Coal Mine Tunnel Large Gas Drainage Crawler Drilling Rig

A technology of gas drainage and large mining height, which is applied in the field of crawler drilling rigs for large mining height gas drainage in coal mine tunnels, and can solve the problem that it is difficult to fully meet the construction requirements of high and low multi-layer holes, the adjustment range of azimuth angle and inclination angle is small, and the height Small adjustment range and other problems, to achieve the effect of compact structure, wide height range and large construction range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

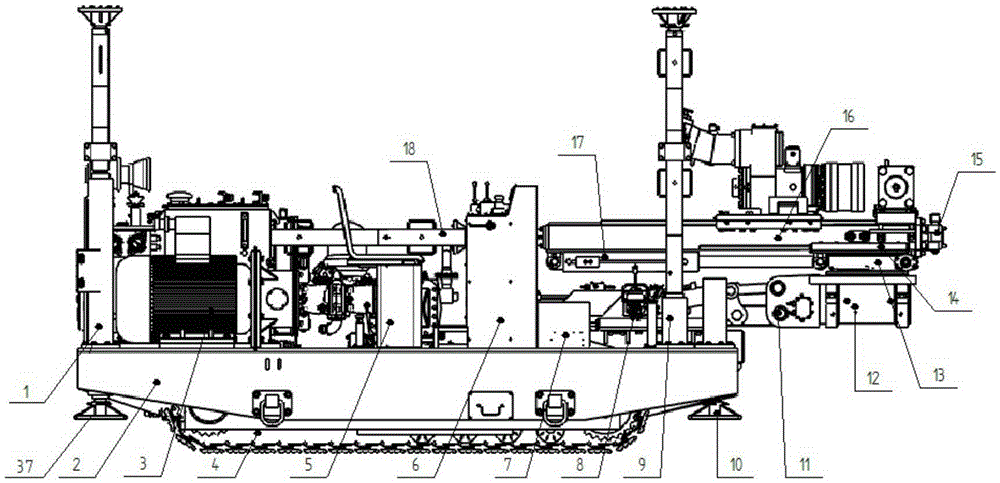

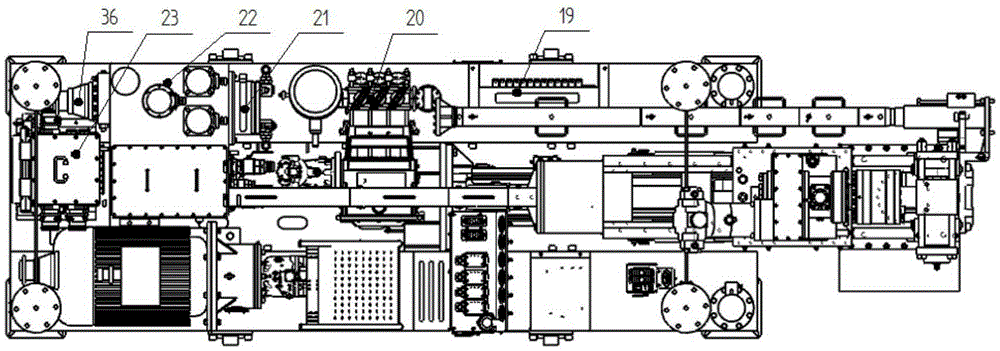

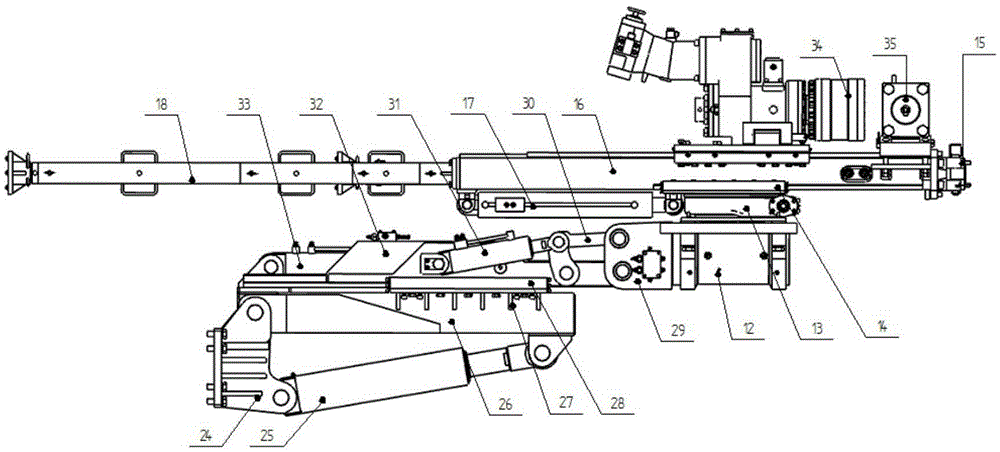

[0019] Attached below Figure 1-5 The present invention will be described in detail with specific embodiments.

[0020] Among them, the crawler drilling rig for large mining and high gas drainage in coal mine tunnels at least includes a body and a displacement drilling device.

[0021] The body includes a crawler car body 2, and two crawler belt assemblies 4 are arranged on both sides of the lower end of the crawler car body 2, and the two crawler belt assemblies 4 drive the crawler car body 2 to move rapidly in the tunnel.

[0022] In order to provide a stable state when drilling, the crawler car body 2 can also be provided with a stabilizing device, which includes a front upper stabilizing device 9 and a front lower stabilizing device 10 positioned at the front end of the crawler car body 2 and a rear rear end of the crawler car body 2. The upper stabilizing device 1 and the rear lower stabilizing device 37, wherein the front upper stabilizing device 9 and the rear upper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com