Template mutually lifting climbing apparatus and method

A formwork and climbing formwork technology, applied in the field of climbing formwork, can solve the problems of large formwork rising, long frame cantilever, and inability to pass through, and achieve the effect of convenient demoulding operation, improved work efficiency, and simple structure of climbing formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

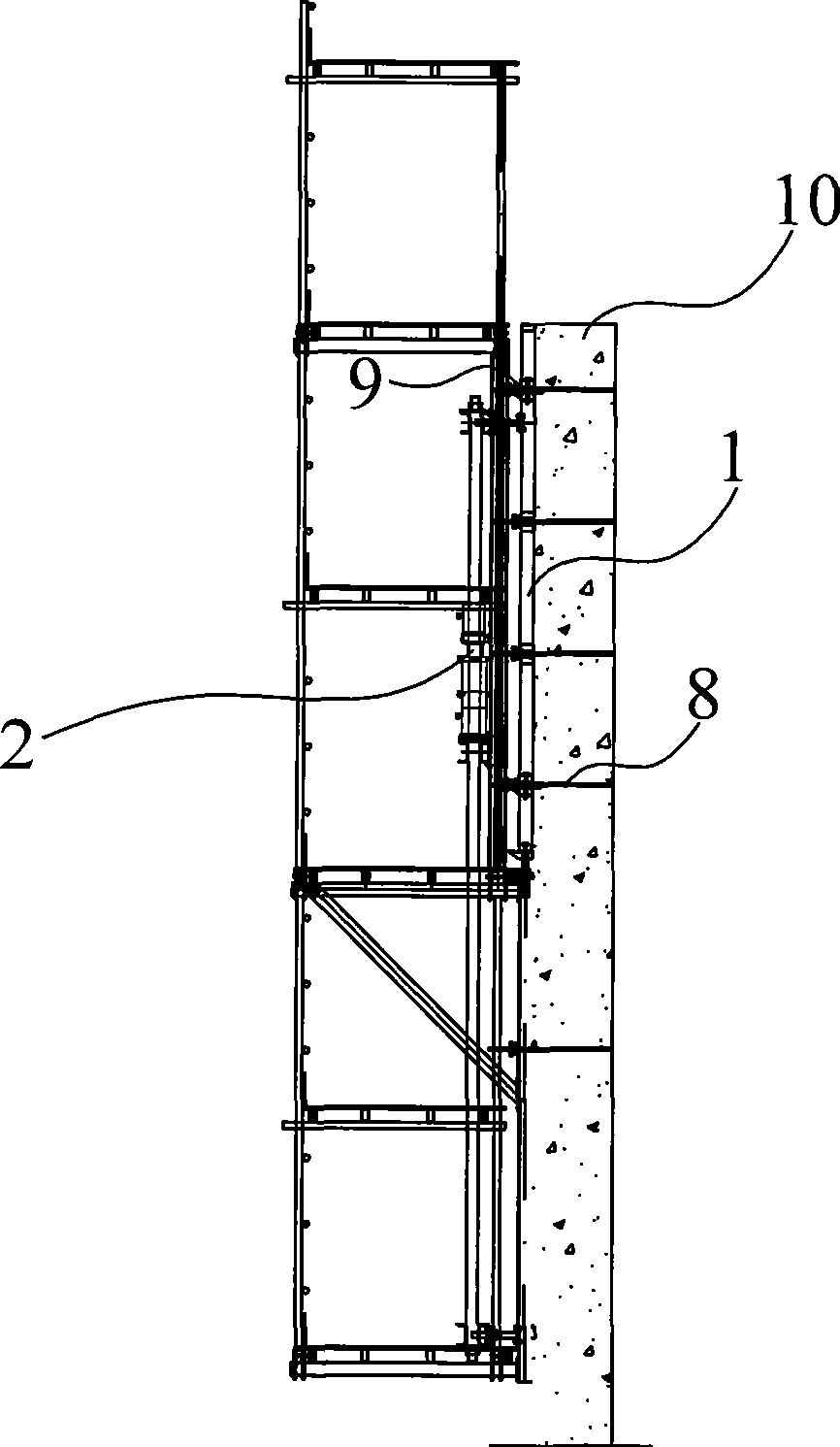

[0029] The formwork inter-lifting climbing formwork device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The present invention realizes the climbing formwork by using mutual climbing between the formworks, wherein the unclimbed formwork is used as the running track of the climbing formwork, and during the whole construction process, the formwork is always connected with the wall by the pull bolts and the telescopic tapered carrier, so Good anti-drop and wind load resistance.

