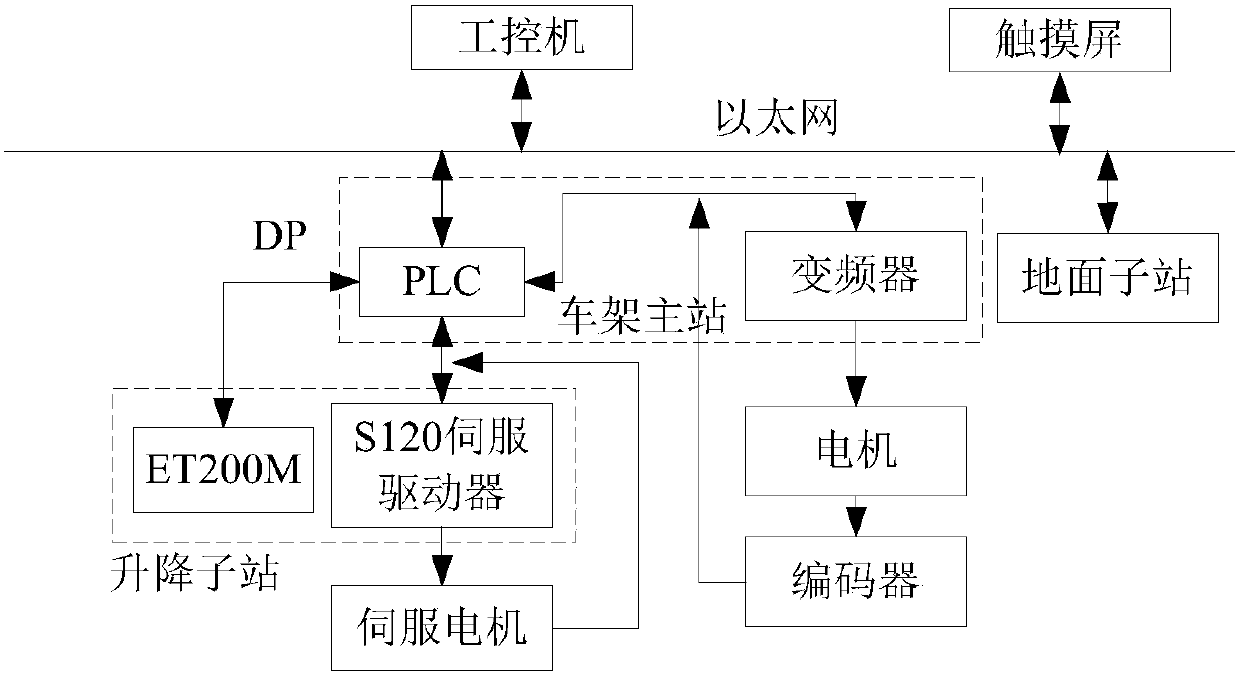

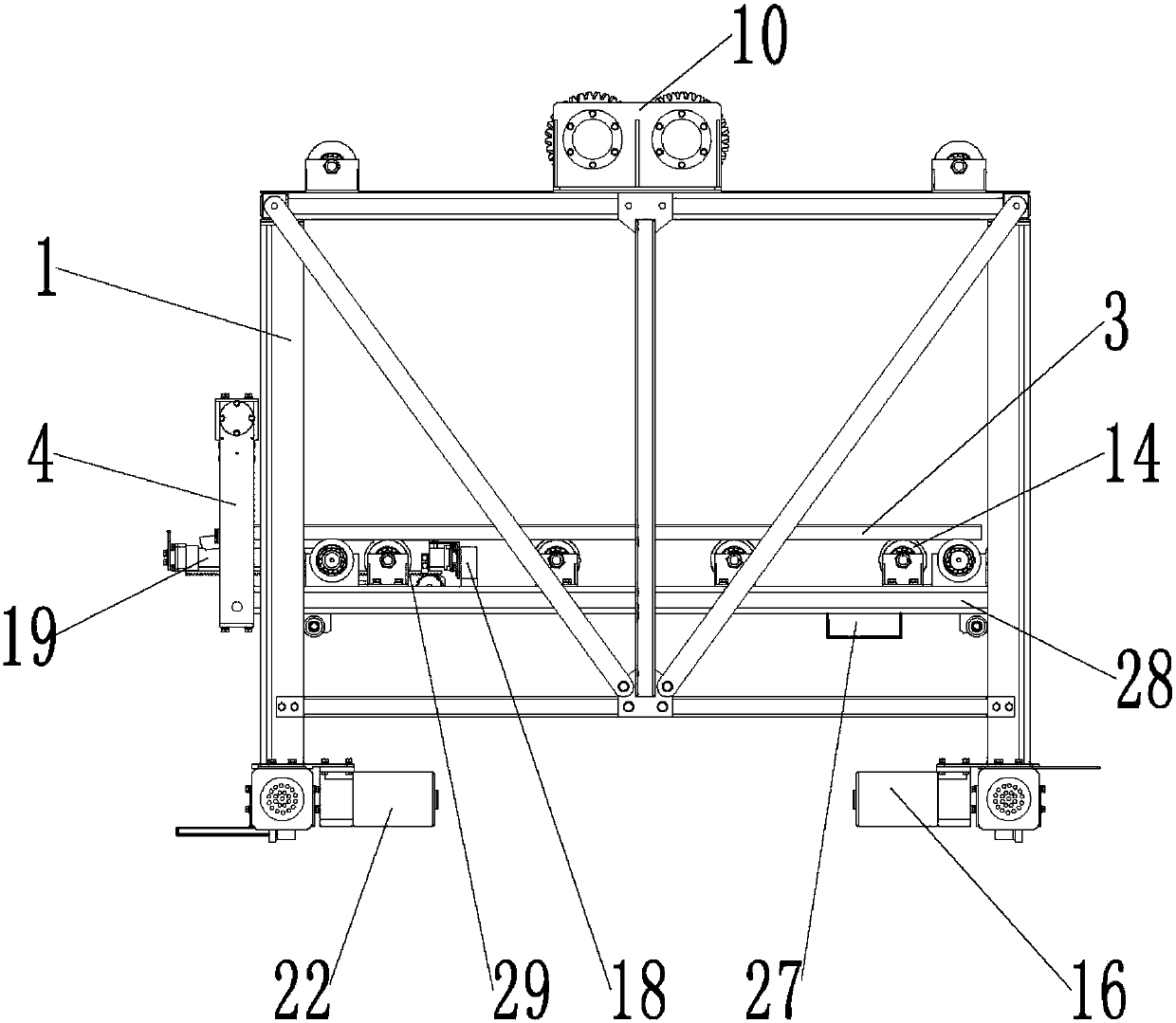

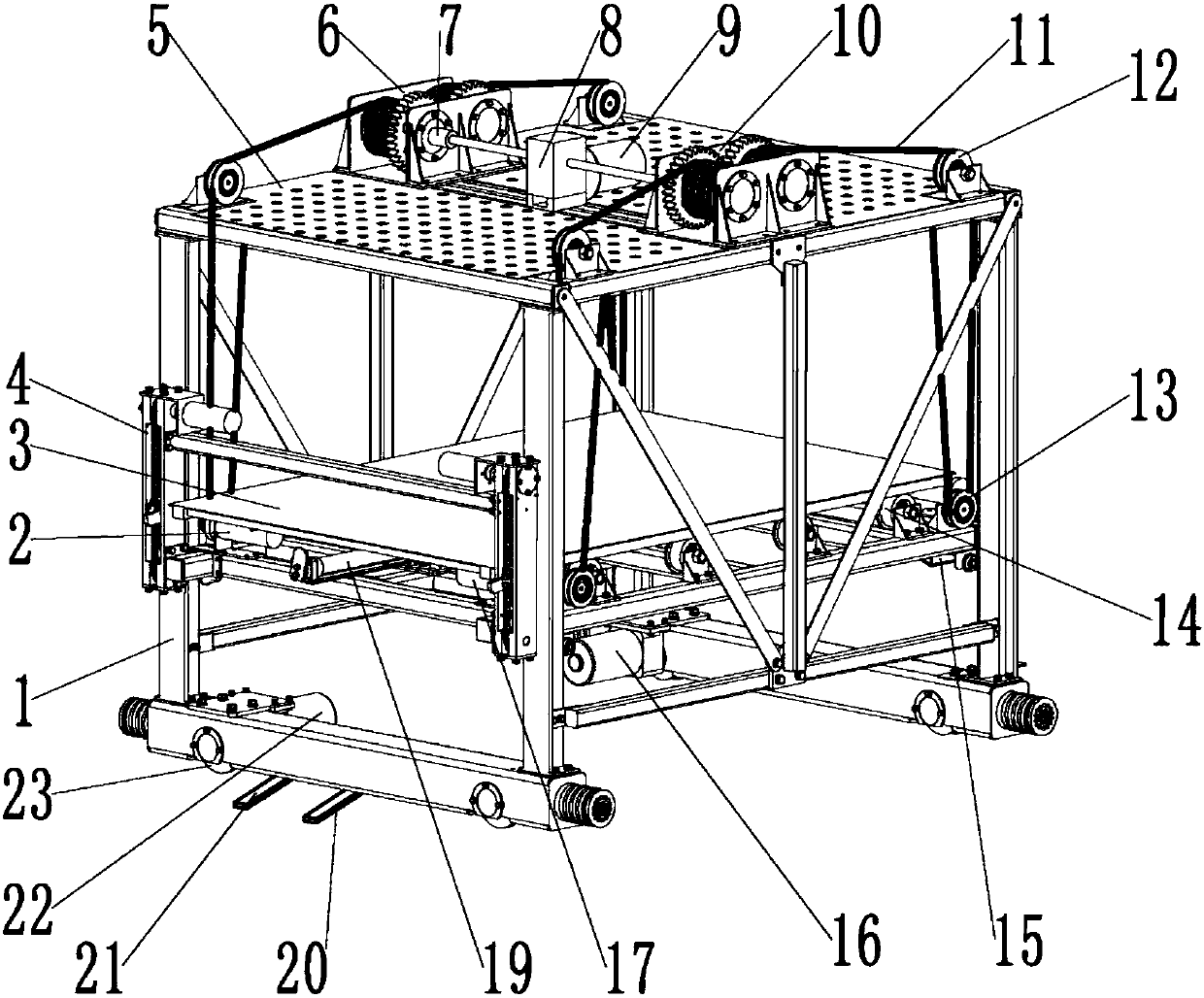

ActiveCN105692221AFast and accurate leveling and alignmentRealize fully automatic intelligent operationStacking articlesProgramme control in sequence/logic controllersTruckVehicle frame

The invention relates to a full-automatic stacking system for a large cement component steam curing kiln. The full-automatic stacking system comprises a control system and a stacking device and is characterized in that the control system and the stacking device are in communication connection through a Profibus-DP network and an industrial Ethernet; the control system comprises an upper computer, a ground substation, a vehicle frame main station and a lifting substation; the upper computer comprises an industrial personal computer and a touch screen; the ground substation is in communication