Low-molecular-weight branched shale inhibitor and water-based drilling fluid thereof

A shale inhibitor and water-based drilling fluid technology, applied in the field of oil and gas field drilling, can solve the problems of clay entanglement, uneven coating, difficult access of polyamine compounds, limitation of inhibition performance, etc., and achieves safe and reliable formulation and improved inhibition performance. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

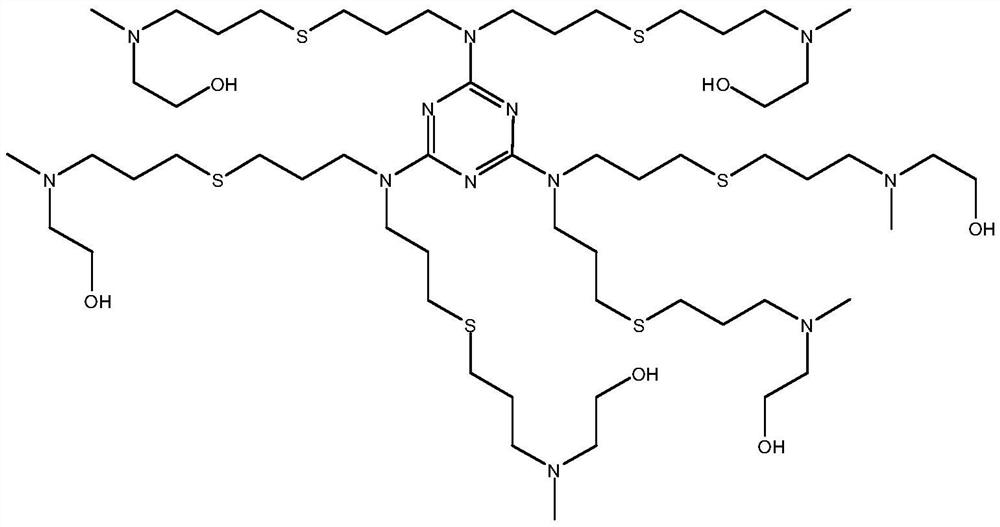

[0025] Using N-methyl-2-hydroxyethylamine, melamine, and diallyl sulfide as raw materials, it is synthesized by the following steps:

[0026] Weigh 9.75 g of N-methyl-2-hydroxyethylamine, 2.1 g of melamine, and 14.82 g of diallyl sulfide. Dissolve N-methyl-2-hydroxyethylamine and diallyl sulfide in 80 ml of methanol, and dissolve melamine in 50 ml of methanol. Then put the methanol solution of N-methyl-2-hydroxyethylamine in a three-necked flask, and titrate the diallyl sulfide methanol solution at a speed of about 1 d / s in an ice-water bath under the condition of nitrogen gas. After the dropwise addition was completed, the temperature was raised to 30° C. for 8 hours. After the reaction was completed, the solvent was distilled off under reduced pressure to obtain the product.

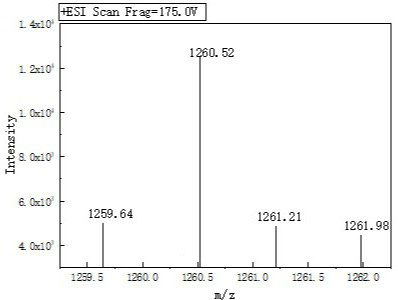

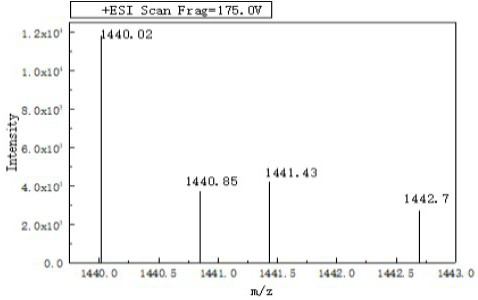

[0027] The product obtained in the previous step was dissolved in 100 ml of methanol and placed in a three-necked flask, then the melamine solution was added into the three-necked flask, and the tempe...

Embodiment 3

[0036] Preparation of water-based drilling fluid:

[0037] The water-based drilling fluid system of this embodiment is composed of the following substances: water, inhibitor, bentonite, sodium carbonate, viscosifier, fluid loss reducer, pH regulator, lubricant, plugging agent, and weighting agent. And based on 100 parts by weight of water, the content of low molecular weight branched shale inhibitor is 1-5 parts by weight, the content of bentonite is 10 parts by weight, the content of sodium carbonate is 0.5 parts by weight, and the content of viscosifier is 5 parts by weight. In parts by weight, the content of the fluid loss reducer is 4 parts by weight, the content of the pH regulator is 1 part by weight, the content of the plugging agent is 5 parts by weight, the content of the lubricant is 0.5 parts by weight, and the content of the weighting agent is 40 parts by weight.

[0038] Among them, the low molecular weight branched shale inhibitor is A1 and A2 successfully prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com