Environment-friendly low-molecular-weight branched polyether ammonia shale intercalation inhibitor

A low molecular weight, branched polyether technology, applied in the field of oil and gas field drilling, can solve the problems of clay entanglement, uneven coating, difficult access of polyamine compounds, limited inhibition performance, etc., and achieves low price, improved inhibition performance, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

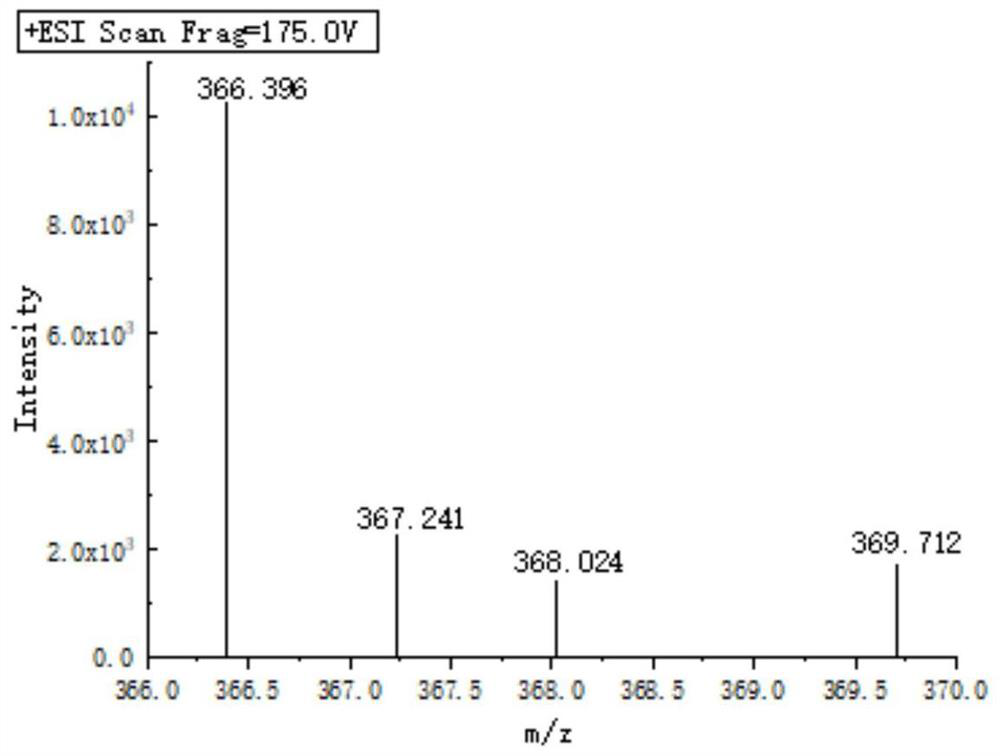

[0028] With carbamic acid N-[2-(2-aminoethoxy) ethyl] methyl ester, vinyl isobutyl ether is used as raw material to prepare low molecular weight branched polyether ammonia by one-pot method, and its specific operation steps are as follows:

[0029] Accurately weigh 0.1 mol of N-[2-(2-aminoethoxy)ethyl]methyl carbamate and 0.3 mol of vinyl isobutyl ether and dissolve them in 100 ml of anhydrous methanol respectively. Put N-[2-(2-aminoethoxy)ethyl]methyl carbamate in a three-necked flask, and place vinyl isobutyl ether in a separate into a liquid funnel and added dropwise into a three-necked flask. After the dropwise addition was completed, the temperature was raised to 80° C., and the reaction was refluxed for 8 hours. After the reaction is completed, the product is rotary evaporated at 65° C. and the absolute vacuum degree is less than 3000 Pa to obtain G3 low molecular weight branched polyether ammonia. Its molecular structural formula is:

[0030]