connection with the vehicle frame main station through the Ethernet, the vehicle frame main station is in communication connection with the lifting substation through the Profibus-DP network, the vehicle frame main station comprises a PLC and a frequency changer control module; the lifting substation comprises an ET200M and an S120 servo driver; the ground substation and the touch screen are mounted in an industrial personal computer control cabinet on the ground; and the ground substation comprises the ET200M. According to the system, full-automation intelligent running of a concrete component pallet truck can be achieved.

Owner:河北省机电一体化中试基地有限公司

Airborne IoT terminal and information transmission method

ActiveCN110445530BMiniaturizationLow profileActive radio relay systemsSatellite radioNetwork communication

The invention discloses an airborne Internet of Things terminal and an information transmission method, which belong to the technical field of the Internet of Things; by installing the airborne Internet of Things terminal in an unmanned aerial vehicle or a general-purpose aircraft, the data transmitted by the on-board sensor is received and transmitted to The satellite radio frequency unit realizes frequency conversion, so that the synchronous or medium-low orbit communication satellite can receive signals through the transmission behavior of the two-dimensional phased array antenna; Networked communication, through the long-distance coverage of satellites, solves the problem of the short transmission distance of the traditional Internet of Things and the inability to achieve cross-regional coverage of information collection; and realizes accurate and fast alignment of satellites when the aircraft is stationary and at high speed, and completes Real-time communication of information.

