A new type of low elastic modulus medical zirconium alloy and its design method

A technology with low elastic modulus and elastic modulus, applied in the field of medical biomaterials, can solve the problems of large workload and experimental error, not considering the interaction between elements, complicated operation, etc., to achieve easy smelting, large reserves, economical high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A design method for a novel medical zirconium alloy with a low elastic modulus, the specific implementation steps of which include:

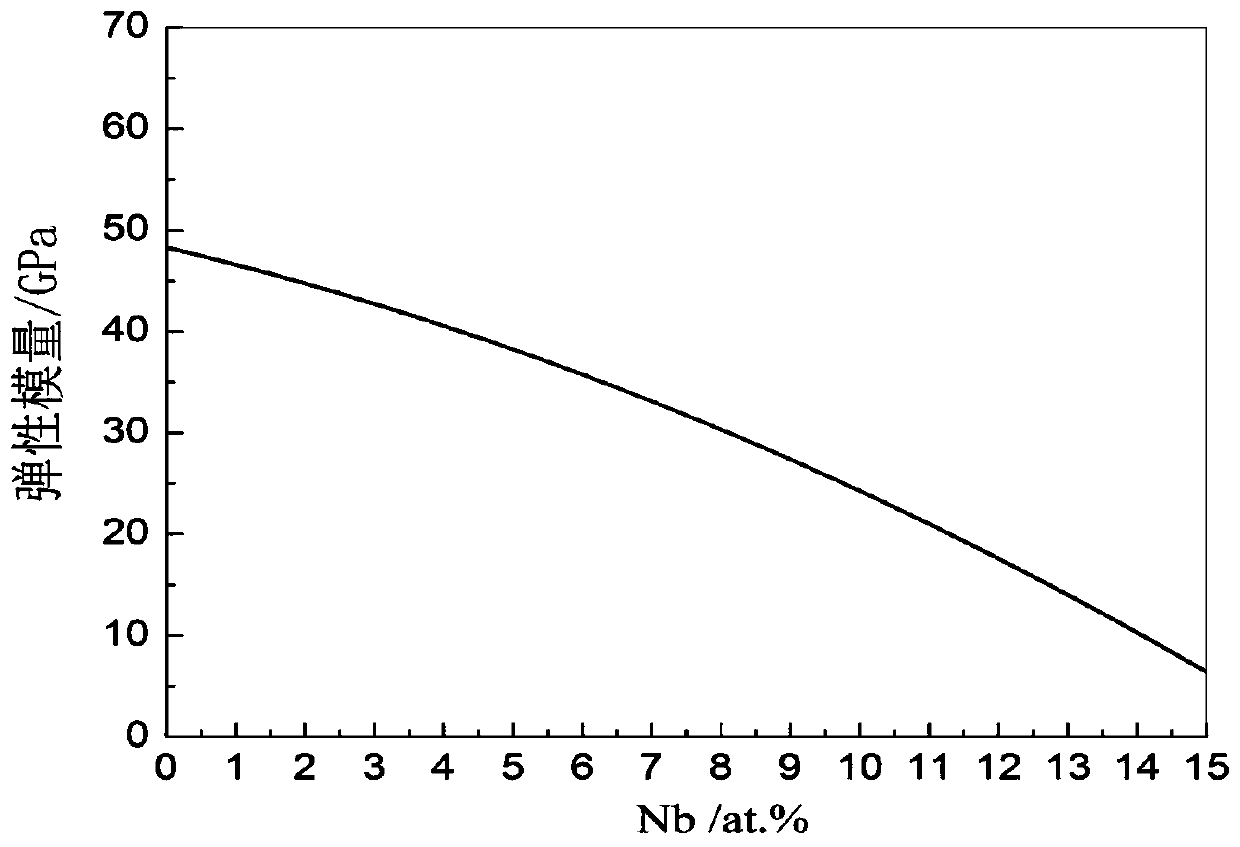

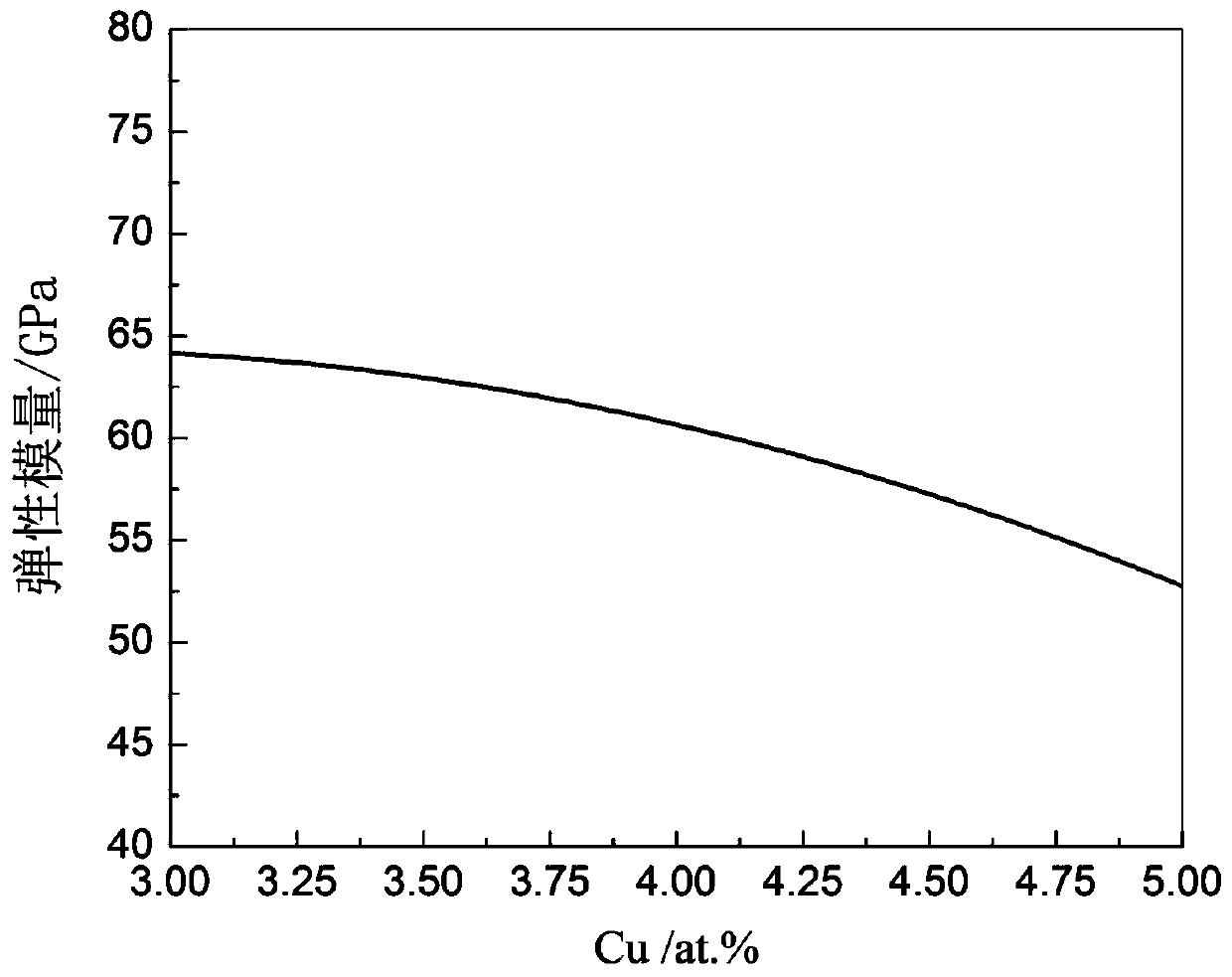

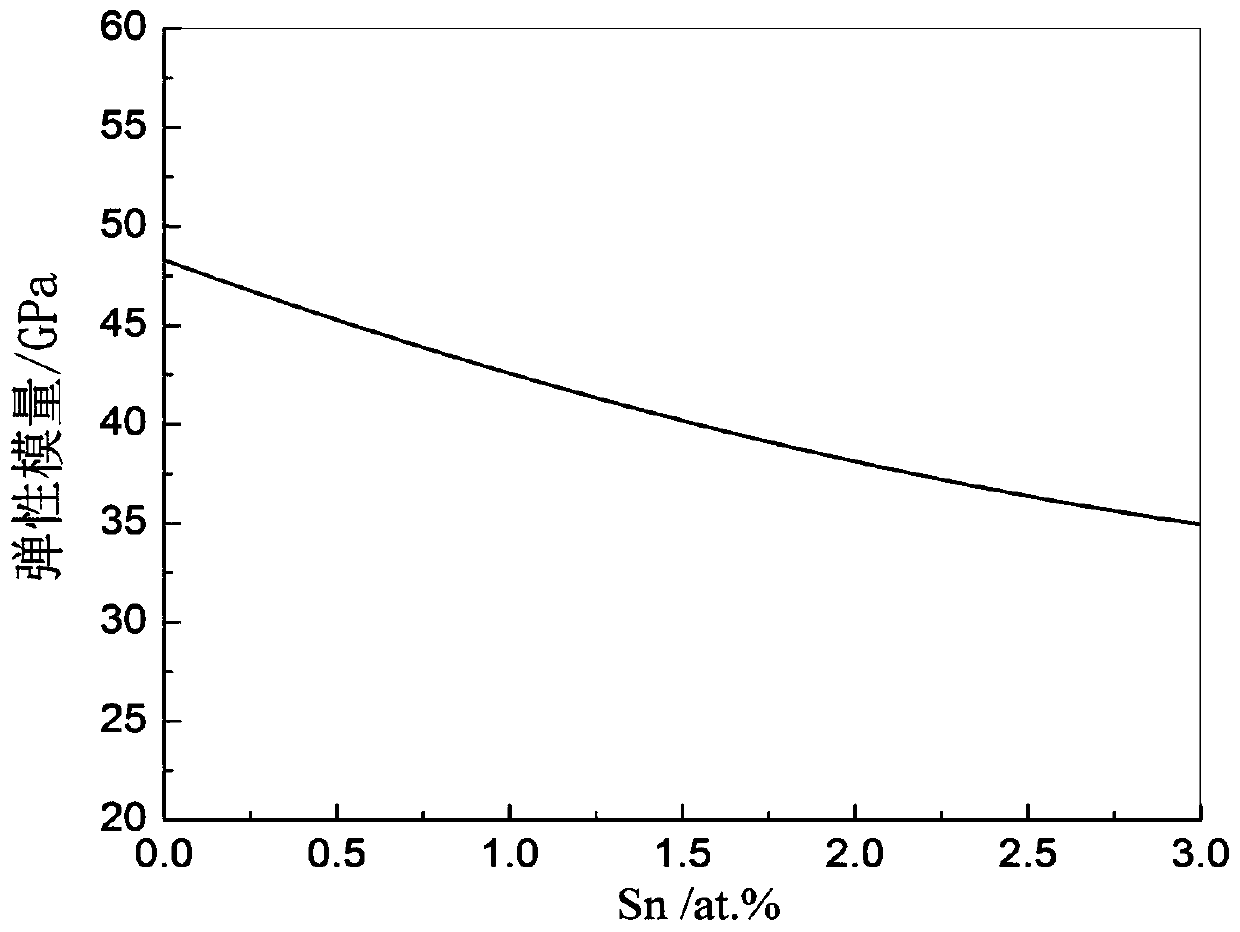

[0047] (1) Based on the alloy phase diagram and alloy strengthening mechanism, select Sn, Cu, and Nb as doping elements to design medical zirconium alloys.

[0048] (2) Composition design of medical zirconium alloys is carried out by using quadratic regression orthogonal rotation combination design, taking the elastic modulus of the alloy as the test index, and taking the contents of tin, copper and niobium as the test factors, the three The factor levels are coded, and the experimental plan is