Patents

Literature

37results about How to "Simplify the drilling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

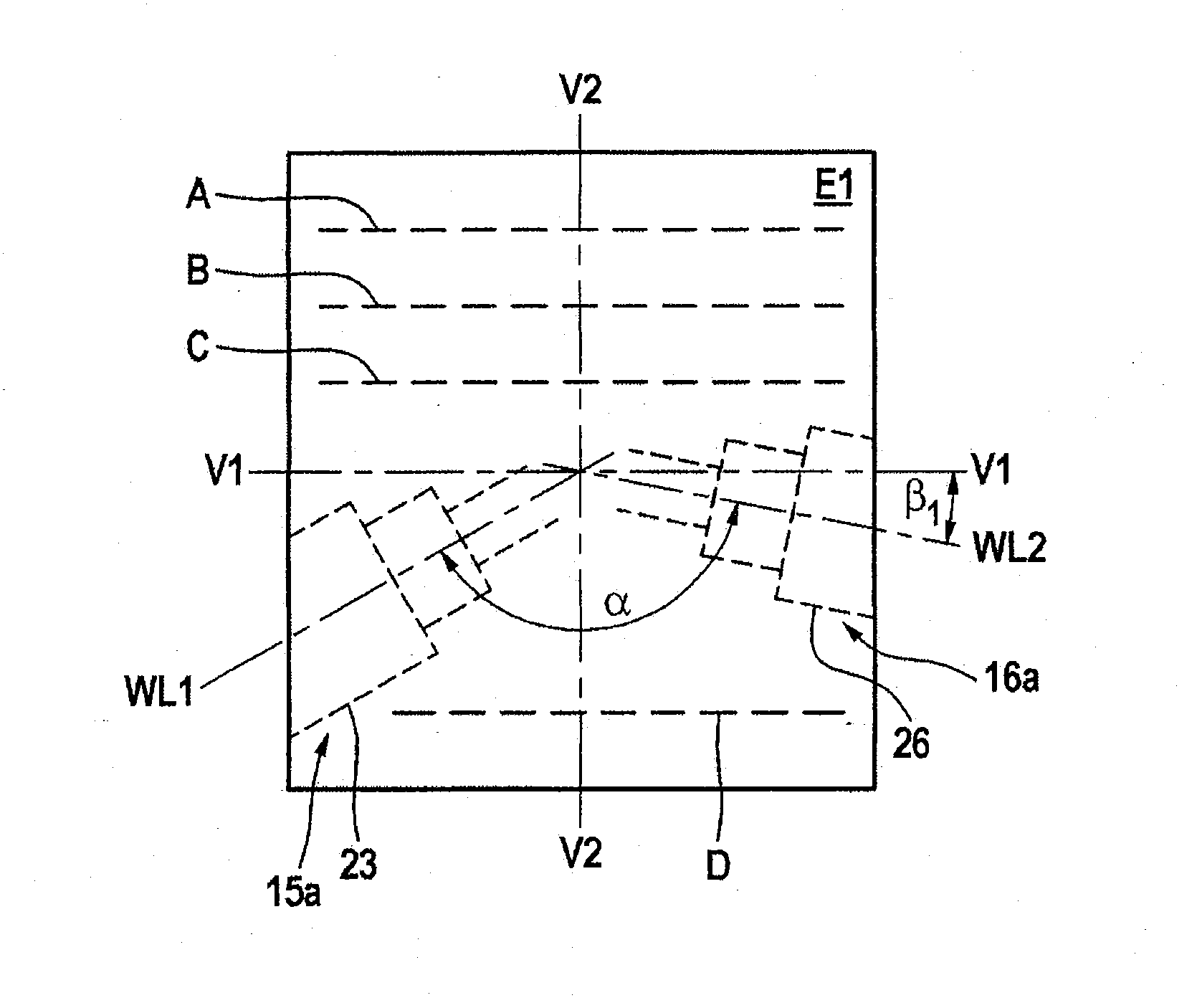

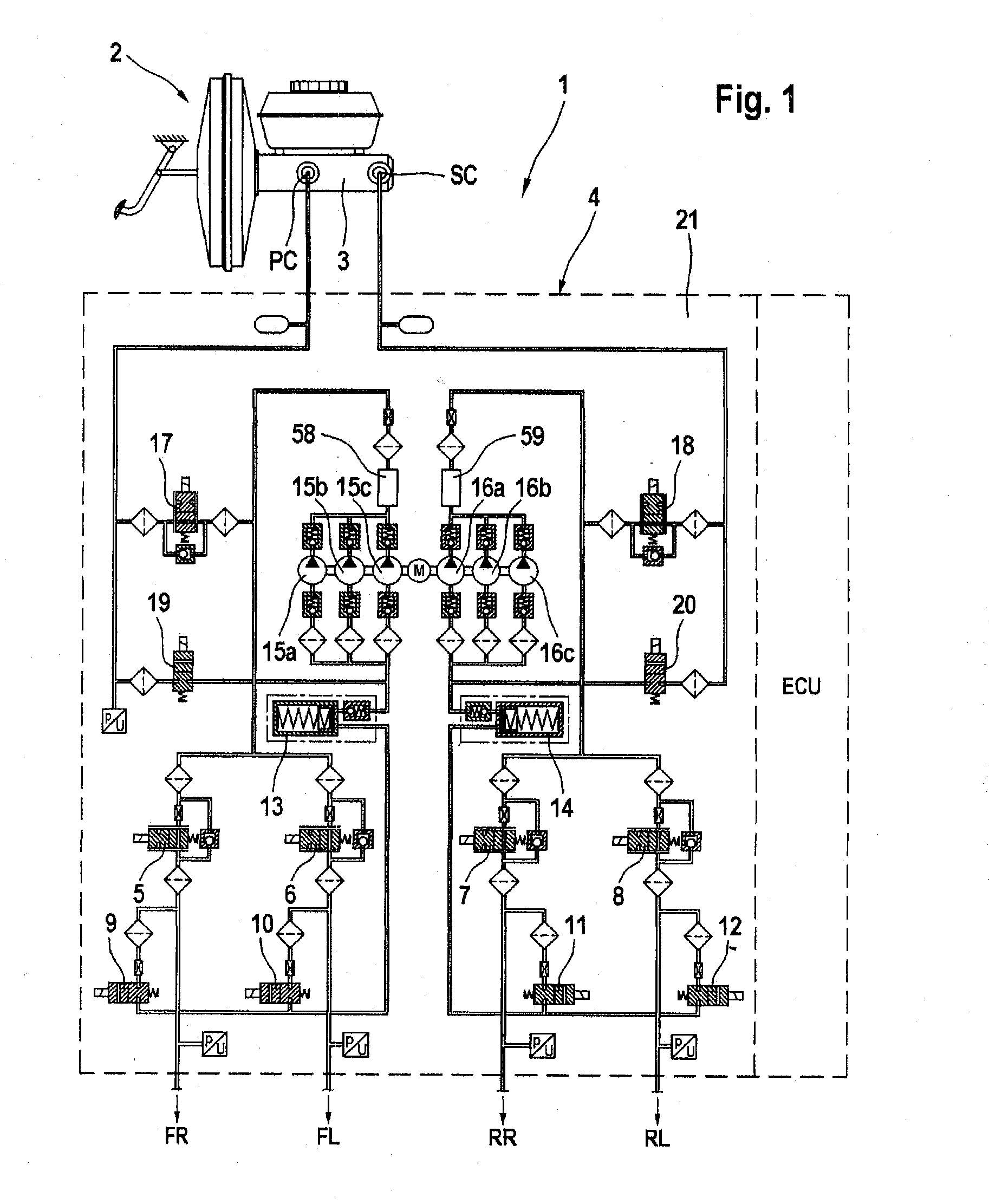

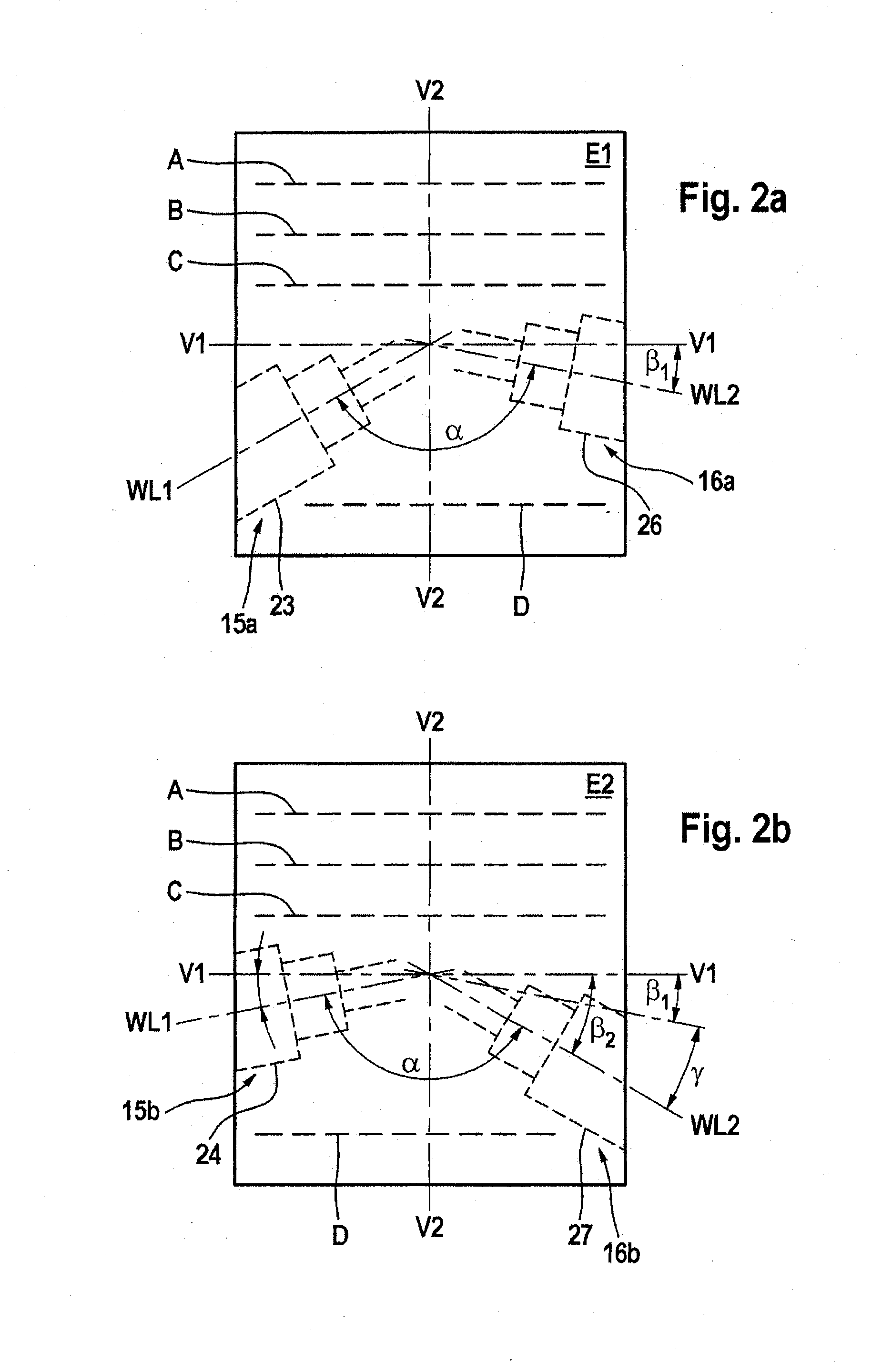

Hydraulic unit for slip-controlled braking systems

ActiveUS8500215B2Improve compromiseAvoid disadvantagesPositive displacement pump componentsBraking action transmissionDrive shaftHydraulic circuit

