Shield mud system applicable to extra-large-diameter tunnel and preparation method

A technology of tunnel shielding and mud, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing construction progress, wear of shield cutters, delays in construction period, etc., to reduce environmental pressure, balance soil pressure, The effect of preventing mud bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

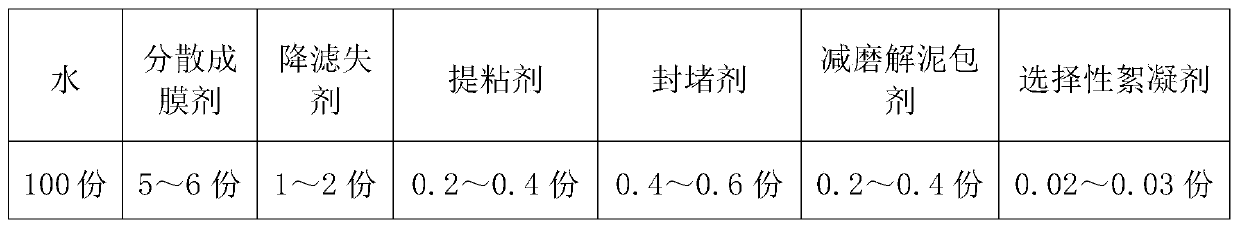

[0020] Embodiments of the present invention also provide a preparation method suitable for a shield mud system of an extra-large diameter tunnel, comprising the following steps:

[0021] S1 Weigh 100 parts by mass of water, add 0.2 to 0.4 parts by mass of anti-friction catabolism agent into the water, stir for 10 minutes under the stirring condition of 6000r / min, and stir evenly;

[0022] S2 Add 5 to 6 parts by mass of dispersed film-forming agent to the solvent in step S1 under the stirring condition of 100r / min, and stir for 16h;

[0023] S3, under the condition of stirring at 6000r / min, add 1-2 parts by mass of fluid loss reducer, 0.2-0.4 parts by mass of viscosity-increasing agent, 0.4-0.6 parts by mass of plugging agent, and The selective flocculant is 0.02-0.03 parts by mass, and it is uniformly stirred to obtain a shield mud system suitable for super-large diameter tunnels.

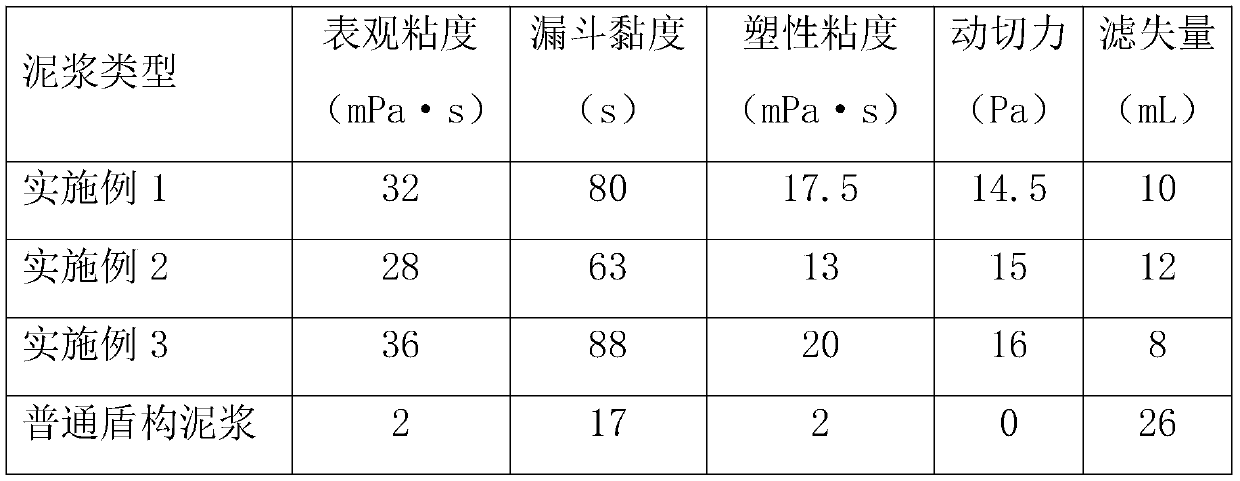

Embodiment 1

[0025] A shield mud system suitable for super-large diameter tunnels, prepared from the following raw materials: 1000ml of water, 50g of sodium bentonite, 15g of low-viscosity carboxymethyl cellulose sodium, 3g of XC xanthan gum, 5g of superfine calcium carbonate, and anti-friction solution Clay bag agent 3g, polyacrylamide 0.3g.

[0026] Preparation:

[0027] S1 Weigh 1000mL of water, and add 0.19g of sodium dodecylbenzenesulfonate (AS-12), 0.38g of polyoxyethylene octylphenol ether (OP-10) and 2.43g of saponified oil into the water, at 6000r / Stir for 10 minutes under the condition of stirring at min speed, and mix evenly to prepare 3g of sludging agent;

[0028] S2 Add 50 g of sodium bentonite to the solvent in step S1 under stirring condition of 100 r / min, and stir for 16 h;

[0029] S3 under the stirring condition of 6000r / min rotating speed, add low-viscosity sodium carboxymethylcellulose 15g, XC xanthan gum 3g, superfine calcium carbonate 5g, polyacrylamide 0.3g to th...

Embodiment 2

[0031] A shield mud system suitable for super-large diameter tunnels, prepared from the following raw materials: 1000ml of water, 40g of sodium bentonite, 20g of low-viscosity carboxymethyl cellulose sodium, 2g of XC xanthan gum, 4g of superfine calcium carbonate, and anti-friction solution Clay bag agent 2g, polyacrylamide 0.2g.

[0032] Preparation:

[0033] S1 Weigh 1000mL of water, and add 0.13g of sodium dodecylbenzenesulfonate (AS-12), 0.25g of polyoxyethylene octylphenol ether (OP-10) and 1.63g of saponified oil into the water, at 6000r / Stir for 10 minutes under the condition of stirring at min speed, and mix evenly to prepare 2g of sludging agent;

[0034] S2 Add 40 g of sodium bentonite to the solvent in step S1 under stirring condition of 100 r / min, and stir for 16 h;

[0035] S3 under the stirring condition of 6000r / min rotating speed, add low-viscosity sodium carboxymethylcellulose 20g, XC xanthan gum 2g, superfine calcium carbonate 4g, polyacrylamide 0.2g to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com