Owner:天宸星通(深圳)科技有限公司

A graphite bar grinding device

ActiveCN114571302BIncrease frictionReduce the chance of driftRevolution surface grinding machinesGrinding drivesEngineeringStructural engineering

The invention relates to the field of surface treatment of graphite rods, in particular to a graphite rod grinding device, which is composed of a rod fixing unit and a grinding unit, the rod fixing unit and the grinding unit are both installed on the ground, and the The bar fixing units are arranged symmetrically on the left and right, the grinding unit is located between the bar fixing units, and the number of grinding units is two, the present invention not only performs surface grinding treatment on the graphite bar, but also can The graphite bar after surface grinding treatment is subjected to surface grinding and polishing treatment, and the surface treatment quality of the graphite bar is greatly improved through the cooperation between two different surface treatments. At the same time, in the present invention, the rod fixing unit is The clamped graphite rod is not easy to be in a suspended state, and the graphite rod has high stability and is not easy to be offset.

Owner:江苏华之沃电气智能科技有限公司

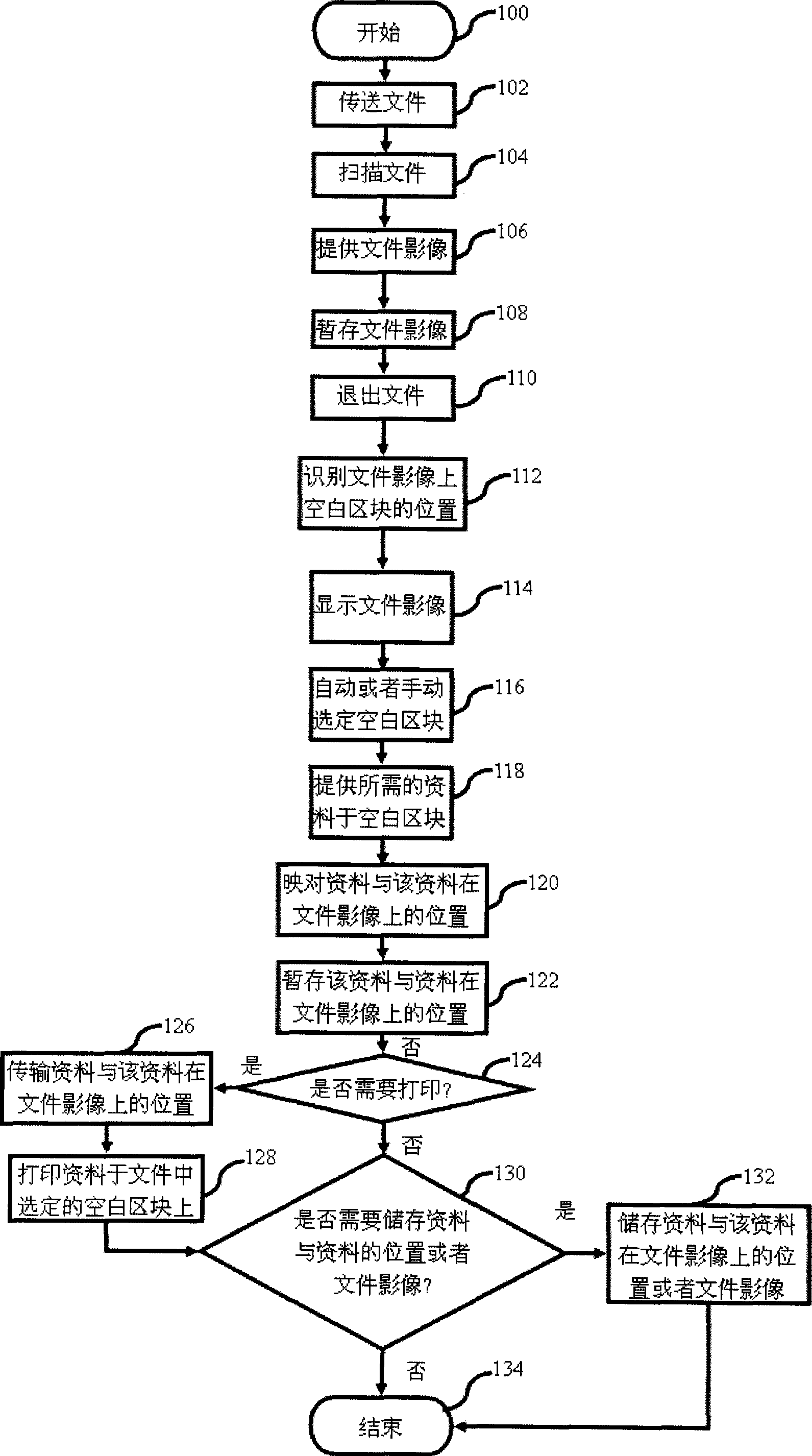

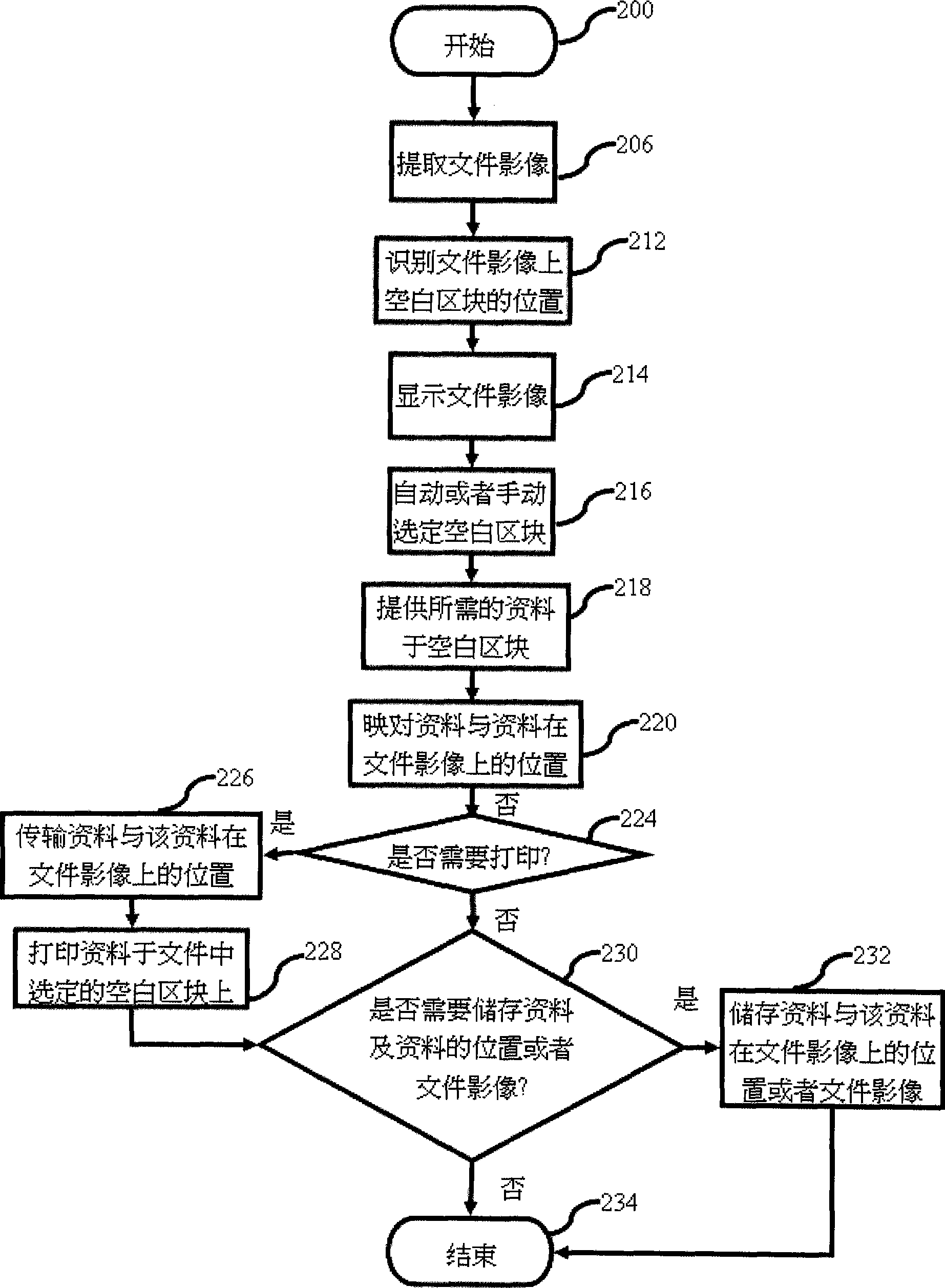

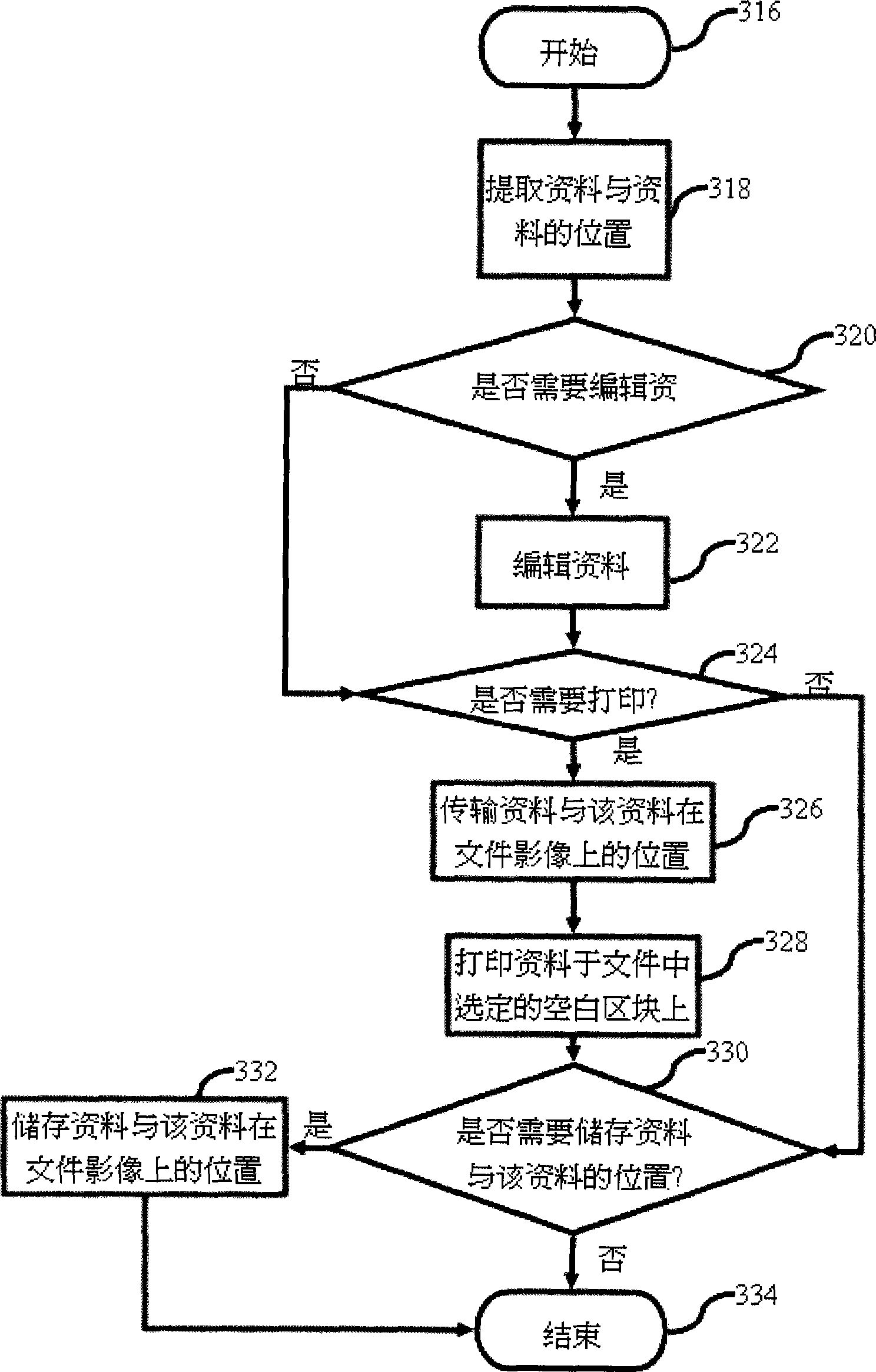

Method and device for combining data with files

InactiveCN101482974AReduce consumptionFast and accurate alignmentModifying/creating image using manual inputSpecial data processing applicationsComputer graphics (images)Database

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

A kind of coated glass integrating sound insulation and heat insulation

ActiveCN110685542BNovel structureImprove sound insulationUnits with parallel planesBi layerEngineering

The invention provides a kind of coated glass integrated with sound insulation and heat insulation, which includes a first glass body, a transparent plate and a second glass body which are stacked in sequence and suspended by spacers to form a first interlayer cavity and a second interlayer cavity; A sealant is filled between the area on the side away from the center of the transparent plate and the transparent plate, the first glass body and the second glass body; the edge of the first glass body is fixedly embedded with a plurality of male parts, and the insertion tube of the male part It