obtained through the quadratic regression orthogonal rotation combination design calculation. The composition ratio of the samples prepared in this test, that is, the factor variation range, is shown in Table 1, and the test factor level coding table is shown in Table 2. According to the above data analysis and calculation, the implementation plan ...

Embodiment 2

[0076] According to the composition design method of Example 1, the atomic percentages of the raw materials in Example 2 are determined to be: 0.6 at.% of tin, 4.6 at.% of copper, 12 at.% of niobium, and 82.8 at.% of zirconium.

[0077] A preparation method of a novel medical zirconium alloy with a low elastic modulus, the specific operation steps are as follows:

[0078] (1) Weighing of raw materials: the purity of tin, copper, niobium and zirconium in each component of the medical zirconium alloy is ≥99.9%. The atomic percent of each alloy element is converted into a weight percent to obtain a weighing ratio scheme. Before weighing the samples, the oxide scales on the surface of the four metal blocks of zirconium, tin, copper and niobium were firstly ground off, and then the metal blocks were clamped into small pieces by hydraulic forceps to facilitate weighing. % by weight of 10g of raw material is taken for subsequent use.

[0079] (2) Preparations before smelting: Befor...

Embodiment 3

[0084]According to the composition design method in Example 1, the atomic percentages of the raw materials in Example 3 are determined to be: tin 0.6 at.%, copper 3.4 at.%, niobium 12 at.%, zirconium 84 at.%.

[0085] A preparation method of a novel medical zirconium alloy with a low elastic modulus, the specific operation steps are as follows:

[0086] (1) Weighing of raw materials: the purity of tin, copper, niobium and zirconium in each component of the medical zirconium alloy is ≥99.9%. The atomic percent of each alloy element is converted into a weight percent to obtain a weighing ratio scheme. Before weighing the samples, the oxide scales on the surface of the four metal blocks of zirconium, tin, copper and niobium were firstly ground off, and then the metal blocks were clamped into small pieces by hydraulic forceps to facilitate weighing. % by weight of 10g of raw material is taken for subsequent use.

[0087] (2) Preparations before smelting: Before smelting zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com