Special-shaped brick manufacturing device and method

A technology for special-shaped bricks and equipment, which is applied in the direction of auxiliary forming equipment, forming indenters, manufacturing tools, etc., can solve the problems of unrealistic manufacturing and production, and achieve the effect of strengthening effective reuse, high yield rate, and reliable demoulding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

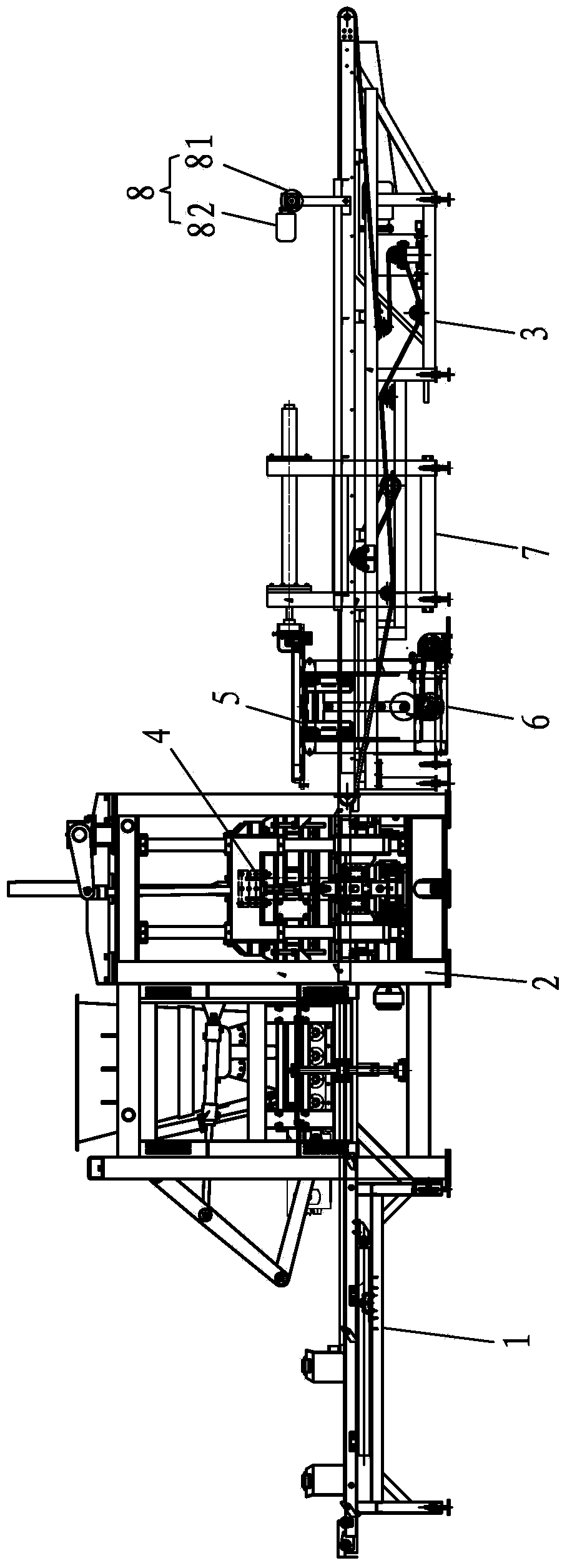

