High-temperature-resistant modified nano silicon dioxide blocking agent and oil-based drilling fluid

A nano-silica and oil-based drilling fluid technology, which is applied in the field of oil and gas field drilling, can solve problems such as well wall instability, and achieve the effects of not easy to agglomerate, stable performance, and excellent plugging rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

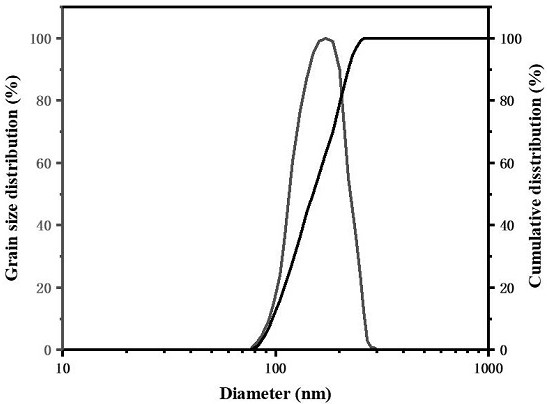

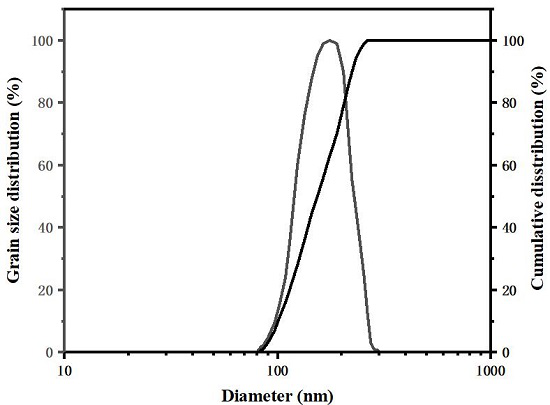

Image

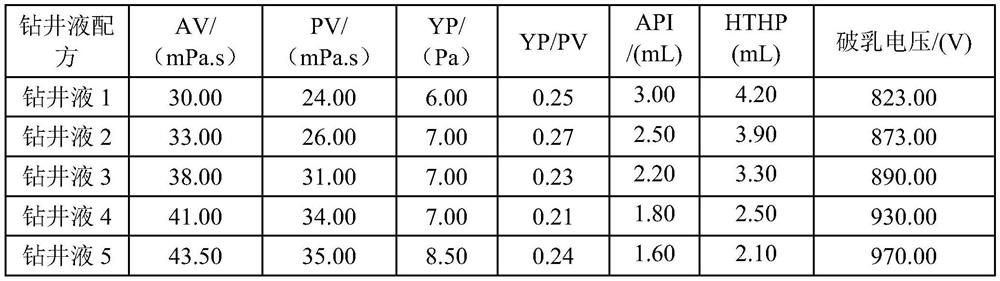

Examples

Embodiment 1

[0025] (1) Modification of silica

[0026] Add 0.25mol nano-silica to 70mL toluene solution, heat up to 50-60°C, stir until dissolved and pass nitrogen gas for 30min, heat up to 90°C and add a certain amount of 3-aminopropyltriethoxysilane ( KH550), react silica and 3-aminopropyltriethoxysilane (KH550) for 5h. Distilled under reduced pressure for 2 hours to obtain a crude product, washed with toluene, filtered to remove unreacted monomers, and dried in vacuum for 2 hours to obtain a modified product of nano-silica.

[0027] (2) Synthesis of secondary amine polymers

[0028] Dissolve the modified product of nano-silica prepared in the previous step with 90-110mL tetrahydrofuran, add 0.24mol 1,5-hexadiene, stir and react at 60°C for 24h, and distill under reduced pressure to obtain the crude product. Vacuum-dry for 2 hours, take a certain amount of dried crude product and add it to 110mL tetrahydrofuran, stir quickly until dissolved, pass nitrogen gas for 30 minutes, keep stir...

Embodiment 2

[0032] (1) Modification of silica

[0033] Add 0.25mol nano-silica to 70mL toluene solution, heat up to 50-60°C, stir until dissolved and pass nitrogen gas for 30min, heat up to 90°C and add a certain amount of 3-aminopropyltriethoxysilane ( KH540), react silica and 3-aminopropyltriethoxysilane (KH540) for 5h. Distilled under reduced pressure for 2 hours to obtain a crude product, washed with toluene, filtered to remove unreacted monomers, and dried in vacuum for 2 hours to obtain a modified product of nano-silica.

[0034] (2) Synthesis of secondary amine polymers

[0035] Dissolve the modified product of nano-silica prepared in the previous step with 110 mL of tetrahydrofuran, add 0.24 mol of diallylamine, stir and react at 60 ° C for 24 h, distill under reduced pressure to obtain the crude product, and dry it in vacuum for 2 h. Take a certain amount of dried crude product and add it to 110mL tetrahydrofuran, stir rapidly until it dissolves, pass nitrogen gas for 30min, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com