Processing device and method for precise control of wall thickness error of rotary shell parts

A processing device and precise control technology, which is applied in the direction of automatic control device, workpiece feed movement control, manufacturing tools, etc., can solve problems such as difficult to meet high contour accuracy and high wall thickness error, low adjustment efficiency, high technical requirements, etc., to achieve guaranteed High coaxiality requirements, automation, easy to use and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

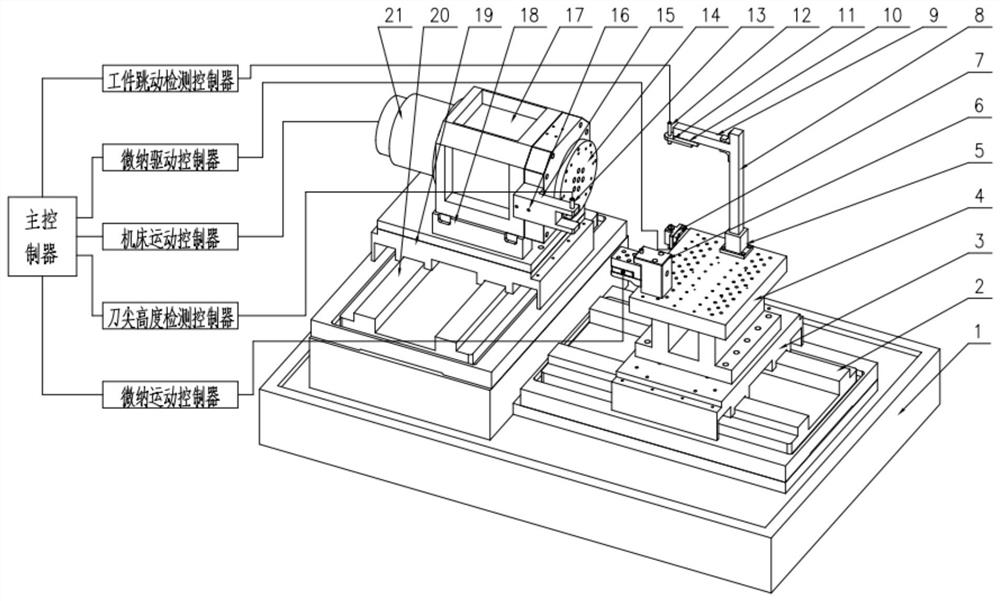

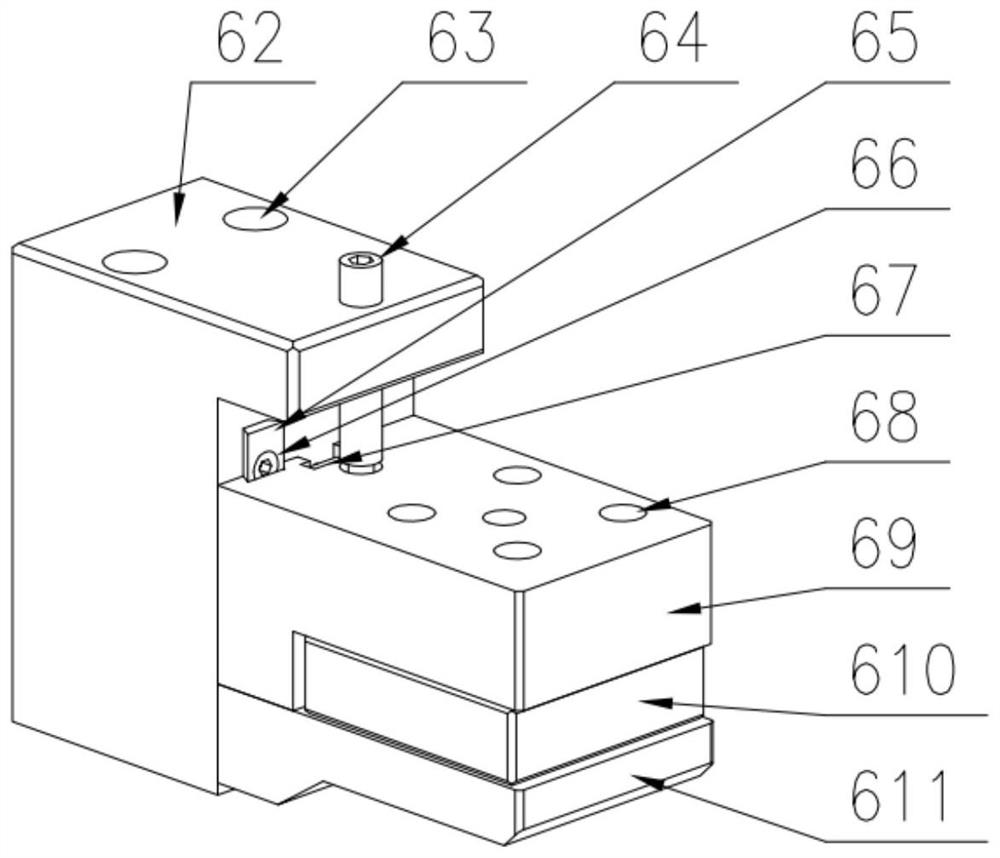

[0050] like Figure 1-11 As shown, the precise control processing device for the wall thickness error of the rotary shell parts includes the main controller, the