Adjustable board multi-angle drilling device for furniture processing

A drilling device and adjustable technology, applied in woodworking safety devices, fixed drilling machines, wood processing equipment, etc., can solve the problems of low stability of furniture wood boards, inability to drill holes in wood boards, and small application range, so as to improve the drilling efficiency. Hole requirements, improve drilling quality, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

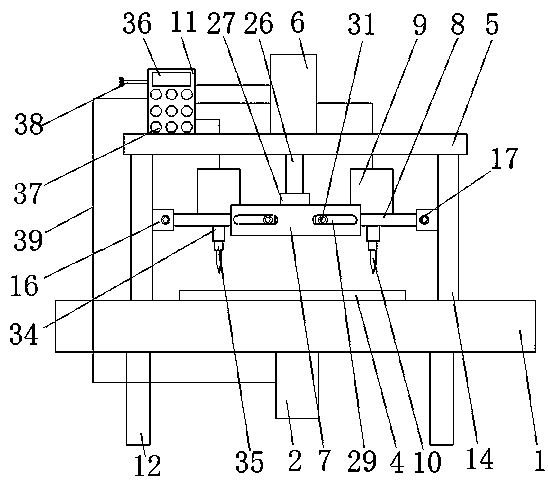

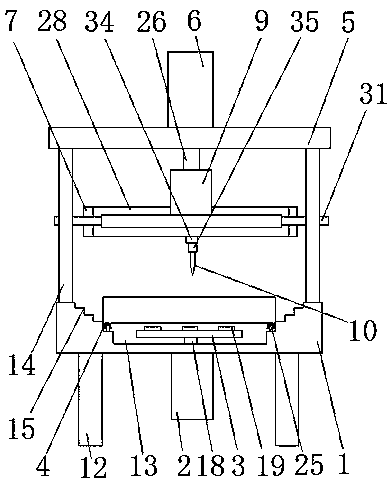

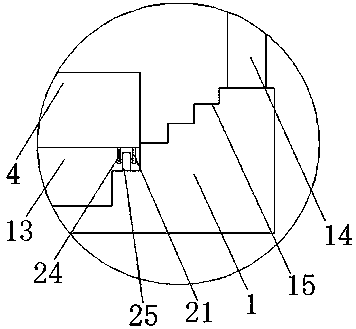

[0026] as attached Figure 1-8As shown, an adjustable multi-angle drilling device for wooden boards for furniture processing, including base 1, cylinder one 2, push plate 3, bearing block 4, top plate 5, cylinder two 6, connecting plate 7, adjusting plate 8, motor 9 1. The drilling column 10 and the controller 11 are characterized in that: the base 1 is arranged on the bracket 12, a bottom groove 13 is arranged on the base 1, and a bearing platform 15 is arranged on the base 1 on both sides of the bottom groove 13 , and the base 1 on both sides of the bottom groove 1 is provided with a column 14, the column 14 is provided with a positioning plate 16, and a bearing 17 is provided on the positioning plate 16, and the cylinder one 2 is arranged on the base 1 bottom, and on the cylinder one 2 is provided with a piston rod one 18, the described push plate 3 is arranged on the piston rod one 18, and on the push plate 3 is provided with a push block 19, on the described bearing block...

Embodiment 2

[0035] as attached Figure 9 As shown, an adjustable multi-angle drilling device for wooden boards for furniture processing, including base 1, cylinder one 2, push plate 3, bearing block 4, top plate 5, cylinder two 6, connecting plate 7, adjusting plate 8, motor 9 1. The drilling column 10 and the controller 11 are characterized in that: the base 1 is arranged on the bracket 12, a bottom groove 13 is arranged on the base 1, and a bearing platform 15 is arranged on the base 1 on both sides of the bottom groove 13 , and the base 1 on both sides of the bottom groove 1 is provided with a column 14, the column 14 is provided with a positioning plate 16, and a bearing 17 is provided on the positioning plate 16, and the cylinder one 2 is arranged on the base 1 bottom, and on the cylinder one 2 is provided with a piston rod one 18, the described push plate 3 is arranged on the piston rod one 18, and on the push plate 3 is provided with a push block 19, on the described bearing block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com