Double-body multi-cylinder high-pressure injection pump

A high-pressure grouting pump, double-body technology, applied in the direction of pumps, liquid variable-capacity machines, machines/engines, etc., can solve the problems of inconvenient operation and maintenance, high cost, complicated equipment, etc., to achieve stable effects and reduce equipment costs. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

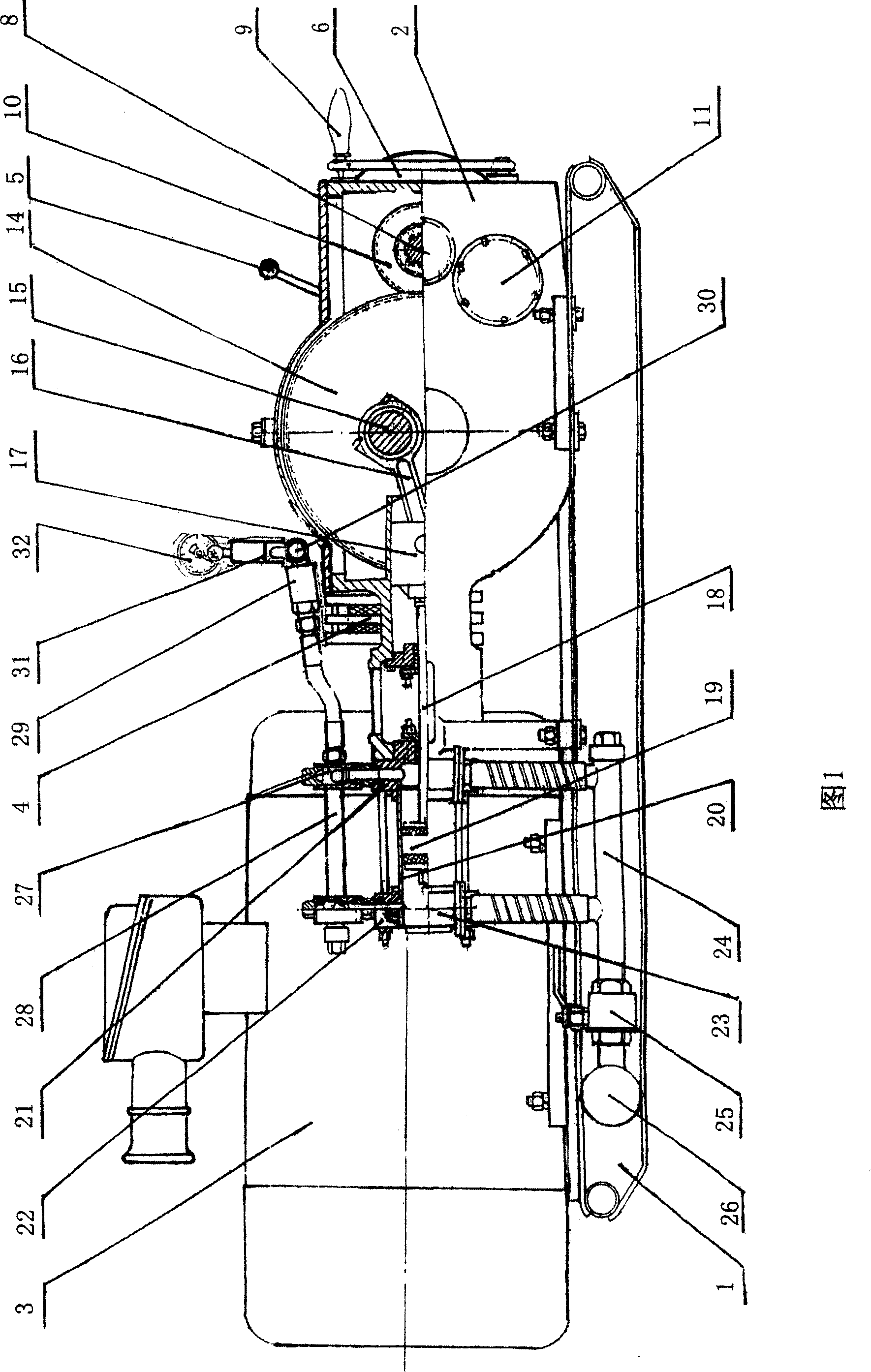

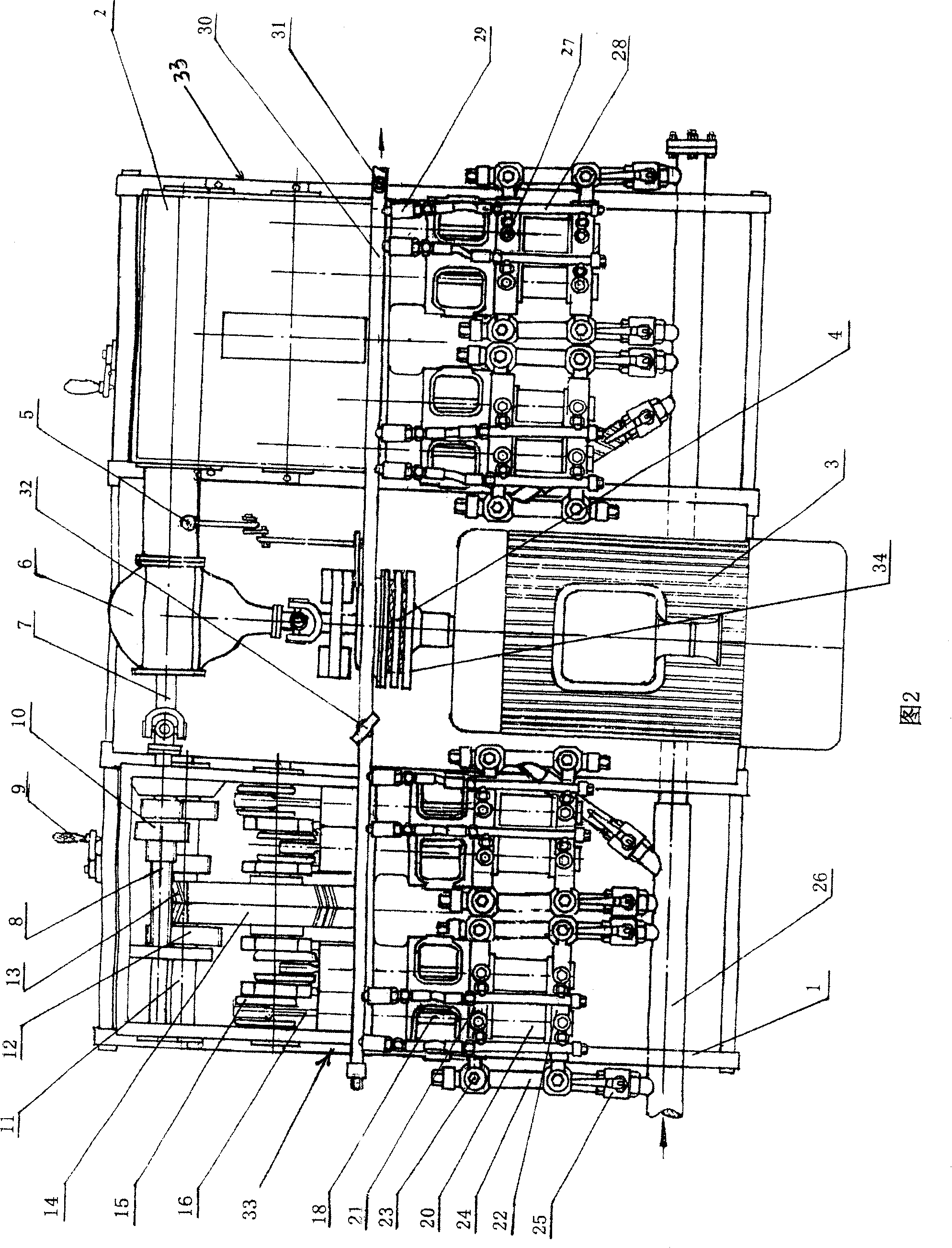

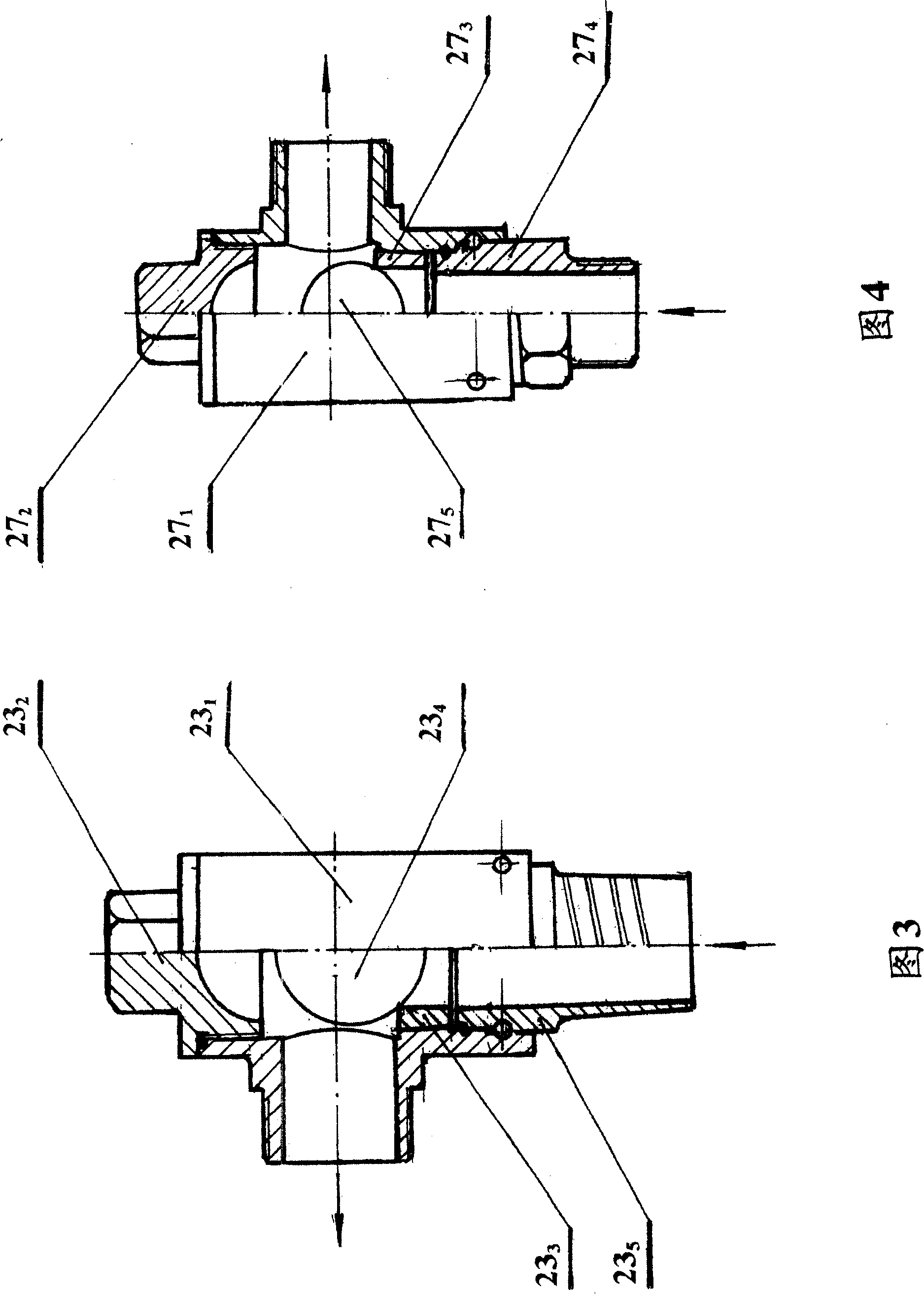

[0027] The double-body multi-cylinder pump includes: pump base 1, 2 racks 2, 1 motor 3, 1 clutch 4, 1 clutch handle 5, 1 reducer. 6. 2 reducer output shafts 7. 2 variable speed sliding spline shafts 8. 2 variable speed handles 9. 2 sets of three variable speed sliding gears 10. 2 transmission shafts 11. 2 sets of three-position variable speed fixed gears 12, 2 1 small herringbone transmission wheel 13, 2 large herringbone gears 14, 2 crankshafts 15, 8 crankshaft connecting rods 16, 8 crosshead sliders 17, 8 piston rods 18, 8 pistons 19, 8 paddles Cylinder barrel 20, 8 cylinder rear glands 21, 8 cylinder front glands 22, 16 sets of slurry suction valves 23, 8 slurry suction confluence pipes 24, 8 2-inch slurry suction control valves 25, 1 Slurry suction main pipe 26, 16 sets of slurry discharge valves 27, 8 slurry discharge confluence pipes 28, 8 one-way check valves 29, 1 slurry discharge main pipe 30, 1 safety valve 31, 1 pressure gauge 32 and other components .

[0028] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com