Full-automatic stacking system for large cement component steam curing kiln and control method of system

A stacking system and steam-cured kiln technology, which is applied in the field of automatic palletizing system and control of large-scale cement component steam-cured kilns, can solve problems such as large weight, large safety hazards, and inclined placement, and achieve fast and accurate leveling and counterpoint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention relates to a full-automatic stacking system and a control method for a steam-cured kiln for large cement components.

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

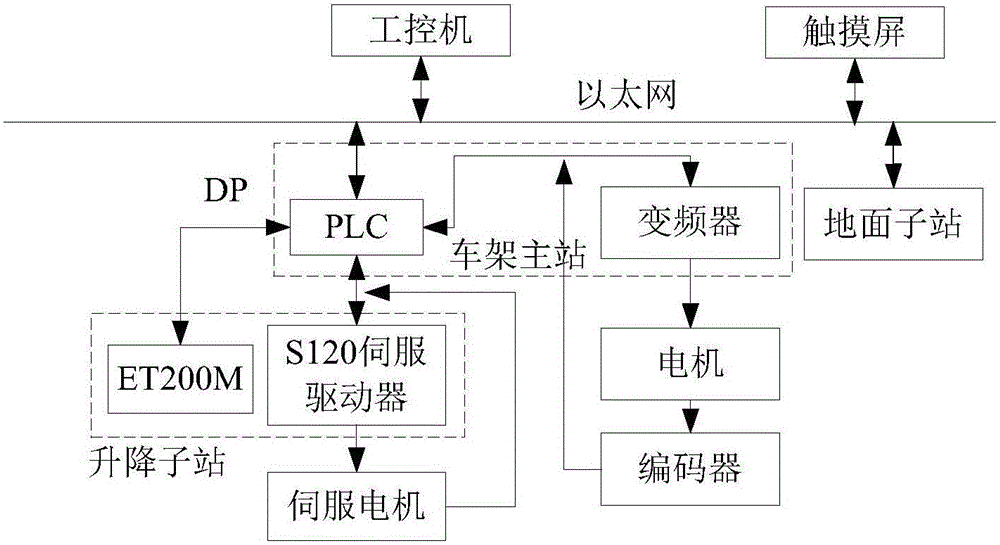

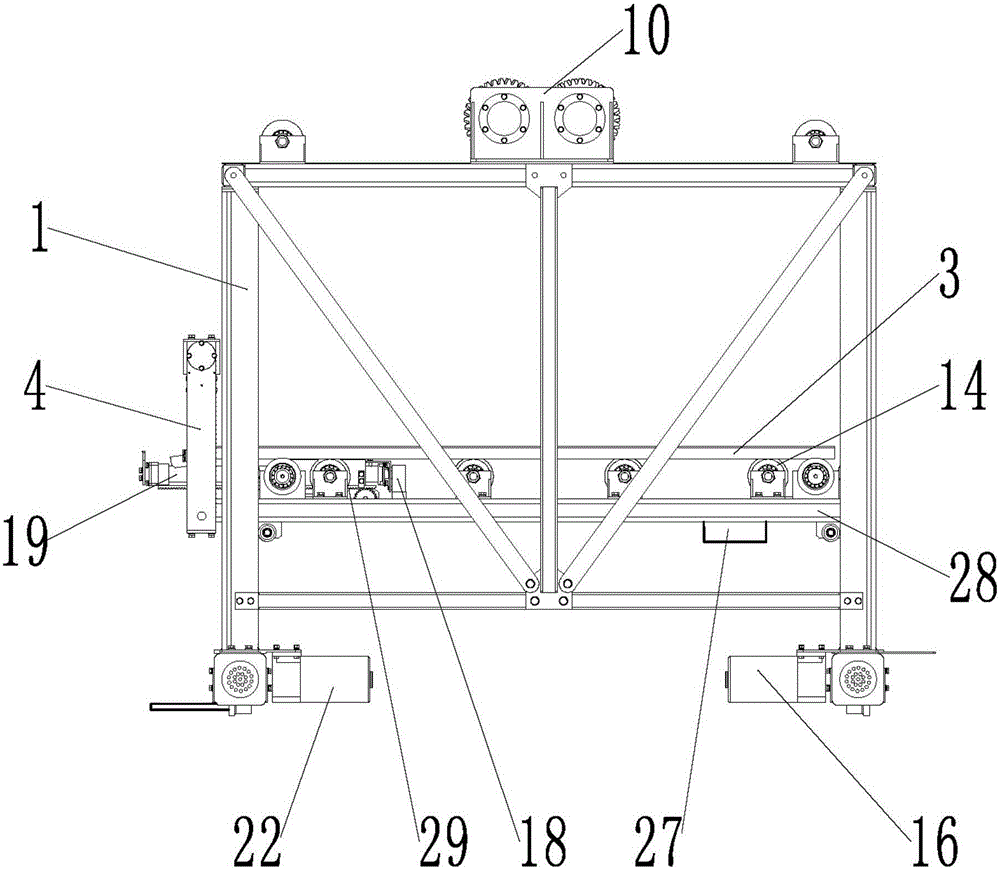

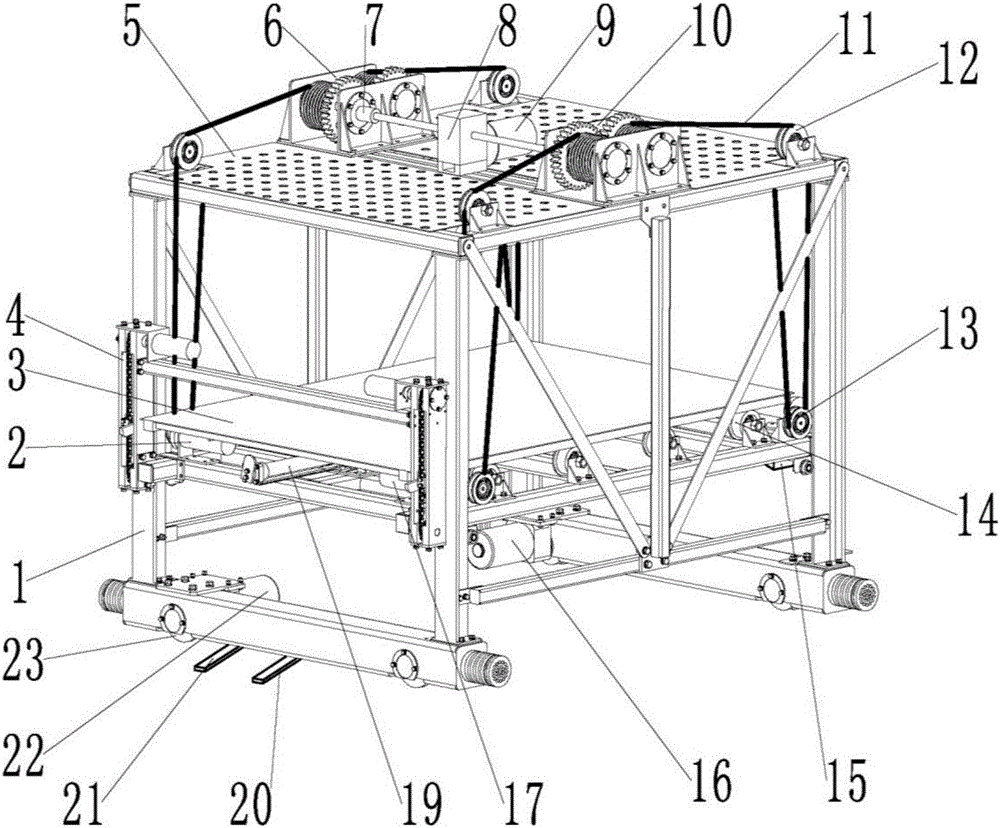

[0031] Specific examples, such as Figure 1 to Figure 5 As shown, the large-scale cement component steam-cured kiln automatic palletizing system includes a control system and a palletizing device. The control system includes a host computer, a ground substation, a frame master station, and a lift substation, the host computer includes an industrial computer and a touch screen, and the ground substation and the frame master station are connected through Ethernet, The main station of the vehicle frame and the lifting sub-station are connected through the Profibus-DP network. The main station of the vehicle frame includes a PLC and a frequency converter. The CPU of the PLC adopts Siemens 315-2PN / DP; the frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com