Non-contact detection and optimum smelting control method for submerged arc furnace electrode

A control method and technology of submerged arc furnace, applied in electrical components, measuring devices, electric heating devices, etc., can solve the problems of high labor intensity, prominent energy consumption, high product input cost, and achieve lower product input cost, labor intensity, The effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

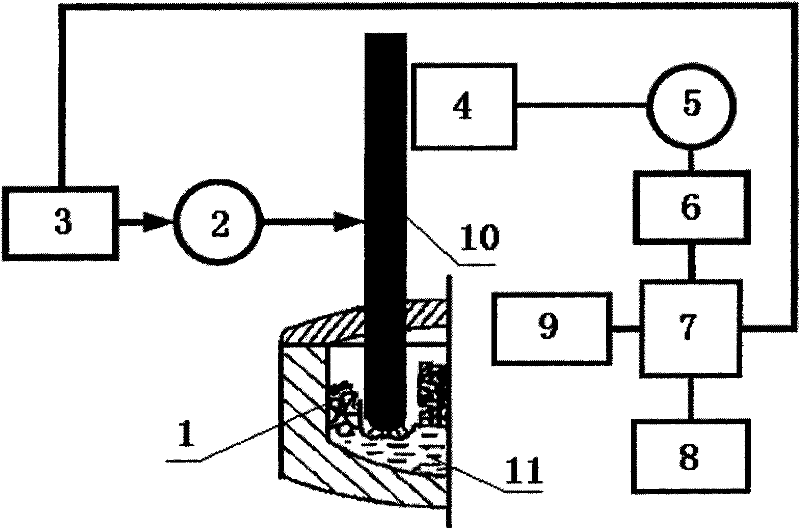

[0027] The present invention installs a non-contact sensor on the relevant parts of the electrodes of the submerged arc furnace to detect the relative length of the electrodes, and installs a position sensor of the conductive beam to detect the balance of the conductive beam and the verticality of the electrodes, and cooperates with the current ring and the bottom of the furnace. The detection of temperature, the detection of material distribution, and the control method to make the electrodes of the submerged arc furnace work in the best smelting state.

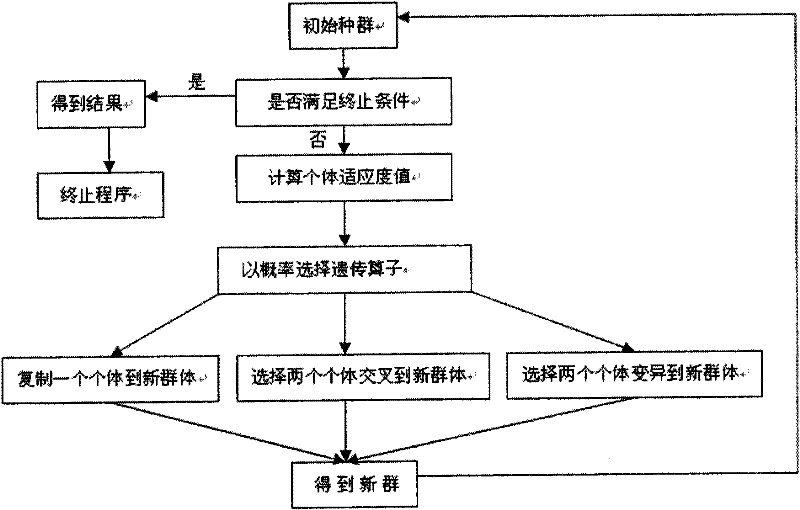

[0028] The present invention adopts the on-line detection technology of the optimal electrode discharge position and working condition parameters, and collects and analyzes data on the relative length and working conditions of the electrodes of the submerged arc furnace based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com