Asphalt stirring equipment and operation method thereof

A kind of asphalt mixing and equipment technology, which is applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of inability to mix asphalt raw materials, low quality of asphalt mixing, uneven asphalt mixing, etc., to improve drilling quality and improve Drilling requirements, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

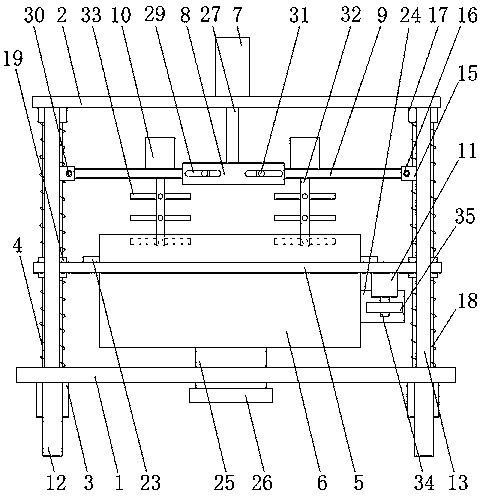

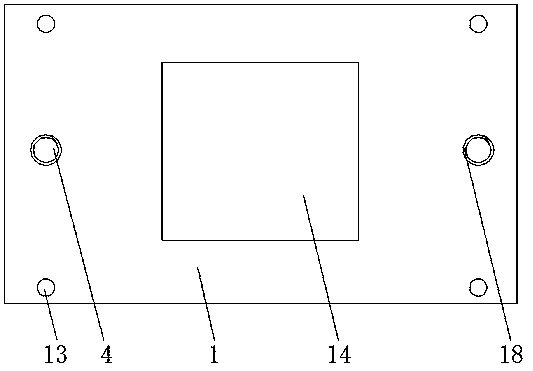

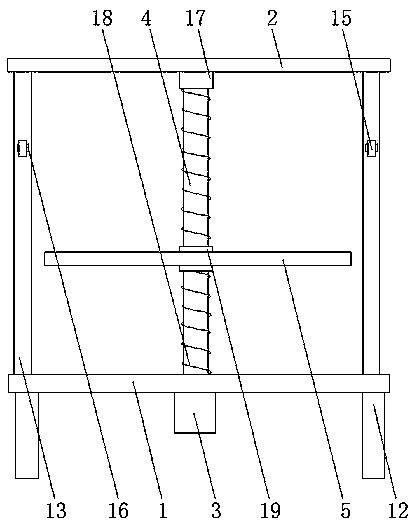

[0031] as attached Figure 1-8 As shown, an asphalt mixing equipment includes an operation table 1, a top plate 2, a motor 3, a rotating shaft 4, a bearing plate 5, a mixing bucket 6, a hydraulic cylinder 7, a connecting plate 8, an adjusting plate 9, a motor 2 10 and a motor Three 11, it is characterized in that: described console 1 is arranged on the bracket 12, vertically is provided with column 13 on console 1, is provided with positioning board 15 on column 13, and is provided with bearing one on positioning board 15 16. Connect the console 1 with the support 12 and the column 13 by welding to enhance the connection strength between the console 1 and the support 12 and the column 13, and improve the structural strength of the stirring equipment. The top plate 2 and the top of the column 13 Connect, and be provided with bearing 2 17 on the back of top plate 2, described motor 1 3 is arranged on the back of console 1, motor 1 3 is installed on the console 1 by bolt, improve...

Embodiment 2

[0044] as attached Figure 9-10 As shown, an asphalt mixing equipment includes an operation table 1, a top plate 2, a motor 3, a rotating shaft 4, a bearing plate 5, a mixing bucket 6, a hydraulic cylinder 7, a connecting plate 8, an adjusting plate 9, a motor 2 10 and a motor Three 11, it is characterized in that: described console 1 is arranged on the bracket 12, vertically is provided with column 13 on console 1, is provided with positioning board 15 on column 13, and is provided with bearing one on positioning board 15 16. Connect the console 1 with the support 12 and the column 13 by welding to enhance the connection strength between the console 1 and the support 12 and the column 13, and improve the structural strength of the stirring equipment. The top plate 2 and the top of the column 13 Connect, and be provided with bearing 2 17 on the back of top plate 2, described motor 1 3 is arranged on the back of console 1, motor 1 3 is installed on the console 1 by bolt, improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com