Shale intercalation inhibitor prepared from environment-friendly hyperbranched polyamino acid

A polyamino acid and inhibitor technology, which is applied in the field of oil and gas field drilling, can solve problems such as clay entanglement, uneven coating, limited inhibition performance, and no adsorption, and achieve the effects of low price, improved inhibition performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1. Synthesis of amino acid methyl ester: Accurately weigh 3.0g of 3-methylaminoalanine and dissolve it in 100ml of anhydrous methanol, then transfer the 3-methylaminoalanine methanol solution to a 500mL three-necked flask, Under the atmosphere and stirring, the temperature was raised to 100°C, and the reaction was refluxed for 12h. After the reaction was finished, 3-methylaminoalanine methyl ester was obtained by rotary evaporation at 85°C and an absolute vacuum less than 3000Pa.

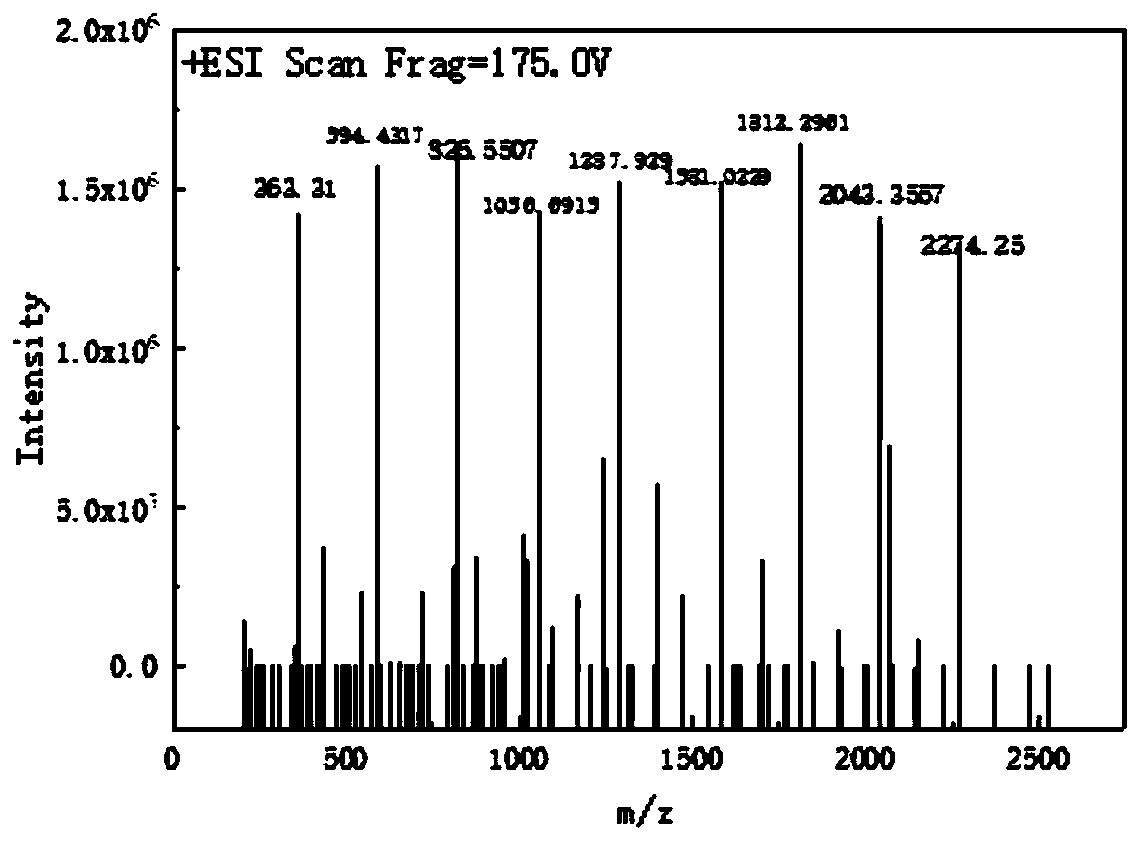

[0025] S2. Synthesis of hyperbranched polyamino acid intermediate: Accurately weigh 2.62g of 3-methylaminoalanine methyl ester obtained in step S1, 3.26g of N-phenylpiperazine and 3.92g of vinyl acrylate and dissolve them in 200ml of chloroform. Transfer the 3-methylaminoalanine methyl ester and N-phenylpiperazine solution to a three-necked flask, and add the vinyl acrylate solution by titration at 0°C under a nitrogen atmosphere with stirring, and the titration time is 25 minutes. After th...

