Hot melt adhesive attached with dry-type PU (polyurethane) on wet-type PU

A technology of hot-melt adhesive and hot-melt adhesive layer, which is applied in the direction of synthetic resin layered products, lamination devices, lamination, etc., can solve the problems of insufficient thickness, non-wearable surface, and insufficient thickness of dry PU leather, and achieve Wide application temperature range, good hydrolysis resistance, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings, but the specific embodiments of the present invention are not limited thereto.

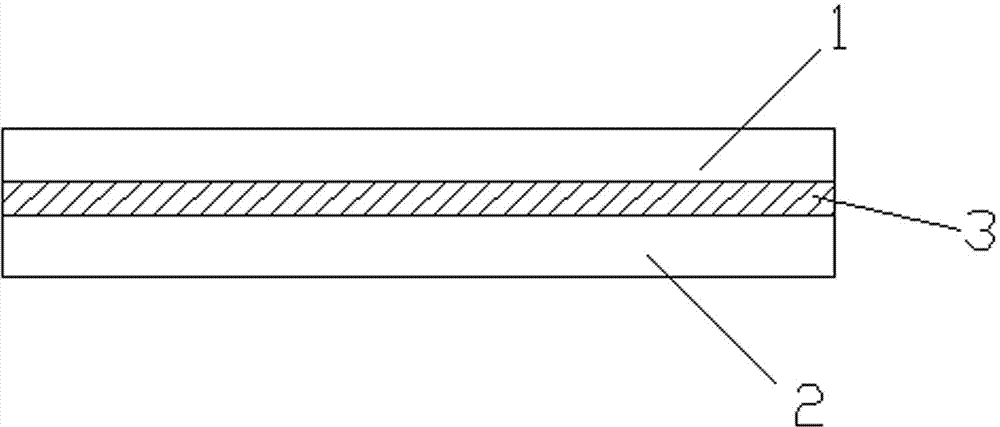

[0022] Such as figure 1 As shown, a kind of TPU hot-melt adhesive provided by the present invention adds wet PU and sticks dry PU again, comprises dry PU film layer 1 and wet PU film layer 2, and the back side of wet PU film layer 2 is provided with TPU hot-melt Adhesive layer 3. Wherein, the TPU hot-melt adhesive layer 3 is used for bonding the present invention on the cloth base, the wet PU film layer 2 can provide larger thickness, better softness and fullness, and the dry PU film layer 1 can Provides good hydrolysis resistance, abrasion resistance, toughness and elasticity.

[0023] Wherein, the dry PU film layer 1 is provided with an embossed or printed layer, so that the present invention can have different designs and colors.

[0024] The thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com