Accurate positioning glass drilling machine

An accurate positioning and drilling machine technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools and other directions, can solve the problems of glass horizontal and vertical positioning cannot be taken into account, the actual operation is not applicable, the positioning structure is complex, etc., to improve drilling. The effect of hole accuracy, positioning accuracy improvement, and easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

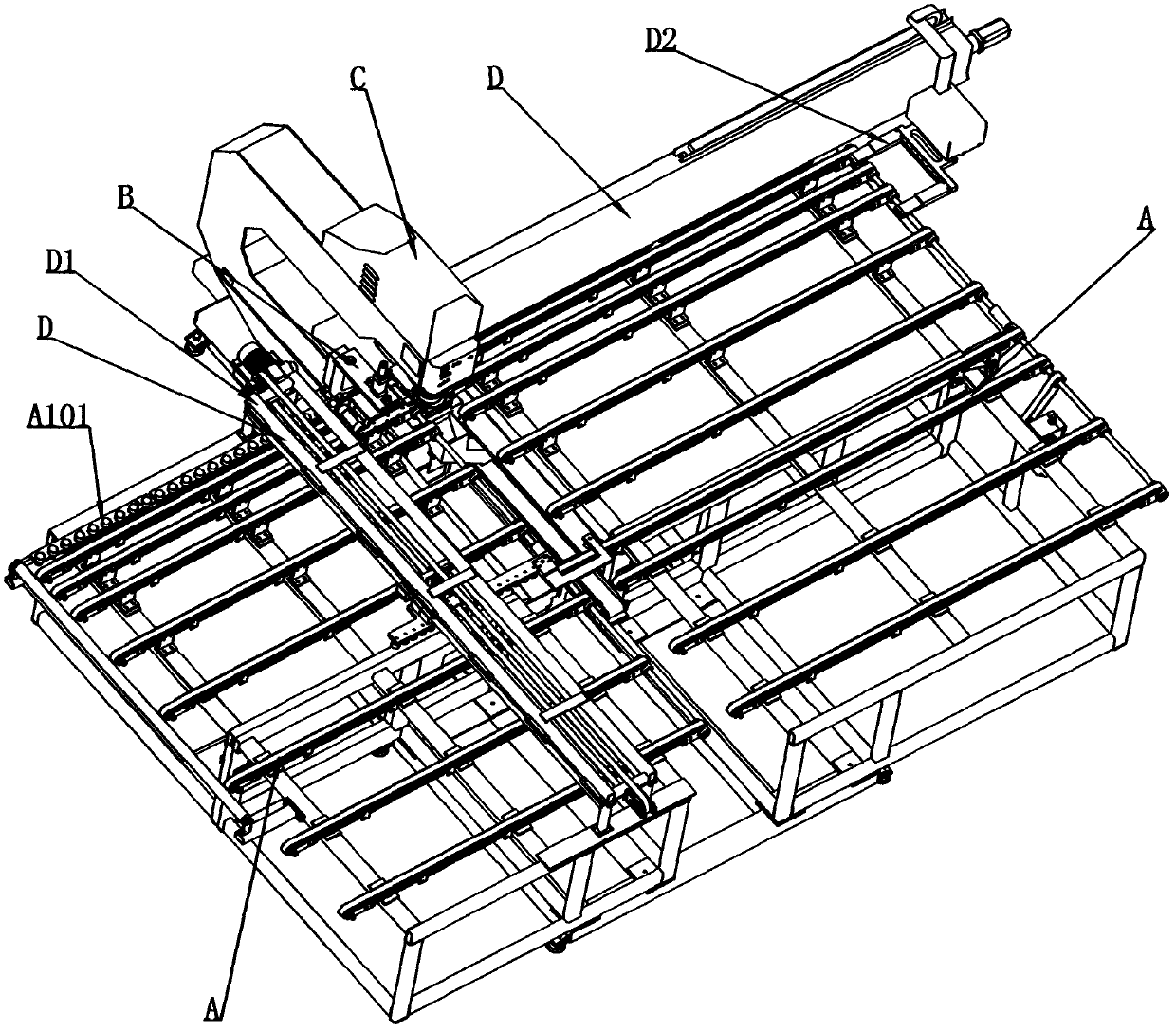

