Demoulding device specially for micro-injection forming instrument

A demoulding device and micro-injection technology, which is applied in the field of processing and manufacturing polymer material performance test specimens, can solve the problems of high risk of injury to demoulding operators, difficulty in ejection, difficulty in guaranteeing spline geometry, dimensional accuracy and appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

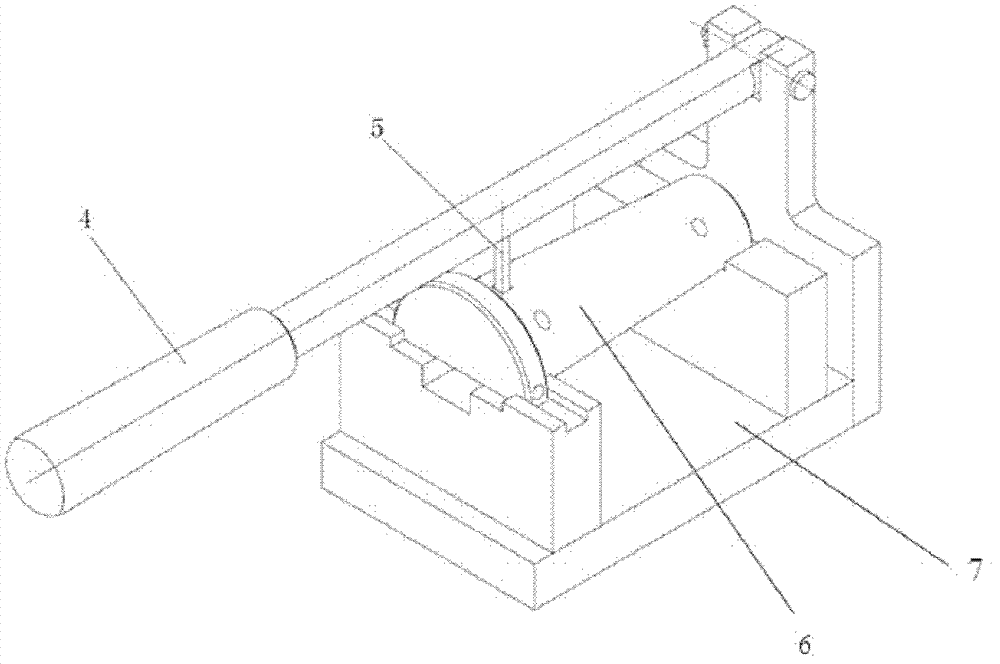

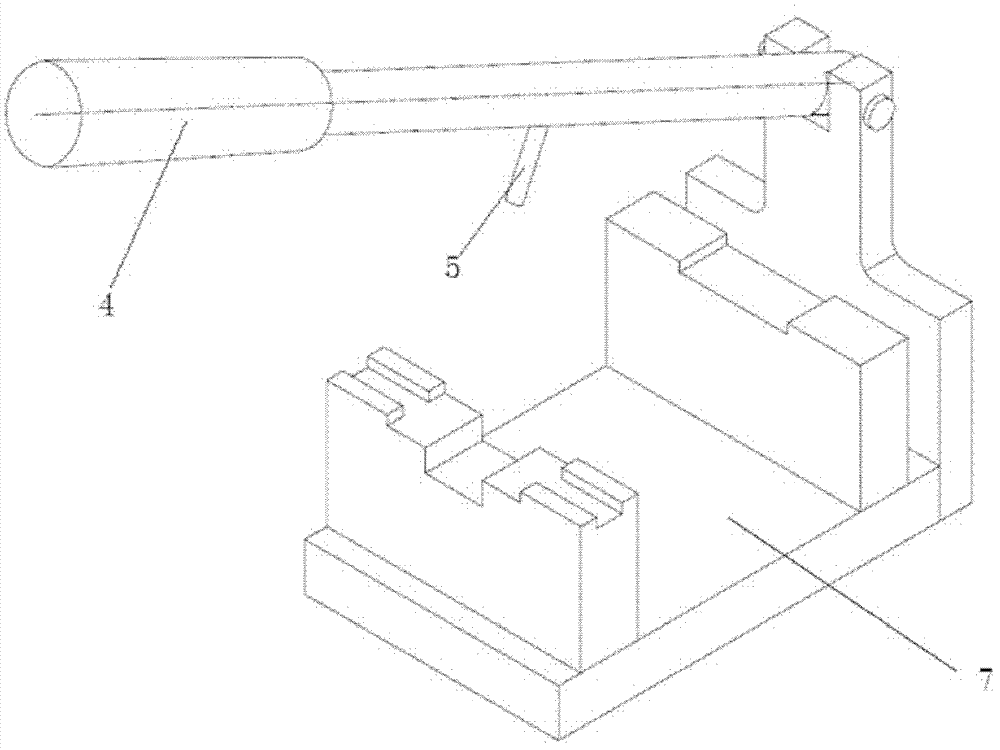

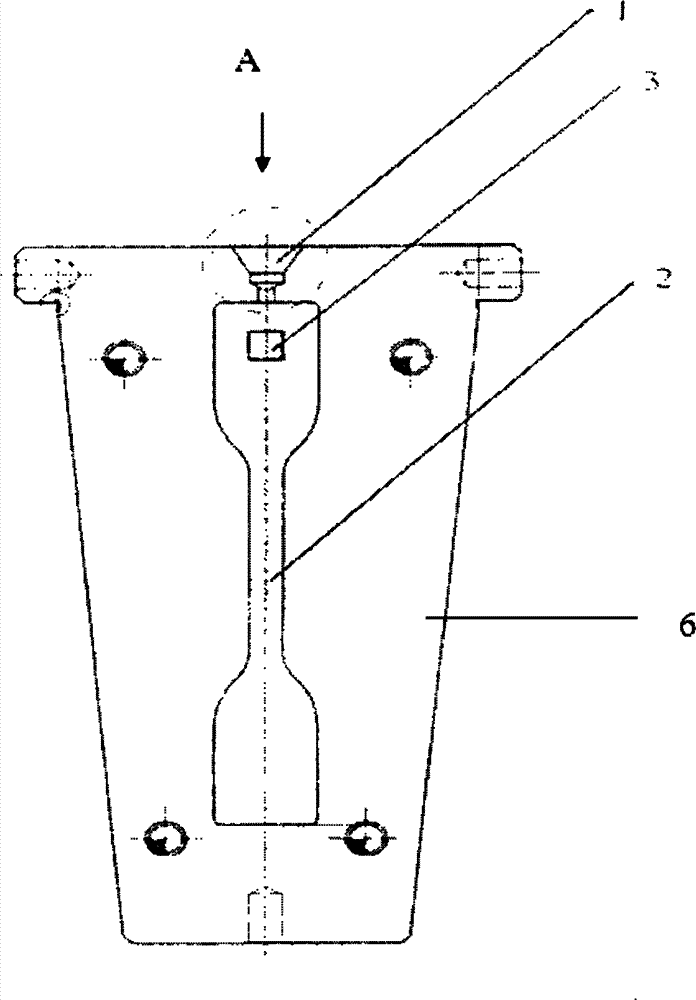

[0029] The special demoulding device for the micro-injection molding instrument of this embodiment has a structure as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, it is composed of a mold flap 6 and a demoulding bed frame 7. The mold flap is half of the mold with an axially cross-sectional composite structure. It is designed with a mold cavity 2 and a spline demoulding thimble 3. The spline demoulding thimble is the cross-sectional size 4mm×4mm square structure, the end surface of the spline against the spline is consistent with the wall surface of the mold cavity, the outer end surface is consistent with the outer edge surface of the mold flap, and is slidingly fitted with the square thimble assembly hole on the mold flap, and the thimble assembly hole is located at the big end of the mold , close to the gate 1. The demoulding bed frame is designed with a mold flap positioning and installation structure and an ejection mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com