Laser welding alignment method for microwave assembly

A technology of laser welding and microwave components, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult alignment of tracks, long alignment time of workpiece tracks, and increased complexity of operators, and achieve alignment Accurate and fast, easy to operate, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] The laser welding platform used in the laser welding alignment method for microwave components of the present invention includes an XY welding platform, a Z-axis lifting platform, a servo motor, a servo driver, a CNC controller, an industrial computer (including two displays) and the like. The working platform is used to provide the environment required for laser welding. The XY working platform, Z-axis lifting table, servo motor, servo driver and CNC controller are used to realize the precise movement and control of XYZ welding components. The industrial computer is used for G code file storage, Downloading and conversion, one of the display screens is used to provide man-machine operation interface, and the other display screen is used for real-time monitoring of welding images.

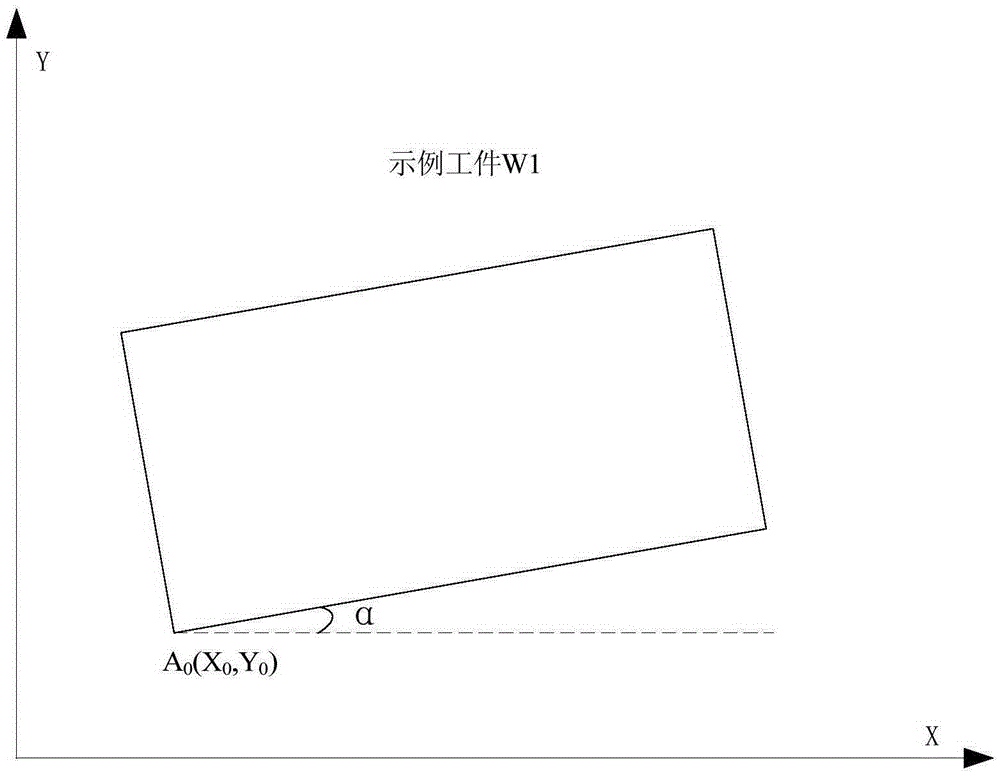

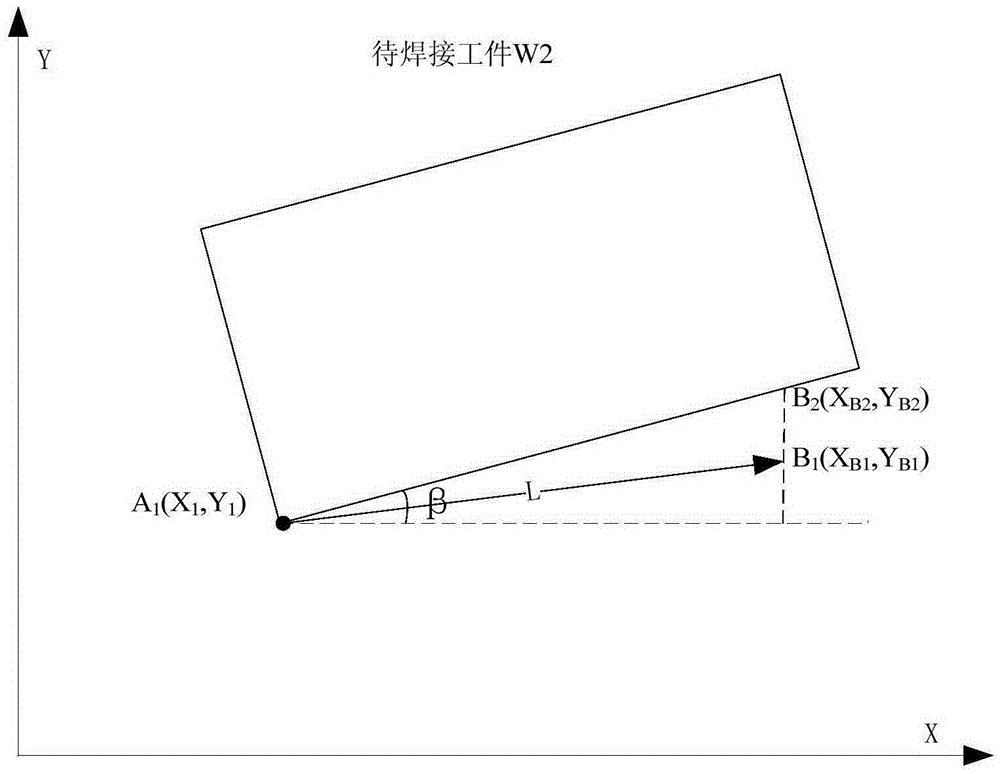

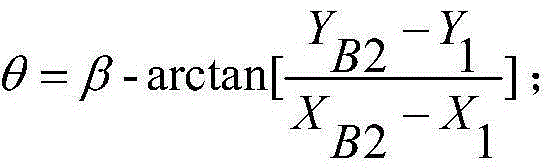

[0022] Such as figure 1 and figure 2 As shown, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com