Arrangement for screw locking electric connecting terminals

A locking device and electrical wiring technology, applied in conductive connections, hand tools suitable for fasteners, nuts, etc., can solve the problems of narrow production tolerance range, narrow structure size determination range, etc., achieve large tolerance range, easy installation , The effect of simple part demoulding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

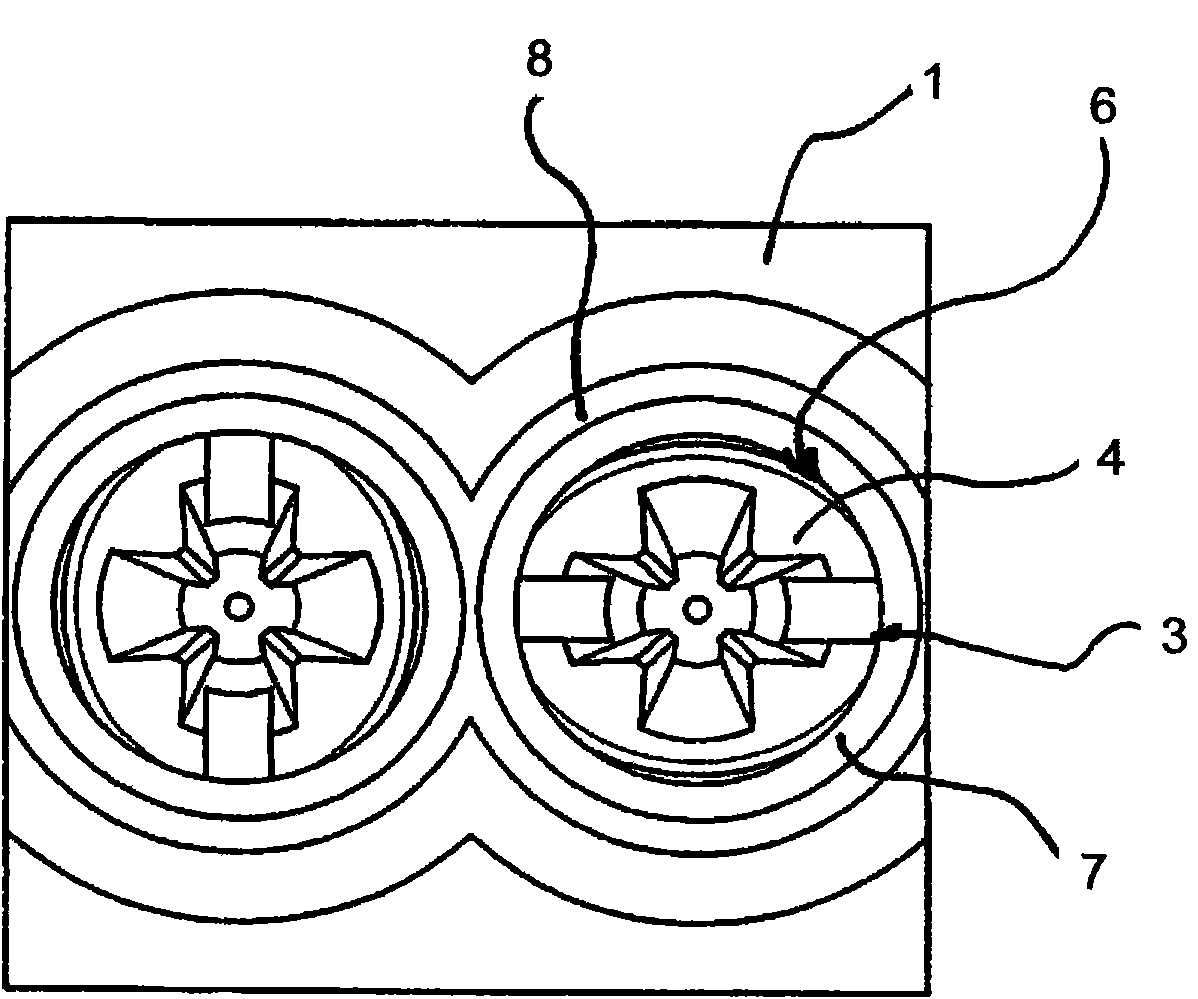

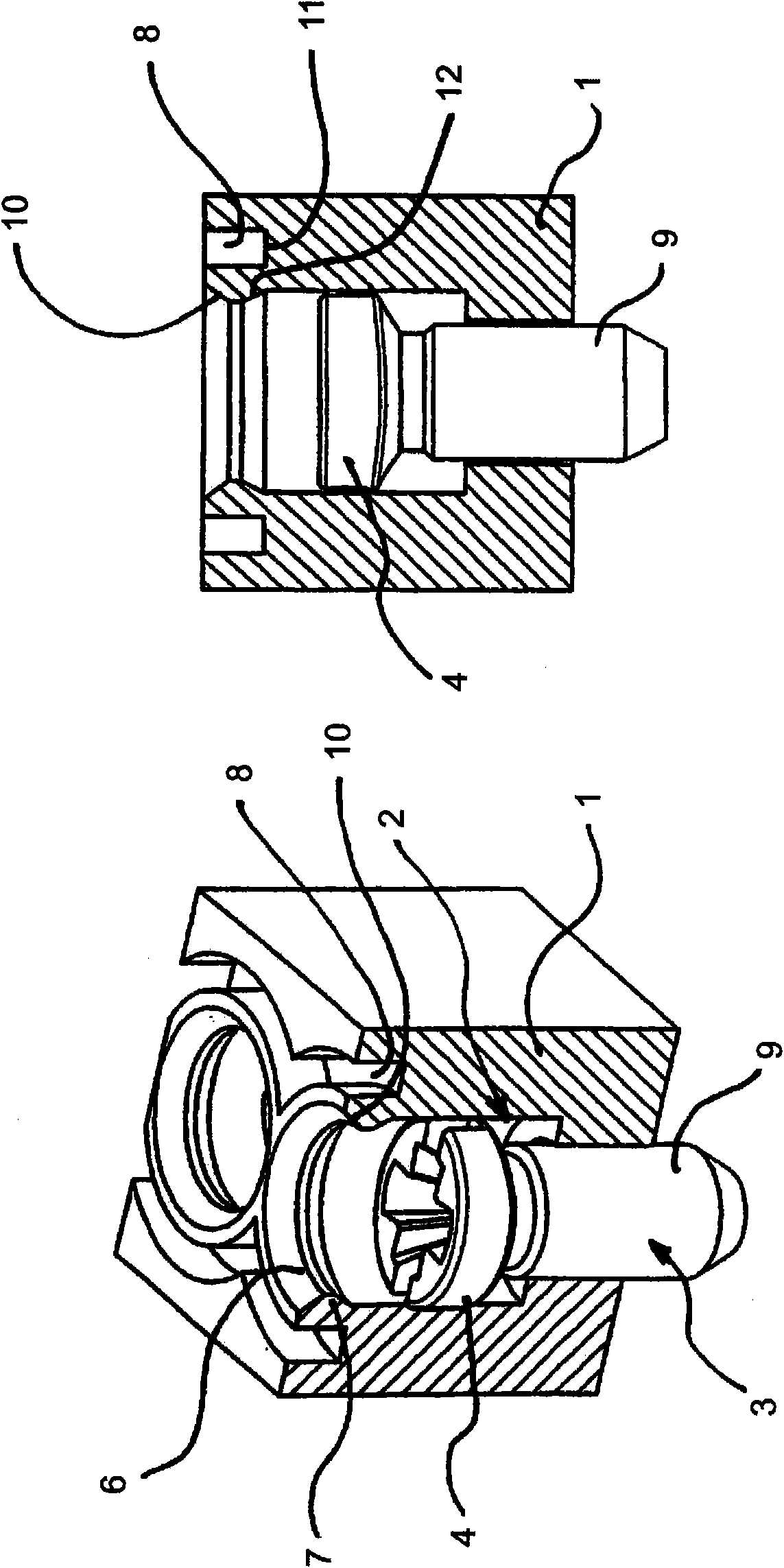