protrudes from the bottom surface of the first glass body; the edge position of the second glass body corresponds to the male head piece and is fixedly embedded with a plurality of female head pieces, the receiving groove of the female head piece protrudes from the top surface of the second glass body, and the transparent plate is provided with A plurality of first through holes, and a plurality of second through holes corresponding to the receiving grooves in the spacer bar; the insertion tube passes through the second through holes and the first through holes to cooperate with the receiving grooves; its novel structure can provide a double-layer interlayer space , to further enhance the effect of sound insulation and heat insulation; the overall structure is convenient for production, assembly and operation.

Owner:广东华玻科技有限公司

Bolt torque detection device

PendingCN113959625AGuaranteed flexibilityFast and accurate alignmentMeasurement of torque/twisting force while tighteningUniversal jointEngineering

The invention relates to the technical field of structure detection, and particularly discloses a bolt torque detection device. The device is used for testing the fastening performance of a bolt and comprises a positioning clamp, a handle piece and a control panel; the positioning clamp is a cylindrical part, a limiting groove is formed in one side of the positioning clamp, a nut of the bolt can be sleeved with the limiting groove, and an adsorption part is further arranged at the bottom of the limiting groove and used for adsorbing the bolt; the handle piece is connected with one end of the multi-stage telescopic rod, and the end, away from the handle piece, of the multi-stage telescopic rod is rotationally connected with the side, without the limiting groove, of the positioning clamp through a universal joint; the control panel is installed on the handle piece and can control the multi-stage telescopic rod to stretch out and draw back, and the positioning clamp can rotate along the axis of the positioning clamp and can rotate relative to the multi-stage telescopic rod. According to the device, through the structural design that the position and the angle of the positioning fixture are adjustable, the detection of the fastening performance of the bolt can be accurately completed, and the detection efficiency is improved while the detection safety is ensured.

