Environment-friendly building steel pipe polishing and paint spraying integrated machine

An all-in-one machine and steel pipe technology, which is applied in painting booths, grinding racks, grinding machines, etc., can solve the problems of unattractive and durable steel pipes, failure to protect the steel pipes, and poor environmental protection functions, so as to reduce the labor load of workers and improve work efficiency. Efficiency and safety improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

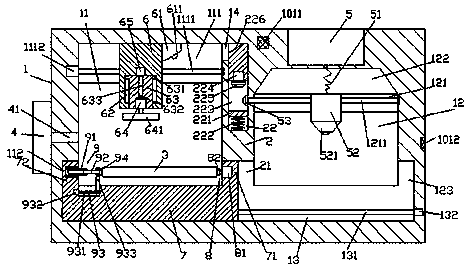

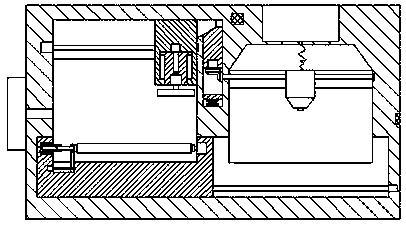

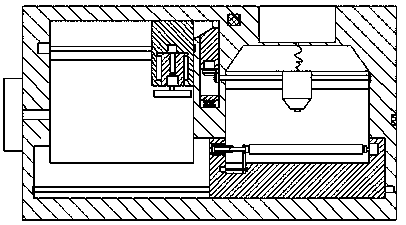

[0025] Such as Figure 1-Figure 4As shown, an environment-friendly building steel pipe grinding and painting all-in-one machine of the present invention includes a body 1 with a first cavity 11 and a second cavity 12 inside the left and right sides, the first cavity 11 and the A partition 2 is arranged between the second cavity 12, and the inner bottom wall of the first cavity 11 is provided with a guide groove 13 extending to the left and right sides, and the bottom of the partition 2 is provided with a bottom and the guide groove. 13 is connected to a communication groove 21 arranged in communication, the first embedded groove 112 is provided in the left inner wall of the first cavity 11 opposite to the left side of the communication groove 21, and the second embedded groove 112 is arranged on the left side of the communication groove 21 opposite to the right side. A second embedded groove 123 is provided in the inner wall on the right side of the cavity 12, and a first thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com