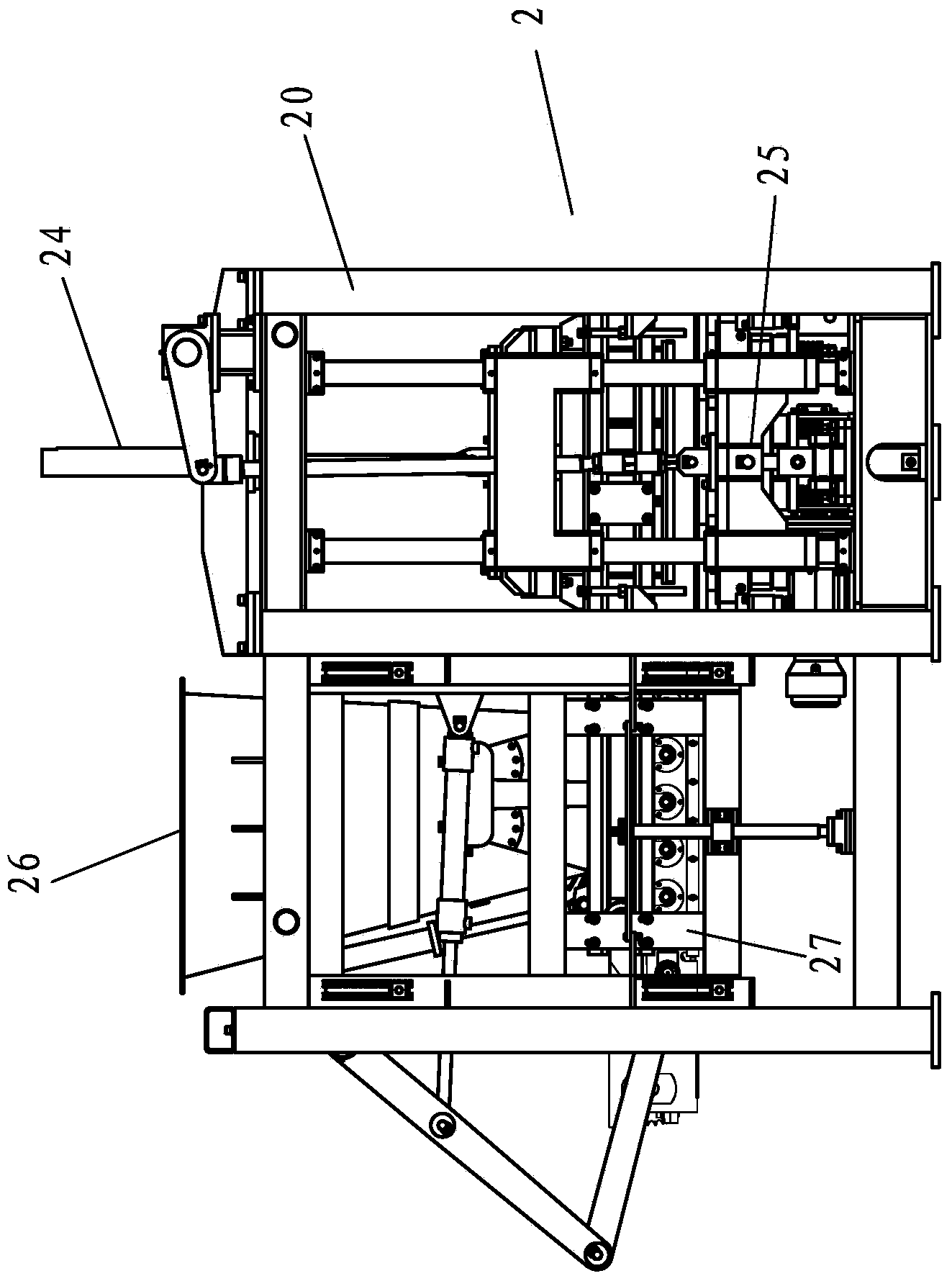

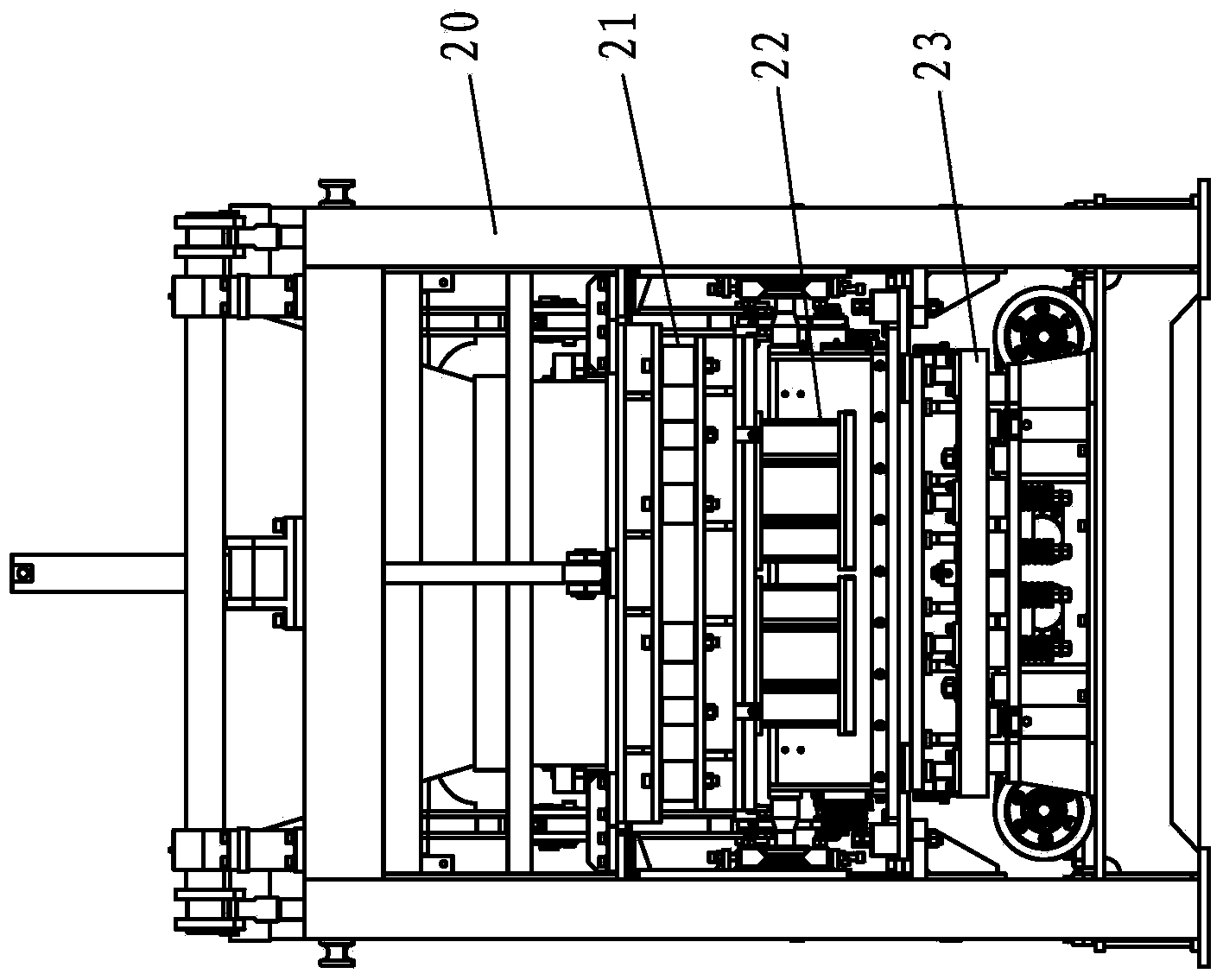

[0066] The invention relates to a brick-making equipment for special-shaped bricks, such as figure 1 As shown, it mainly includes a plate feeding machine 1, a block forming machine 2, a compound conveyor 3, a die connecting device 4, a forming bottom plate 5 and a bottom plate lifting device 6.

[0067] The board feeding machine 1 is arranged at the rear end of the block forming machine 2, and is used to transfer the flat pallet to the vibrating table located below the block forming machine 2. The composite conveyor 3 is arranged at the front end of the block forming machine 2, and the composite conveyor 3 performs back-and-forth conveying movement relative to the block forming machine 2. On the one hand, it transports the forming bottom plate 5 back and forth, and on the other hand, it transports the demoulded bricks together with the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com