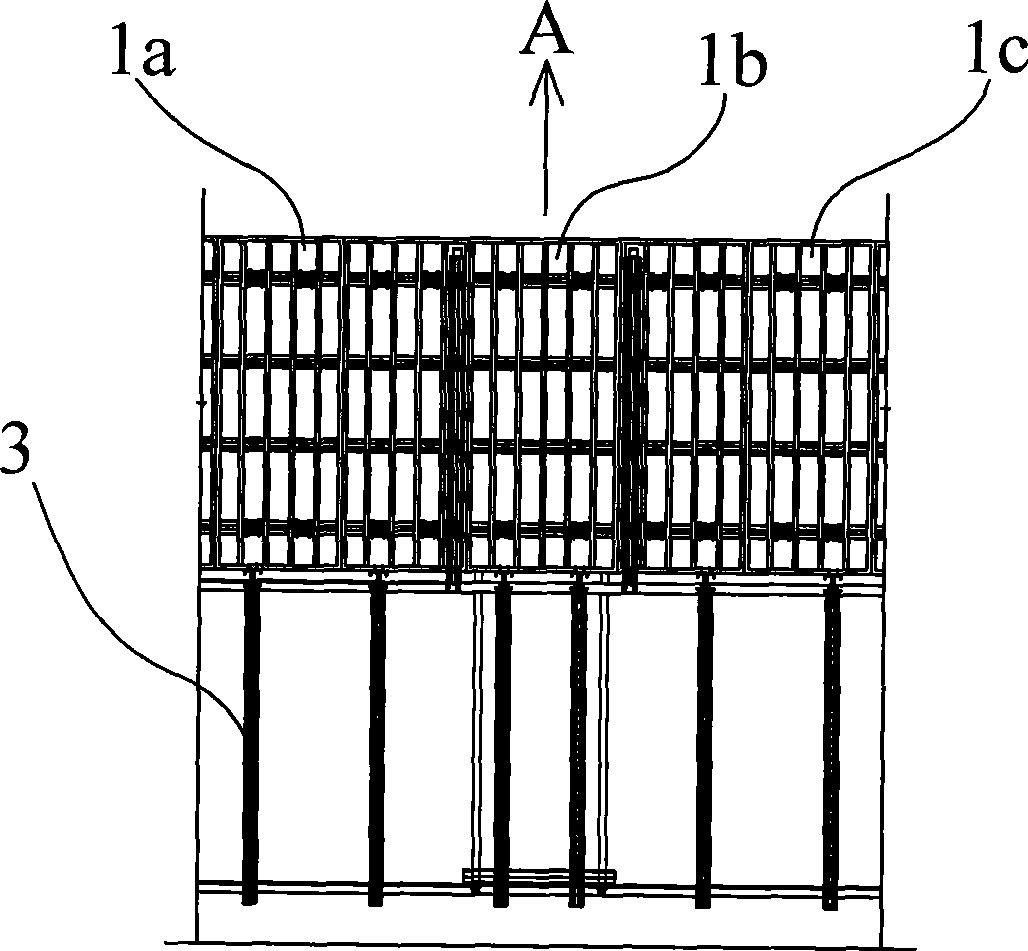

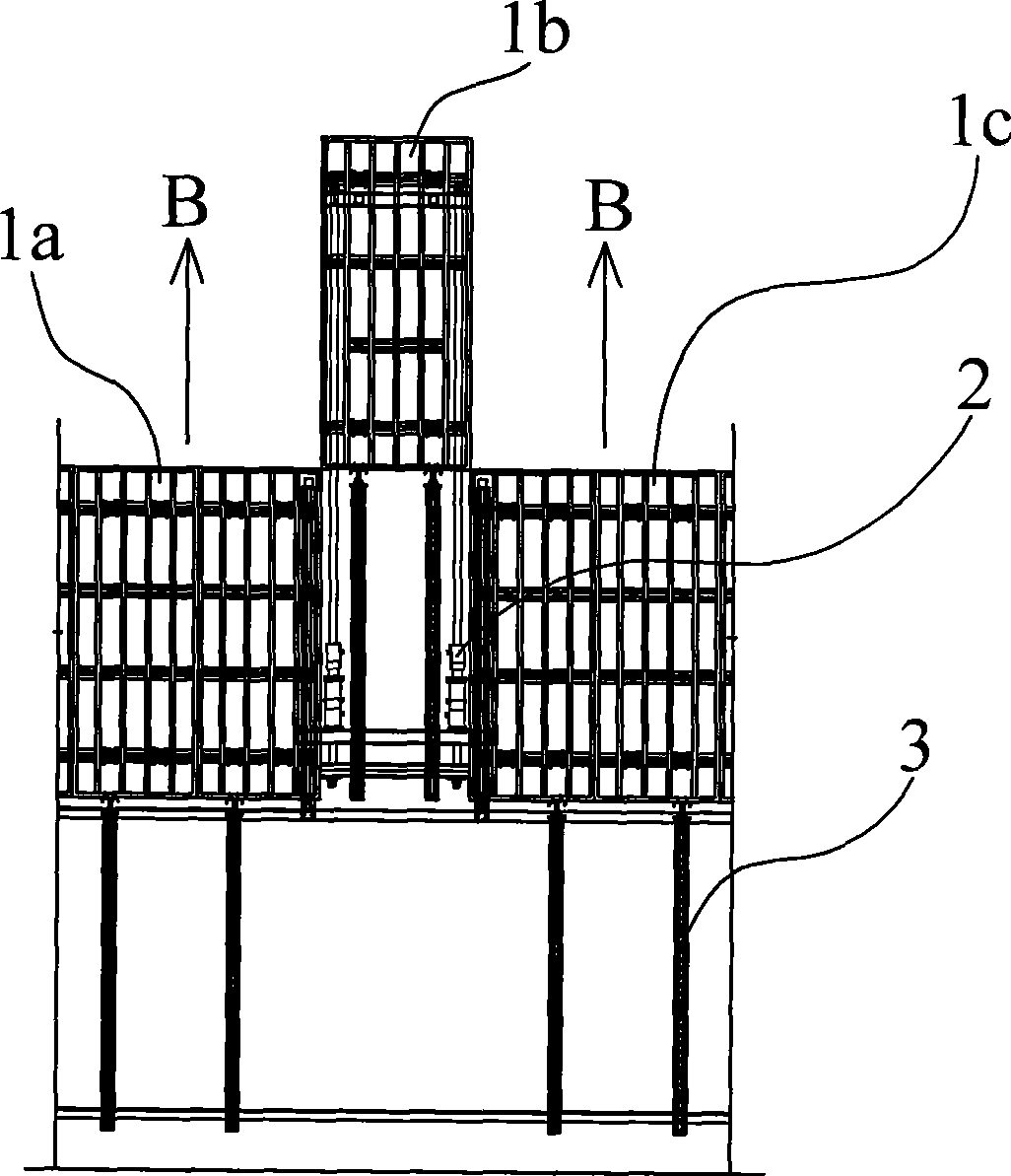

[0031] refer to Figure 1A , Figure 1B , figure 2 and image 3 As shown in , compared with the prior art, the formwork climbing formwork device of the present invention abandons the climbing frame and does not need to install additional guide rails as the running track for the formwork to climb. It mainly includes formwork 1, used to support The carrier body of the formwork 1 and the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com