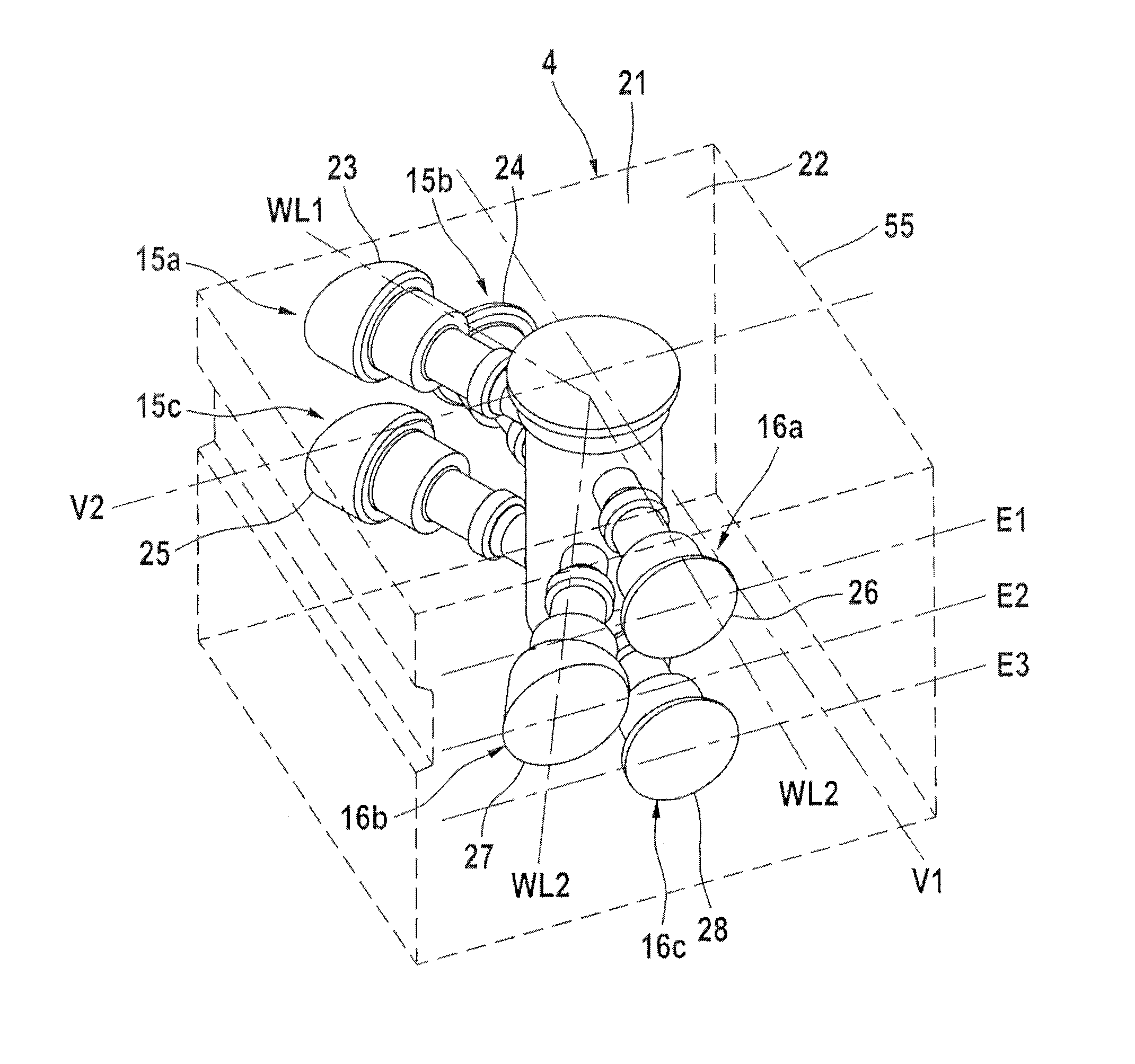

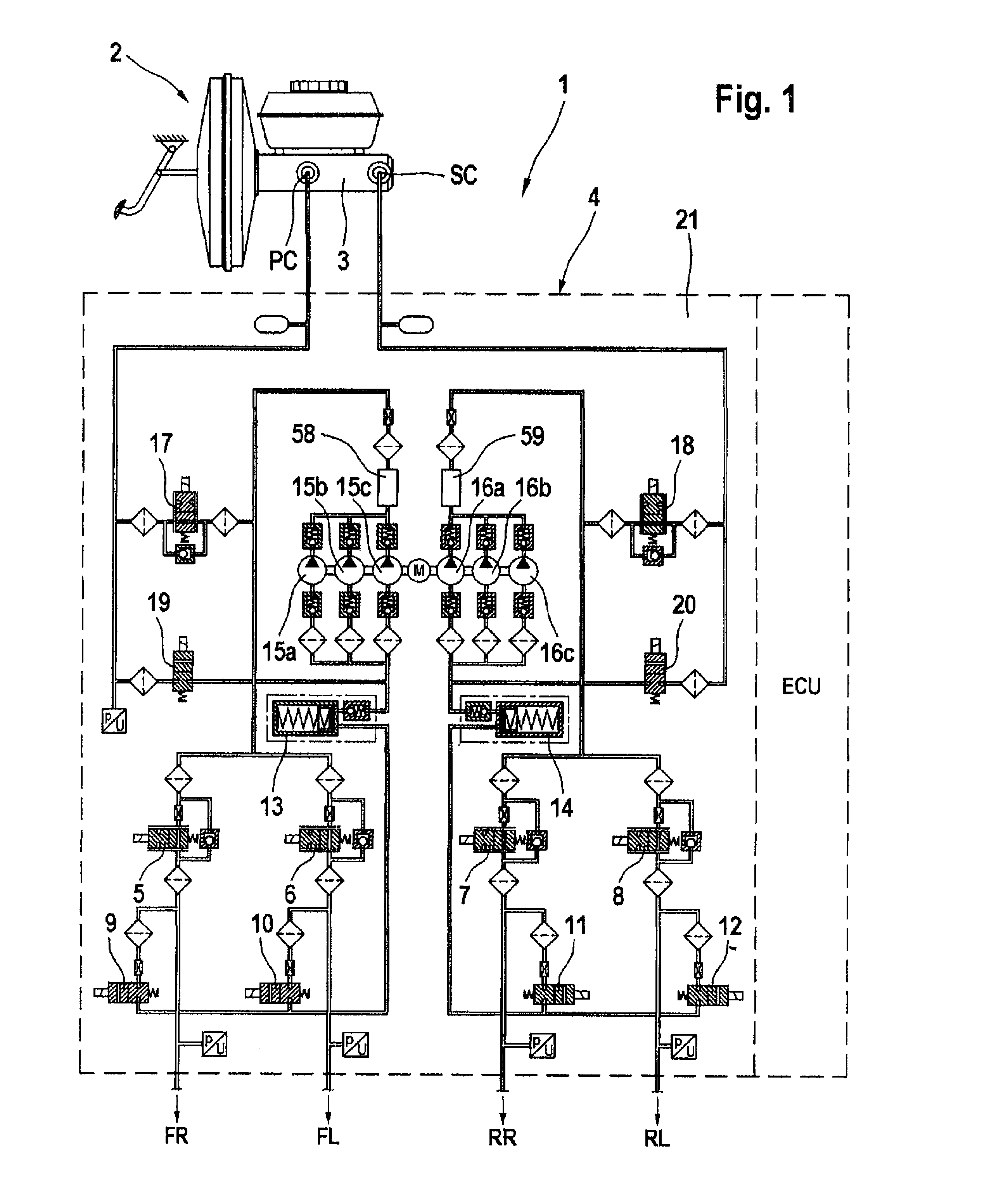

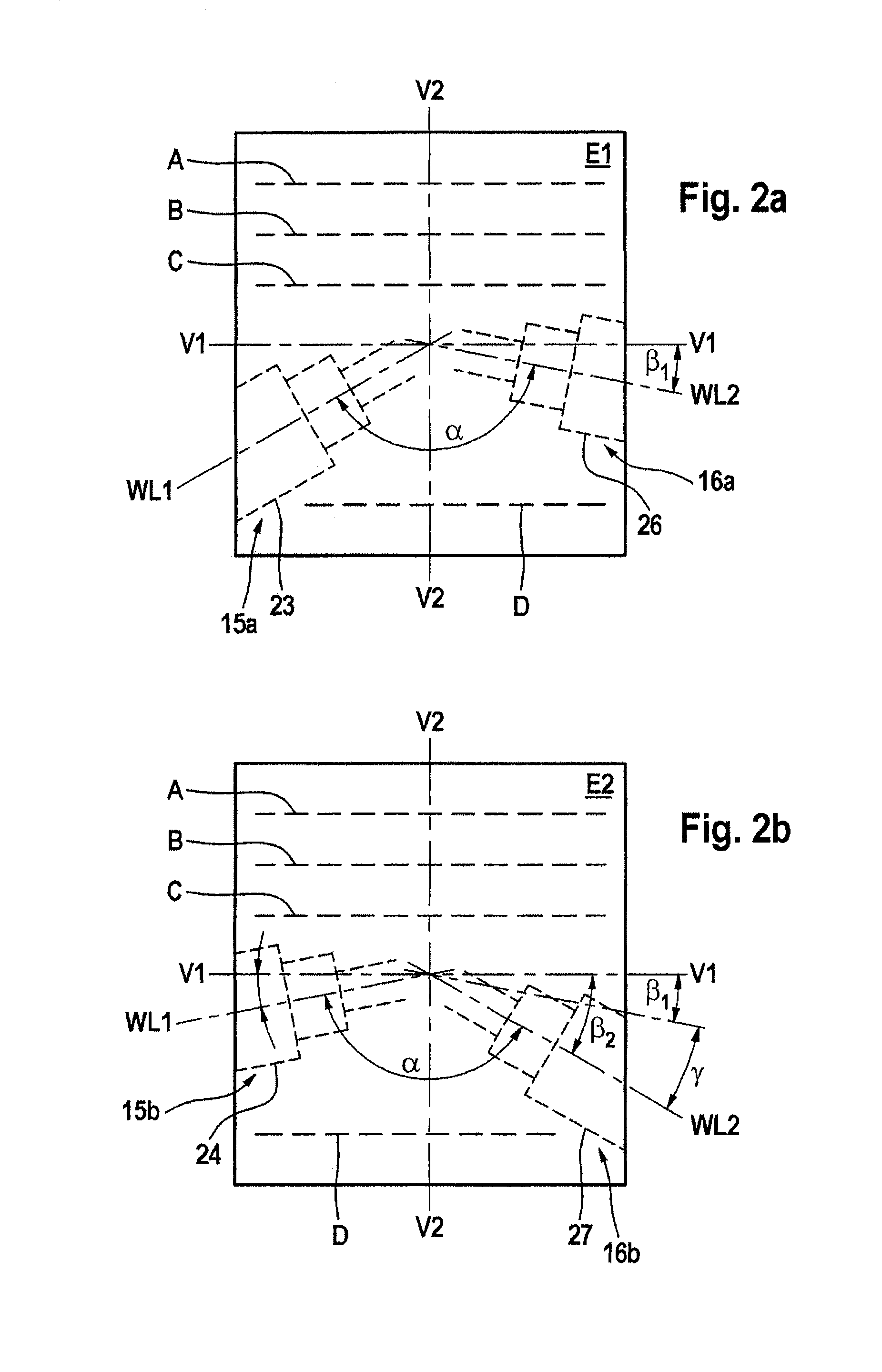

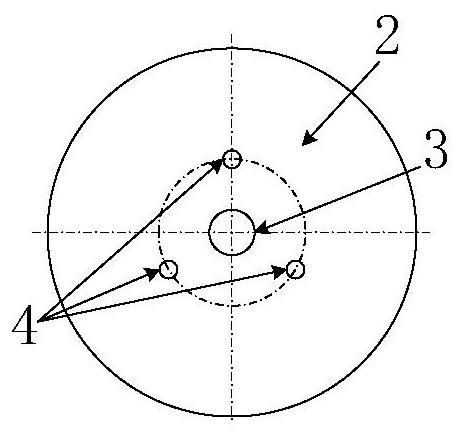

A hydraulic unit for slip-controlled braking systems has a plurality of receiving holes for transport devices associated with a plurality of hydraulic circuits bundled into groups, wherein the receiving holes are disposed at a distance from each in parallel with the upper side and a drive shaft having eccentrics located at the plane spacing for driving the transport devices. In order to provide a compromise optimized for manufacturing a small, convenient hydraulic unit, it is proposed that three theoretical planes (E1, E2, E3) are arranged in parallel to the upper side, each receiving two V-shaped receiving holes for transport devices disposed at an angle to each other, and that the drive shaft includes three separate eccentrics for driving the transport devices.

