Design and preparation of mold for pipy composite materials suitable for RTM (resin transfer molding) process

A composite material and tubular mold cavity technology, which is applied in the field of mold structure design of the resin transfer molding process of tubular composite materials, can solve the problems of mold design and preparation of three-dimensional tubular composite materials, etc., and achieves simple and easy demoulding operation. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

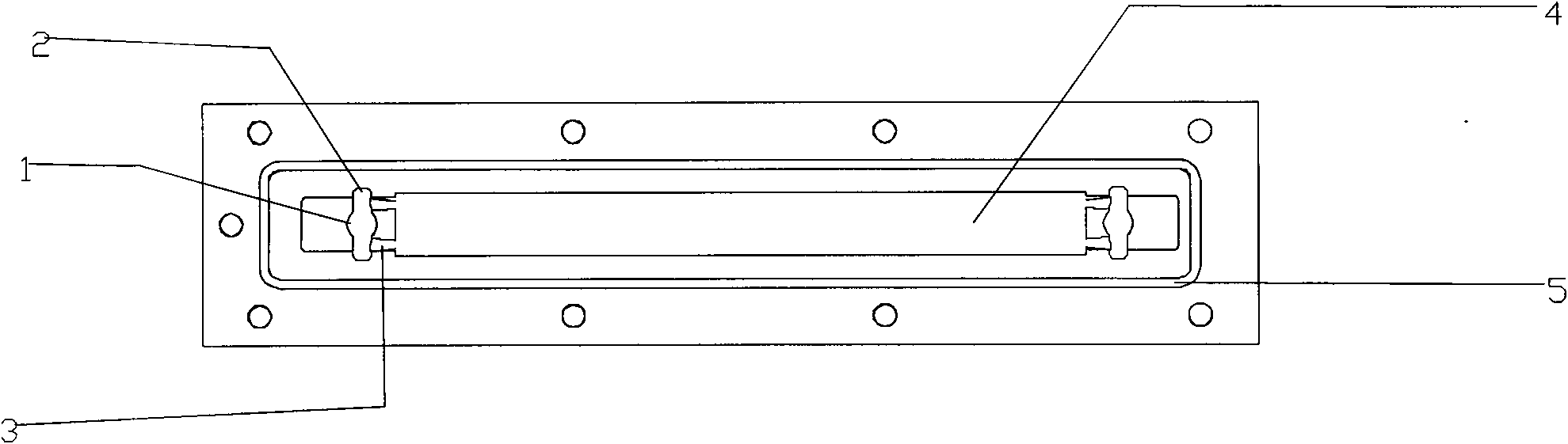

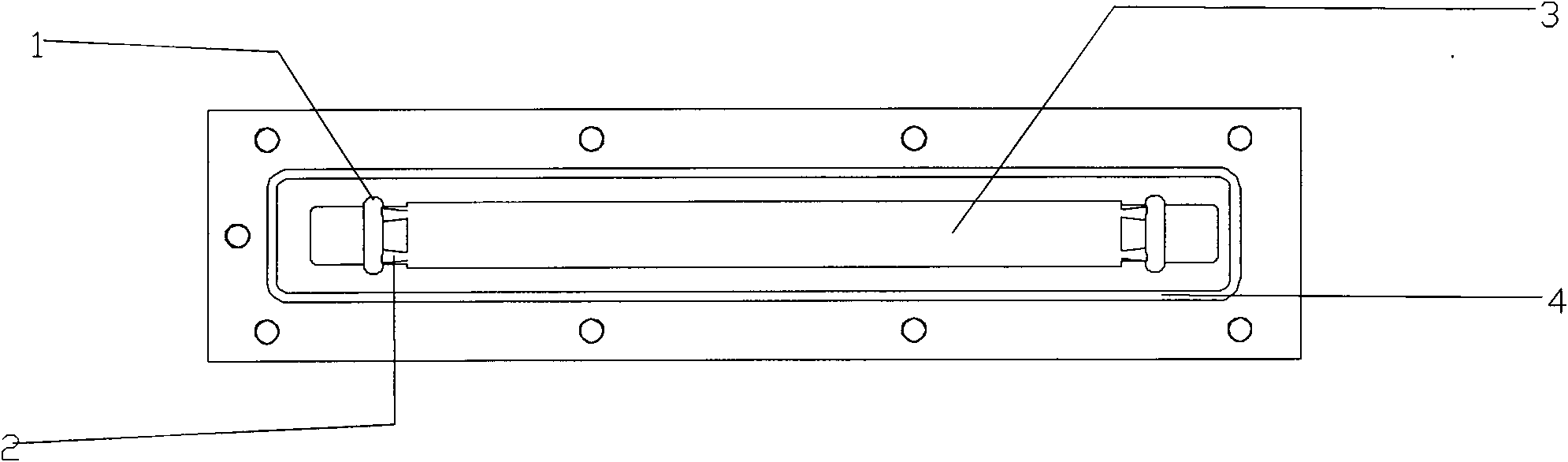

[0016] figure 1 1 is the injection port, 2 is the annular groove embedded in the half circumference of the outer mold, 3 is the channel for the resin to enter the mold cavity from 2, 4 is the inner wall of the outer mold, and 5 is the the seal groove.

[0017] figure 2 It is the lower half of the outer mold of the female mold. When injecting resin, the resin first fills 2 through the injection port 1 along the annular path, and then enters the mold cavity formed by the inner core and the outer mold through the channel 3 and soaks the fabric.

[0018] image 3 It is the inner core of the cylindrical male mold.

[0019] Figure 4 It is the top view of the mold after it is closed. 1 is the resin injection port, 2 is the resin outlet, and 3 is the fastening screw.

[0020] Figure 5 is the overall perspective view of the mold, 1 is the injection port, 2 is the annular groove embedded in the upper and lower half of the outer mold of the female mold, 3 is the channel for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com