Flexible-outside rigid-inside multi-walled carbon nanotube nano plugging agent and oil-based drilling fluid

A technology of multi-walled carbon nanotube and nanometer plugging agent, which is applied in the field of oil and gas field drilling, can solve problems such as wellbore instability, and achieve the effects of high temperature resistance and plugging performance, stable performance and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

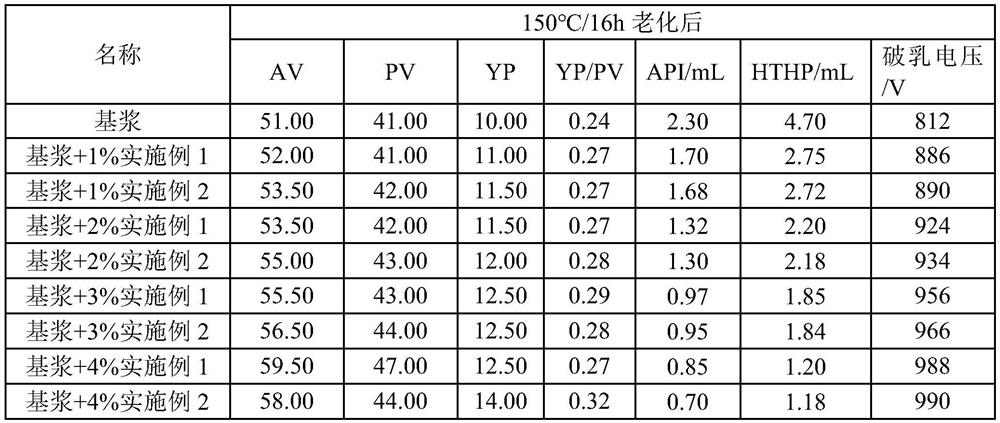

Embodiment 1

[0025] (1) Synthesis of Multi-walled Carbon Nanotubes Grafted Amino Compounds

[0026] Add 0.5-0.6mol of hydroxylated titanium dioxide into 120mL of toluene solution, raise the temperature to 80-90°C and add 0.1-0.2mol of amino-containing silane coupling agent while stirring, to make hydroxylated titanium dioxide and amino-containing silane coupling agent react 5h, distilled under reduced pressure for 2h to obtain the crude product, washed with toluene, filtered to remove unreacted monomer, and dried in vacuum for 2h to obtain modified nano-titanium dioxide, disperse the modified nano-titanium dioxide with 100-110mL of toluene, add 0.25mol containing 1 , 3-diallyl urea, reacted at 65°C for 36h, distilled under reduced pressure for 2h, washed with toluene, filtered, removed unreacted monomer, dried in vacuum for 2h, took 0.25mol of the dried product and added it to 100mL In toluene, stir until dispersed, keep flowing nitrogen for 30min, slowly add 0.25mol 1,2-divinylbenzene, he...

Embodiment 2

[0030] (1) Synthesis of Multi-walled Carbon Nanotubes Grafted Amino Compounds

[0031] Add 0.5-0.6mol of hydroxylated titanium dioxide into 120mL of toluene solution, raise the temperature to 80-90°C and add 0.1-0.2mol of amino-containing silane coupling agent while stirring, to make hydroxylated titanium dioxide and amino-containing silane coupling agent react 5h, distilled under reduced pressure for 2h to obtain the crude product, washed with toluene, filtered to remove unreacted monomer, and dried in vacuum for 2h to obtain modified nano-titanium dioxide, disperse the modified nano-titanium dioxide with 100-110mL of toluene, add 0.25mol containing 1 , 3-diallyl-2-thiourea, reacted at 65°C for 36 hours, distilled under reduced pressure for 2 hours, washed with toluene, filtered, removed unreacted monomers, dried in vacuum for 2 hours, and took 0.25mol of dried Add the product into 100mL toluene, stir until dispersed, keep flowing nitrogen for 30min, slowly add 0.25mol 1,3-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com