Owner:CONTINENTAL TEVES AG & CO OHG

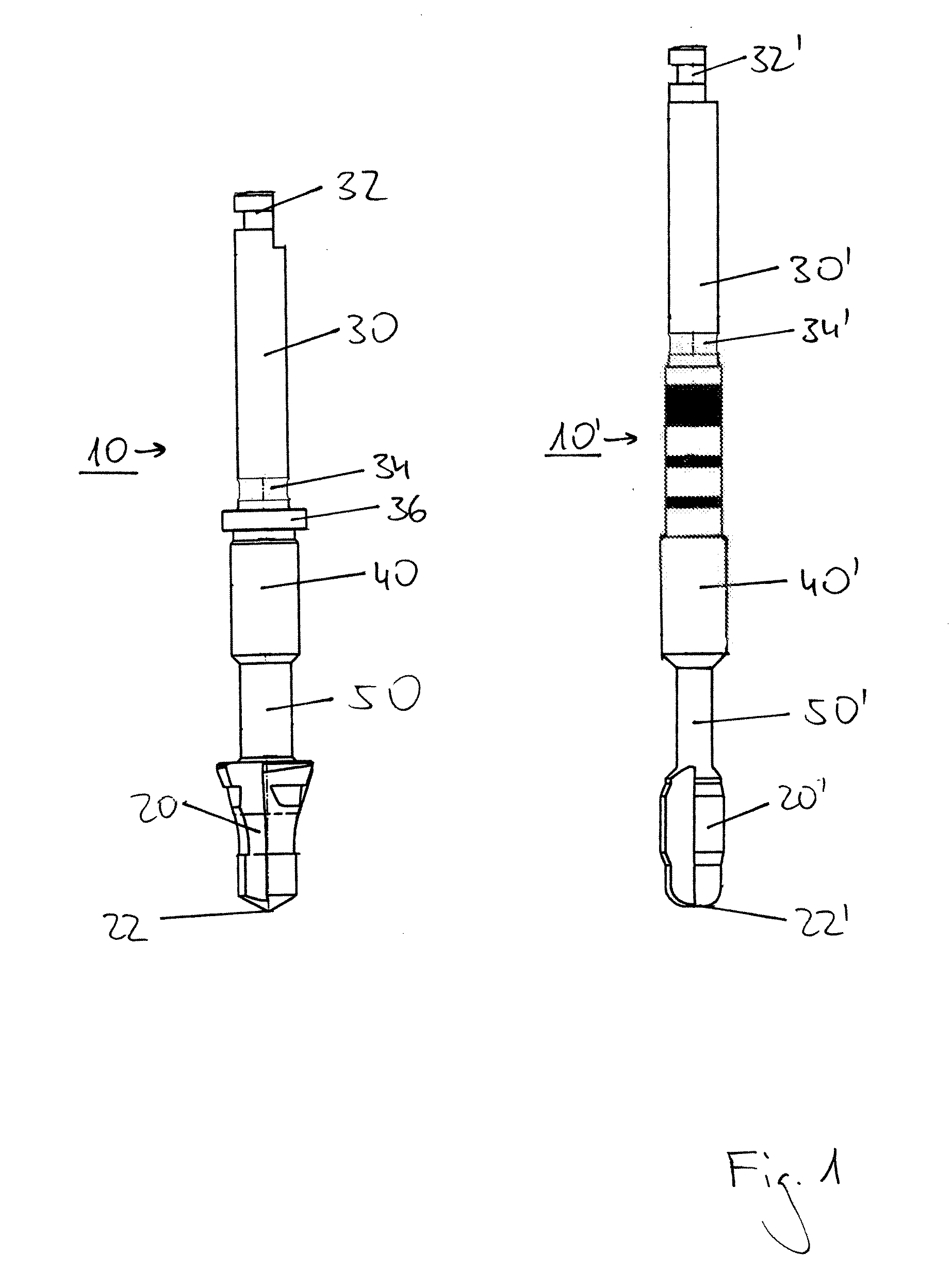

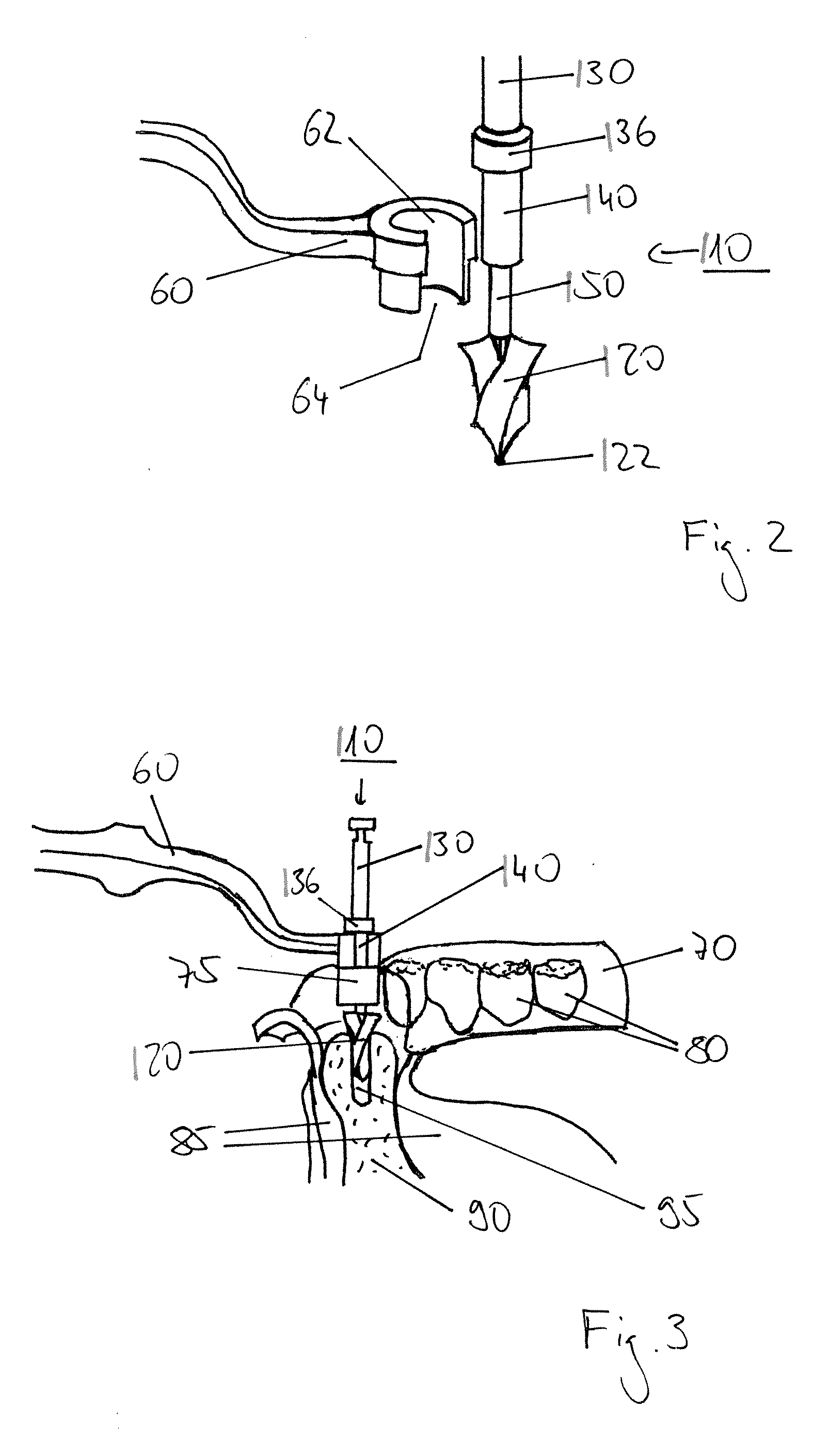

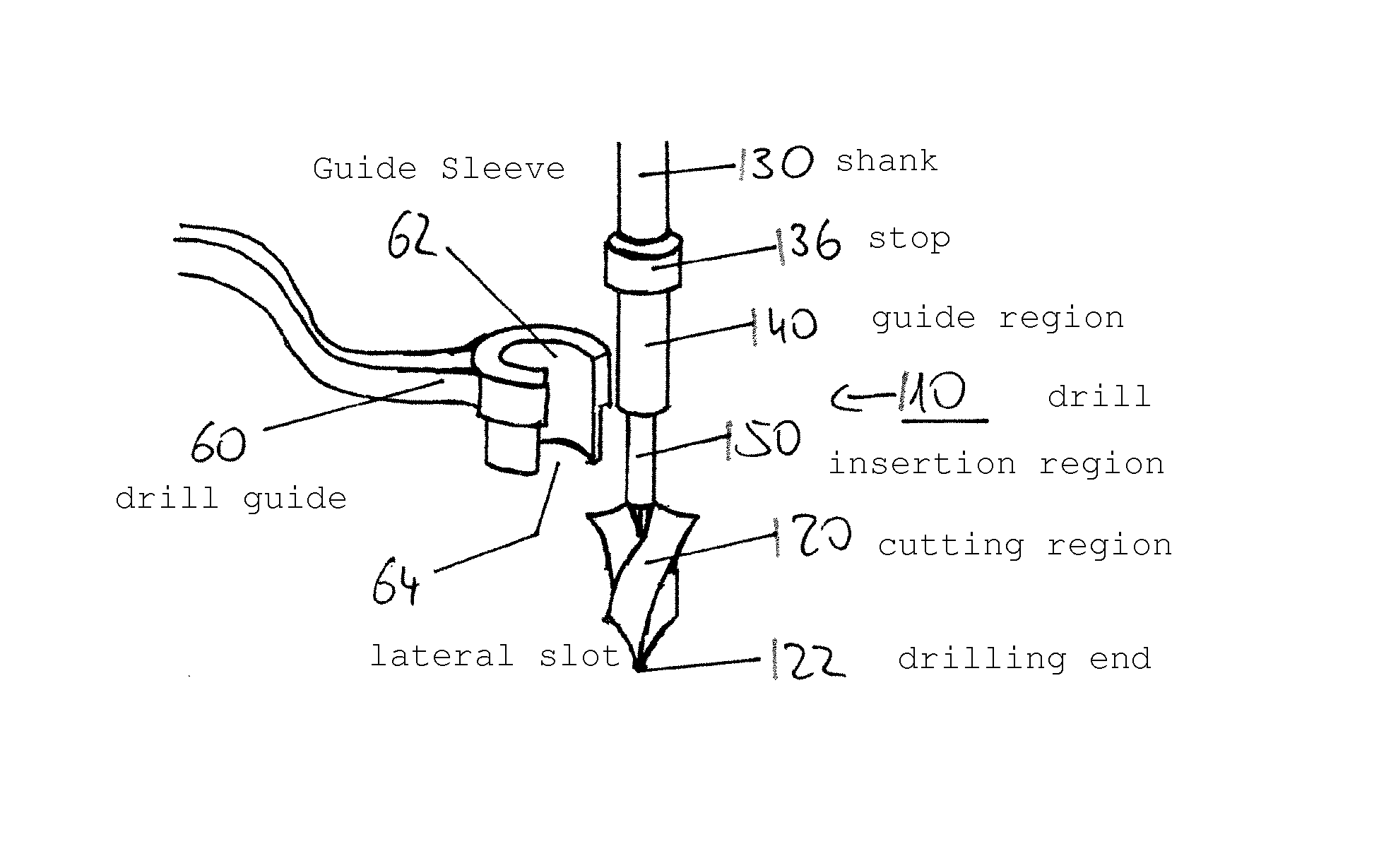

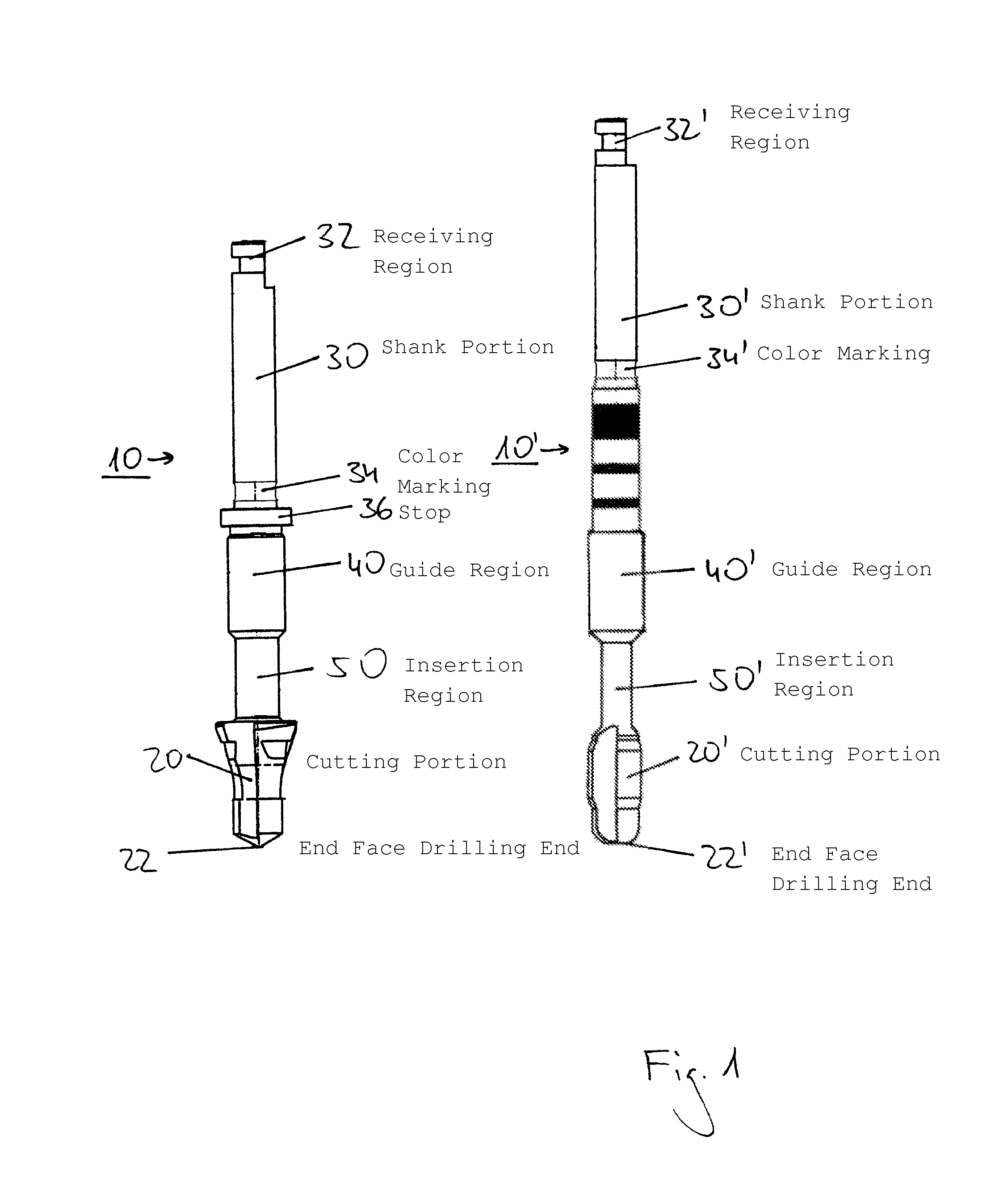

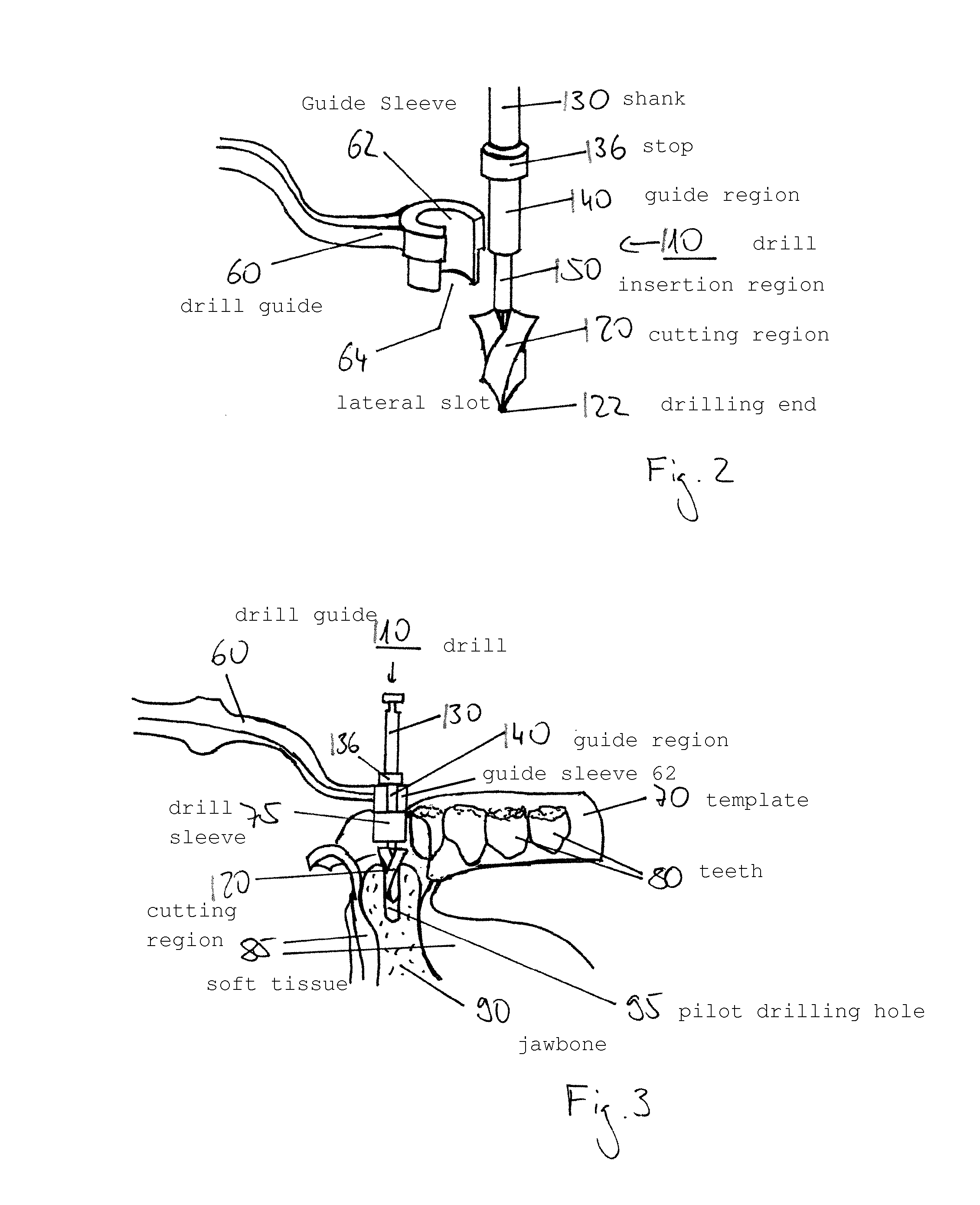

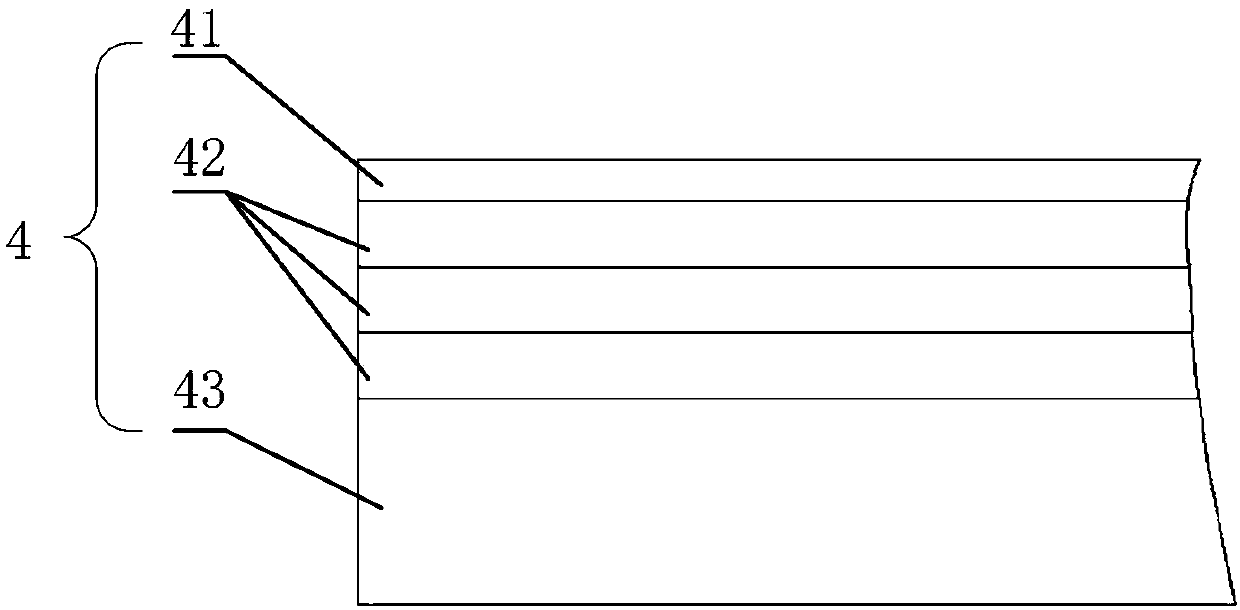

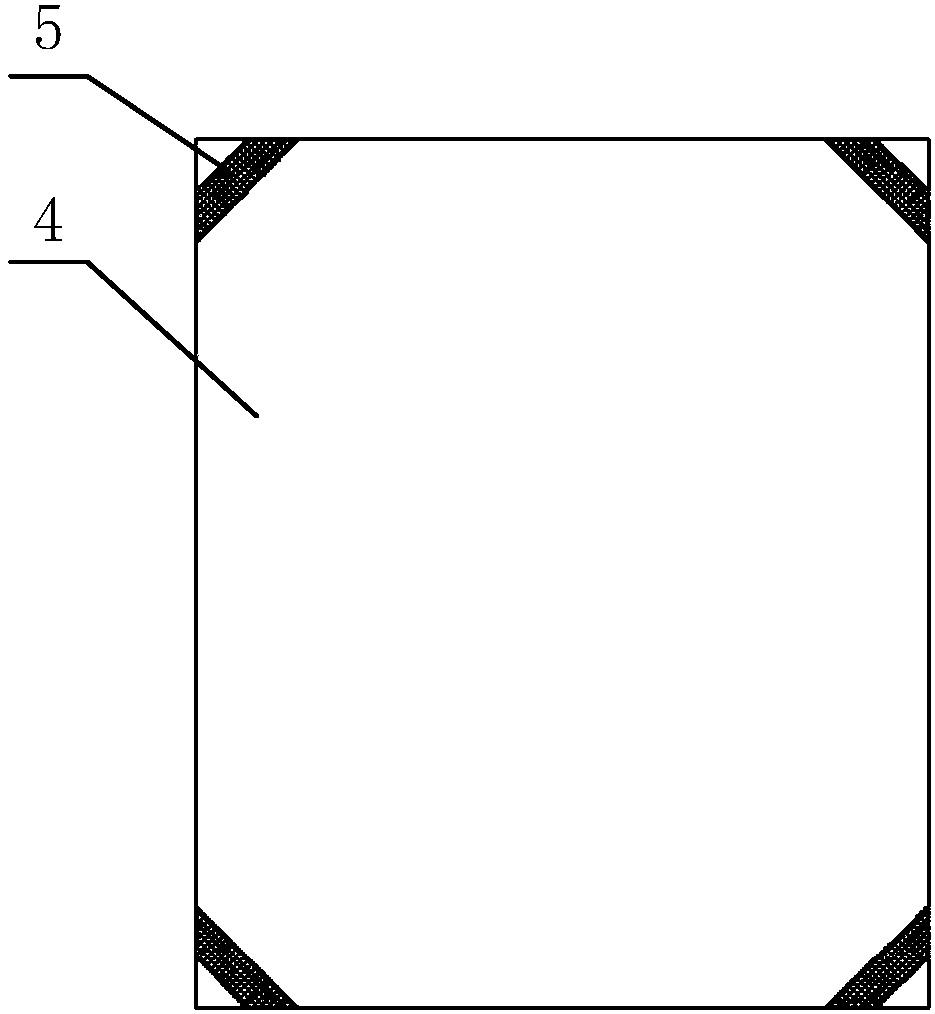

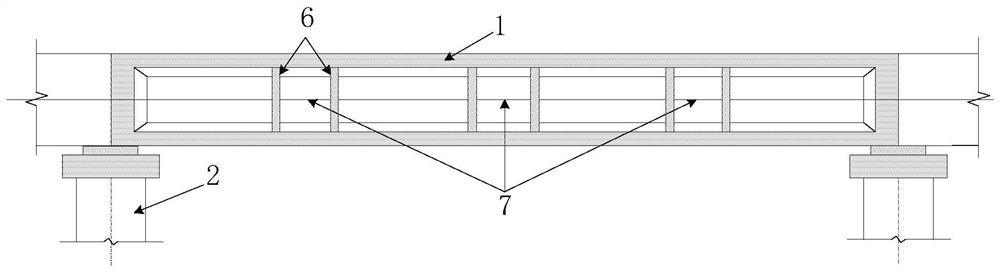

Set of dental drills

ActiveUS20100151412A1Prevents excessively deep penetrationSimplify the drilling processDental implantsDental toolsEngineeringDrill bit

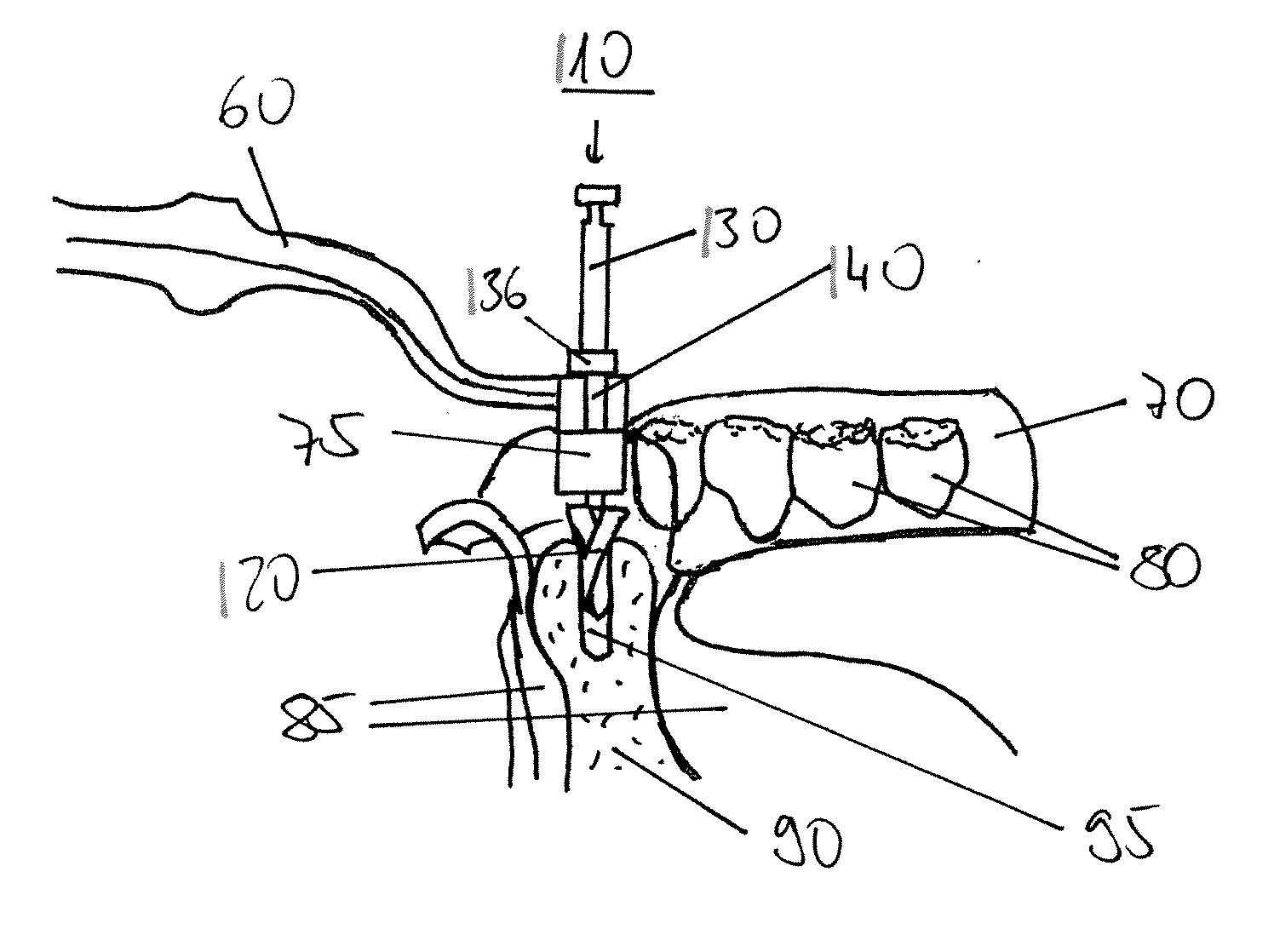

Set of dental drills having two or more dental drills (10, 10′), each of dental drills (10, 10′) having a cutting portion (20, 20′) that has an end-face drilling end (22, 22′) and a shank portion (30, 30′) that has a receiving region (32, 32′) intended to be received in a drill holding device. The shank portions (30, 30′) of the dental drills each have a substantially circular-cylindrical guide region (40, 40′) for guiding the dental drills, the guide regions (40, 40′) of the two or more dental drills being of the same diameter.