Owner:SGIS SONGSHAN CO LTD

Brake Caliper Test Bench

ActiveCN106680000BRealize hoistingImprove assembly efficiencyMachine part testingRailway vehicle testingReciprocating motionEngineering

The invention provides a brake clamp testbed. The brake clamp testbed comprises a support capable of fixing a brake clamp, and a rotary disc unit capable of linearly reciprocating in the direction vertical to the support. Two limiting units capable of hoisting the brake clamp are installed on the top of the support, first through holes capable of being connected with the two ends, in the clamping direction, of the brake clamp in a sleeving mode are formed in the limiting units, and the support is provided with a first driving unit capable of driving the brake clamp to rotate around the axes of the first through holes. The rotary disc unit comprises a rotary disc with the two side faces capable of being clamped by the brake clamp at the same time, and a second sliding base capable of supporting the two sides of the rotary disc. The second sliding base is connected with a second driving unit capable of driving the second sliding base to linearly move. The test result is accurate, and the assembly efficiency of the brake clamp is high.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Processing device and method for precise control of wall thickness error of rotary shell parts

ActiveCN111716147BThe wall thickness error satisfiesControl errorAutomatic control devicesMeasurement/indication equipmentsKinematic controllerMicro nano

A processing device and method for precisely controlling the wall thickness error of rotary shell parts, belonging to the field of precision / ultra-precision processing, including a main controller, a precision detection device for workpiece run-out, a precision adjustment device for workpiece position, a precision detection device for the height of a tool tip, and a tool tip High precision adjustment device and auxiliary structure. Among them, the workpiece runout precision detection device is used to precisely detect the runout of parts; the workpiece position precision adjustment device is used to realize accurate and fast alignment of the workpiece; the tool tip height precision detection device includes a tool tip height detection controller, a tool tip height detection sensor, etc. , used for precision checking of the height of the knife tip; the precision adjustment device for the height of the knife tip includes a micro-nano motion controller, a knife holder base, a dovetail guide rail, an upper and lower knife holder block, a micro-nano lifting platform, etc., to realize the micro-nano height of the knife tip Adjustments for precision. The invention has a simple device and a simple method, can realize the processing requirements of high contour accuracy and high wall thickness error of rotary parts, and is easy to realize automation.

Owner:DALIAN UNIV OF TECH

Fully automatic palletizing system and its control method for steam-cured kilns of large cement components

ActiveCN105692221BRealize fully automatic intelligent operationEfficient processStacking articlesProgramme control in sequence/logic controllersFrequency changerIndustrial Ethernet

The invention relates to a full-automatic stacking system for a large cement component steam curing kiln. The full-automatic stacking system comprises a control system and a stacking device and is characterized in that the control system and the stacking device are in communication connection through a Profibus-DP network and an industrial Ethernet; the control system comprises an upper computer, a ground substation, a vehicle frame main station and a lifting substation; the upper computer comprises an industrial personal computer and a touch screen; the ground substation is in communication connection with the vehicle frame main station through the Ethernet, the vehicle frame main station is in communication connection with the lifting substation through the Profibus-DP network, the vehicle frame main station comprises a PLC and a frequency changer control module; the lifting substation comprises an ET200M and an S120 servo driver; the ground substation and the touch screen are mounted in an industrial personal computer control cabinet on the ground; and the ground substation comprises the ET200M. According to the system, full-automation intelligent running of a concrete component pallet truck can be achieved.

Owner:河北省机电一体化中试基地有限公司

Ear-nose-throat endoscope device

The invention belongs to the technical field of medical instruments, and particularly relates to an ear-nose-throat endoscope device which comprises a shell, an endoscope body is fixedly mounted on one side of the shell, an adjusting barrel is fixedly mounted on the side, close to the endoscope body, of the shell, and an expanding and supporting assembly is rotationally connected to one side of the adjusting barrel; the expanding and supporting assembly capable of expanding the examination part of the patient is arranged outside the endoscope body, the expanding and supporting assembly is composed of the four expanding plates distributed in the central symmetry mode, and the four expanding plates can be tightly attached to the outer portion of the endoscope body, so that the overall occupied area of the expanding and supporting assembly is reduced; when the endoscope body is inserted into an examination part, the four expansion plates can be driven to expand at the same time by sliding the auxiliary adjusting assembly, so that the examination part of the patient is expanded, the endoscope body can conveniently observe the examination part, and the examination efficiency is improved. And the operation is simple and convenient.

Owner:焦粤农

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com