Tube stamping engraving die

A technology of fonts and tubes, applied in stamping, decorative art, printing, etc., can solve problems such as poor lettering effect, lower lettering efficiency, and difficulty in demoulding, and achieve the effects of easy extraction, improved lettering efficiency, and good lettering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

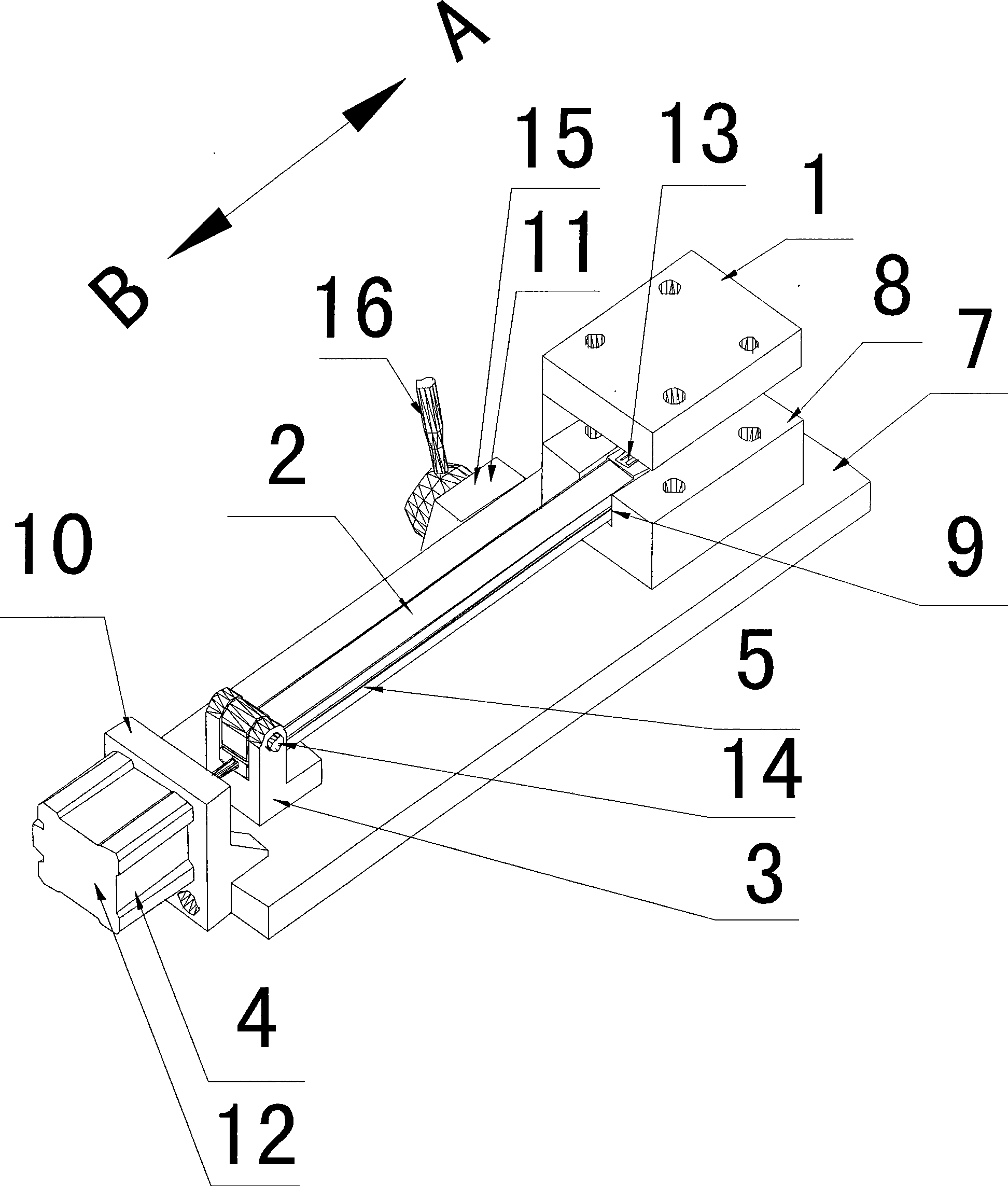

[0028] Example 1: Combining figure 1 , figure 2 Shown is a specific embodiment of the pipe stamping lettering die device of the present invention, which consists of an upper module 1, a lower module 2, a bracket 3, a power mechanism 4, a core block 5, a bottom plate 7, a lower module seat 8, and a mounting seat 10 and control device 11 constitute.

[0029] The upper module 1 is engraved with concave characters ( figure 1 Invisible due to the view), and the lower module 2 is engraved with a convex font 13 matching the concave font.

