Easy-to-remove type die-casting die

A die-casting mold and pattern technology, applied in the field of easy-release die-casting molds, can solve problems such as affecting production efficiency and inability to guarantee, and achieve the effects of convenient processing, improved production efficiency, and simple release operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

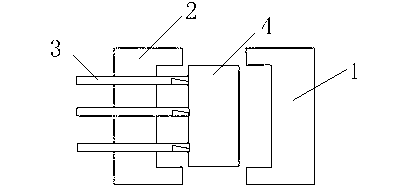

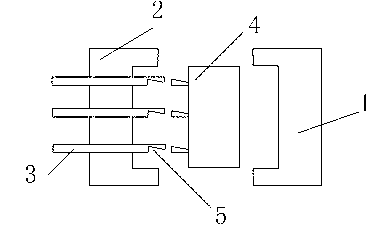

[0012] Such as figure 1 , figure 2 A kind of easy-off pattern die-casting mold shown, comprises fixed mold assembly, and its difference is: the processing surface of the fixed mold assembly that the present invention adopts is provided with movable mold assembly, and fixed mold assembly and A cavity is formed between the movable mold components. At the same time, considering the need of demoulding, a through hole is arranged on the movable mold assembly, and a thimble assembly is arranged in the through hole. Moreover, in order to facilitate rapid demoulding, a demoulding connecting end is distributed on the working end of the thimble assembly located in the cavity.

[0013] As far as a preferred embodiment of the present invention is concerned, considering the demoulding requirements in actual work and operation, and avoiding the breakage of the thimble assembly due to uneven force, the thimble assembly used is composed of at least three elongated thimbles.

[0014] Looki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com