Rock debris separating method for gas drilling

A separation method and gas drilling technology, which are applied in construction and other directions, can solve the problems that the capacity of the cyclone separator cannot be too large, cannot be satisfied, and the gas processing capacity is small, so as to achieve the effect of improving the primary separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

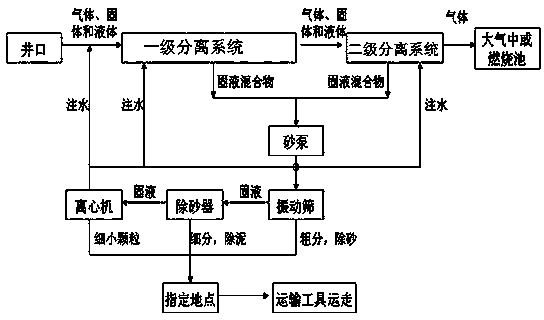

[0047] A cuttings separation method for gas drilling, comprising the following process steps:

[0048] a. First start the circulating water treatment system, make the water in the whole system circulate and reach balance, and then start the gas drilling;

[0049] b. During drilling, the gas and solid returned from the wellhead are mixed with the circulating water of the circulating water treatment system to form a mixed fluid before separation, so that the dust in the solid is dissolved in the water;

[0050] c. The mixed fluid first enters the primary separation system to remove coarse particles with a particle size greater than 10 microns, and the gas carries fine particles, water droplets or water mist to the secondary separation system, and after washing in a water bath, fine particles greater than 5 microns are removed , water droplets or water mist to obtain purified gas and solid-liquid mixture;

[0051] d. The solid-liquid mixture is sent to the circulating water trea...

Embodiment 2

[0066] The applicable drilling medium of the present invention is air, nitrogen and natural gas, and consists of a separation system and a circulating water treatment system, wherein the separation system is the core of the present invention. The separation system is divided into a first-level gravity, inertia and spray dust removal system and a second-level water bath washing system. The main function is to separate the gas in the return fluid from the solid-liquid, and the separated purified gas is directly discharged into the atmosphere or burned in the combustion pool. . The circulating water treatment system consists of a first-stage vibrating screen, a second-stage desander, and a third-stage centrifuge. The main function is to separate the solid from the liquid from the separation system. The solids are transported to the designated place. Specific steps are as follows:

[0067] 1. Before use, install the equipment on the sand discharge pipeline from the wellhead, and...

Embodiment 3

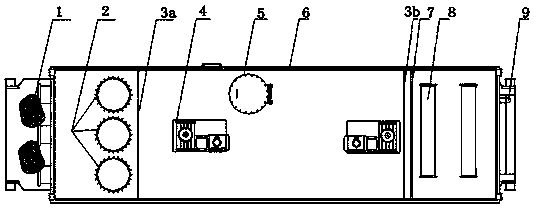

[0075] This embodiment illustrates the primary separation system in the present invention.

[0076] The first-stage separation system includes inlet diverter 1, anti-erosion baffle 2, first spoiler 3a, second spoiler 3b, first-stage stirring device 4, first-stage manhole 5, liquid level compensation port 6, nozzle Shower 7, primary exhaust port 8, overflow port 9, primary liquid level gauge 10, primary electric control box 11, primary sand discharge port 12, primary sand removal port 13, etc. The inlet splitter 1 divides the gas-solid-liquid mixed fluid into three paths and enters the first-stage separation tank. The whole separation device is skid-mounted, and the auxiliary pump is separated from the first-stage sand discharge port 12 and the liquid level compensation port 6 respectively. The liquid level in the tank is controlled to achieve the dynamic balance of the liquid level in the tank, and the first-level exhaust port 8 is directly connected to the ignition pool or th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com