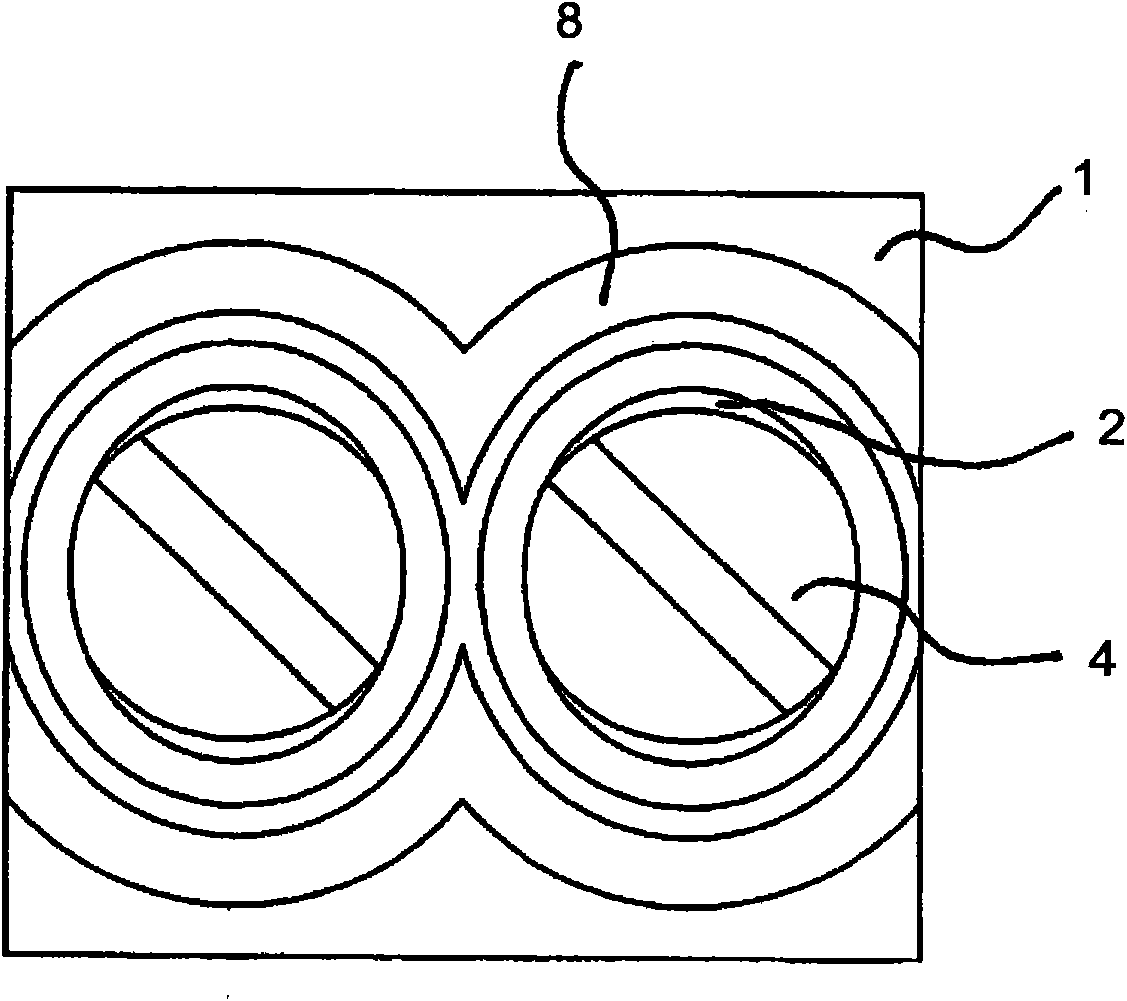

[0020] Figure 1 to Figure 4 The screw locks for the terminal blocks are shown respectively. Therein, the device comprises a body or shell-like part 1 made of an insulating deformable material, for example of plastic material. Formed in the body or shell-like part 1 is a vertically extending well 2, into which a screw 3 can be sunkly inserted, comprising a screw head 4, as in particular figure 2 with Figure 4 shown in . In order to ensure the automatic locking of the screw 3 or make the screw 3 inseparable, according to figure 1 with figure 2 In a first embodiment of the present invention, a striped structure 6 may be provided in the area of the well wall 5 . Wherein, the stripe structure 6 is designed in such a way that the stripe structure 6 can be elastically deformed when the screw head 4 passes through, that is, during the screw-in process. That is to say, when the screw head 4 sinks into the shaft structure 2 , the stripe structure 6 is pressed back, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com