Owner:STRAUMANN HLDG AG

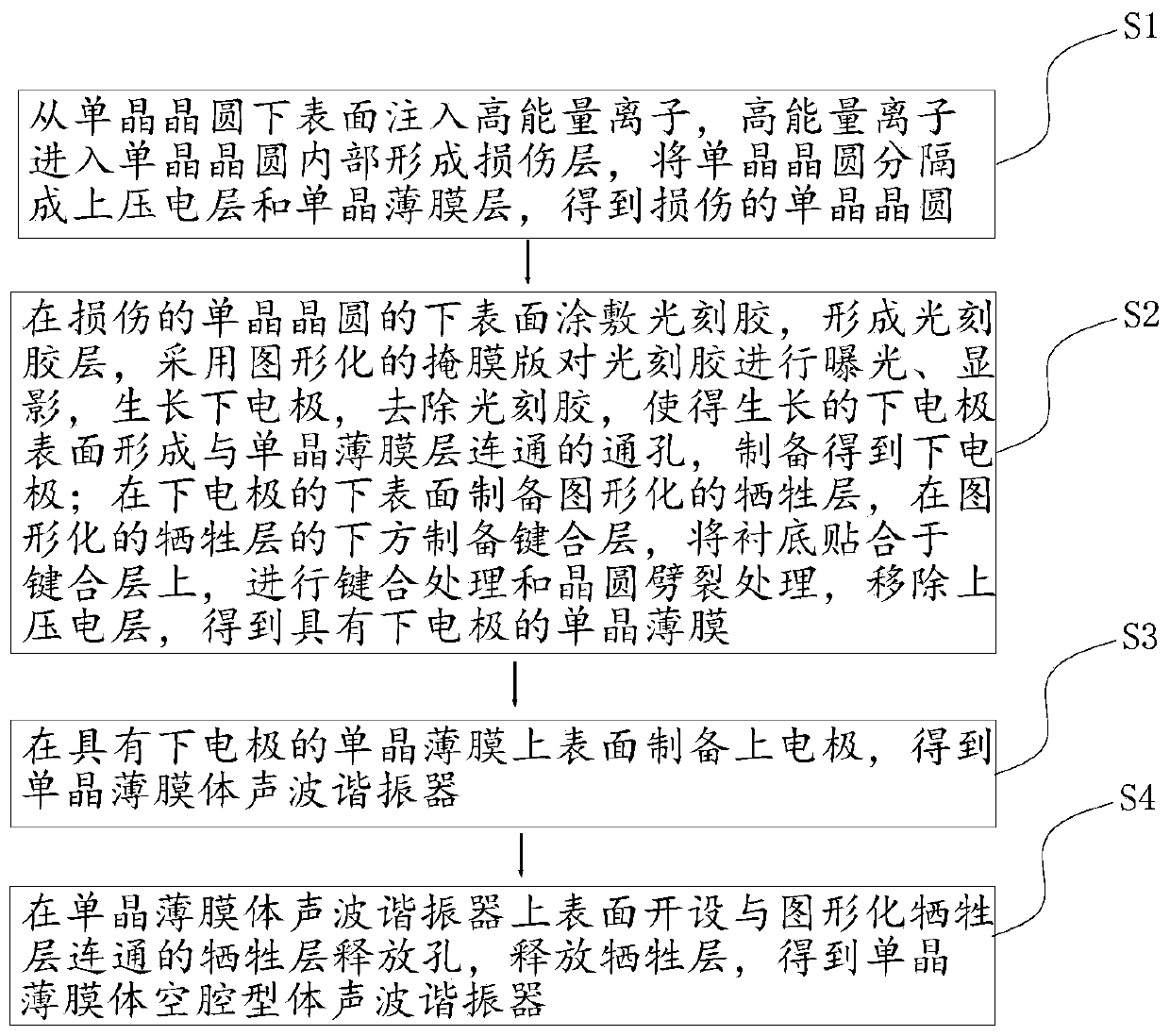

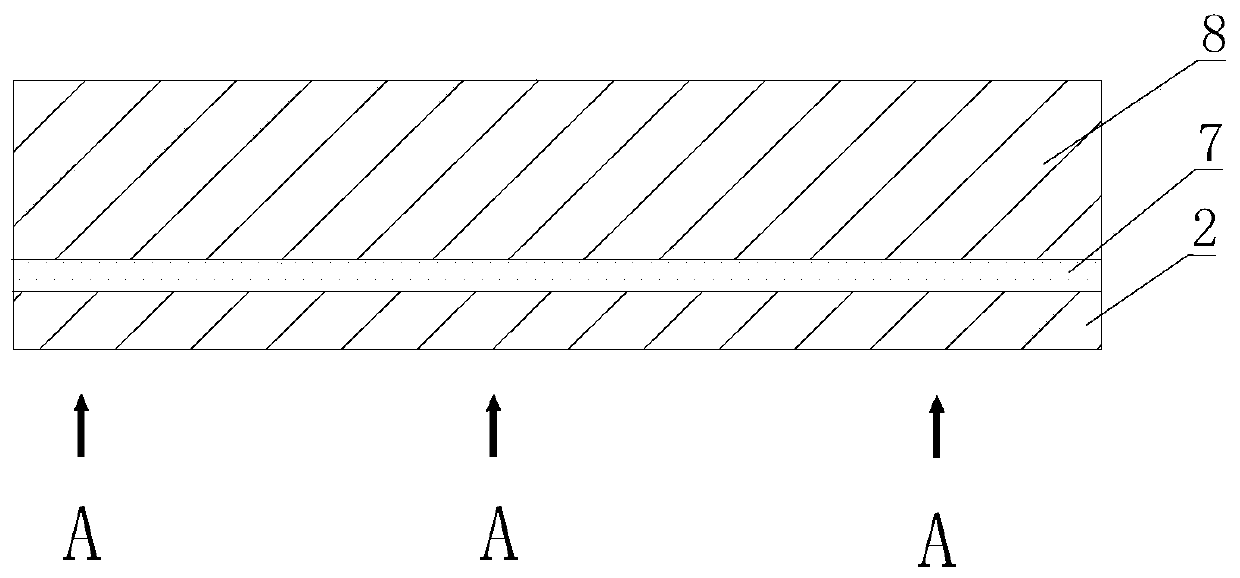

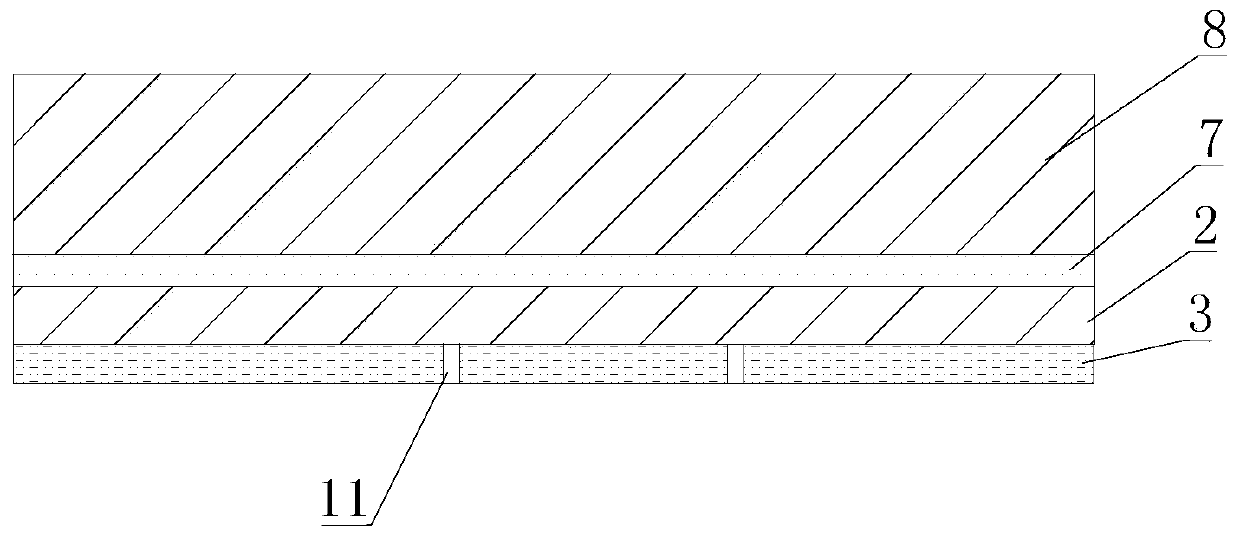

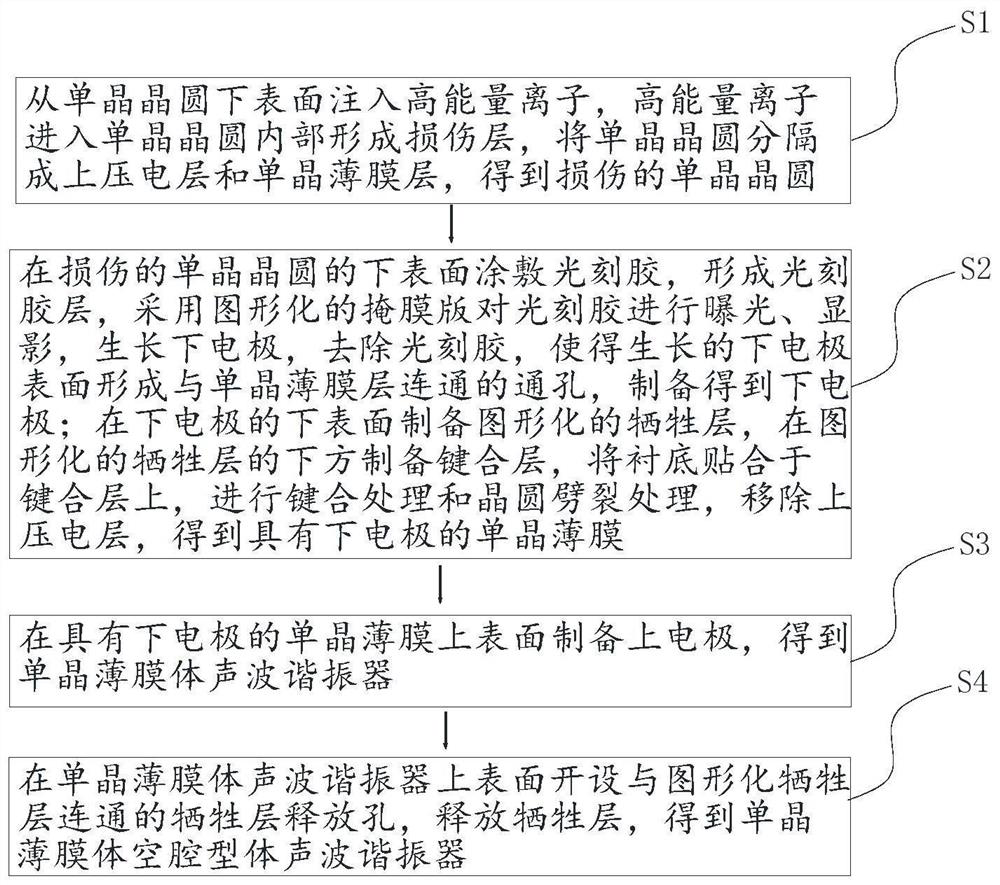

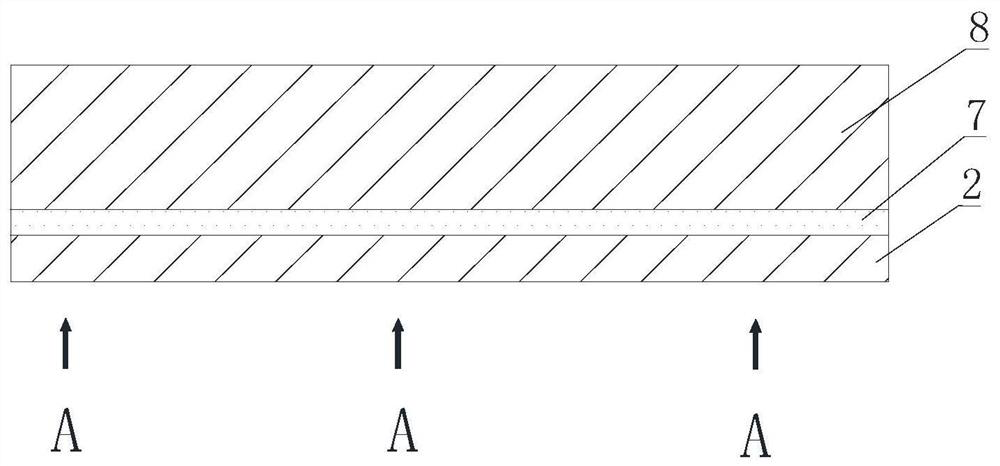

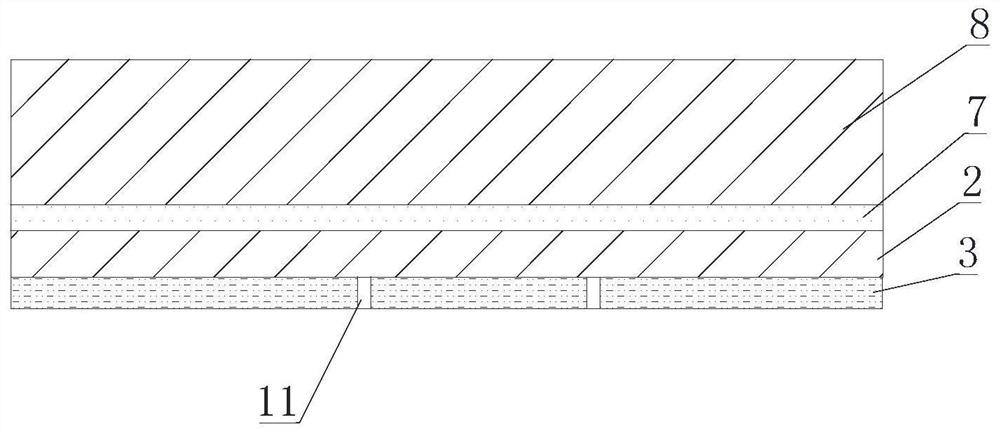

Preparation method of single crystal film bulk acoustic wave resonator and bulk acoustic wave resonator

ActiveCN110011632AAffect qualityGuaranteed performancePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksIsolation effectSingle crystal

The invention relates to the technical field of preparation of acoustic resonators, in particular to a preparation method of a single crystal film bulk acoustic resonator and the bulk acoustic resonator. The invention aims to solve problems that by using a preparation method of a single crystal film cavity type bulk acoustic wave resonator, through the design that a lower electrode which covers the lower surface of the whole single crystal thin film layer and has conductive and isolation effects is prepared on the lower surface of the single crystal thin film layer, in a binding process, bubbles generated by the bonding layer cause cracks to be generated on the single crystal film layer, so that the single crystal film layer is warped or sunken or even broken, and the overall performance of the cavity type bulk acoustic wave resonator is influenced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

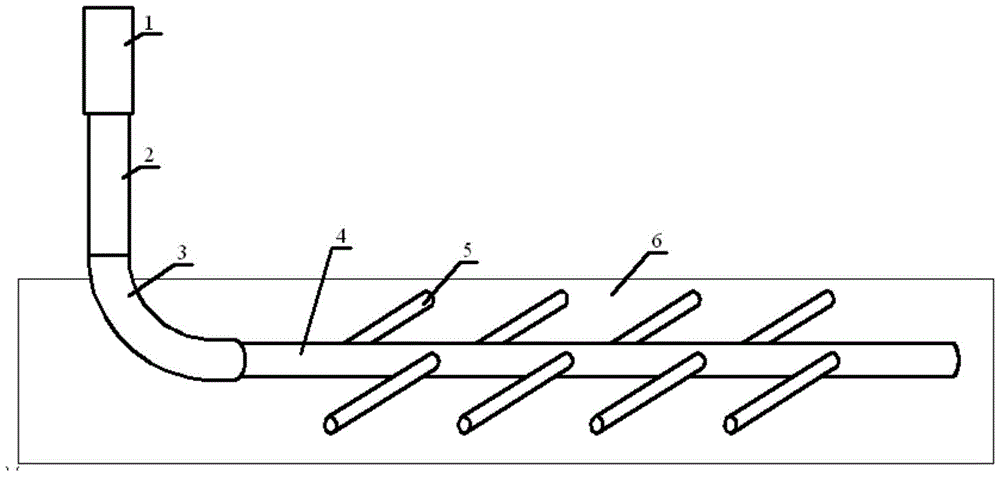

Method for drilling and completion of horizontal branched well for coal bed gas

ActiveCN104912479AStable supportSimplify the drilling processFluid removalDrilling machines and methodsSurface layerWell drilling

The invention discloses a method for drilling and completion of a horizontal branched well for coal bed gas. The method comprises the following steps: step 1: drilling a first-opening surface layer section, a second-opening straight well section and an incline angle buildup section of the horizontal branched well by adopting a conventional drilling tool combination, and after finishing drilling, arranging casing pipes so as to fix the well; step 2: drilling a third-opening coal bed horizontal section by adopting a casing pipe well drilling tool combination until a designed well depth is reached, and pulling out a directional drilling tool combination at the bottom of the well from the casing pipe with a steel wire fishing device; and step 3: adopting a radial lateral well drilling tool with a super-short radius so as to mill the casing pipe and drill the branched well in a coal bed. According to the method disclosed by the invention, pumping termination time can be shortened during drilling a main well hole of the coal bed, the coal bed can be effectively supported, the swabbing effect of well drilling is avoided, and accidents of collapse of a horizontal well and burying of the drilling tools are reduced; a well drilling technology of the branched well is greatly simplified, the well drilling risk of the branched well is reduced, the operation period is shortened, and the cost of drilling the branched well for the coal bed gas is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

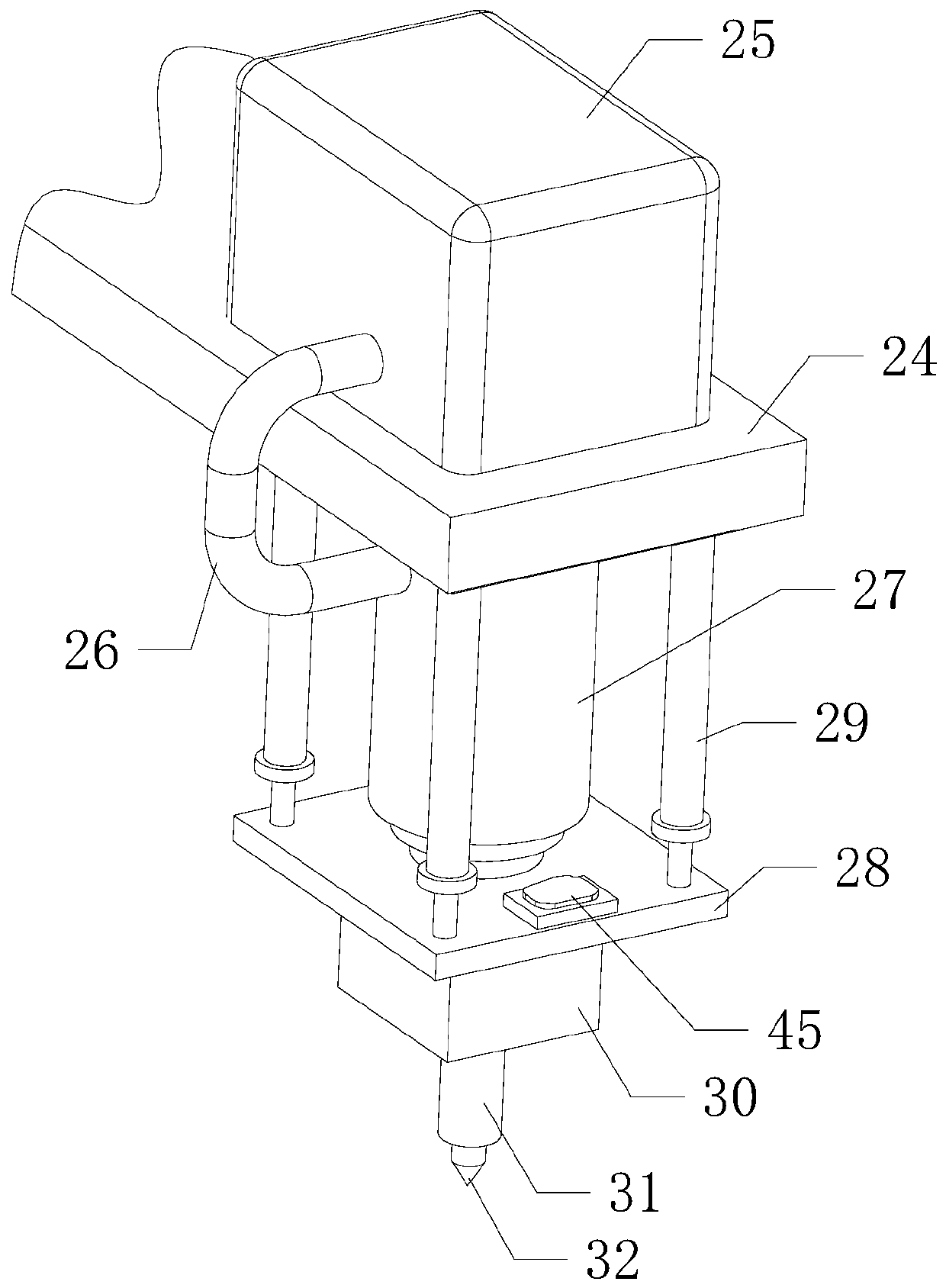

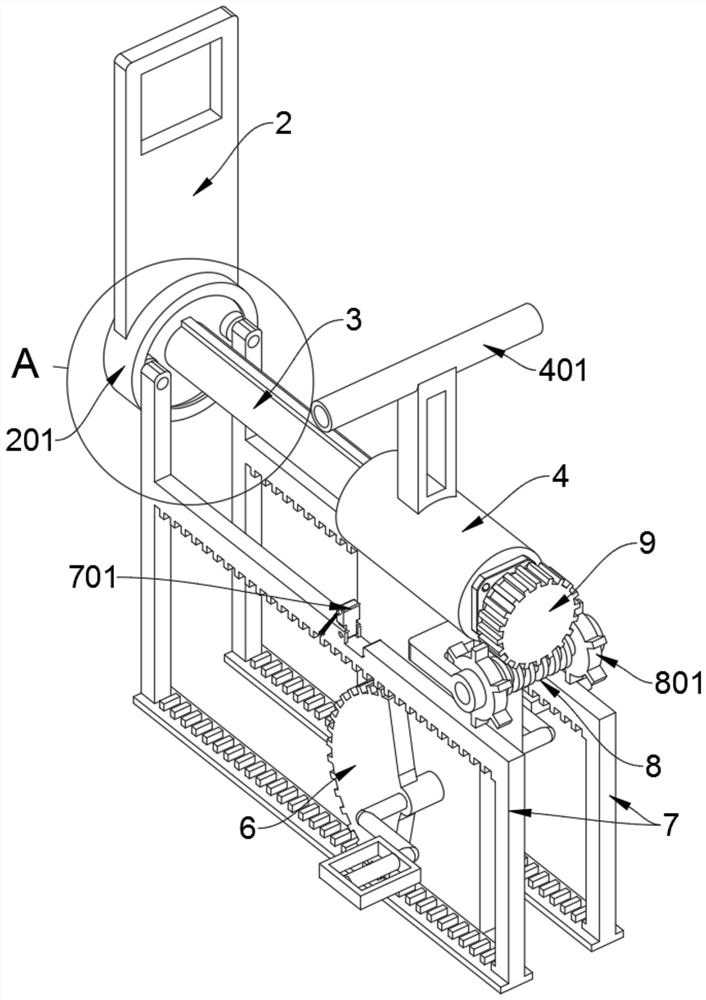

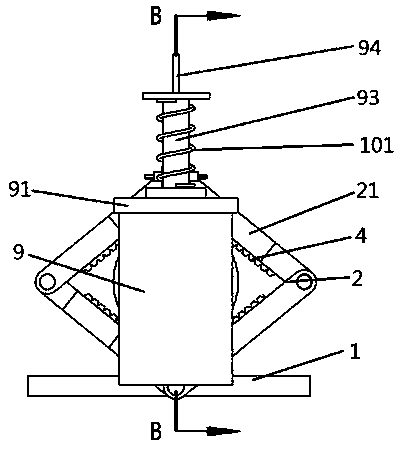

Production and machining equipment for relief butterfly valves

ActiveCN110788361AGuaranteed machining accuracyAvoid leaningPositioning apparatusBoring/drilling componentsReduction driveElectric machinery

The invention relates to the technical field of mechanical equipment, in particular to production and machining equipment for relief butterfly valves. The production and machining equipment comprisesa base, a workbench, a positioning plate, a first mounting plate, an air cylinder, a pushing rod, a clamping plate, a motor seat, a first motor, a first rotating shaft and a speed reducer, wherein thebottom end of the workbench is mounted on the front side of the top end of the base, an adjusting device is arranged on the right side of the top end of the workbench, the left end of the adjusting device is connected with the right end of the positioning plate, and the bottom end of the positioning plate is contacted with the top end of the workbench. According to the production and machining equipment for the relief butterfly valves, punching operation is carried out on the different positions on the valves, so that a punching process of the valves is effectively simplified, the punching time is shortened, the time and physical force for manually positioning the valves multiple times are saved, and the working efficiency is improved; and meanwhile, the position of a drill bit is precisely controlled, so that the position precision of a valve hole is effectively improved, the machining quality of the valves is improved, and the practicability and the reliability are improved.

Owner:SHANDONG ZHUCHENG JIANHUA VALVE MFG

Hydraulic unit for slip-controlled braking systems

ActiveUS20100231033A1Compact structureReduce complexityPositive displacement pump componentsBraking action transmissionDrive shaftHydraulic circuit

A hydraulic unit for slip-controlled braking systems has a plurality of receiving holes for transport devices associated with a plurality of hydraulic circuits bundled into groups, wherein the receiving holes are disposed at a distance from each in parallel with the upper side and a drive shaft having eccentrics located at the plane spacing for driving the transport devices. In order to provide a compromise optimized for manufacturing a small, convenient hydraulic unit, it is proposed that three theoretical planes (E1, E2, E3) are arranged in parallel to the upper side, each receiving two V-shaped receiving holes for transport devices disposed at an angle to each other, and that the drive shaft includes three separate eccentrics for driving the transport devices.

