Numerical control grass drill

A drilling machine and glass technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve problems such as difficulty in application, and achieve the effects of flexible and convenient use, accurate positioning and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

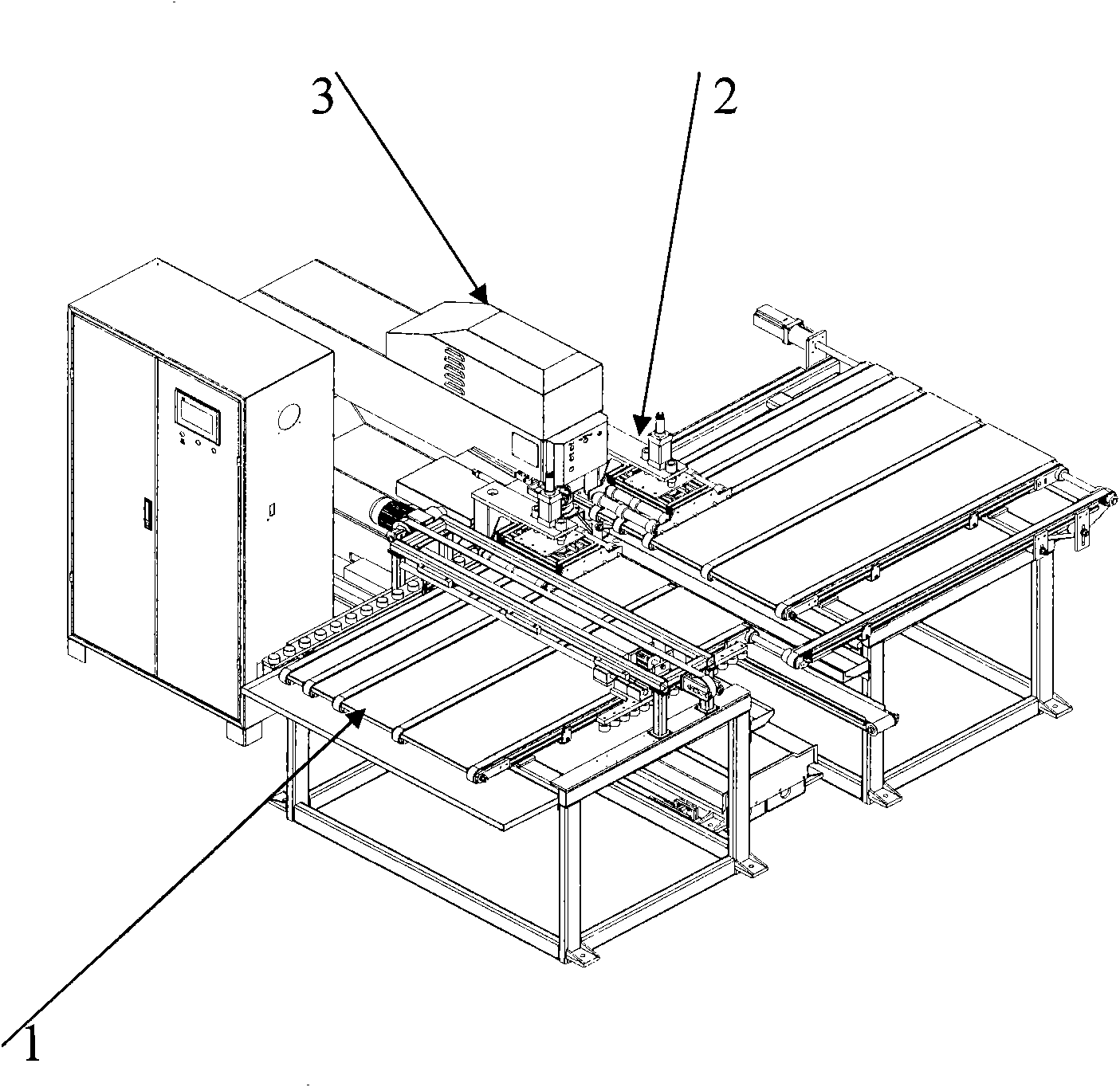

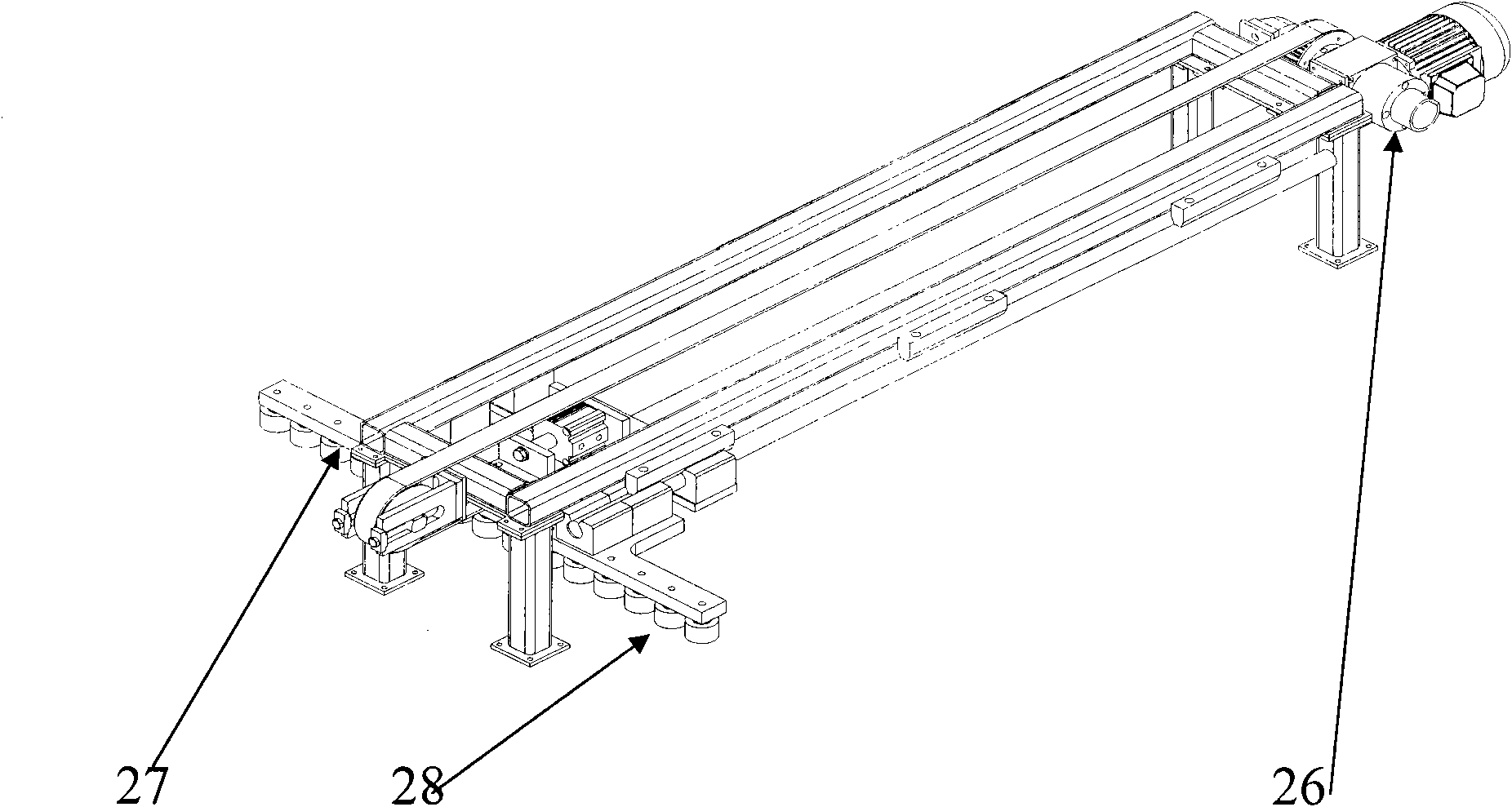

[0030] see figure 1 . A numerical control glass drilling machine appearance diagram, the drilling machine, including a glass conveying device 1, a pressing device 2, a drilling device 3 and their corresponding control devices, under normal circumstances, the glass passes through the glass conveying device 1, After reaching the drilling device 3, the pressing device 2 is fixed and pressed, and then the drilling operation is carried out through the drilling device 3. After the drilling is completed, it is transmitted through the glass conveying device 1. All these actions are set in advance. The corresponding control device can be realized by using the existing automatic control technology such as PLC.