machine tool motion controller, the workpiece runout precision detection device, the workpiece position precision adjustment device 7, the tool tip height precision detection device, and the tool tip height precision adjustment device 6 , and its subsidiary structure, said subsidiary structure comprises bed 1, Z-axis guide rail 2, Z-axis support plate 3, marble seat 4, main shaft (C-axis) seat 17, main shaft (C-axis) cushion 18, X-axis Pallet 19, X-axis guide rail 20, main shaft (C-axis) 21.

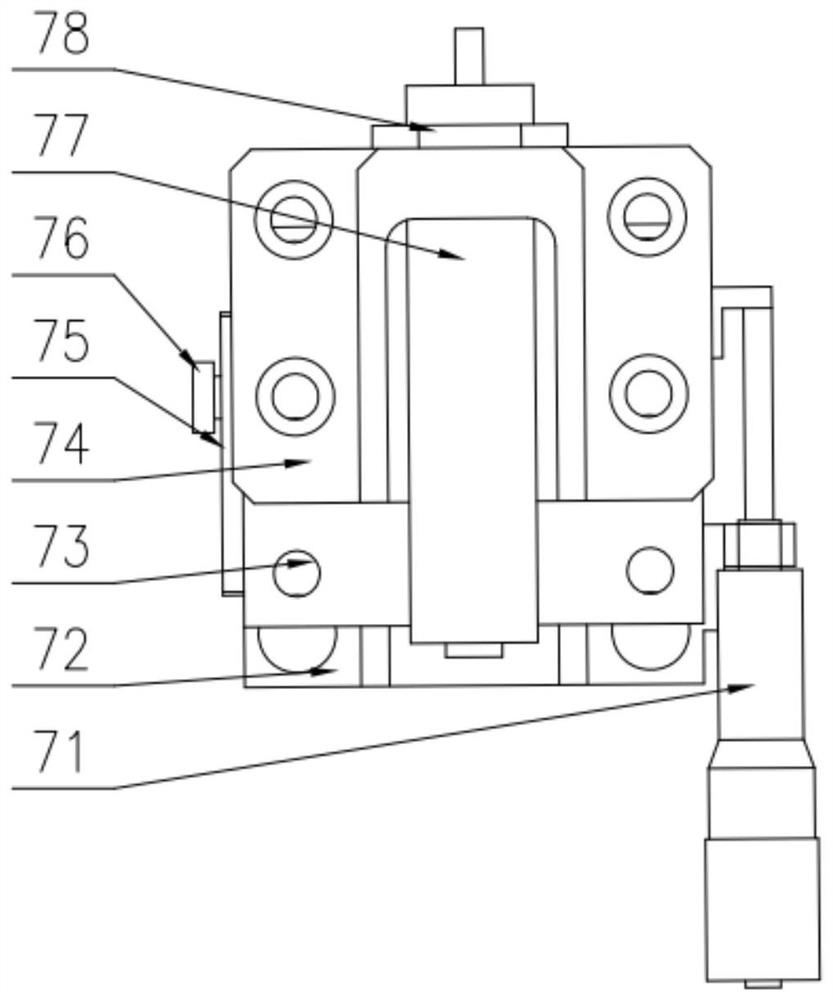

[0051] The workpiece jumping precision detection device includes a workpiece jumping detection controller, a jumping detection device base 5, a jumping detection device column 8, a jumping detection device crossbeam 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com