Owner:CONTINENTAL TEVES AG & CO OHG

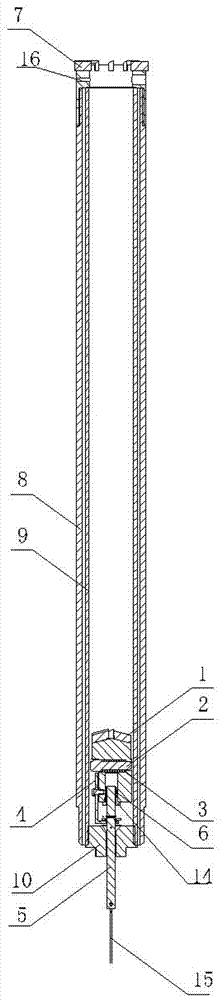

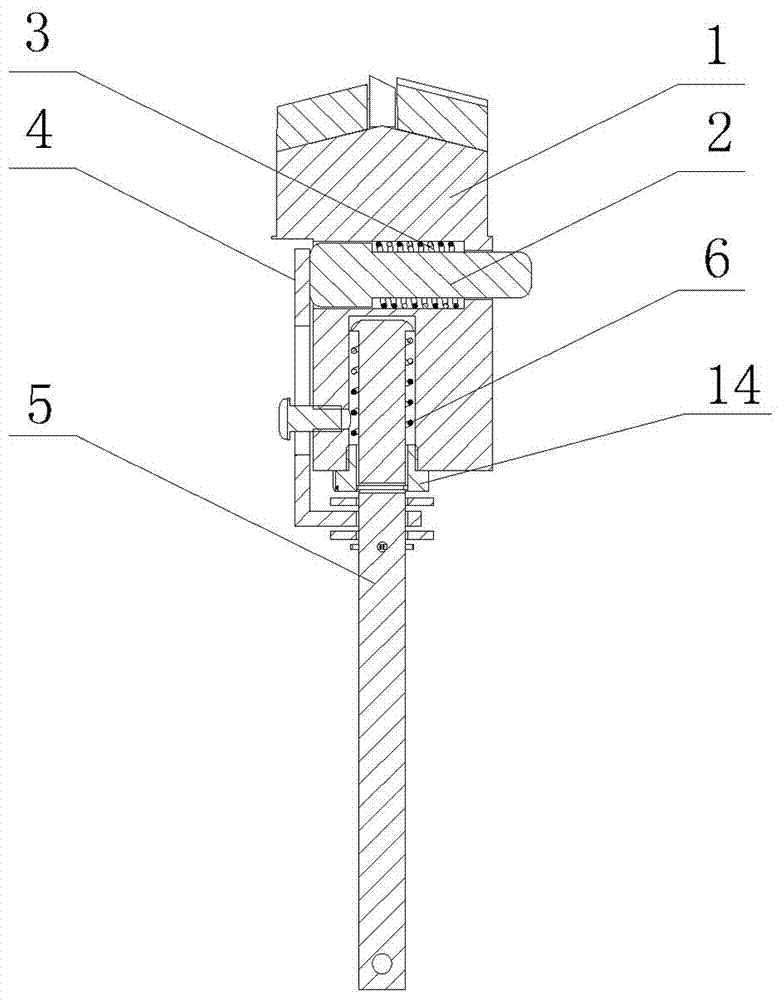

Measuring head of pneumatic instrument

InactiveCN105783796ASimplify the drilling processSolve the weight-on-bit problemUsing fluid meansEngineeringOpen air

The invention relates to a measuring head of a pneumatic instrument. The measuring head comprises a measuring head body including an air hole end and a ventilating hole end. Slotting is carried out in the air hole end; a pair of symmetric circular venting holes is formed in the slot; and an internal thread is formed in the groove in an annular hole. The ventilating hole end includes an external thread end and an air inlet port; slotting is carried out in the external thread end; and a through hole is formed in the air inlet port and extends to the external thread end and is communicated with the slot in the external thread end. In the prior art, hole drilling is carried out on a measuring head in an integrated entity mode and three holes are perpendicular to each other to form an inverted T shape; and when the measuring head is thickened and dimension of the measuring head is increased, the processing becomes difficult. Therefore, on the one hand, the opened air hole distance is reduced by separating the measuring head; and on the other hand, the thickness of the hole formed inside the measuring head is reduced. And thus the hole drilling process is simplified; and a problem that hole drilling needs the high drilling pressure can be solved.

Owner:SUZHOU GUOLIANG MEASURE TECH CO LTD

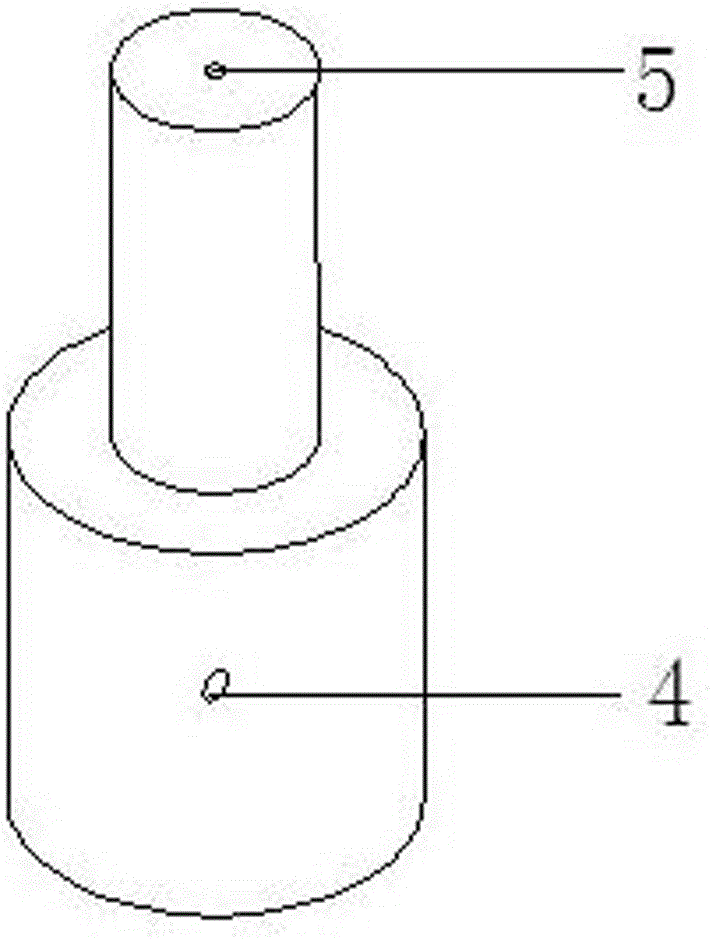

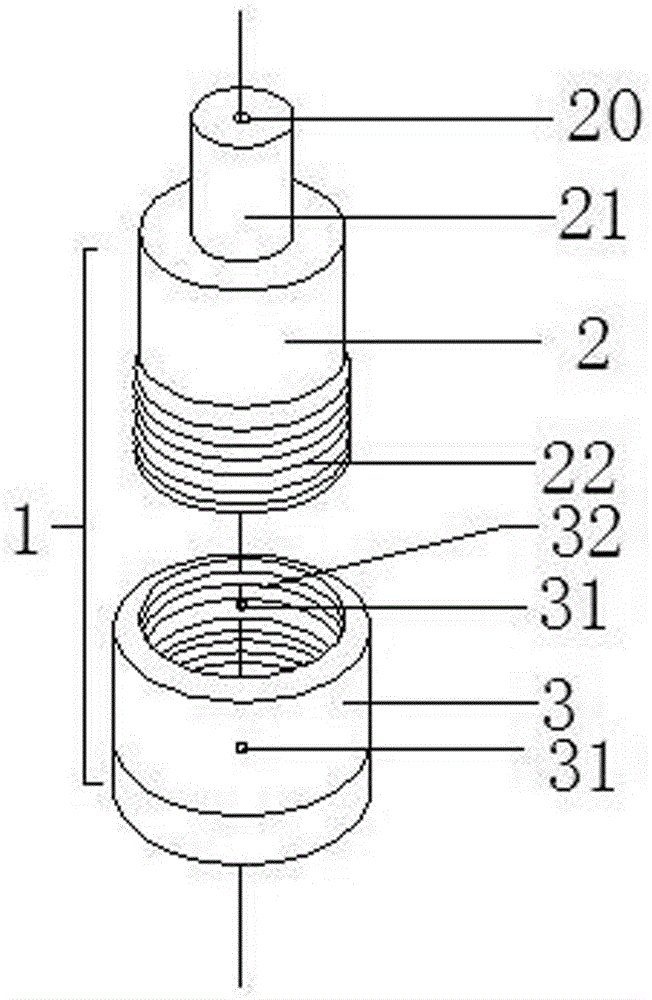

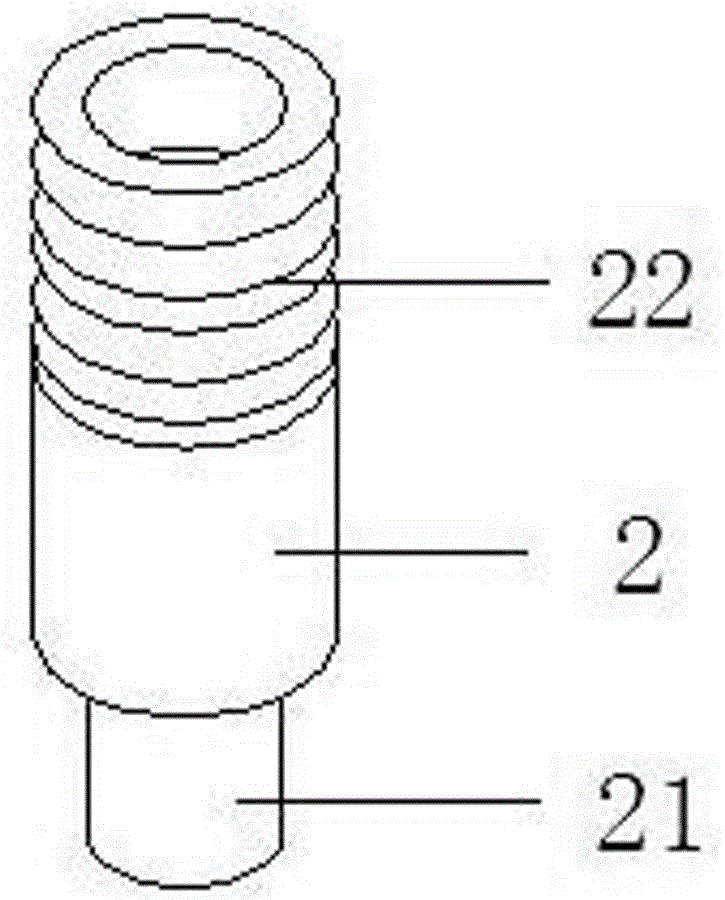

Mother-son drill bit spot sampling device

The invention relates to a mother-son drill bit spot sampling device comprising a coring pipe, and the coring pipe comprises an inner cylinder and an outer cylinder; the end portion of the coring pipe is provided with a mother drill bit, drill teeth are fixedly installed on the mother drill bit at an interval, a son drill bit is embedded into the mother drill bit, and the mother drill bit is connected with the son drill bit through a locking device; the locking device comprises a locking latch, a baffle plate and a draw bar, the locking latch is arranged in pin holes in the mother drill bit and the son drill bit in a penetrating manner, the baffle plate is connected with the draw bar through a pin, the exterior of the locking latch is sleeved by a latch spring, and the upper end of the draw bar is arranged in the bottom of the son drill bit in a penetrating manner. The mother-son drill bit spot coring device takes fast spot sampling required by coal seam gas extraction effect examination as the technical condition, the mother and son drill bits are locked and drill in a linked manner when sampling is not carried out, an unlocking device is started when a predetermined sampling position is reached, the mother drill bit takes samples in the manner of a sampling pipe, time is saved, positioning is accurate and sample mixing can be avoided, and the aim of fast spot sampling is achieved.

Owner:HENAN POLYTECHNIC UNIV

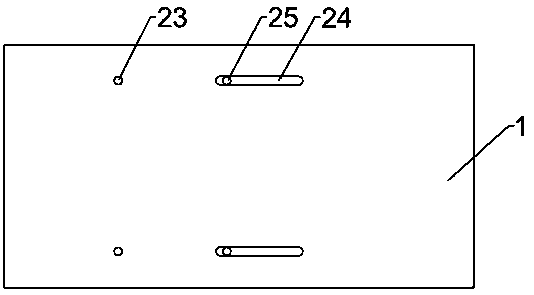

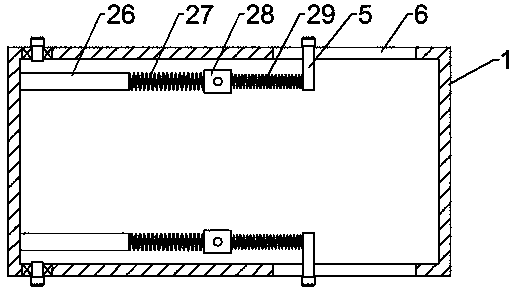

Set of dental drills

ActiveUS8770974B2Simplify the drilling processRisk of confusionDental implantsDental toolsEngineeringDrill bit

Set of dental drills having two or more dental drills (10, 10′), each of dental drills (10, 10′) having a cutting portion (20, 20′) that has an end-face drilling end (22, 22′) and a shank portion (30, 30′) that has a receiving region (32, 32′) intended to be received in a drill holding device. The shank portions (30, 30′) of the dental drills each have a substantially circular-cylindrical guide region (40, 40′) for guiding the dental drills, the guide regions (40, 40′) of the two or more dental drills being of the same diameter.

Owner:STRAUMANN HLDG AG

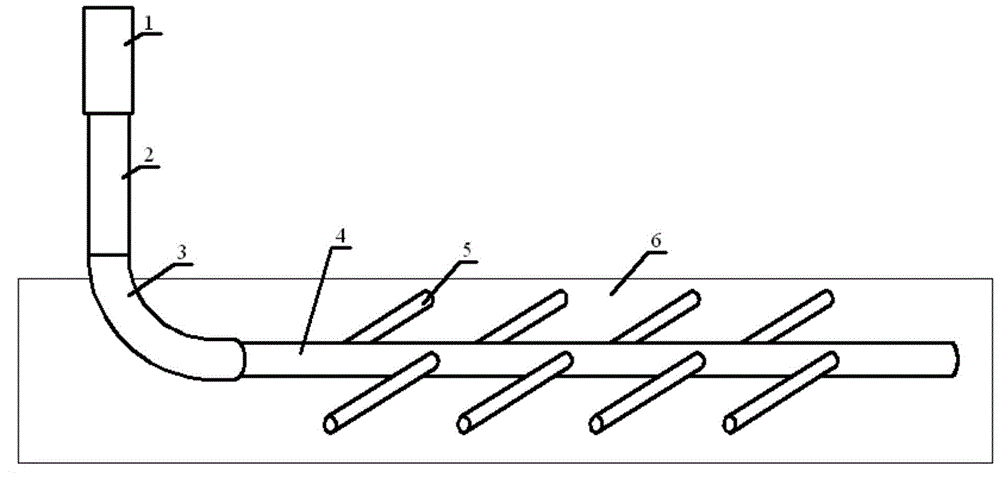

Long-axis deep hole drilling device and method for removing chips through circulating water

PendingCN113414631ASimplify the drilling processGood effectTransportation and packagingMaintainance and safety accessoriesSurface roughnessDrainage tubes

The invention relates to a long-axis deep hole drilling device and method for removing chips through circulating water. The device comprises a lathe, a deep hole drill bit, a water inlet unit and a water drainage unit. The water inlet unit is composed of a water inlet device and a first feeding device. The water drainage unit is composed of a water drainage pipe and a second feeding device. The water inlet device comprises a shell, a rotary water inlet barrel, a front end sleeve and a wedge-shaped sealing sleeve. The first feeding device and the second feeding device can both conduct feeding movement in the longitudinal direction of the lathe. According to the long-axis deep hole drilling device and method, the drilling procedure is simplified, a good effect is achieved on deep hole drilling of long-axis parts, and the drilling precision, coaxiality and in-hole surface roughness can be guaranteed; and the problem of poor sealing performance of a circulating water path of existing deep hole drilling equipment is solved, and the chip removal capacity during drilling is greatly improved.

Owner:ANSHAN ZHENGFA SURFACE TECHN & ENG CO LTD

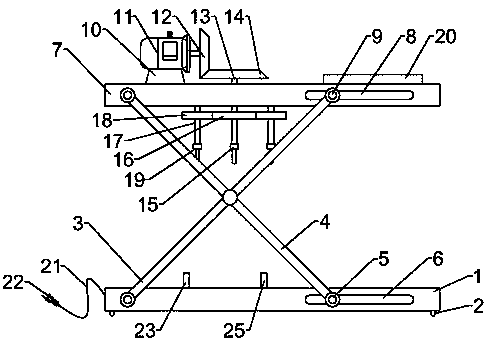

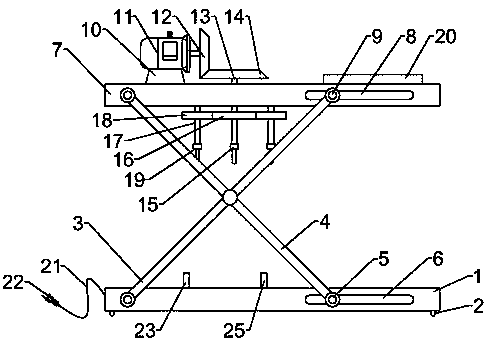

Drilling equipment for electronic device machining

InactiveCN109648112ASimple structureEasy to usePositioning apparatusBoring/drilling componentsMachiningDrill bit

The invention discloses drilling equipment for electronic device machining, and relates to drilling equipment. A machining bottom plate is included. A first rotation rod is rotationally connected to the left side of the machining bottom plate in a front-back symmetry manner. An equal-length second rotation rod is hinged to the middle portion of the first rotation rod. The lower end of the second rotation rod is rotationally with a first limiting sliding rod. A first limiting sliding groove is formed in the right side of the lower portion of the machining bottom plate and is in sliding connection with the first limiting sliding rod. A top plate is rotationally connected to the top of the second rotation rod. A second limiting sliding groove is formed in the right side of the top plate. Thetop of the first rotation rod is rotationally connected with a second limiting sliding rod which is in sliding connection with the second limiting sliding groove. The drilling equipment is simple in structure and convenient to use; during usage, the drilling process can be simplified, drilling can be conducted without accurate manual device positioning; the device drives a drill bit to descend fordrilling through downward pressing of the top plate, an electronic device is accurately positioned in the top plate descending process, and the drilling efficiency is effectively improved.

Owner:广安职业技术学院

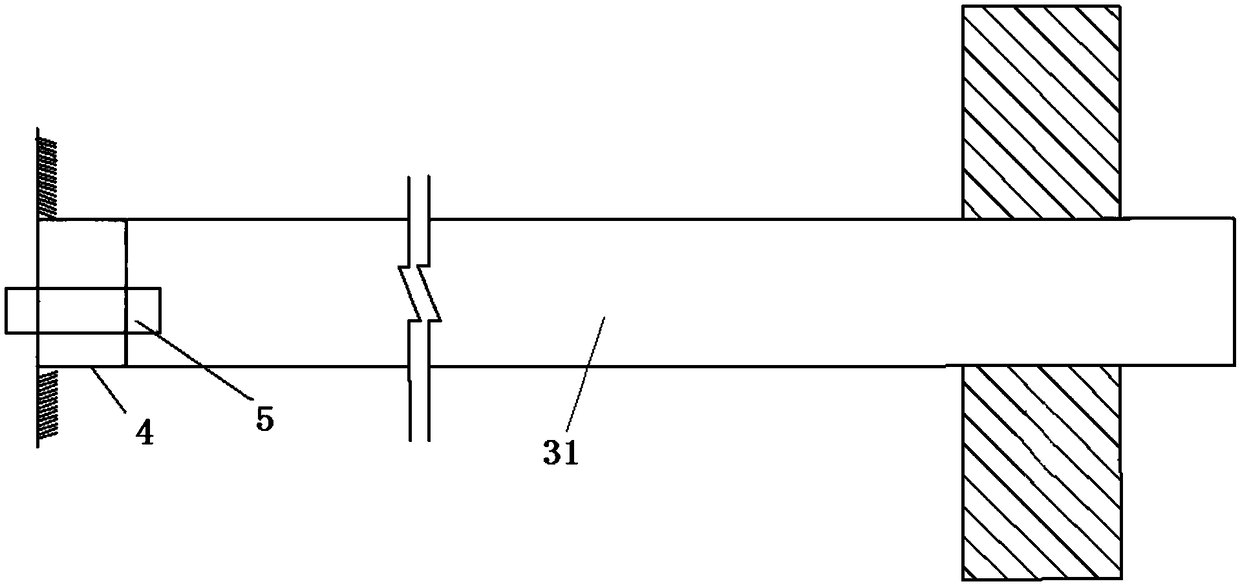

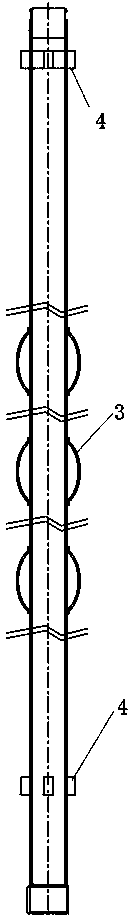

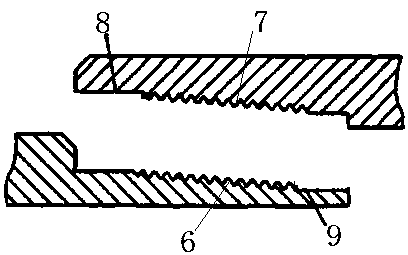

Drilling rod applicable to small-well-hole and large-displacement well drilling

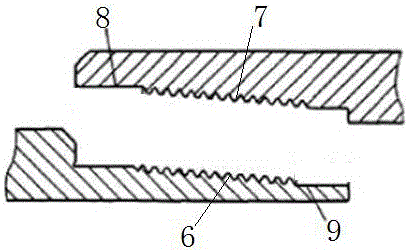

ActiveCN106014280AIncreased torsional strengthEnsure safetyDrilling rodsDrilling casingsInterference fitWell drilling

The invention relates to a drilling rod applicable to small-well-hole and large-displacement well drilling. The drilling rod does not need to be subjected to procedures of pulling out the drilling rod, piling a support and inserting an oil pipe, a petroleum drilling process is simplified, the petroleum drilling efficiency is improved and the cost is saved; meanwhile, a secondary shoulder is additionally arranged at an engaged part of a male buckle small end and a female buckle large end; the secondary shoulder and a main shoulder form a double-shoulder structure; a main shoulder face and a thread section have certain interference fit and the secondary shoulder just has a certain auxiliary upper buckle positioning function, so that the interference fit between the main shoulder face and the thread section is accurately realized; and furthermore, the secondary shoulder can also bear one part of load at a working state and has certain overload protection effect, and the anti-torque strength of the drilling rod can also be improved and the safety of the drilling rod is guaranteed.

