Stator potting method and motor comprising stator produced by stator potting method

A stator and glue filling technology, applied in the manufacture of motor generators, adhesives, electromechanical devices, etc., can solve the problems of long downtime and high cost of processing methods, and achieve the effect of increasing shrinkage, reducing cleaning difficulty, and improving adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

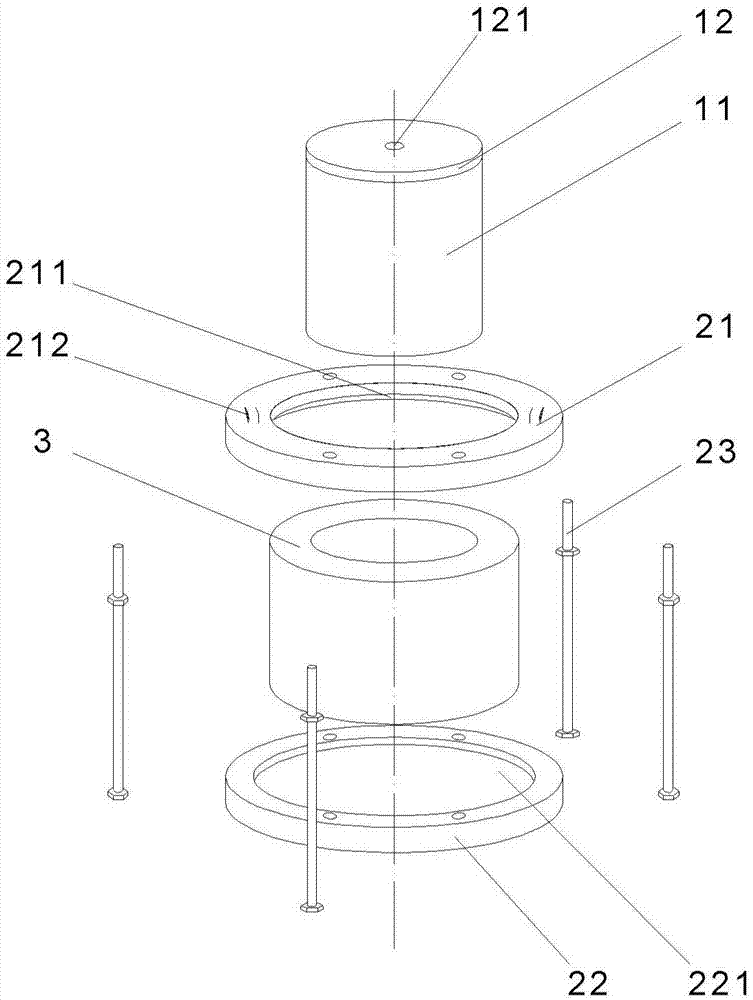

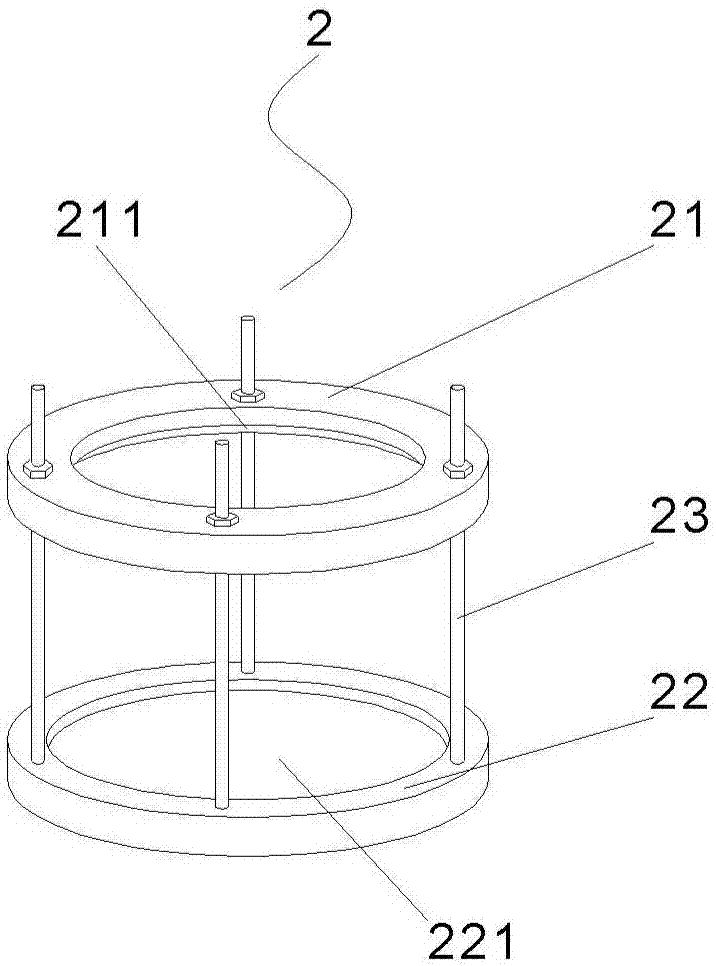

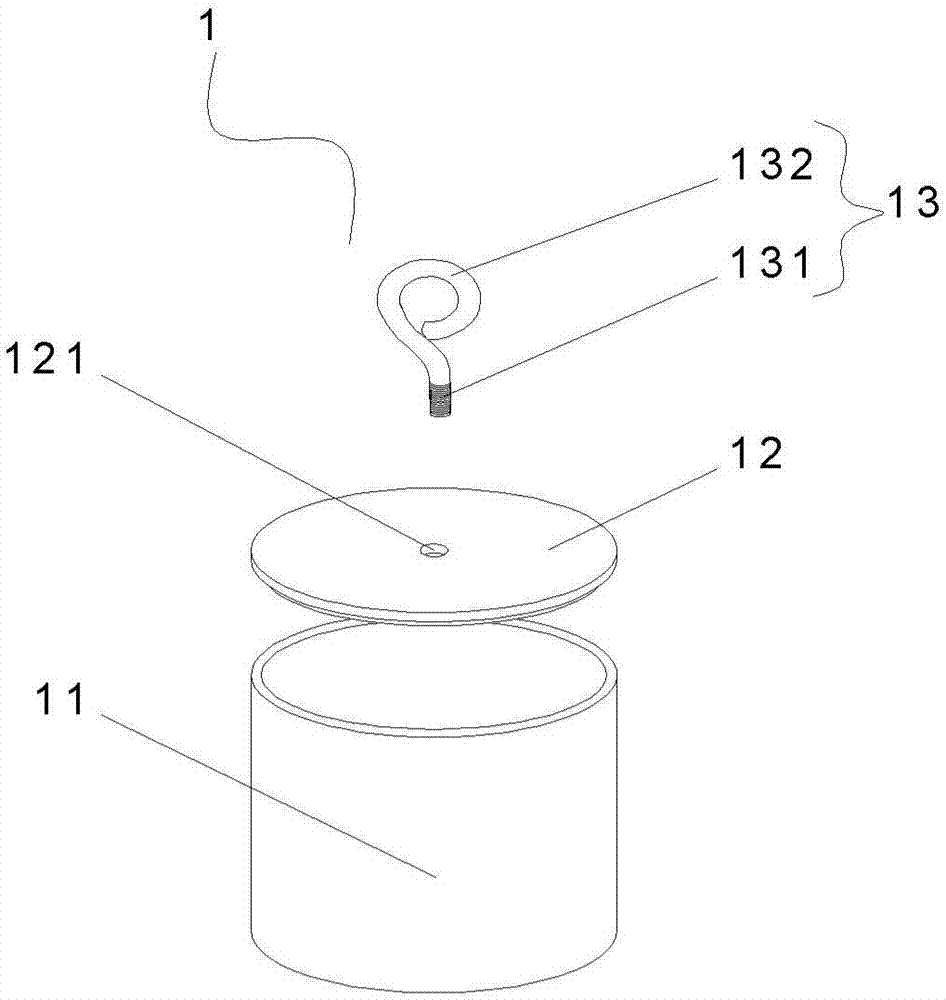

[0050] The invention provides a stator glue filling method and a motor including a stator produced by the method. The stator that is easy to stick to grease is potted with sealant to form a smooth stator surface, which greatly reduces the difficulty of cleaning the motor without affecting the performance of the motor; the stator glue filling method has fewer steps and is easy to operate. There will be no pollution, fully consider the structure of the stator, cleverly seal the upper and lower ends, seal the side of the stator, seal the stator hole, and then pour the sealant from the top, and use the downward fluidity of the sealant itself to fill the gap by itself. inside the stator.

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0052] In an exemplary embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com