A kind of dental composite core resin and preparation method thereof

A composite core and dental technology, applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of poor wear resistance, limited ratio of filler to resin matrix, low strength, etc., to meet the requirements of bonding strength and prevent filling fineness Excess material, the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

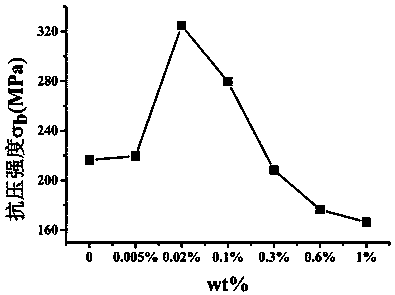

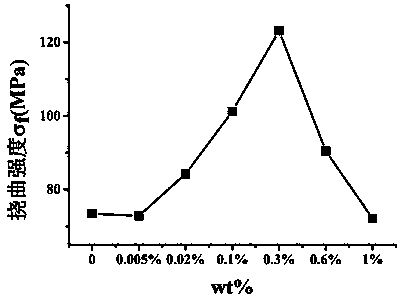

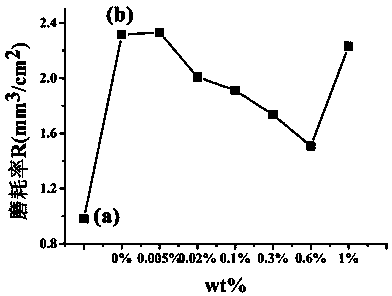

[0029] A dental composite core resin, mainly composed of the following raw materials: modified nano-diamond 0.02%, modified nano-silica 2%, quartz powder 34.68%, nano-zirconia 2%, colorant (TiO 2 ) 0.1%, resin matrix 60% (urethane dimethacrylate), also includes initiator (camphorquinone) and co-initiator (dimethylaminoethyl methacrylate), the amount of the initiator The ratio of the consumption of the resin matrix to the consumption of the resin matrix is 0.6%, and the ratio of the consumption of the co-initiator to the consumption of the resin matrix is 0.6%.

[0030] The modified nano-diamond is prepared by the following method: adding the nano-diamond to the ethanol solution, ultrasonically dispersing for 30min, the ultrasonic frequency is 35kHZ, then adding the γ-MPS coupling agent hydrolyzate, at 40°C, the stirring speed is 100rpm , after stirring for 24 hours, centrifuge at a centrifugal speed of 4000rpm for 5 minutes and 3 times, then wash with an ethanol solution, ...

Embodiment 2

[0042] A dental composite core resin, mainly composed of the following raw materials: modified nano-diamond 0.1%, modified nano-silica 1%, quartz powder 45%, nano-zirconia 1.8%, coloring agent (TiO 2 ) 0.1%, resin matrix 50% (urethane dimethacrylate), also includes initiator (camphorquinone) and co-initiator (dimethylaminoethyl methacrylate), the amount of the initiator The ratio of the amount of the co-initiator to the amount of the resin matrix is 1%, and the ratio of the amount of the co-initiator to the amount of the resin matrix is 1%.

[0043] The modified nano-diamond is prepared by the following method: add the nano-diamond to the ethanol solution, ultrasonically disperse for 40min, the ultrasonic frequency is 45kHZ, then add the γ-MPS coupling agent hydrolyzate, at 50°C, the stirring speed is 150rpm After stirring for 18 hours, centrifuge at a centrifugal speed of 2000 rpm for 10 minutes and 5 times, then wash with an ethanol solution, take the precipitate and dry...

Embodiment 3

[0055] A dental composite core resin, mainly composed of the following raw materials: modified nano-diamond 0.6%, modified nano-silica 10%, quartz powder 43.32%, nano-zirconia 5%, colorant (TiO 2 ) 0.2%, resin matrix 40% (urethane dimethacrylate), also includes initiator (camphorquinone) and co-initiator (dimethylaminoethyl methacrylate), the amount of the initiator The ratio of the consumption of the resin matrix to the consumption of the resin matrix is 0.08%, and the ratio of the consumption of the co-initiator to the consumption of the resin matrix is 0.8%.

[0056] The modification or pretreatment method of modified nano-diamond, modified nano-silica, quartz powder, and nano-zirconia and the preparation method of dental composite core resin are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com