Vertical rail brace and rail wing fixation system composed of the vertical rail brace

A rail support and vertical technology, which is applied in the field of railway turnout wing rail fixing system manufacturing, can solve the problems that the stability of the wing rail cannot be guaranteed, and the fixing system needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

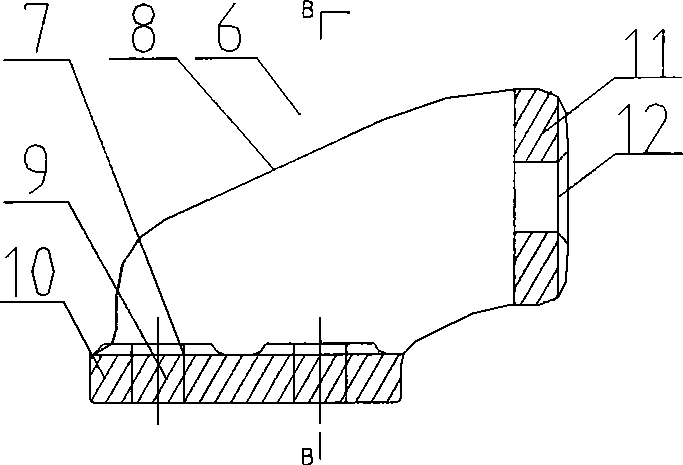

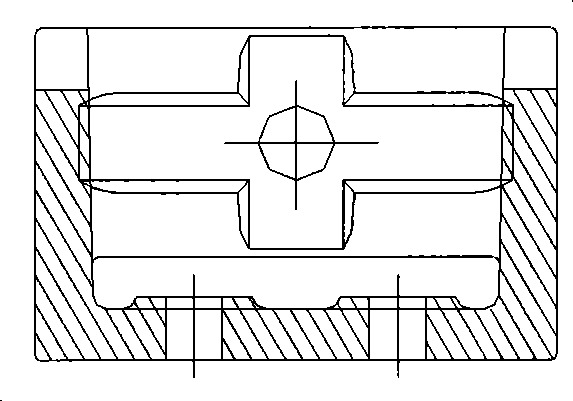

[0016] Embodiment 1: with reference to attached Figure 2~4 . The vertical rail brace 6 is composed of a vertical rail brace 11, an inclined rail brace side plate 12 and a rail brace bottom plate 10. The upper end of the inclined rail brace side plate 12 is connected with the vertical rail brace 11 to form an integral structure. The lower end of the support plate 11 is connected with the rail support base plate 10 to form an integral structure. There are connection holes on the surface of the vertical rail support plate 11 and it is connected with the wing rail 1 by locknuts and backing plates. hole. Vertical rail braces and buckle plates are realized by combining casting and machining. During assembly, the vertical rail braces are drilled with the Hack bolt holes of the backing plate, and then the backing plate and fasteners are installed to form frog wings. Rail fixing system structure, the existing technology can meet the processing requirements.

Embodiment 2

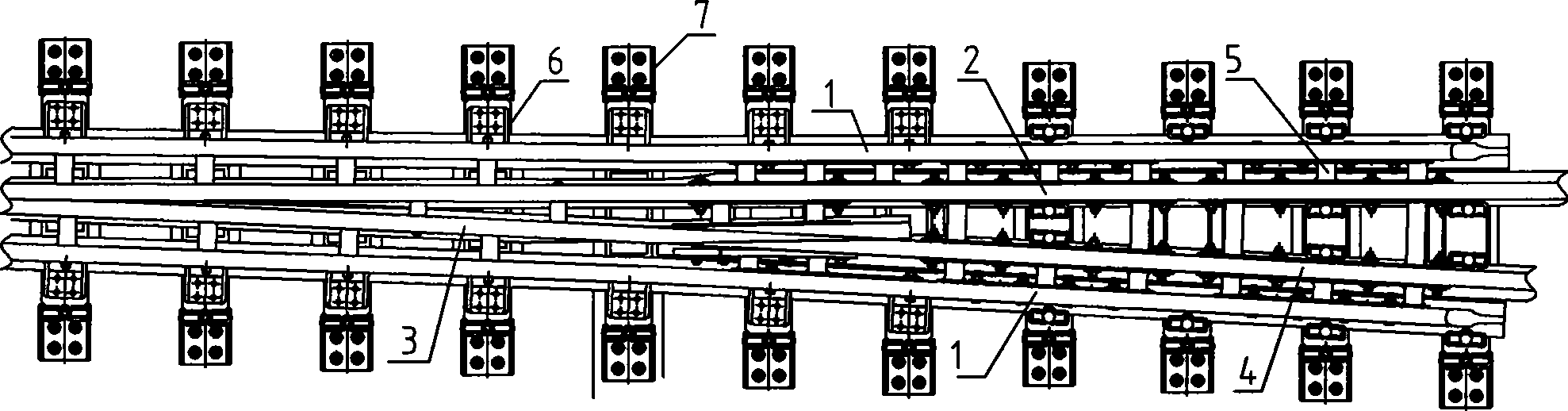

[0017] Embodiment 2: with reference to attached figure 1 and 6 ~7. On the basis of Embodiment 1, the frog wing rail fixing system composed of vertical rail braces includes wing rail 1, long core rail 2, short core rail 3, fork and tip rail 4, and vertical rail brace 6 passes through High-strength bolts and anti-loosening nuts are connected to the wing rail 1, the vertical rail brace 6 is connected to the bottom plate through four Huck bolts, the two ends of the backing plate are connected to the buckle plate 7 through fasteners, and the buckle plate 7 is connected to the switch tie bolts The sleeper is connected, and the wing rail forms a whole through the vertical rail support 6, lock nut, backing plate, fastener, buckle plate and switch sleeper.

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 2, the frog wing rail fixing method is composed of vertical rail braces. The vertical rail braces are connected to the wing rails through high-strength bolts and locknuts. Bolt holes are drilled and connected to the bottom plate through four Huck bolts to achieve a never-loose connection. The two ends of the backing plate are connected to the buckle plate through fasteners. The rail support, lock nut, backing plate, fastener, buckle plate and switch sleeper form a whole, which realizes the reliable fixing of the wing rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com