Plastic injection mold and injection molding method

An injection mold and plastic technology, applied in the direction of coating, can solve the problems of reduced stability, slow ejection speed, injection molding failure, etc., to achieve the effect of improving production efficiency, improving molding quality, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

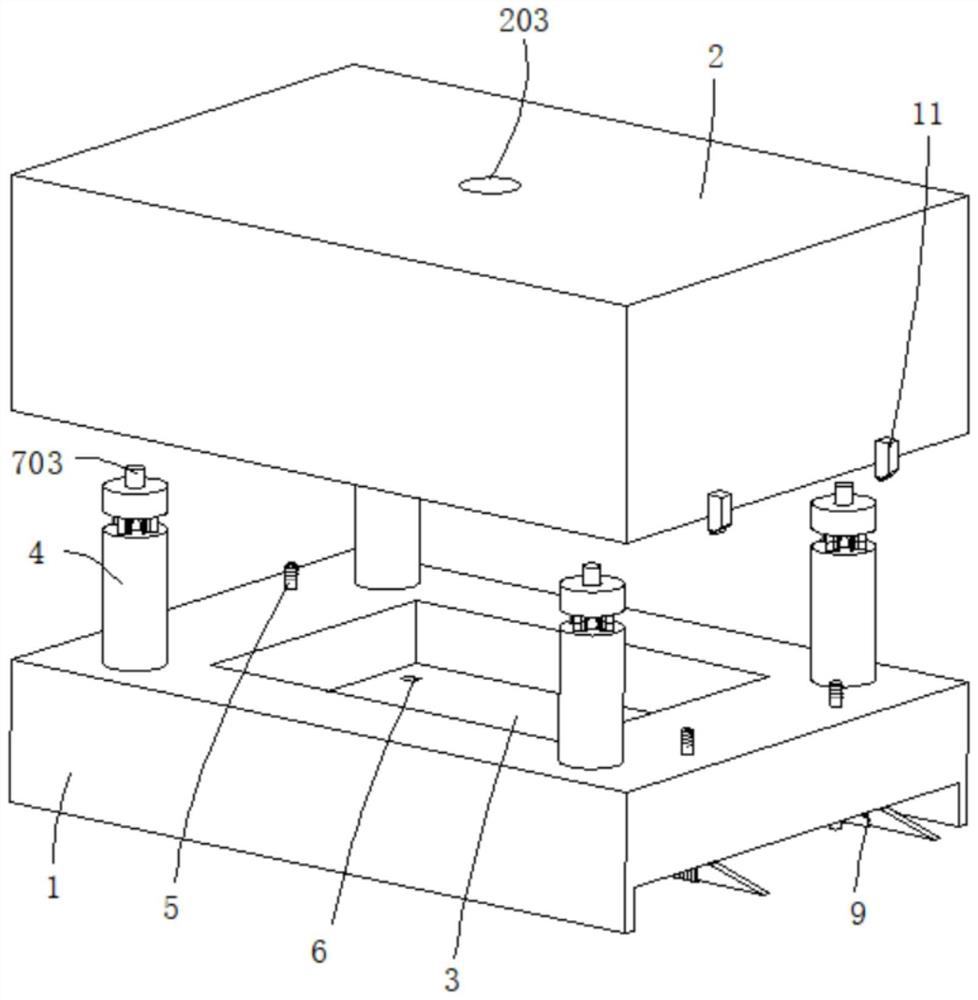

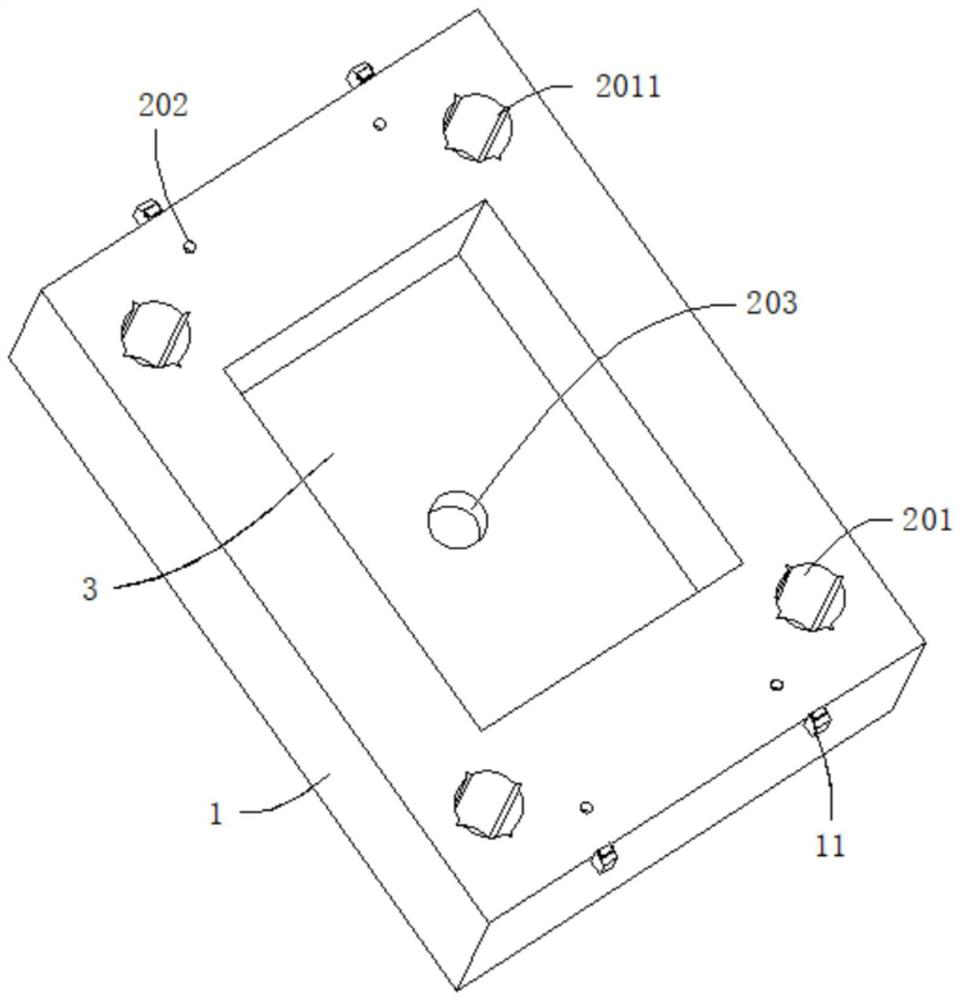

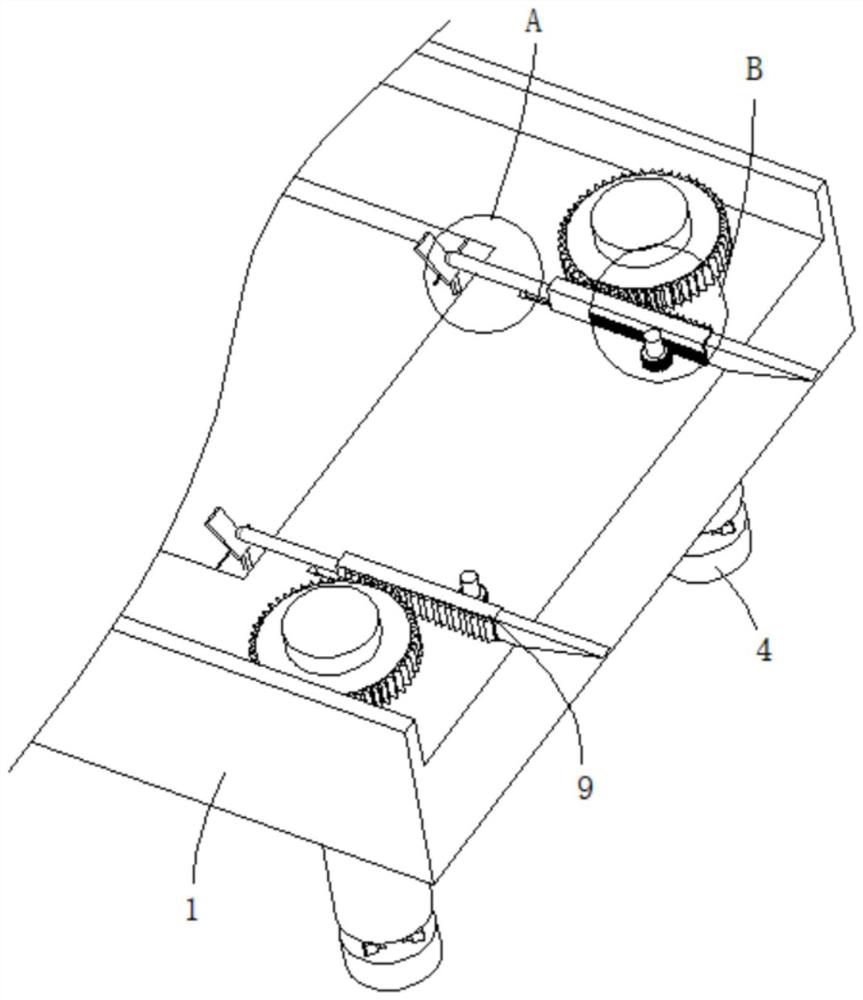

[0041] refer to figure 1 , figure 2 , image 3 and Figure 4 , a plastic injection mold, comprising a lower mold seat 1 and an upper mold seat 2 matched with the lower mold seat 1, characterized in that the lower mold seat 1 and the upper mold seat 2 are both provided with a mold cavity 3, two mold cavities 3. A molding cavity for the injection mold is formed. The upper mold base 2 is provided with a first slot 201 and a second slot 202. The upper mold base 2 is also provided with an injection port 203. The first clamping column 4 and the second clamping column 5 are matched with the first clamping slot 201 and the second clamping slot 202. The first clamping column 4 is provided with an anti-loose mechanism, and the anti-loose mechanism includes an expansion support assembly and an anti-loose assembly. An ejector rod 6 is movably connected in the lower die base 1 , and an ejector mechanism for driving the ejector rod 6 to work is arranged on the lower die base 1 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com