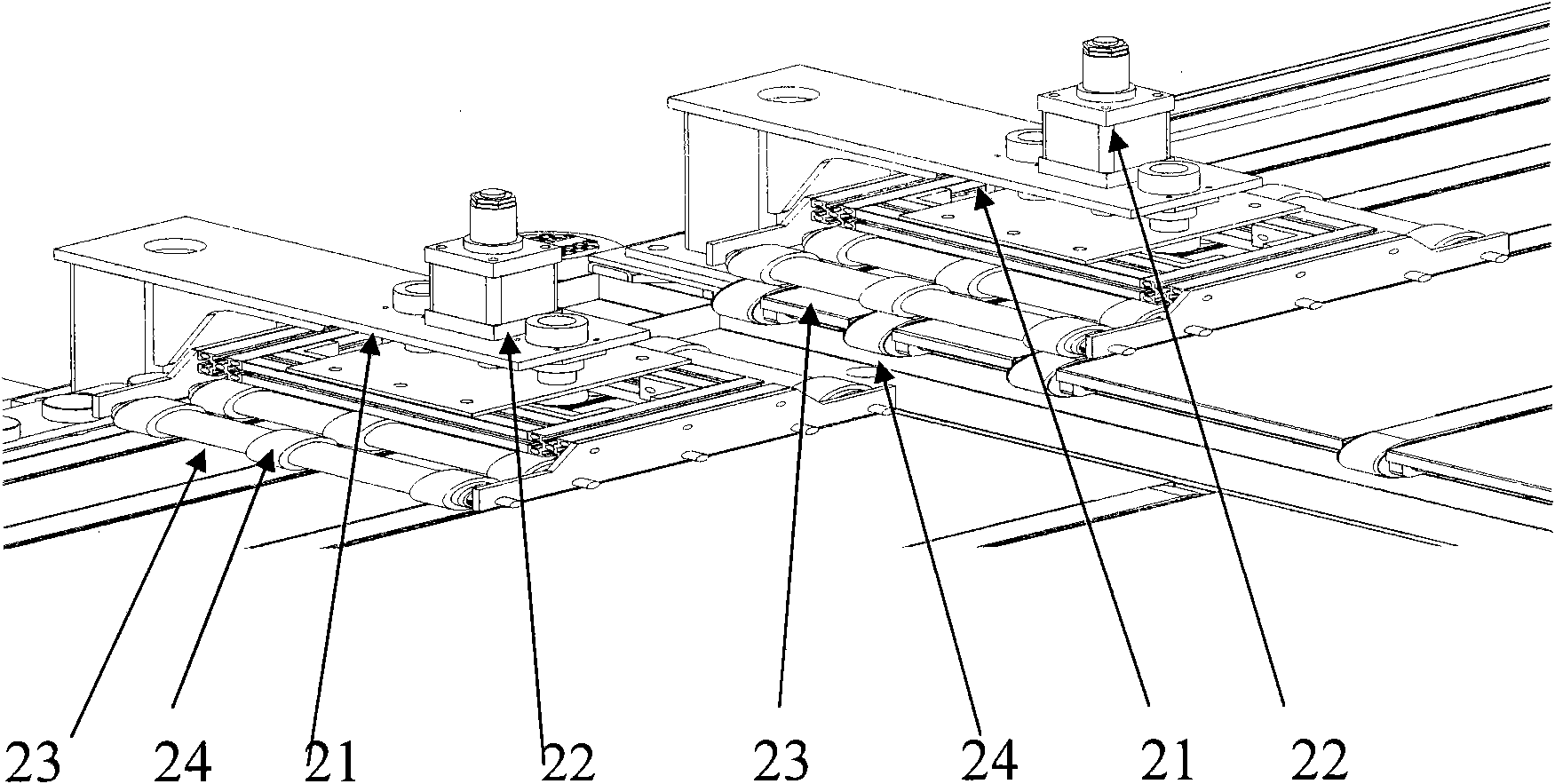

[0031] The clamping device can include an upper clamping mechanism and a side clamping mechanism. The processed glass is tightened and fixed in the up and down direction through the upper clamping mechanism and the glass conveying device, and the processed glass is tightened and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com