Owner:DP MASTER MFG

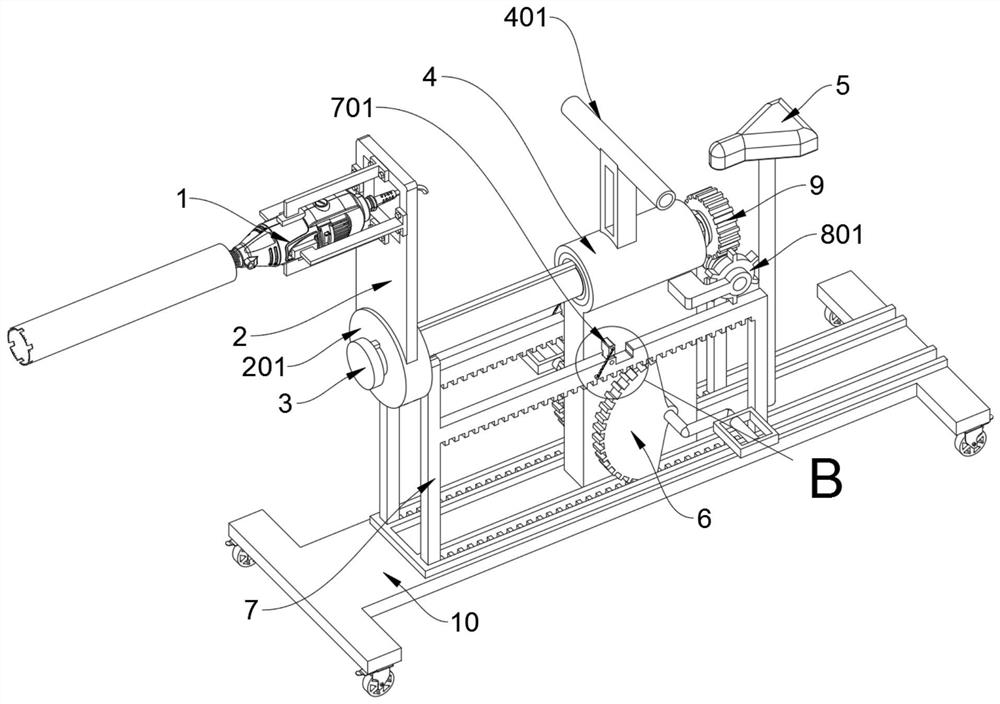

Perforating device for concrete wall surface

ActiveCN111619019AEliminates the need for manual transfer adjustmentsRealize linkage adjustmentWorking accessoriesStone-like material working toolsGear wheelBevel gear

The invention discloses a perforating device for a concrete wall surface, relates to the technical field of perforating equipment, and solves the problems that an opened circular hole is not perfectly-circular because internal-external staggering is caused due to the irregularity of manual adjustment for a surrounding track of an electric drill, and high physical power consumption is caused because a worker generally needs to stand and violently pushes the electric drill with a hand during drilling. The perforating device for the concrete wall surface comprises an installation plate, a supportrotary shaft, a pushing frame and a base, wherein an electric drill is installed on a top end section of the installation plate in a manner of being locked forwards; the rear half section of the support rotary shaft is rotationally installed on a location shaft sleeve in a penetrating manner, and a worm gear is installed at the rear end of the support rotary shaft in a sleeved manner; and a saddle is installed on the rear half section of the base in a supporting manner, a location shaft sleeve is supported and welded to the middle part of the base, and two bevel gears are rotationally installed on a vertical supporting plate at the bottom of the location shaft sleeve in the form of left-right correspondence. According to the perforating device for the concrete wall surface, two guide wheels are capable of ensuring that a rotary ring can still be rotationally connected with two pushing frames during normal self-rotation.

Owner:淄博聚德建筑安装有限公司

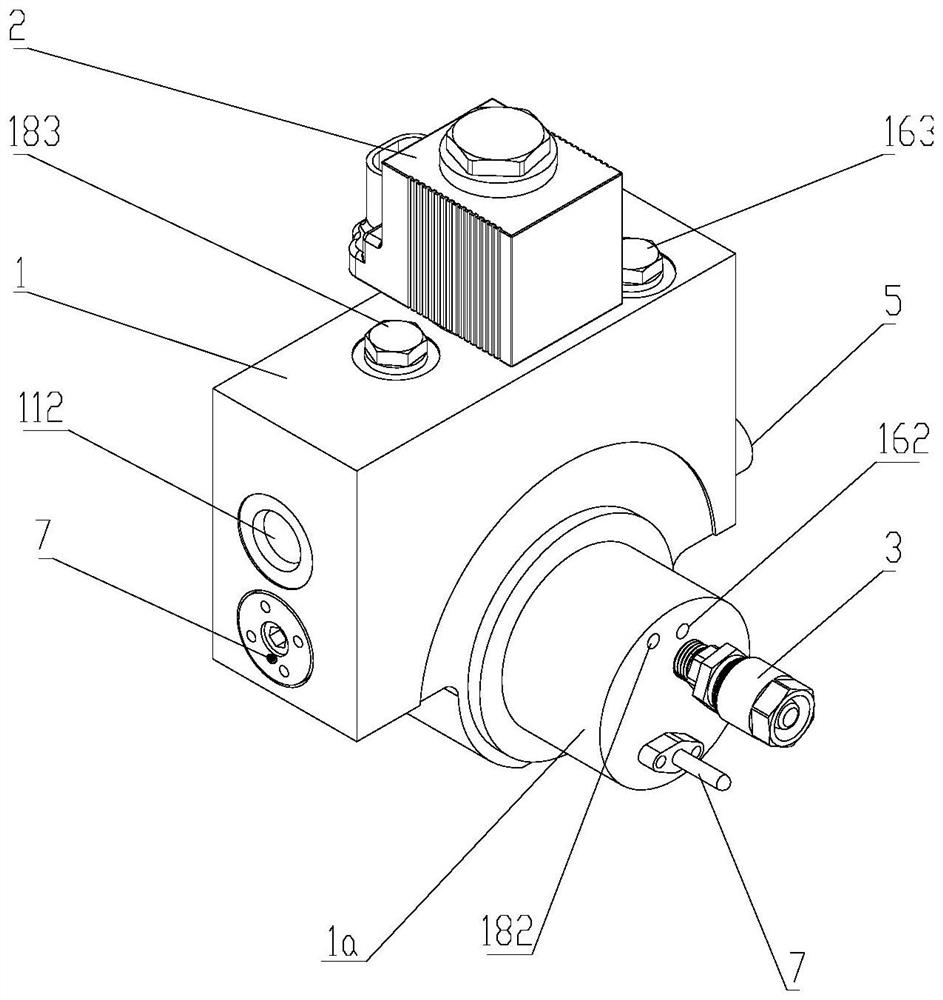

Gas cylinder valve and gas cylinder group

InactiveCN113048267AReduce processing difficultyReduce processing costsOperating means/releasing devices for valvesDispersed particle filtrationGas cylinderEngineering

The invention provides a gas cylinder valve and a gas cylinder group. The gas cylinder valve comprises an installation body and an electromagnetic valve, the installation body is provided with a main channel penetrating through the two ends of the installation body, a gas inlet is formed in one end of the main channel, a gas outlet is formed in the other end of the main channel, and a one-way valve only allowing gas to enter the main channel is arranged at the gas inlet or a pipeline used for communicating with the upstream of the gas inlet. The installation body is further provided with a first valve hole, the first valve hole communicates with the main channel, and the installation body is further provided with an inflation and deflation channel used for communicating with the interior of a bottle body of a gas bottle; and the electromagnetic valve comprises a first valve seat detachably installed in the first valve hole and a first valve element detachably installed in the first valve hole, the first valve seat is provided with a first gas hole communicating with the main channel, and a first sealing ring forms sealing between the first valve seat and the first valve hole. According to the gas cylinder valve and the gas cylinder group, the valve seat and the valve element are detachably installed on the installation structure through a gas adding valve and the gas bottle, and the problem that an existing valve seat cannot be maintained after sealing fails is solved.

Owner:西安伯肯氢能科技有限公司

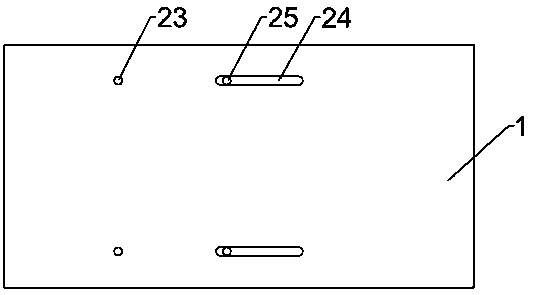

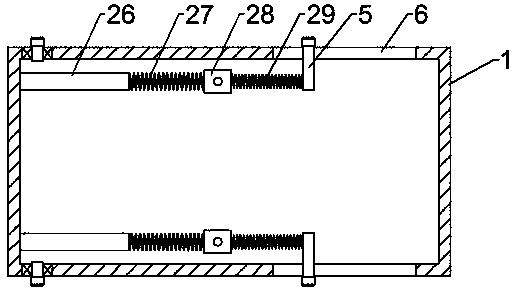

Drilling machine table top and drilling machine

PendingCN110405844AStable structureAvoid unevennessMetal working apparatusButt jointDrilling machines

The invention relates to the technical field of circuit board production, in particular to a drilling machine table top and a drilling machine. The drilling machine table top comprises a workbench, astretchable device and a vacuum adsorption device, one end of the stretchable device is fixed on the workbench, the other end of the stretchable device is used for bearing a circuit board, the stretching and retracting direction of the stretchable device is perpendicular to the workbench so as to support the circuit board, then a bottom supporting space is formed between the circuit board and theworkbench, the vacuum adsorption device is used for being in butt joint with the bottom surface of the circuit board so as to enable the circuit board to be adsorbed and fixed to the stretchable device. According to the provided drilling machine table top, the bottom supporting space can be formed between the circuit board and the workbench through the stretchable device, then bottom supporting extracting and conveying of the circuit board are facilitated, the higher reliability is achieved, moreover, the problem that a structure layer of the circuit board is not flat is solved, the structureis simple, the operation is convenient, moreover, the cost is low, and the development prospect is good.

Owner:SUZHOU VEGA TECH CO LTD

A kind of drilling equipment for electronic device processing

InactiveCN109648112BSimple structureEasy to usePositioning apparatusBoring/drilling componentsMachiningDrill bit

The invention discloses drilling equipment for electronic device machining, and relates to drilling equipment. A machining bottom plate is included. A first rotation rod is rotationally connected to the left side of the machining bottom plate in a front-back symmetry manner. An equal-length second rotation rod is hinged to the middle portion of the first rotation rod. The lower end of the second rotation rod is rotationally with a first limiting sliding rod. A first limiting sliding groove is formed in the right side of the lower portion of the machining bottom plate and is in sliding connection with the first limiting sliding rod. A top plate is rotationally connected to the top of the second rotation rod. A second limiting sliding groove is formed in the right side of the top plate. Thetop of the first rotation rod is rotationally connected with a second limiting sliding rod which is in sliding connection with the second limiting sliding groove. The drilling equipment is simple in structure and convenient to use; during usage, the drilling process can be simplified, drilling can be conducted without accurate manual device positioning; the device drives a drill bit to descend fordrilling through downward pressing of the top plate, an electronic device is accurately positioned in the top plate descending process, and the drilling efficiency is effectively improved.

Owner:广安职业技术学院

Gas extraction method for protected layer

PendingCN109441526APrevent overrunningSolve the problem of stagnant waterGas removalEngineeringProtection layer

The invention discloses a gas extraction method for a protected layer. The gas extraction method comprises the following steps that a bottom plate roadway is constructed at a protected layer bottom plate, a layer-penetrating drilled hole is constructed in the bottom plate roadway and penetrates through the protected layer, a hole-sealing pipe is put into the hole downwards, and gas in the protected layer is extracted; and a gateway of the bottom plate roadway is sealed by a sealing wall, and the gas entering a protecting layer is extracted through a reserved gas extraction pipeline. The gas extraction method has the beneficial effects that gas extraction of the protected layer and the protecting layer is achieved, the drilled hole is temporarily sealed and extracted through the hole-sealing pipe, the situation that the gas in the hole overflows, and consequently, the roadway gas exceeds the limit can be prevented, the problems of limited hole diameter and water accumulation in the pipeline in traditional hole sealing, connecting, extraction processes are effectively solved, and the hidden danger that the road side are pressed, consequently, the pre-embedded extraction pipeline is disconnected, and the pipeline impacts with ironware in the roadway to generate sparks is avoided; and the construction cost of the drilled hole is saved.

