Plastic ball solid lubricating agent for drilling fluid and method for preparing plastic ball solid lubricating agent

A technology of solid lubricants and plastic balls, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as limited resistance to temperature, extrusion resistance, restrictions, uneven density distribution, etc., to achieve improved resistance High temperature performance and anti-extrusion performance, effective lubrication and anti-seize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

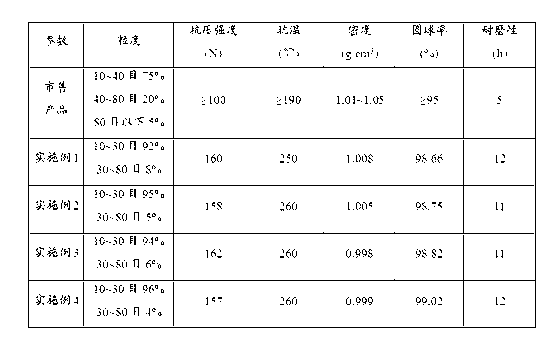

Examples

Embodiment 1

[0020] One, the preparation raw material of the plastic ball solid lubricant for drilling fluid of the present embodiment is by weight:

[0021] 35 parts of styrene, 10 parts of divinylbenzene, 5 parts of acrylic acid, 5 parts of polytetrafluoroethylene, 10 parts of paraffin, 15 parts of silicon dioxide, 0.5 parts of benzoyl peroxide, 0.5 parts of polyvinyl alcohol, lauryl 0.5 parts of benzenesulfonic acid.

[0022] Two, the preparation method of the plastic ball solid lubricant for drilling fluid of the present embodiment is:

[0023] (a) Deblocking: Styrene and divinylbenzene are filtered with 201 resin column to remove their own polymerization inhibitors;

[0024] (b) Soaking: put styrene, divinylbenzene, acrylic acid, polytetrafluoroethylene, paraffin, silicon dioxide and benzoyl peroxide into the reaction kettle after weighing according to the proportion, add 2 times the weight of the solid material to remove Ionized water, soak for 30 minutes at 20°C;

[0025] (c) Cro...

Embodiment 2

[0029] One, the preparation raw material of the plastic ball solid lubricant for drilling fluid of the present embodiment is by weight:

[0030] 45 parts of styrene, 8 parts of divinylbenzene, 10 parts of acrylic acid, 7 parts of polytetrafluoroethylene, 15 parts of paraffin, 12 parts of silicon dioxide, 0.7 parts of benzoyl peroxide, 0.5 parts of polyvinyl alcohol, lauryl 0.8 parts of benzenesulfonic acid.

[0031] Two, the preparation method of the plastic ball solid lubricant for drilling fluid of the present embodiment is:

[0032] (a) Deblocking: Styrene and divinylbenzene are filtered with 201 resin column to remove their own polymerization inhibitors;

[0033] (b) Soaking: Styrene, divinylbenzene, acrylic acid, polytetrafluoroethylene, paraffin, silicon dioxide and benzoyl peroxide are weighed in proportion and put into the reaction kettle, and 2.5 times the weight of the solid material is added to remove Ionized water, soak for 30 minutes at 10°C;

[0034] (c) Cross...

Embodiment 3

[0038] 1. The drilling solution of this embodiment of the preparation raw material for the plastic ball solid lubricant is based on the weight of the weight:

[0039] 56 parts of styrene, 6 parts of divinylbenzene, 9 parts of acrylic acid, 10 parts of polytetrafluoroethylene, 12 parts of paraffin, 10 parts of silicon dioxide, 0.9 parts of benzoyl peroxide, 0.8 parts of polyvinyl alcohol, lauryl 1.2 parts of benzenesulfonic acid.

[0040] Second, the preparation method of the drilling solution of the plastic ball solid lubricant of this embodiment is:

[0041] (A) Desert: The vertical vector that comes with the 201 resin column filter with the 201 resin column;

[0042] (b) Soaking: put styrene, divinylbenzene, acrylic acid, polytetrafluoroethylene, paraffin, silicon dioxide and benzoyl peroxide into the reaction kettle after weighing according to the proportion, add 2 times the weight of the solid material to remove Ionized water, soak for 20 minutes at 25°C;

[0043] (c) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com