Dredger type drill

A drilling rig and machine type technology, which is applied in the direction of rotary drilling rig, percussion drilling, rotary drilling, etc., can solve the problems of health damage of operators, difficulty in hiring operators, poor working conditions, etc., and save auxiliary work Time, flexible and convenient work, and wide range of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

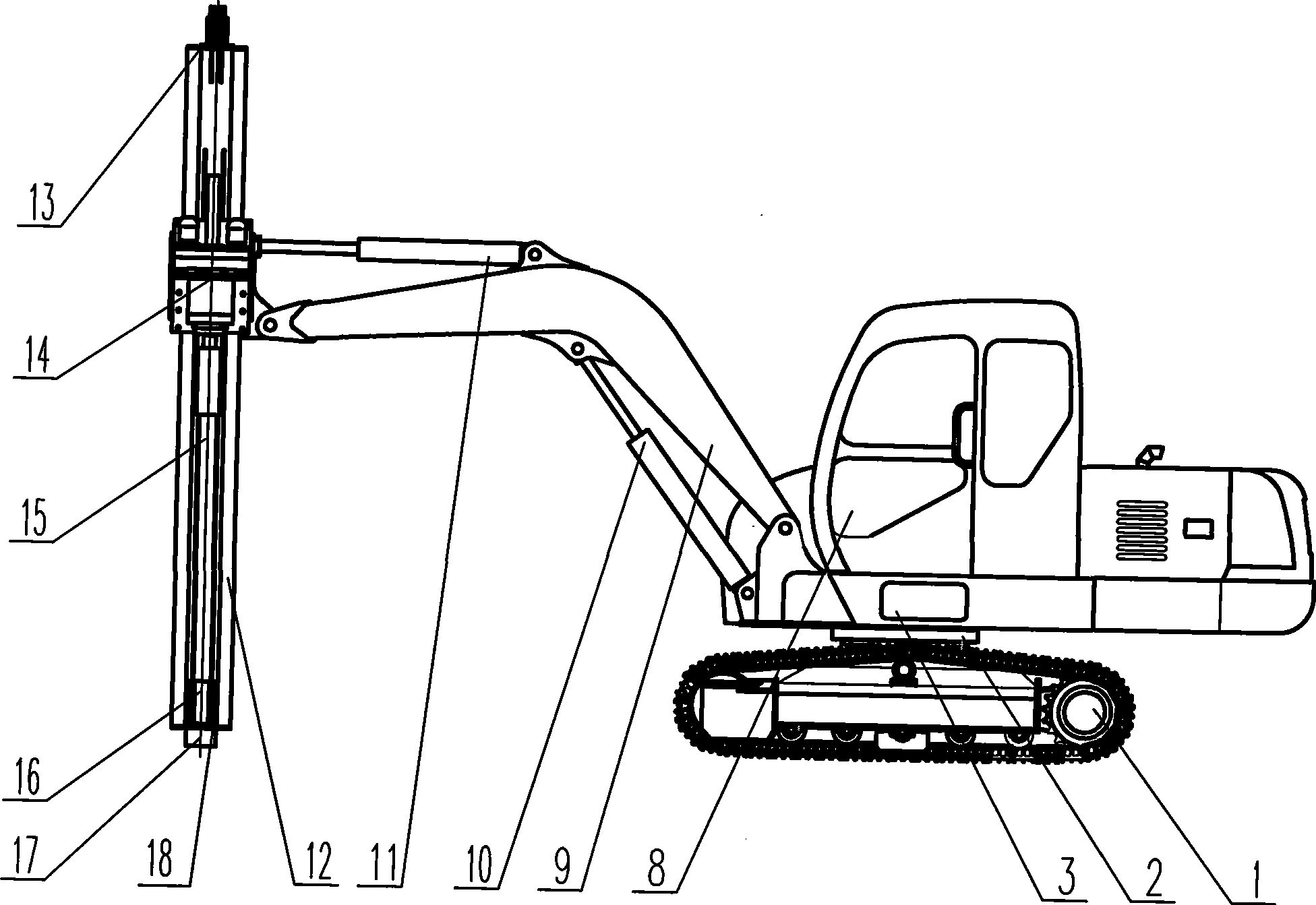

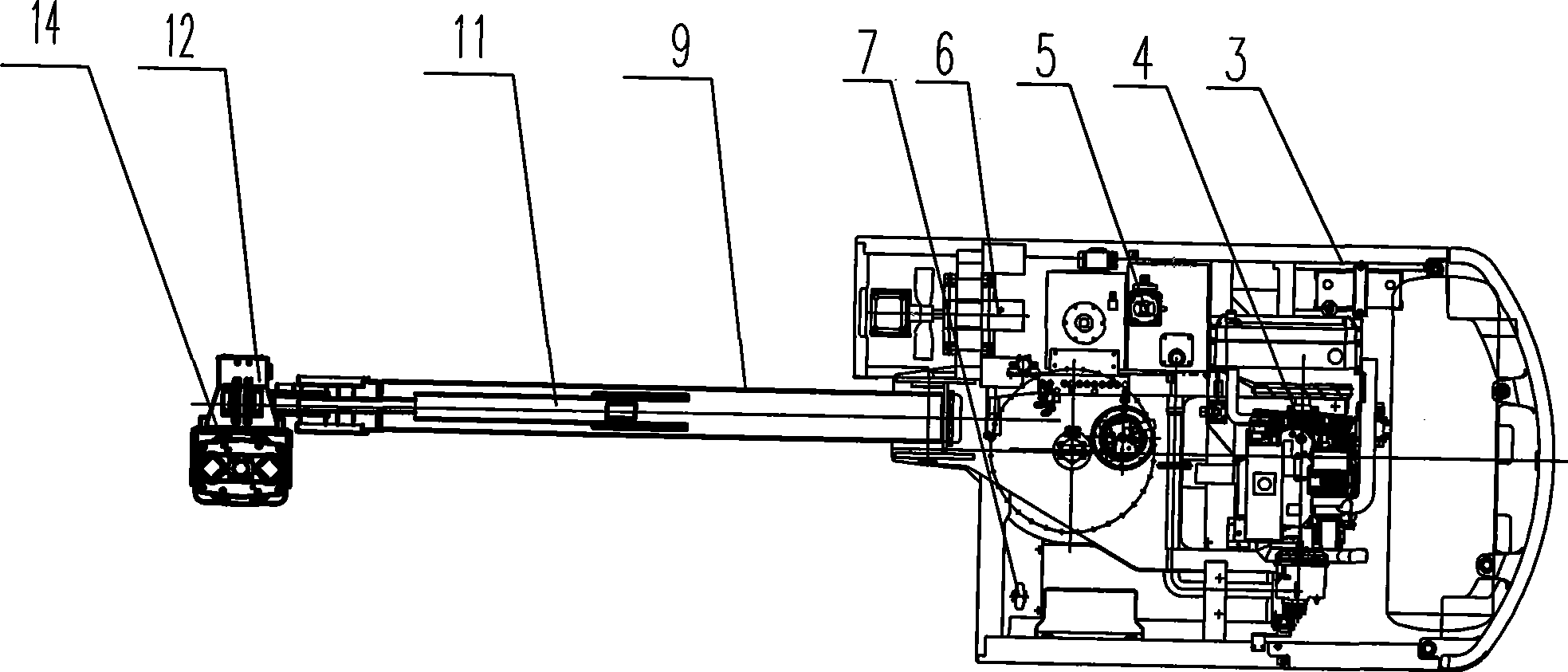

[0012] see figure 1 and figure 2 , a platform slewing mechanism 2 is arranged on the walking chassis 1, a platform 3 is arranged on the platform slewing mechanism 2, a cab 8, a diesel engine power system 4, a hydraulic system 5 and an operation control system 7 are arranged on the platform 3, and the platform 3 A boom 9 is hinged at the front end, and a boom lifting cylinder 10 is arranged between the boom 9 and the platform 3. A drill frame 12 is hinged at the front end of the boom 9, and a drill frame upright is hinged between the drill frame 12 and the boom 9. Bottom oil cylinder 11, oil cylinder wire rope propulsion system 13, rotary power head or hydraulic rock drill 14, drill pipe 15, guide 16, dust collection cover 18 and drill bit 17 are provided on the drill frame 12, drill frame pitch oil cylinder 11 and rotary power The head or hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com