High-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer for water-based drilling fluid and preparation method of high-temperature-resistant and high-salt-resistant micro-crosslinking hydrophobic association tackifying filtrate reducer

A water-based drilling fluid and hydrophobic association technology, applied in the field of drilling, can solve the problems of drilling fluid viscosity increase, large viscosity change, unfavorable drilling fluid rheological performance stability, etc., to reduce fluid loss and viscosity change with temperature. The effect of small, excellent fluid loss reduction performance and viscosity increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

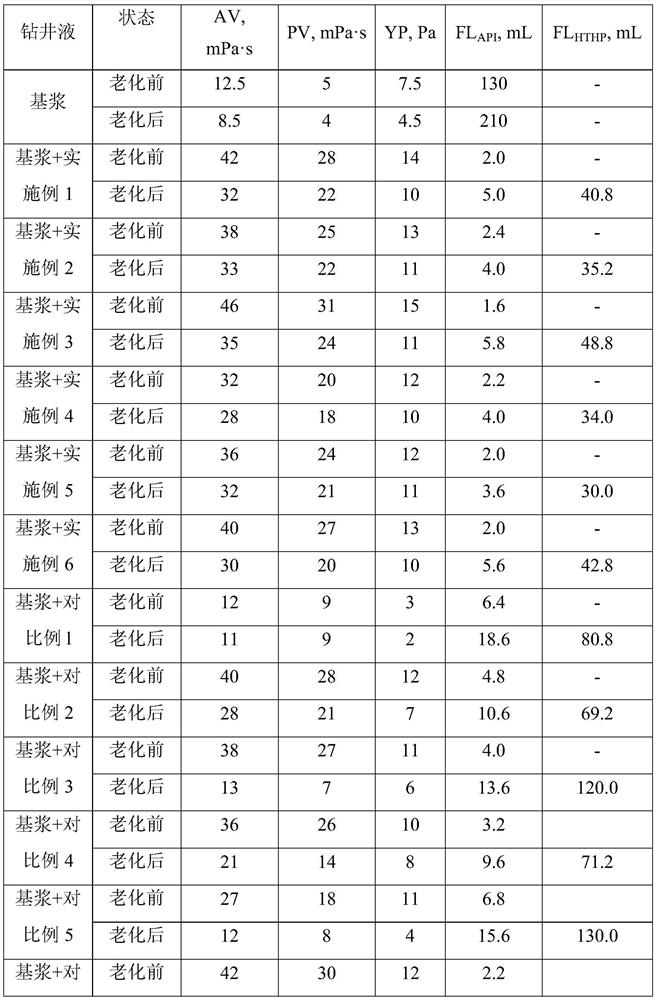

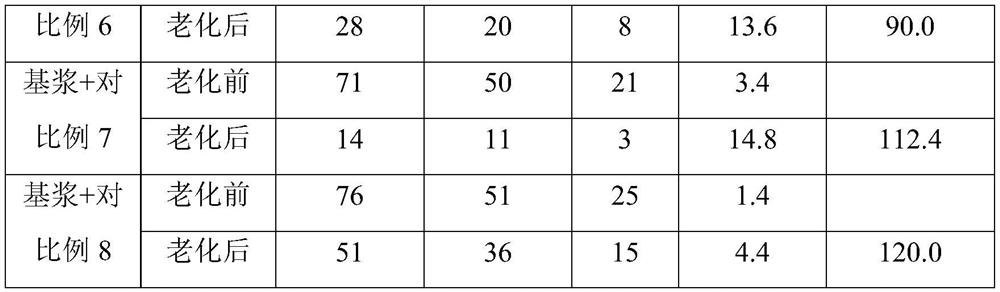

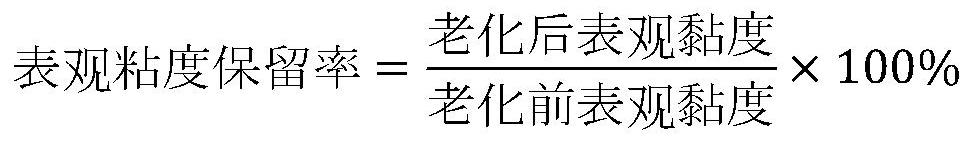

Examples

preparation example 1

[0035] Mix ethanol and water in a volume ratio of 1:10 to prepare 100 mL of ethanol aqueous solution; under nitrogen protection and stirring conditions, mix 5 g of γ-methacryloyloxypropyltrimethoxysilane with 5 g of dimethoxy(methyl) base) phenylsilane was added to the above ethanol aqueous solution, the pH of the system was adjusted to 5.5 with a mass fraction of 10% HCl solution, and the reaction was performed at a constant temperature of 60 °C for 4 h; after the reaction was completed, the obtained product was dried at 65 °C to constant weight, The obtained transparent liquid is the hyperbranched polysiloxane crosslinking agent ZB1.

preparation example 2

[0037]Mix ethanol and water in a volume ratio of 1:10 to prepare 100 mL of ethanol aqueous solution; under nitrogen protection and stirring, mix 5 g of γ-methacryloyloxypropyltrimethoxysilane with 4 g of dimethoxy(methyl) base) phenylsilane was added to the above aqueous ethanol solution, the pH of the system was adjusted to 5.5 with a mass fraction of 10% HCl solution, and the reaction was performed at a constant temperature of 60 °C for 3 h; after the reaction was completed, the obtained product was dried at 65 °C to constant weight, The obtained transparent liquid is the hyperbranched polysiloxane crosslinking agent ZB2.

Embodiment 1

[0039] A preparation method of a high temperature resistant and high salt resistant micro-crosslinking hydrophobic association viscosity-increasing and fluid-loss reducing agent for water-based drilling fluid, comprising the following steps:

[0040] Add 100g distilled water and 0.5g sodium dodecyl sulfate to a 250mL beaker, stir with a magnetic stirrer at 200r / min until fully dissolved; weigh 20g acrylamide, 10g sodium styrene sulfonate, 4g maleic anhydride, 2g Lauryl methacrylate and 0.2 g of cross-linking agent ZB1 were added to the beaker, stirred until fully dispersed and uniform; the pH of the reaction system in the beaker was adjusted to 7 with 40% NaOH solution, and the reaction system was transferred to a three-necked flask, The water bath was heated to 65°C under magnetic stirring; under nitrogen protection, 0.1 g of ammonium persulfate was added to the flask, and the reaction was kept constant at 65°C for 4 h and nitrogen was passed through the reaction; The viscous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com