Owner:HUAINAN MINING IND GRP

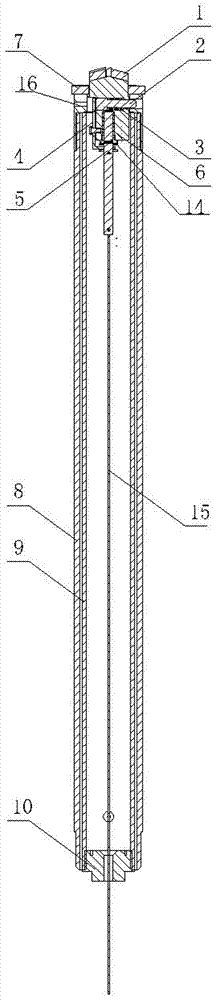

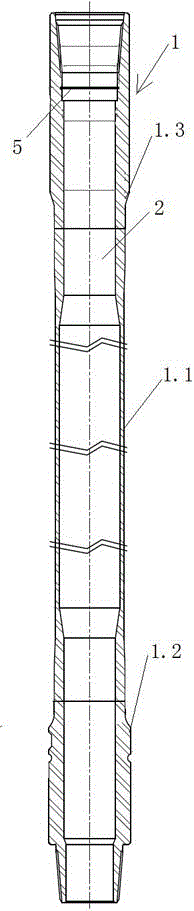

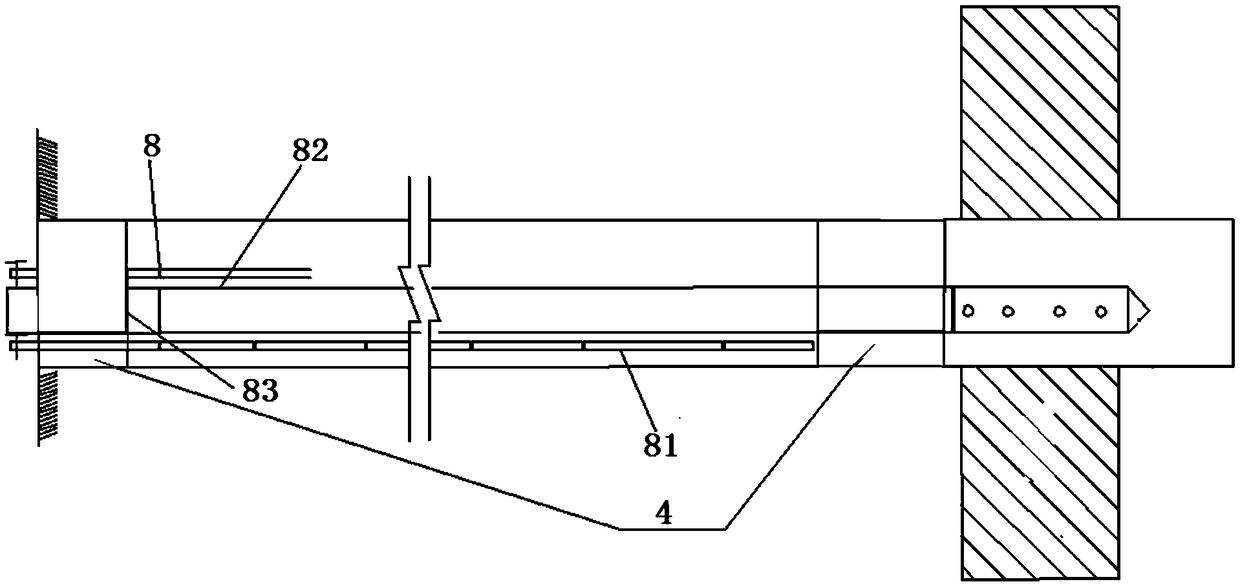

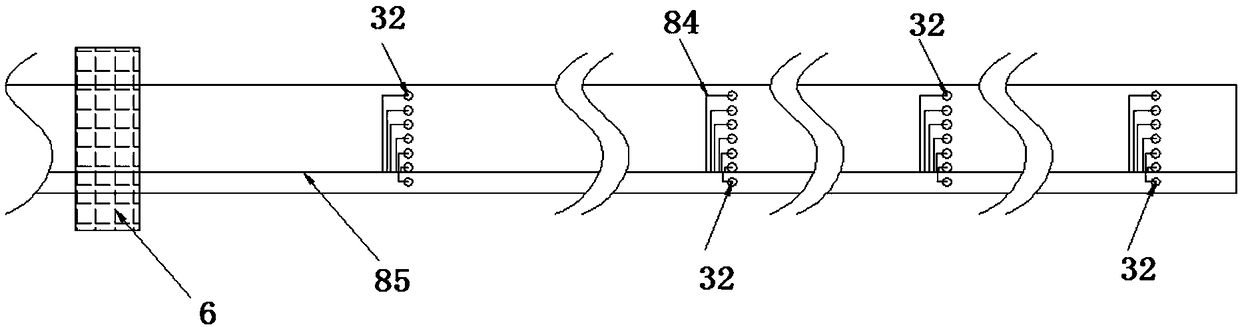

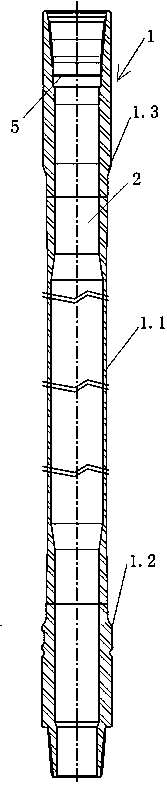

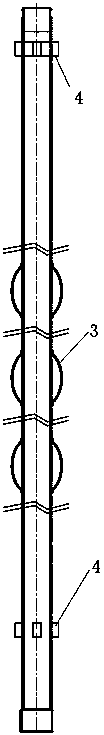

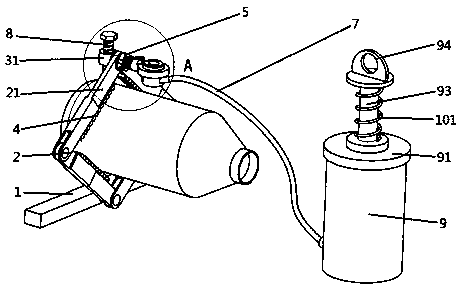

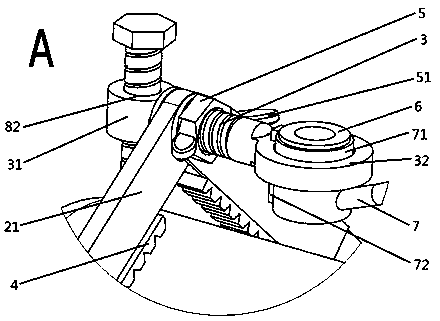

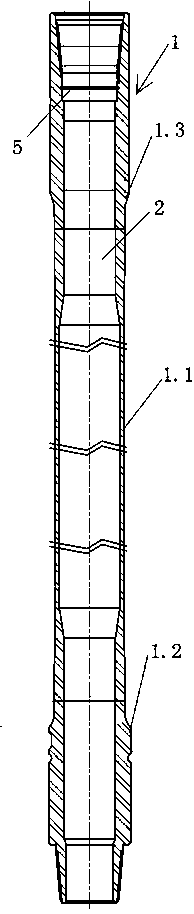

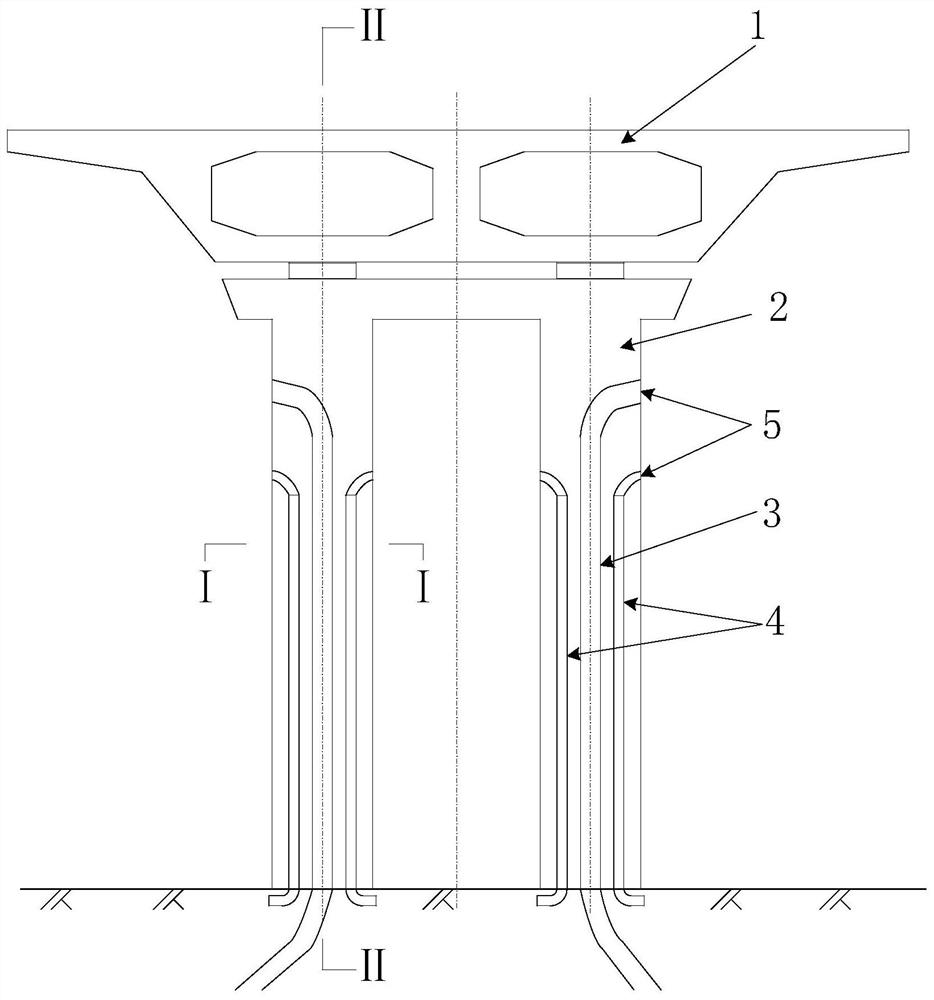

Oil pipe built-in oil drill pipe

ActiveCN105804667BSimplify the drilling processImprove drilling efficiencyDrilling rodsDrilling casingsOil drillingPetroleum

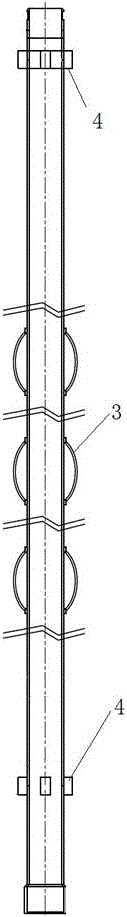

The invention discloses an oil drill rod with a built-in oil pipes. The oil drill rod with the built-in oil pipes is characterized by comprising a drill rod (1) and oil pipes (2); the body of the drill rod (1) consists of a main rod (1.1) in the middle, and a male connector (1.2) and a female connector (1.3) at the two ends of the drill rod (1), wherein the oil pipes (2) are placed in the drill rod (1); a plurality of spring centralizers (3) are arranged on the outer parts of the intermediate sections of the oil pipes (2) in a sleeving manner; a block-shaped centralizer (4) is arranged at each of the positions, close to the two ends, of the oil pipes (2); when two oil drill rods are connected, the drill rods (1) are in threaded connection and matching with each other through the male connector (1.2) and the female connector (1.3); the oil pipes (2) are buckled and matched with each other through clamping springs (5). According to the oil drill rod with the built-in oil pipes, the oil pipes are fixed to the interior of the drill rod; the drill rod is only required to be drilled into a seabed without performing the processes of unplugging the drill rod, arranging a support, and inserting the oil pipes when oil is drilled, so that an oil drilling process is simplified; the oil drilling efficiency is improved; the offshore oil drilling cost is saved.

Owner:DP MASTER MFG

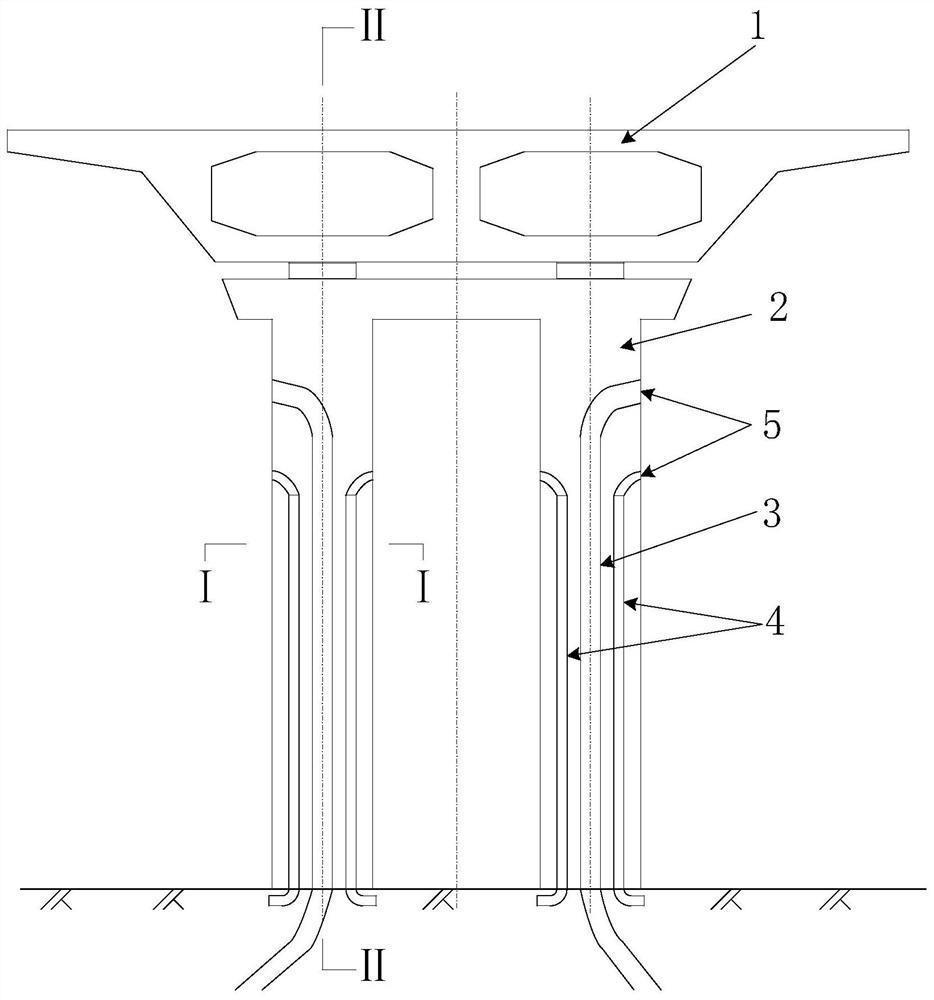

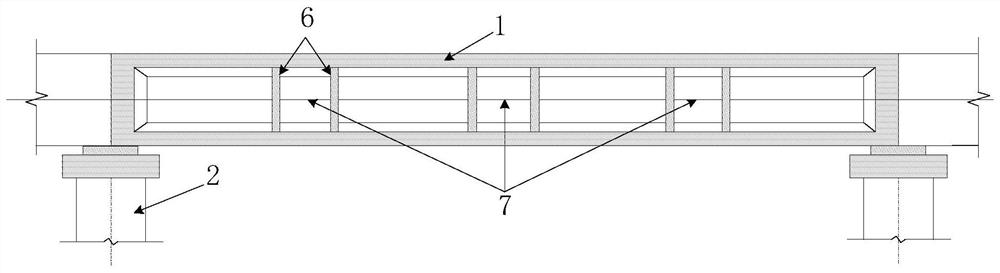

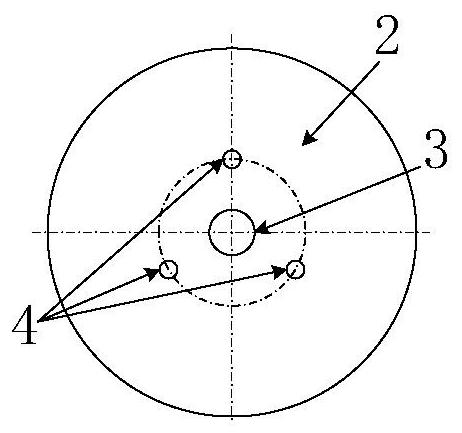

A full-section hydraulic blasting demolition method of an urban viaduct

ActiveCN113389151BReduce usageImprove safety hazardsBuilding repairsBridge strengtheningDetonatorArchitectural engineering

The invention discloses a full-section hydraulic blasting demolition method of an urban viaduct, comprising: adding a built-in reserved hole design and a groove design; using the vertical pre-buried pipes of the bridge columns, beams and plates to make a matching template and fix it on the The reinforced skeleton of the bridge is formed by pouring concrete at one time; the built-in large pre-buried holes are used for drainage, and the three pre-buried small holes are used to arrange lighting, communication lines, and traffic monitoring cables; the three pre-buried small holes of each pier of the viaduct are dismantled and arranged in the three pre-buried small holes The cables are used as compensation holes; high-precision delayed detonators are used for charging, networking, protection, and detonation to control the detonation sequence of the blasting points of each pier and the hydraulic blasting points of the box girder; The beam was split into three parts and collapsed. The invention reduces the blasting and demolition drilling construction process, reduces the drilling cost, reduces the harmful effects such as noise and dust, and has high environmental protection, short construction period and low cost.

Owner:WUHAN BLASTING ENG

Rotary water spraying type glass bottle punching auxiliary clamping support

InactiveCN109968546AIngenious designEasy to operateWorking accessoriesStone-like material working toolsPunchingEngineering

The invention relates to a rotary water spraying type glass bottle punching auxiliary clamping support. The rotary water spraying type glass bottle punching auxiliary clamping support is characterizedin that a quadrilateral lock frame which is formed by movably connecting a barreled water barrel and connecting rods is a main body, and a fixed seat is arranged below the quadrilateral lock frame for supporting; a detachable fixed cover and a sliding rod which penetrates through the fixed cover and can slide up and down in the barreled water barrel are arranged on the barreled water barrel to beused a main body; the top end of the quadrilateral lock frame is provided with the connecting rods which are connected with one another through a threaded rod, and the two ends of the threaded rod are provided with a locking fixing sleeve and a drilling fixing sleeve respectively; and a water inlet pipe fixing sleeve and a rotating sleeve are arranged in the middle of the drilling fixing sleeve.According to the rotary water spraying type glass bottle punching auxiliary clamping support, the glass bottle is locked through the quadrilateral lock frame composed of the connecting rods, the design is ingenious, and the operation is convenient; in addition, the design of an oblique cutting water inlet on the rotating sleeve enables the rotating sleeve to continuously carry out water spraying in the process of rotating along with a drilling hole, so that the use is convenient, the punching efficiency is improved, and the punching operation process is simplified.

Owner:SUQIAN ZHIPENG INTELLIGENT TECH CO LTD

Preparation method of single crystal thin film bulk acoustic wave resonator and bulk acoustic wave resonator

ActiveCN110011632BAffect qualityGuaranteed performancePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksBonding processThin membrane

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

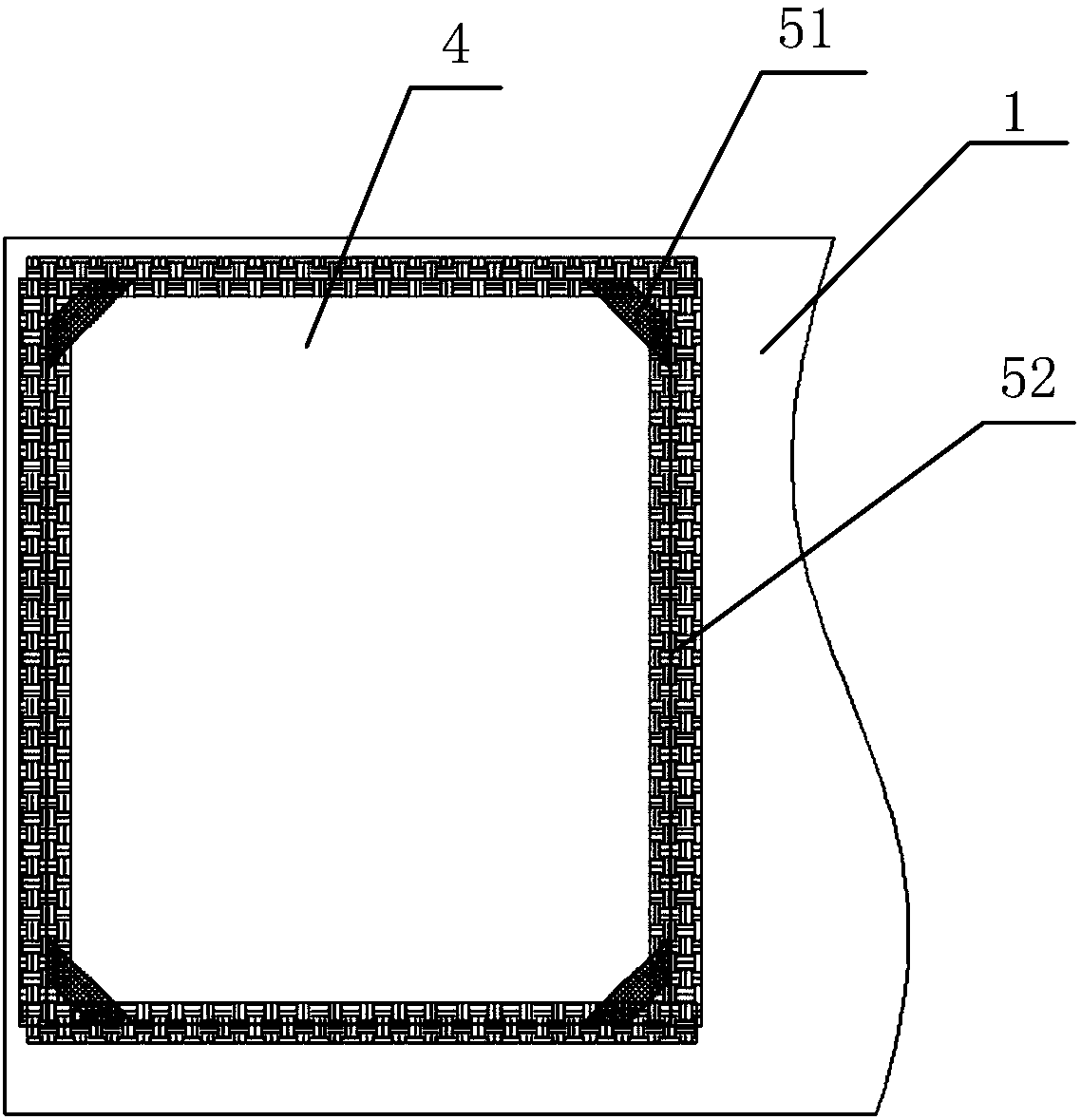

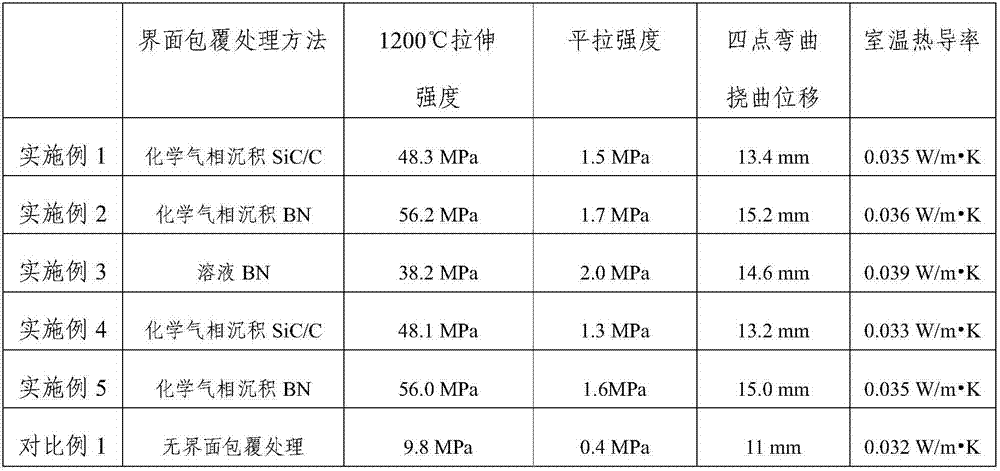

A kind of external heat-proof material and preparation method thereof

ActiveCN106584942BImprove high temperature mechanical propertiesImprove mechanical properties at room temperatureLamination ancillary operationsLaminationThermal insulationTemperature resistance

The invention relates to an external thermal insulation material and a preparation method thereof. Specifically, the external thermal insulation material comprises a first faceplate layer, a second faceplate layer and a core aerogel layer, wherein the core aerogel layer is positioned between the first faceplate layer and the second faceplate layer; the first faceplate layer and the second faceplate layer are made of a fiber preform compounded with an aerogel precursor and a ceramic precursor; the core aerogel layer is mainly made of a fiber matrix compounded with an aerogel precursor; fiber surfaces of the fiber preform and the fiber matrix are subjected to interface coating treatment. By adopting the material, the problem of interface coating treatment on a high strain coordination ceramic faceplate can be solved, the temperature resistance grade and the deformation coordination property of a heat-proof and thermal insulating material can be improved, and the material has advantages of high temperature resistance and high strain coordination properties, so that components of relatively large sizes can be designed, and the application range of the material can be widened.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Drilling and Completion Method of Coalbed Gas Horizontal Branch Well

ActiveCN104912479BStable supportSimplify the drilling processFluid removalDrilling machines and methodsSurface layerWell drilling

The invention discloses a method for drilling and completion of a horizontal branched well for coal bed gas. The method comprises the following steps: step 1: drilling a first-opening surface layer section, a second-opening straight well section and an incline angle buildup section of the horizontal branched well by adopting a conventional drilling tool combination, and after finishing drilling, arranging casing pipes so as to fix the well; step 2: drilling a third-opening coal bed horizontal section by adopting a casing pipe well drilling tool combination until a designed well depth is reached, and pulling out a directional drilling tool combination at the bottom of the well from the casing pipe with a steel wire fishing device; and step 3: adopting a radial lateral well drilling tool with a super-short radius so as to mill the casing pipe and drill the branched well in a coal bed. According to the method disclosed by the invention, pumping termination time can be shortened during drilling a main well hole of the coal bed, the coal bed can be effectively supported, the swabbing effect of well drilling is avoided, and accidents of collapse of a horizontal well and burying of the drilling tools are reduced; a well drilling technology of the branched well is greatly simplified, the well drilling risk of the branched well is reduced, the operation period is shortened, and the cost of drilling the branched well for the coal bed gas is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Drill pipes suitable for extended reach drilling in slim holes

ActiveCN106014280BIncreased torsional strengthEnsure safetyDrilling rodsDrilling casingsInterference fitWell drilling

The invention relates to a drilling rod applicable to small-well-hole and large-displacement well drilling. The drilling rod does not need to be subjected to procedures of pulling out the drilling rod, piling a support and inserting an oil pipe, a petroleum drilling process is simplified, the petroleum drilling efficiency is improved and the cost is saved; meanwhile, a secondary shoulder is additionally arranged at an engaged part of a male buckle small end and a female buckle large end; the secondary shoulder and a main shoulder form a double-shoulder structure; a main shoulder face and a thread section have certain interference fit and the secondary shoulder just has a certain auxiliary upper buckle positioning function, so that the interference fit between the main shoulder face and the thread section is accurately realized; and furthermore, the secondary shoulder can also bear one part of load at a working state and has certain overload protection effect, and the anti-torque strength of the drilling rod can also be improved and the safety of the drilling rod is guaranteed.