Embodiment 2

[0028] S1. Synthesis of amino acid methyl ester: Accurately weigh 3.5g of D,L-δ-N-methylornithine and dissolve it in 100ml of anhydrous methanol, then dissolve D,L-δ-N-methylornithine in methanol Transfer to a 500 mL three-necked flask, and raise the temperature to 100° C. under stirring in a nitrogen atmosphere, and reflux for 12 h. After the reaction, the D,L-δ-N-methylornithine methyl ester was obtained by rotary evaporation at 85° C. and an absolute vacuum of less than 3000 Pa.

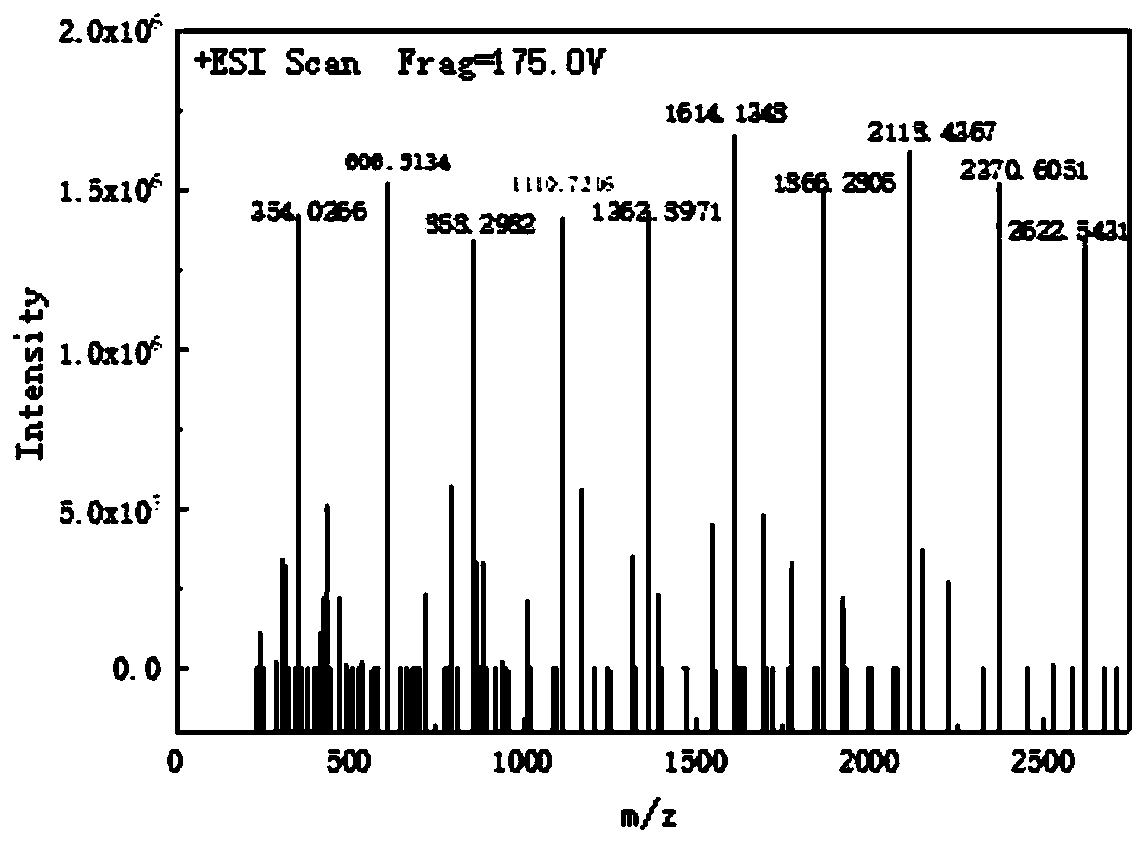

[0029] S2. Synthesis of hyperbranched polyamino acid intermediates: Accurately weigh 3.20 g of D,L-δ-N-methylornithine methyl ester, 3.26 g of N-phenylpiperazine and 3.92 g of vinyl acrylate obtained in step S1 and dissolve them respectively In 200ml of chloroform, transfer D,L-δ-N-methylornithine methyl ester and N-methylpiperazine solution to a 500ml three-necked flask, and titrate Add vinyl acrylate solution, titration time is 25min. After the titration was completed, the temperature was rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com