Punching die for automobile covering parts

A technology for automobile cover parts and punching, which is applied in the direction of perforating tools, cleaning methods and tools, manufacturing tools, etc., which can solve the problems of high processing difficulty, lack of power for lateral movement, difficult processing, etc., and it is difficult to control the precision and precise control , Processing precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

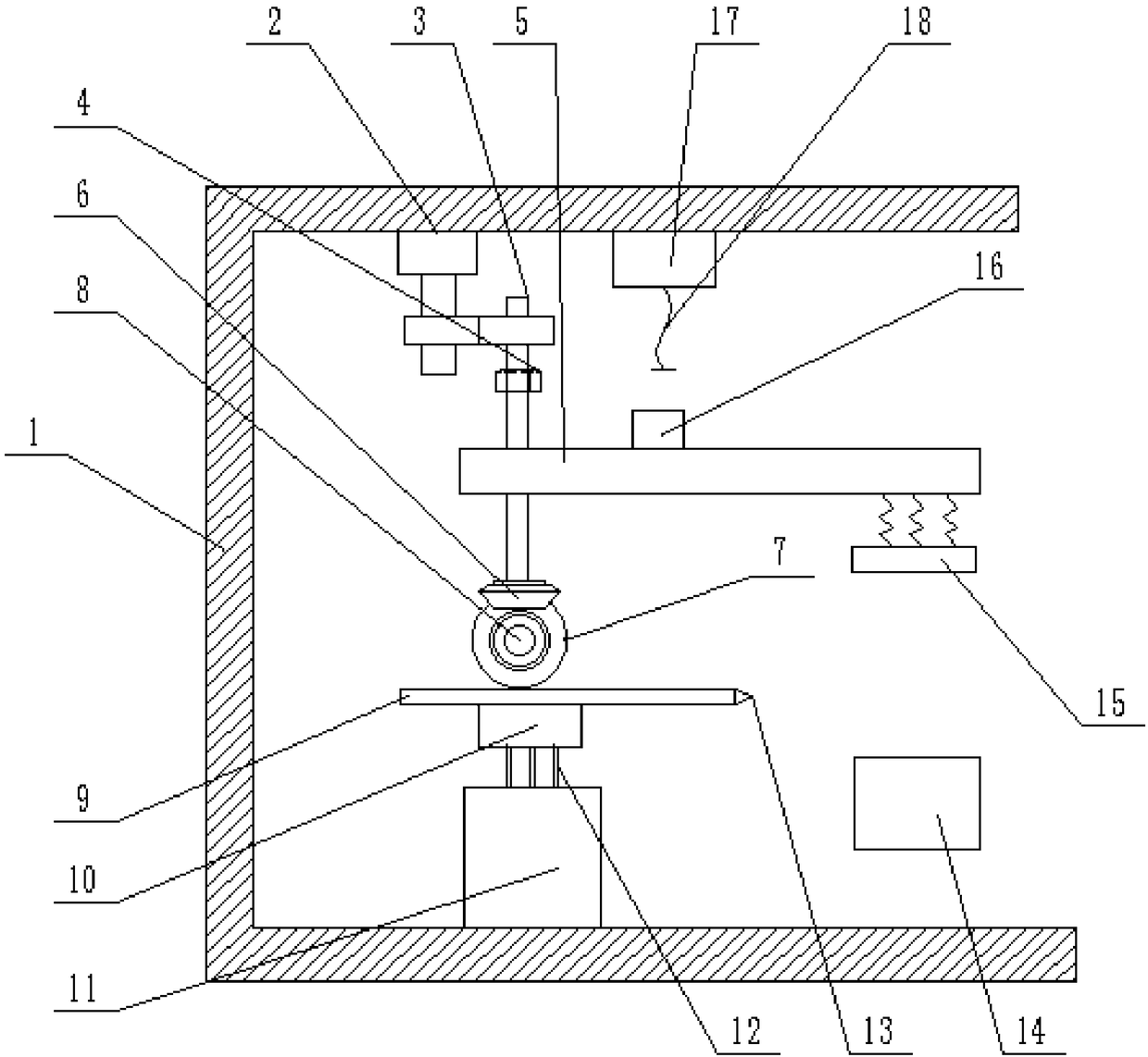

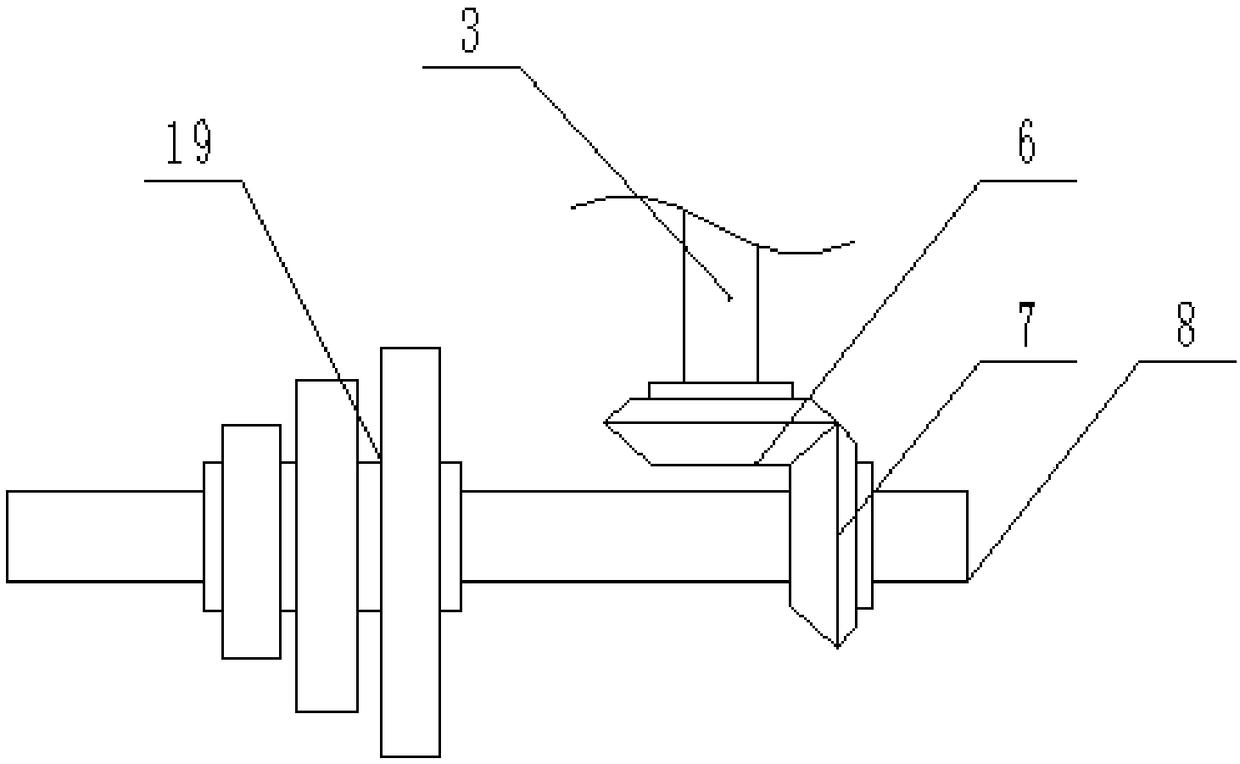

[0024] The reference signs in the drawings of the description include: frame 1, rotating motor 2, first rotating shaft 3, nut 4, upper mold base 5, first bevel gear 6, second bevel gear 7, second rotating shaft 8, rack 9. Fixed seat 10, piston barrel 11, piston rod 12, drill bit 13, lower mold base 14, pressing plate 15, electromagnet 16, power supply 17, wire 18, triple gear 19.

[0025] Such as figure 1 As shown, the mold for punching an automobile cover part includes a frame 1, and the frame 1 is provided with a first rotating shaft 3 and a rotating motor 2, and the first rotating shaft 3 includes a spline section, a thread section and In the clamping section, a spline sleeve is connected outside the spline section, and a driven gear is connected outside the spline sleeve. The output shaft of the rotary motor 2 is provided with a driving gear meshing with the driven gear. A nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com