Forklift pallet fork stamping and combined weld production line

A production line and fork technology, which is applied in the field of fork fork stamping and welding production line, can solve the problems of low quality of welding parts, influence welding quality, waste, etc., and achieve the effects of convenient and quick demoulding, improving welding quality and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

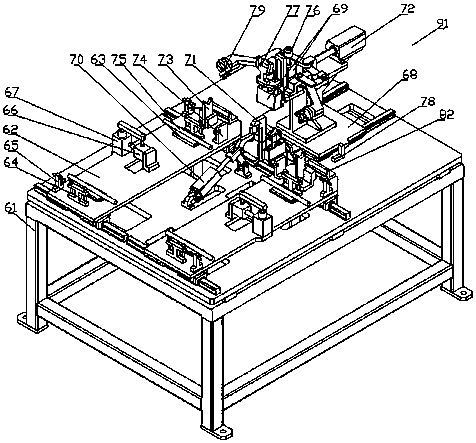

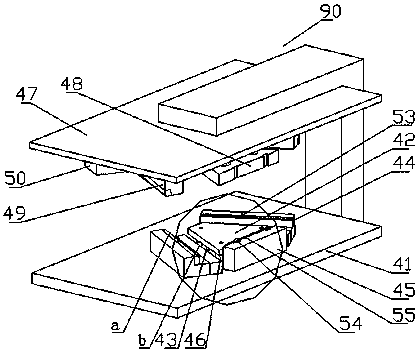

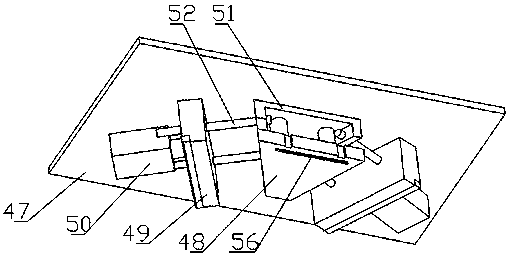

[0012] As shown in the drawings, the forklift fork stamping assembly welding production line of the present invention includes a stamping machine 90 and a fork welding tool 91, a handling manipulator 92 is arranged between the stamping machine 90 and the fork welding tool 91, and a tripod is arranged on the stamping machine 90 Stamping die, tripod stamping die includes a lower die and an upper die, the lower die includes a lower die base 41, a stripper plate 42, a stripper plate lifting hydraulic cylinder 43, a pair of dies 44 and a positioning block 45, and the bottom of the stripper plate 42 There is a set of guide pillars 46, and a set of guide pillars pass through holes on the lower mold base 41. A set of guide pillars 46 are respectively located in the holes. The stripping plate lifting hydraulic cylinder 43 is installed on the lower mold base 41, and drives the stripping plate 42. Move up and down; a pair of dies 44 are symmetrically installed on the lower die base 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com