Embodiment 2

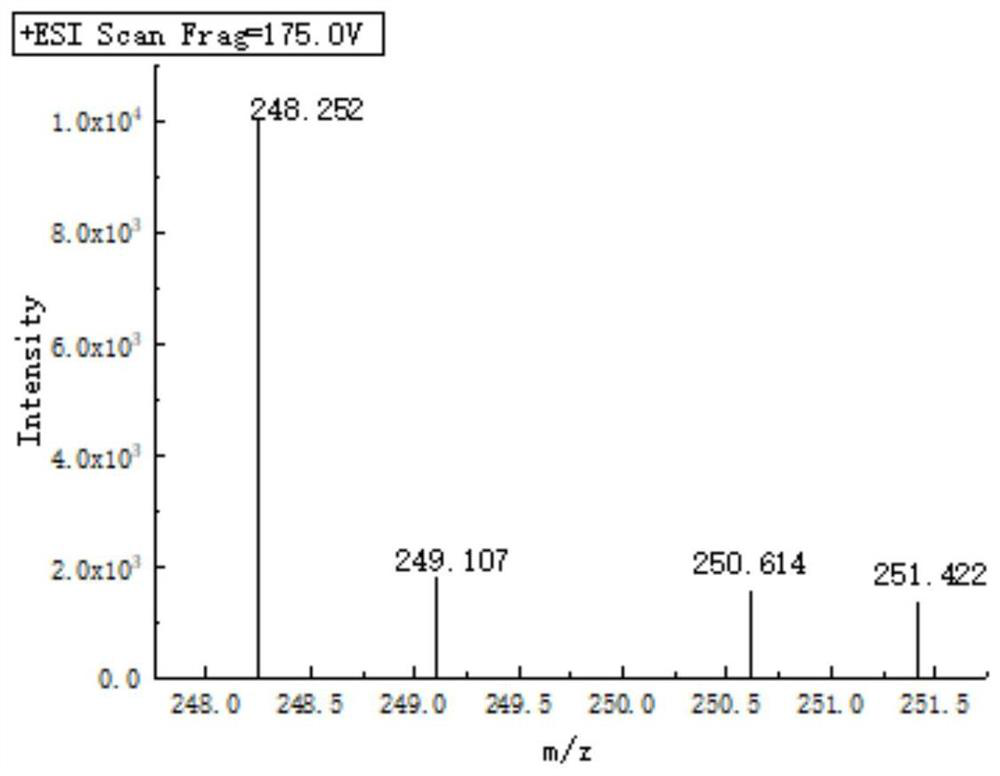

[0032] N-[2-(2-aminoethoxy) ethyl] methyl carbamate and vinyl isobutyl ether are used as raw materials to prepare low-molecular-weight branched polyether ammonia by a step-by-step synthesis method. The specific operation steps are as follows:

[0033] Accurately weigh 0.1 mol of N-[2-(2-aminoethoxy)ethyl]methyl carbamate and 0.1 mol of vinyl isobutyl ether and dissolve them in 100 ml of anhydrous methanol respectively. Put N-[2-(2-aminoethoxy)ethyl]methyl carbamate in a three-necked flask, and place vinyl isobutyl ether in a separate into a liquid funnel and added dropwise into a three-necked flask. After the dropwise addition was completed, the temperature was raised to 80° C., and the reaction was refluxed for 8 hours. After the reaction is completed, the product is rotary evaporated at 65° C. and the absolute vacuum degree is less than 3000 Pa to obtain G1 low molecular weight branched polyether ammonia. Its molecular structure is

[0034]

[0035] Accurately weigh 0....

Embodiment 3

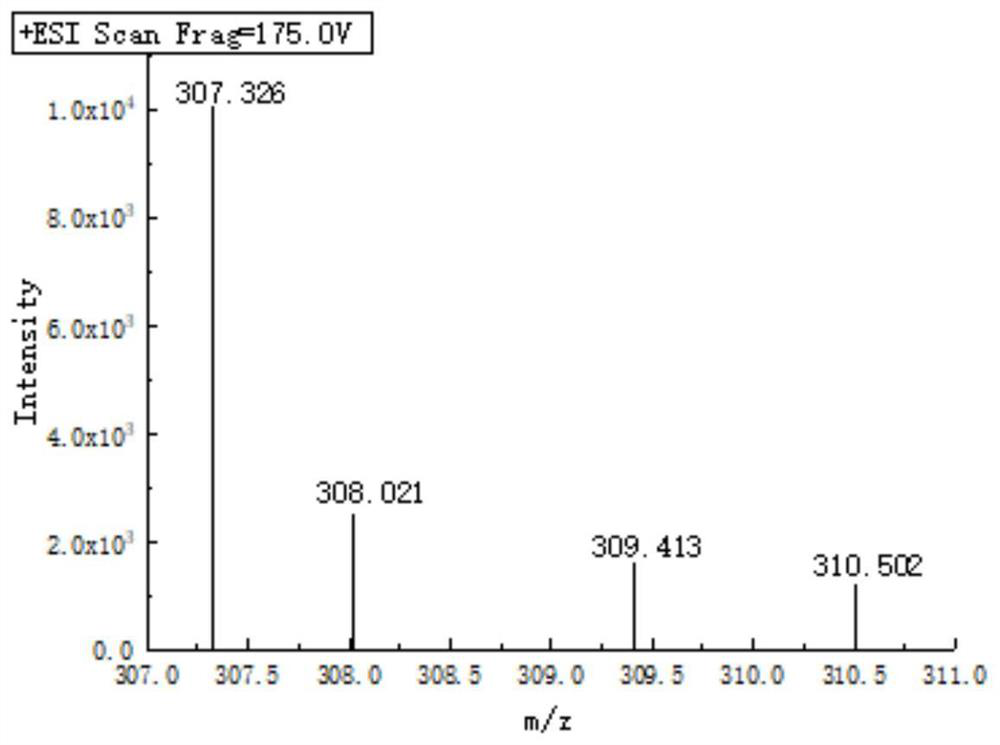

[0040] N-[2-[2-(2-aminoethoxy) ethoxy] ethyl] methyl carbamate and vinyl n-butyl ether are used as raw materials to prepare low molecular weight branched polyether ammonia by step-by-step synthesis. The specific operation steps are as follows:

[0041] Accurately weigh 0.1mol of N-[2-[2-(2-aminoethoxy)ethoxy]ethyl]methyl carbamate and 0.1mol of vinyl n-butyl ether and dissolve them in 100ml of anhydrous methanol middle. N-[2-[2-(2-aminoethoxy)ethoxy]ethyl]methyl carbamate was placed in a three-necked flask, and the ethylene The n-butyl ether was placed in a separatory funnel and added dropwise into a three-necked flask. After the dropwise addition was completed, the temperature was raised to 80° C., and the reaction was refluxed for 8 hours. After the reaction is completed, the product is rotary evaporated at 65° C. and the absolute vacuum degree is less than 3000 Pa to obtain G1 low molecular weight branched polyether ammonia.

[0042] Its molecular structure is

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com