Coal mine TBM advanced exploration split type remote control drilling machine and advanced exploration construction method

An advanced detection and split-type technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems that restrict the popularization and application of TBM equipment, affect the accuracy of advanced detection, and cannot achieve accurate prediction, etc., to achieve drilling position and posture Easy to adjust, convenient construction operation, reduce the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

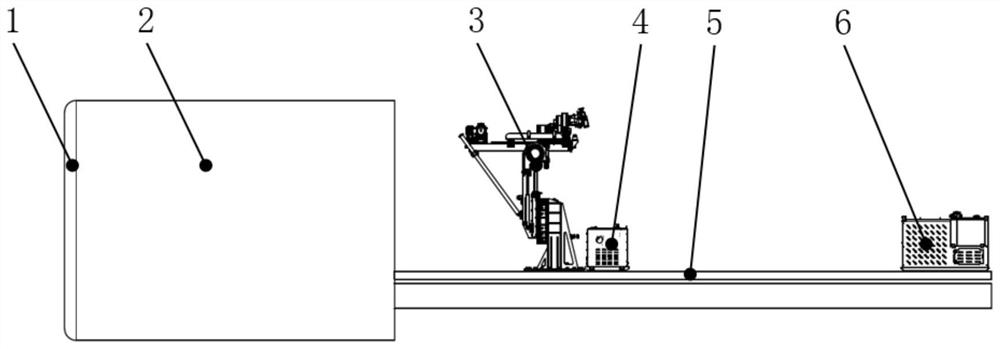

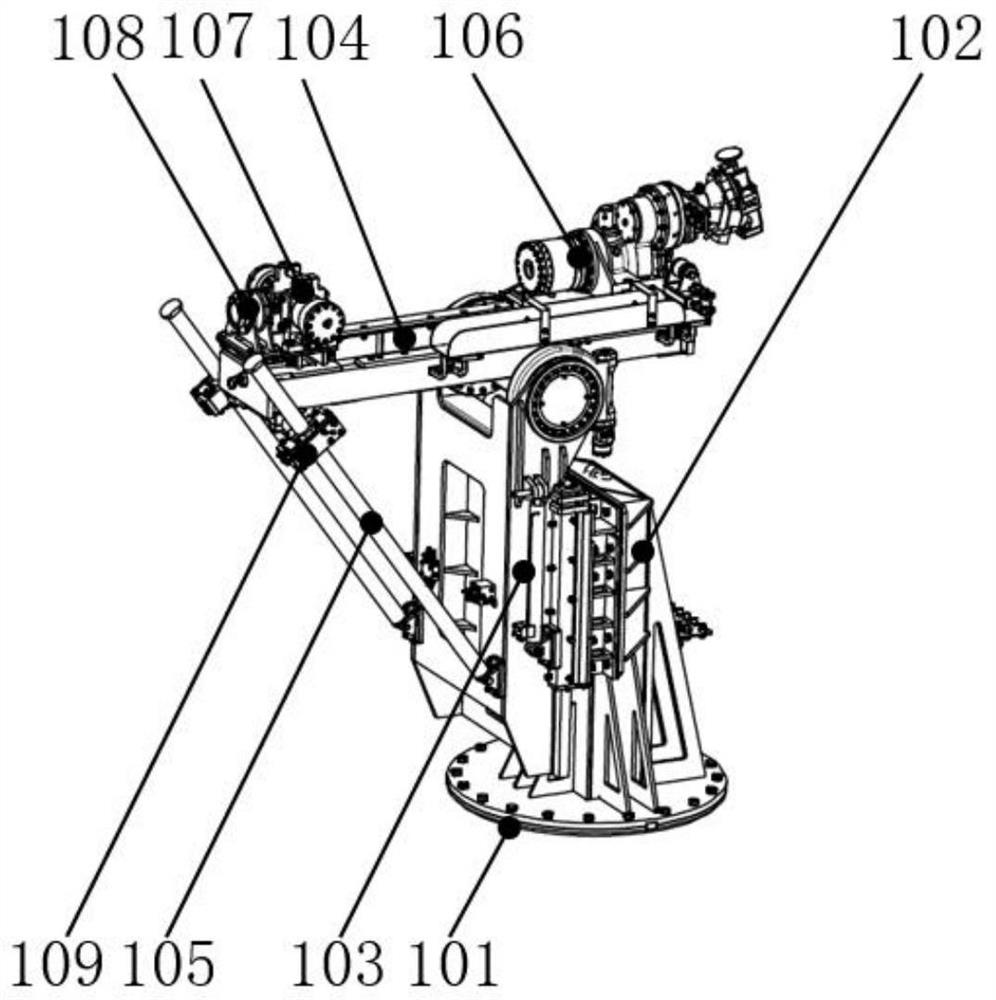

[0042] The invention discloses a remote control drilling rig for advanced detection split type suitable for coal mine TBM, such as figure 1 As shown, the drilling rig is mainly composed of three parts: a main engine 3 , an operating platform 4 , and a pumping station 6 .

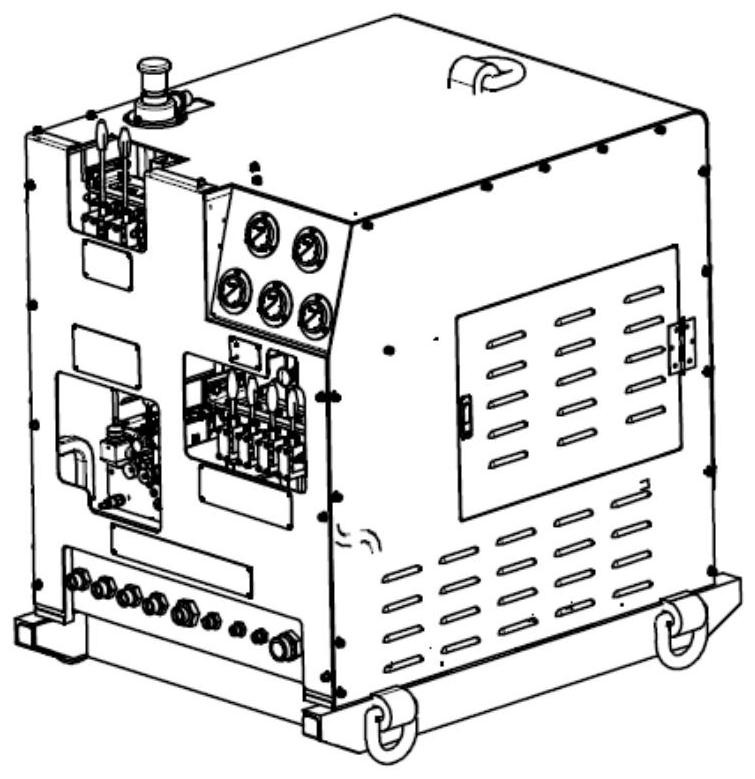

[0043]The main engine 3 is arranged on the trailer at the rear of the TBM propulsion mechanism. The drilling machine body can rotate around the TBM excavation axis in a circumferential direction, and the construction radius of the drilling hole can be adjusted by lifting the oil cylinder. The operating console is arranged near the main engine, and is mainly used for the distribution and precise adjustment of hydraulic power. The hydraulic pump station 6 is arranged behind the trailer to provide power for the whole drilling rig.

[0044] Compared with the existing advanced exploration drilling rigs commonly used in TBM, this drilling rig has a large torque and a large propulsion force, which is more suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com