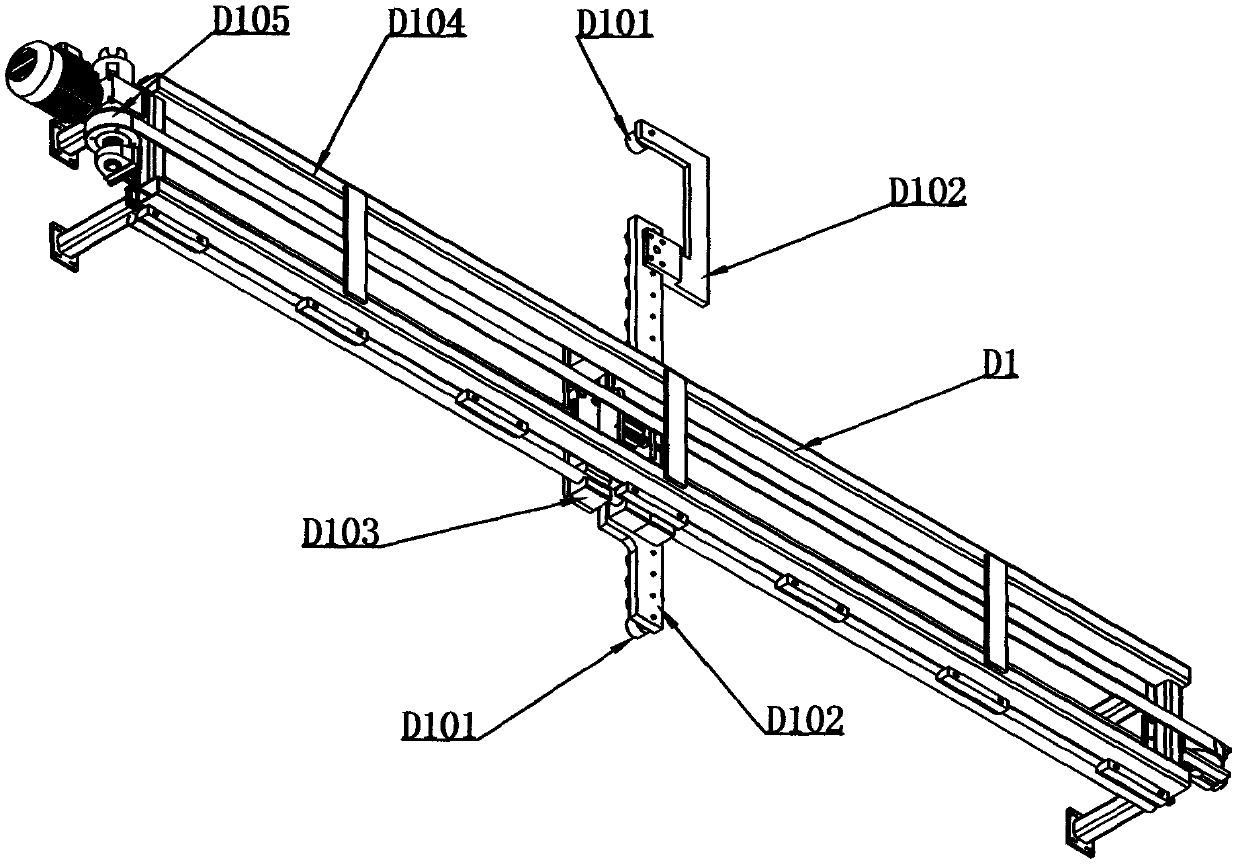

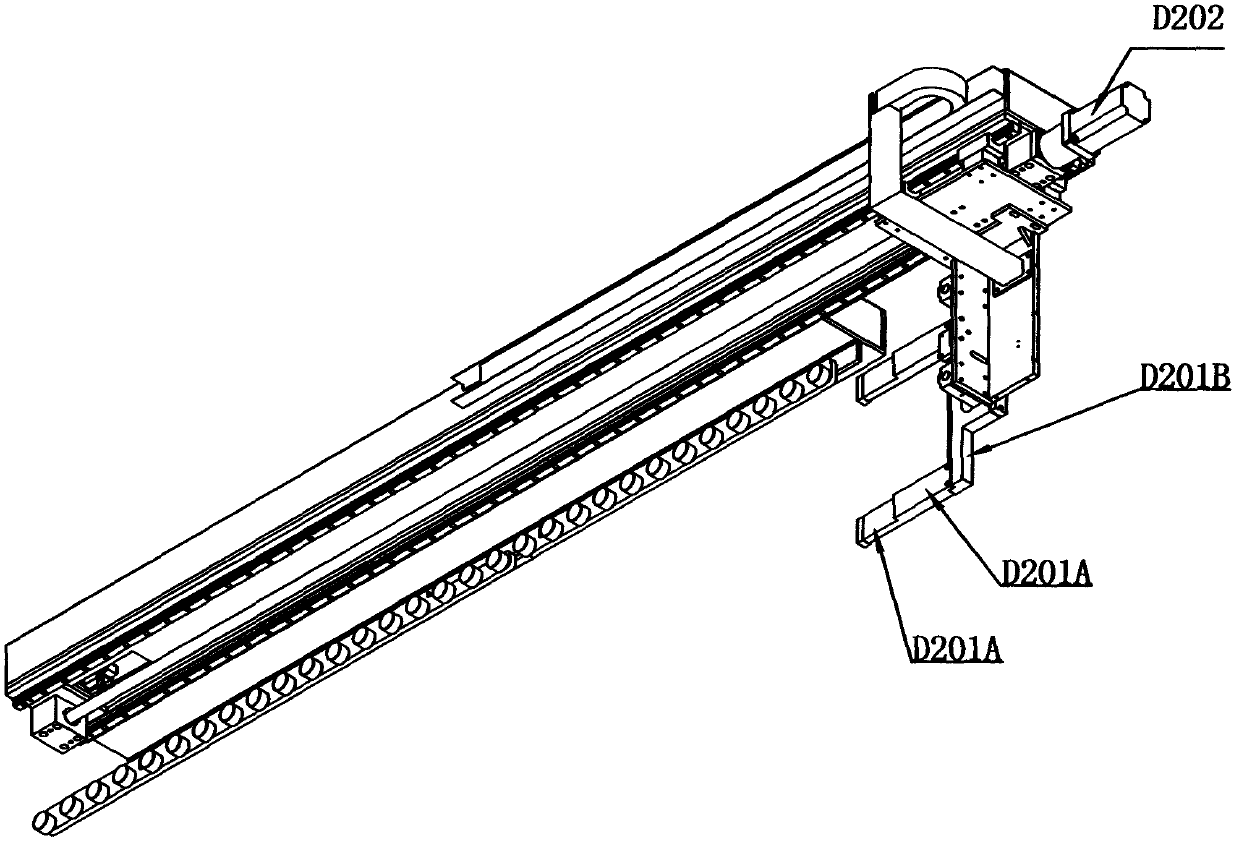

[0034] An accurate positioning glass drilling machine of the present invention is improved on the basis of the patent titled "A CNC Glass Drilling Machine" (patent application number: CN201010567608.4) filed by the applicant on November 29, 2010. For a better understanding of this patent application, please refer to this patent application, patent application publication (announcement) date: 2011.04.06, publication (announcement) number: CN102001821A), the invention discloses a CNC glass drilling machine, including glass conveying The device, pressing device, drilling device and corresponding control device are characterized in that: the glass conveying device includes a number of guide rails arranged along the glass running direction, a conveying belt that can rotate up and down around the guide rail, a rotating shaft that controls the rotation of the belt, and a driving motor The pressing device is an upper pressing mechanism arranged on the top of the glass conveying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com