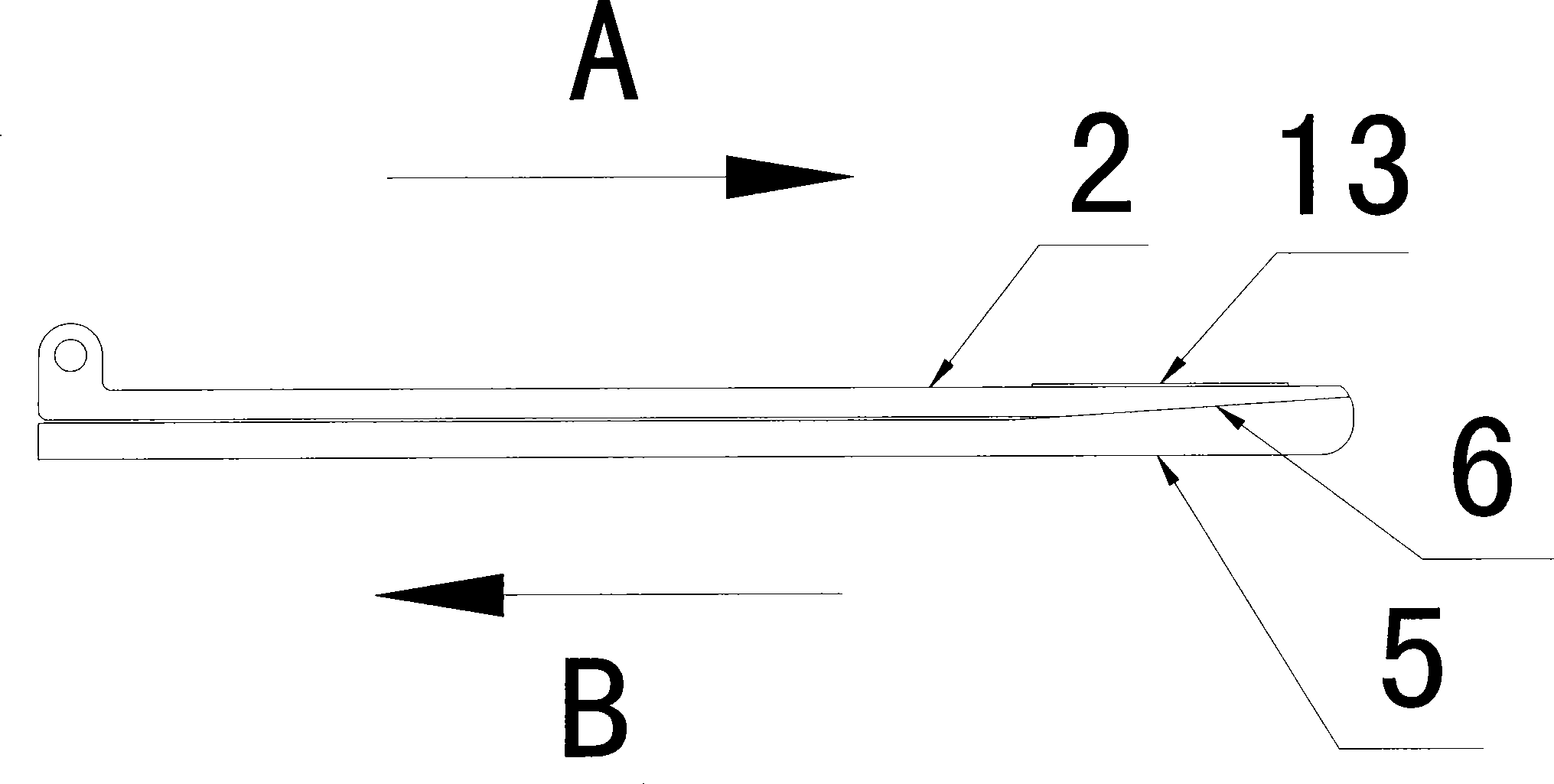

[0030] The bracket 3 is fixed on the bottom plate 7 , and one end of the lower module 2 is pinned to the bracket 3 , so that it can swing up and down around the pin shaft 14 .

[0031] The core pulling block 5 is located below the lower module 2 , and one end thereof is connected to the power mechanism 4 . In this embodiment, the power mechanism 4 is a cylinder 12 , and the corresponding control device 11 is a cylinder valve 15 . The cylinder ...

