Manual drilling machine for drilling holes in thin plate

A manual drilling and thin plate technology, used in drilling/drilling equipment, boring/drilling, clamping, etc., can solve the problems of prolonged production cycle, inability to meet economic requirements, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

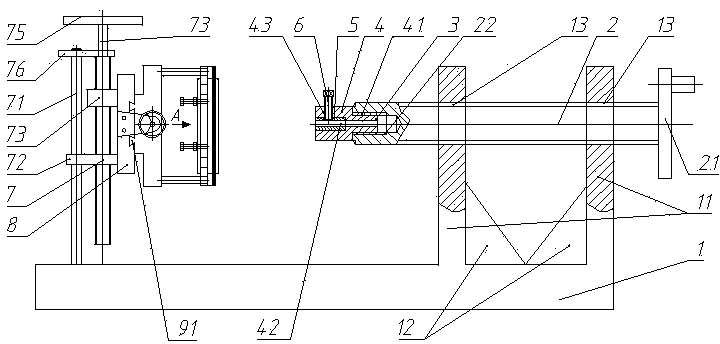

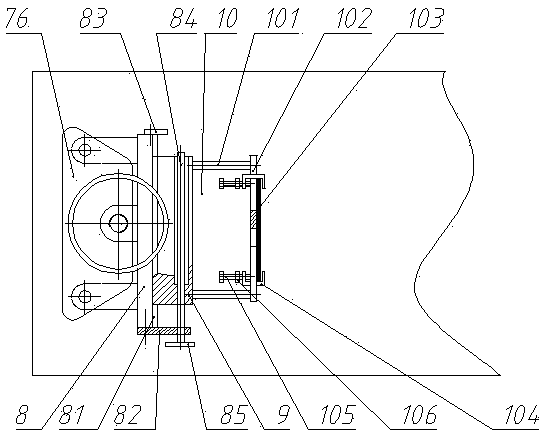

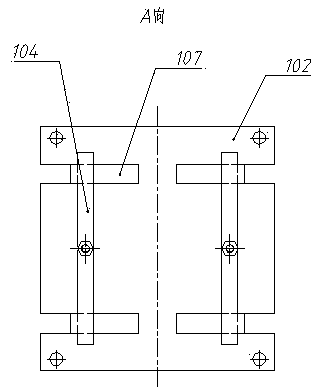

[0015] Below in conjunction with accompanying drawing, the manual drilling machine of thin plate drilling of the present invention is further described:

[0016] Depend on figure 1 , figure 2 , image 3 and Figure 4 It can be seen that the present invention includes a base 1, a drilling screw 2, a drill bit clamping device 3, an adjusting device 7 and a fixing device 10. One end of the base 1 is fixed with two parallel support plates 11, and the other end is Two parallel guide posts 71 are fixedly arranged; each of the support plates 11 is provided with a threaded hole I13, and the drilling screw 2 passes through the threaded holes I13 of the two support plates 11 to form a thread pair, and the drilling screw 2 One end is provided with a handwheel I21, and the other end is provided with a threaded hole II22, which is threadedly connected with the drill bit clamping device 3.

[0017] The drill clamping device 3 includes a mounting head 4, a drill sleeve 5 and a clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com