Embodiment 2

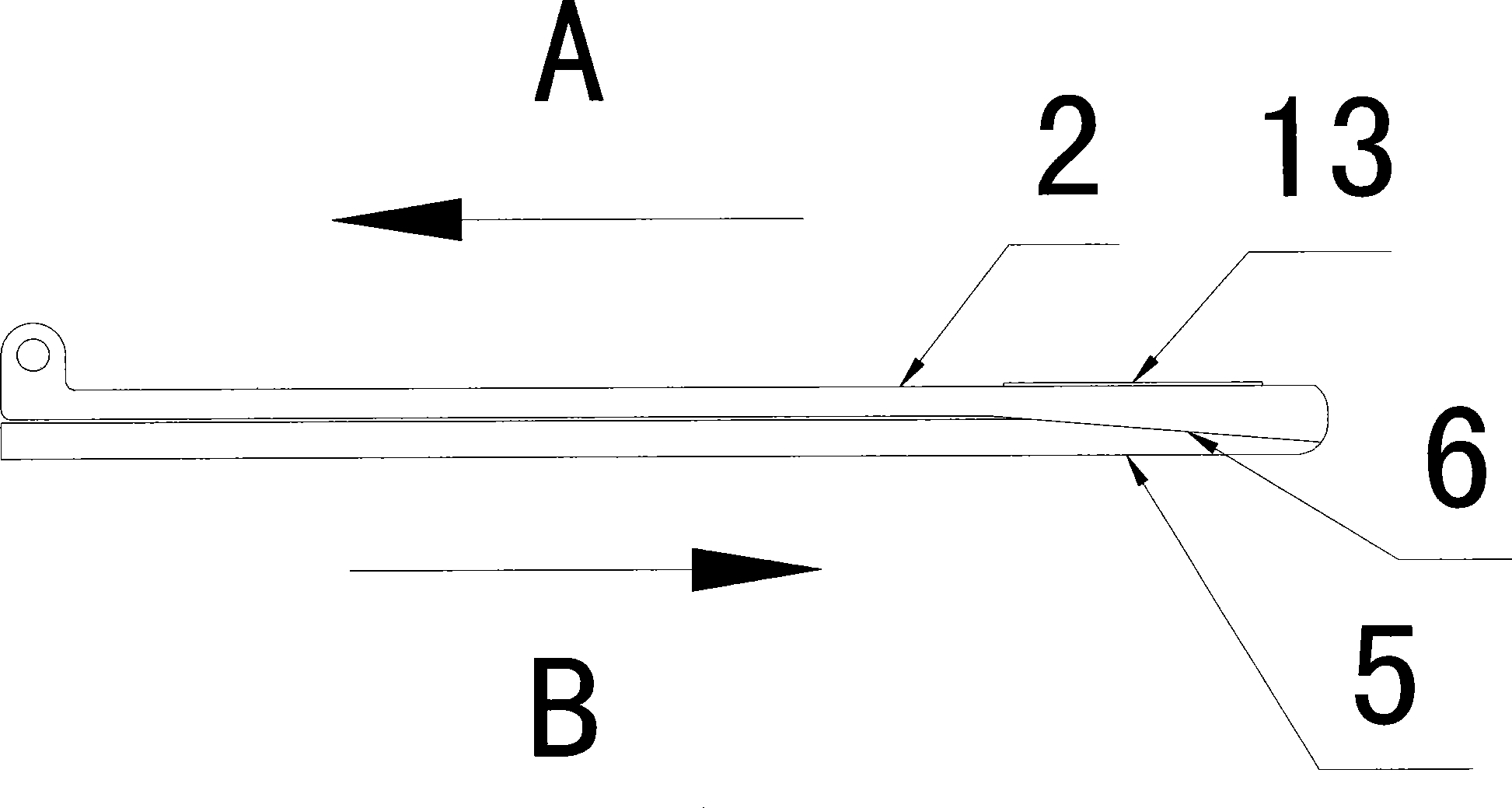

[0042] Example 2: Combining figure 1 and image 3 Shown is another specific embodiment of the tubular stamping lettering die device of the present invention. The structure of this embodiment is basically the same as that of Embodiment 1 and will not be described again. The only difference is that the upper part of the core pulling block 5 and the lower part of the lower module 2 can be The inclined surfaces 6 that are attached to each other are inclined downwards, of course, the inclination is also 0.15.

[0043] and if image 3 Shown, when adopting this embodiment to stamp lettering on pipe material 17, its working process is just opposite compared with embodiment 1:

[0044] Cylinder 12 pulls core block 5 back (as image 3 In the direction indicated by the middle arrow A), the inclined surface 6 on the core-pulling block 5 and the inclined surface 6 on the lower module 2 are separated from each other, and the thickness between the lower module 2 and the core-pulling block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com