Owner:DP MASTER MFG

Full-section hydraulic blasting demolition method for urban viaduct

ActiveCN113389151AReduce usageImprove safety hazardsBuilding repairsBridge strengtheningRebarDrill hole

The invention discloses a full-section hydraulic blasting demolition method for an urban viaduct. The method comprises the following steps: adding a built-in reserved hole design and a groove design; manufacturing and fixing a matched formwork to a bridge steel reinforcement framework through vertical pre-buried pipelines of stand columns, beams and plates of a bridge, and pouring concrete for one-time forming, wherein built-in large pre-buried holes are used for draining water, and the three small pre-buried holes are used for arranging lighting and communication lines and traffic monitoring cables; dismantling cables arranged in the three pre-buried small holes of each pier of the viaduct and using thes mall holes as compensation holes; performing explosive charging, networking, protecting and detonating, and using a high-precision delay detonator for controlling the detonating sequence of each bridge pier blasting point and a box girder water pressure blasting point; and when the viaduct continuously collapses span by span, dividing each section of box girder into three parts to collapse. According to the method, the blasting demolition drilling construction procedure is reduced, the drilling cost is reduced, the harmful effects of noise, dust and the like are reduced, the environmental protection property is high, the construction period is short, and the cost is low.

Owner:WUHAN BLASTING ENG

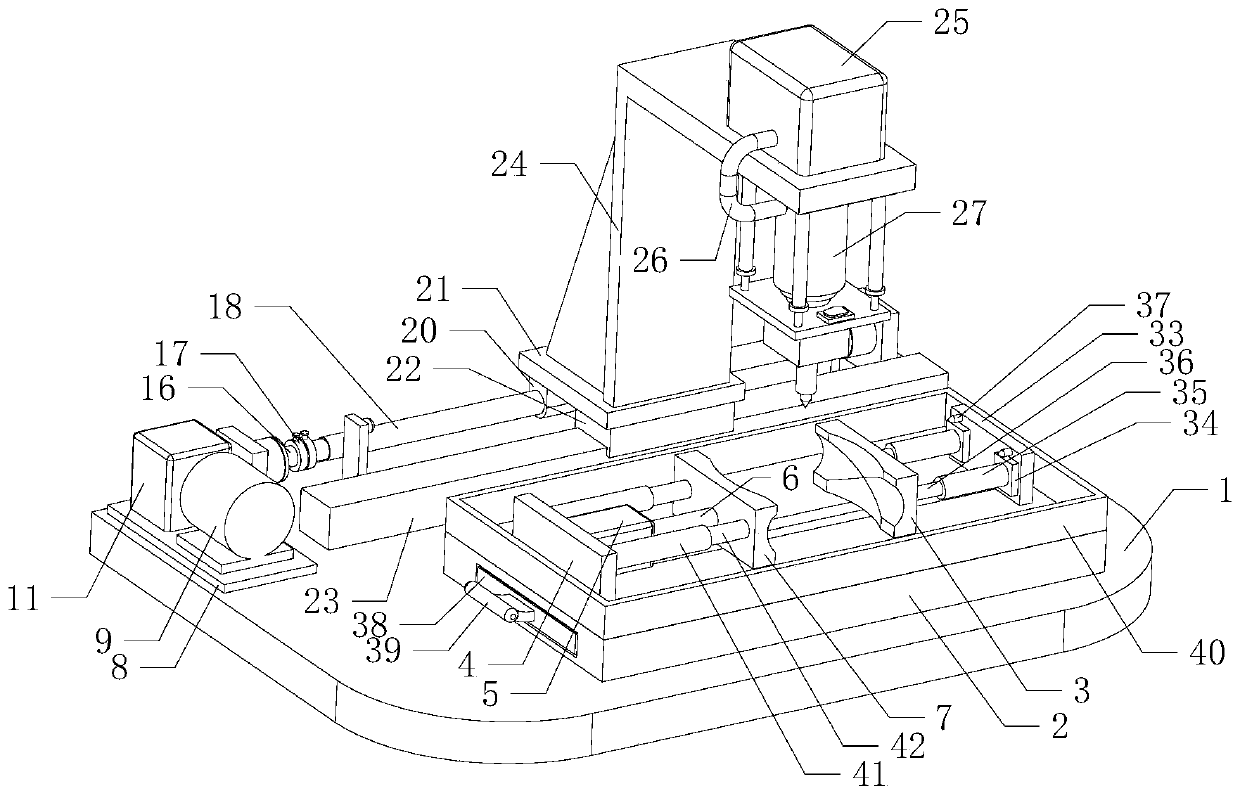

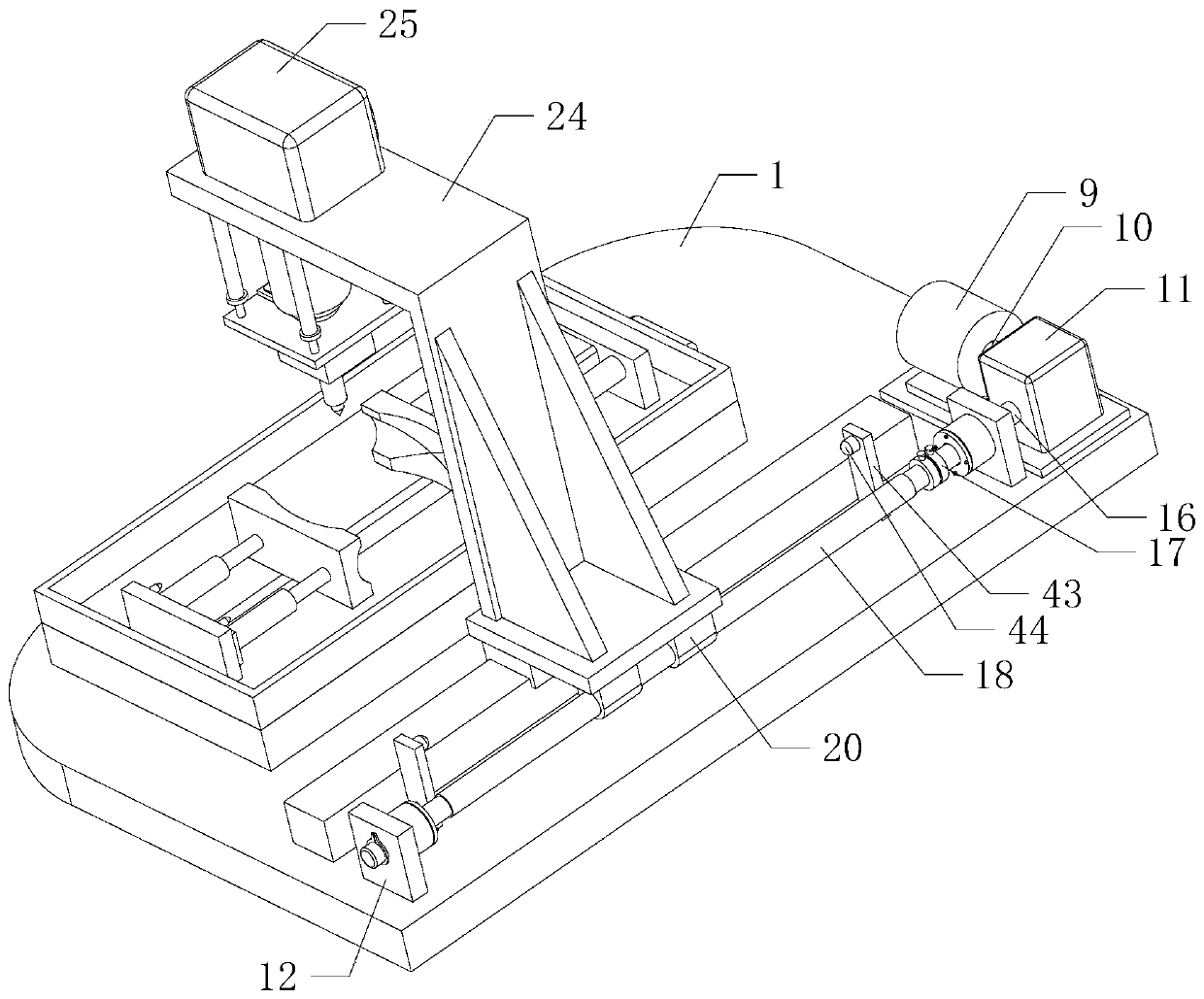

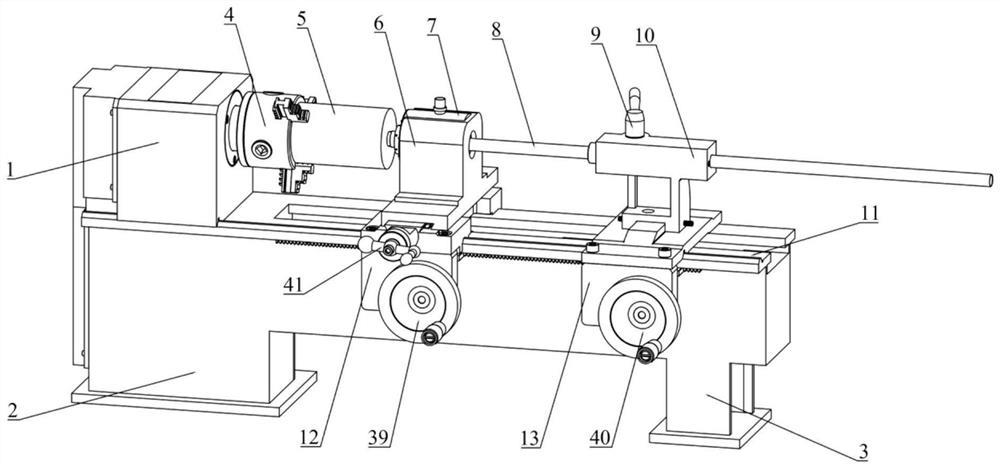

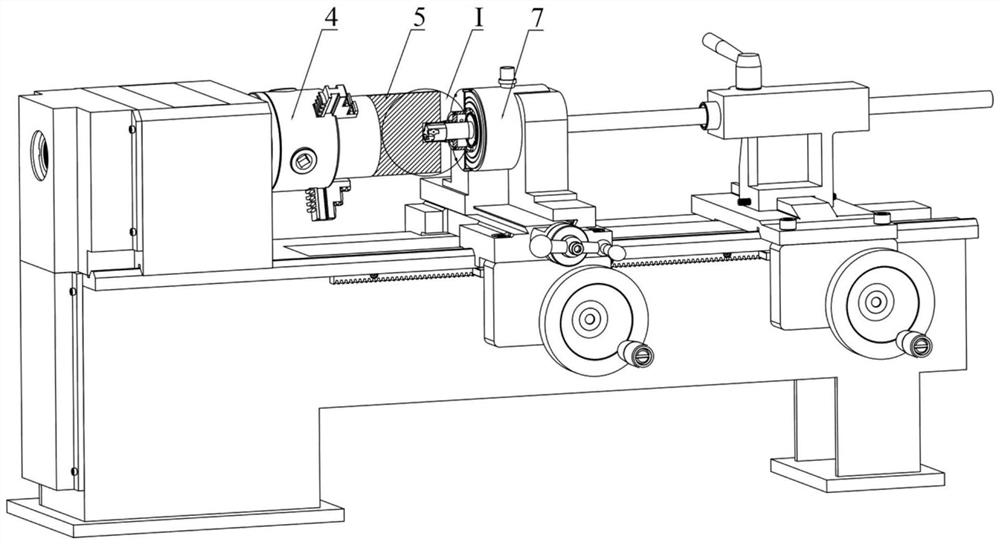

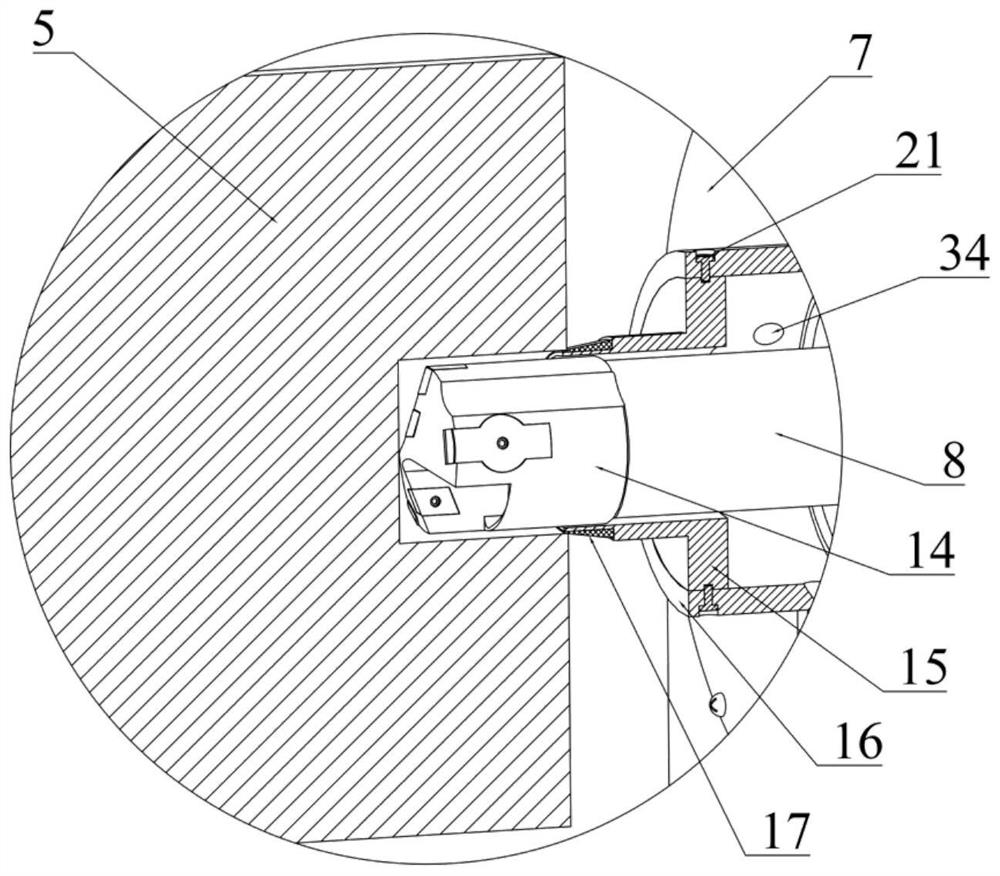

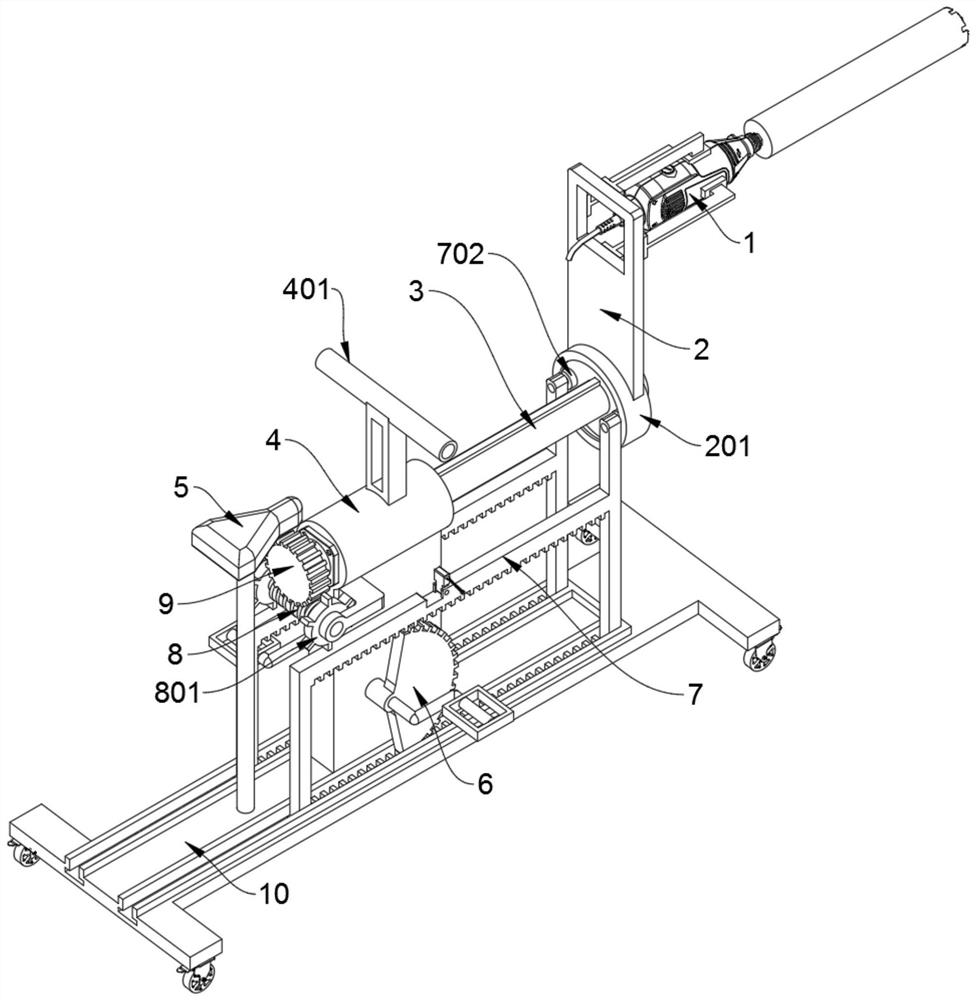

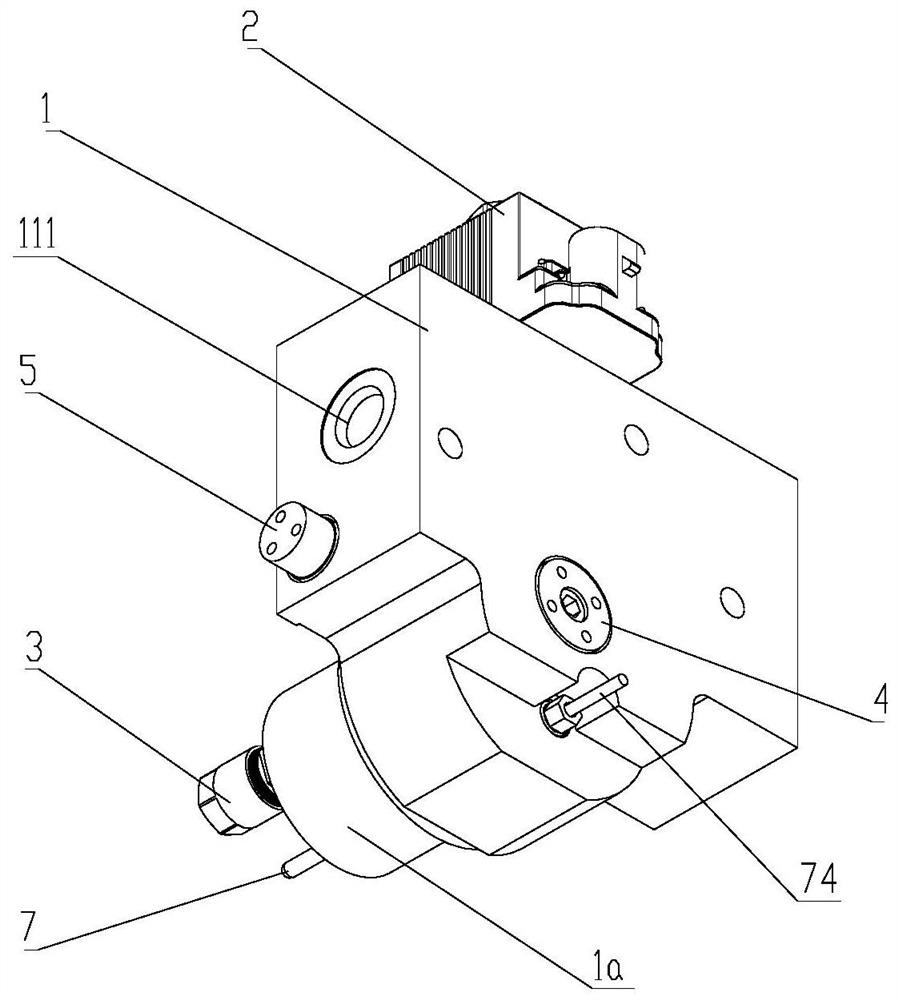

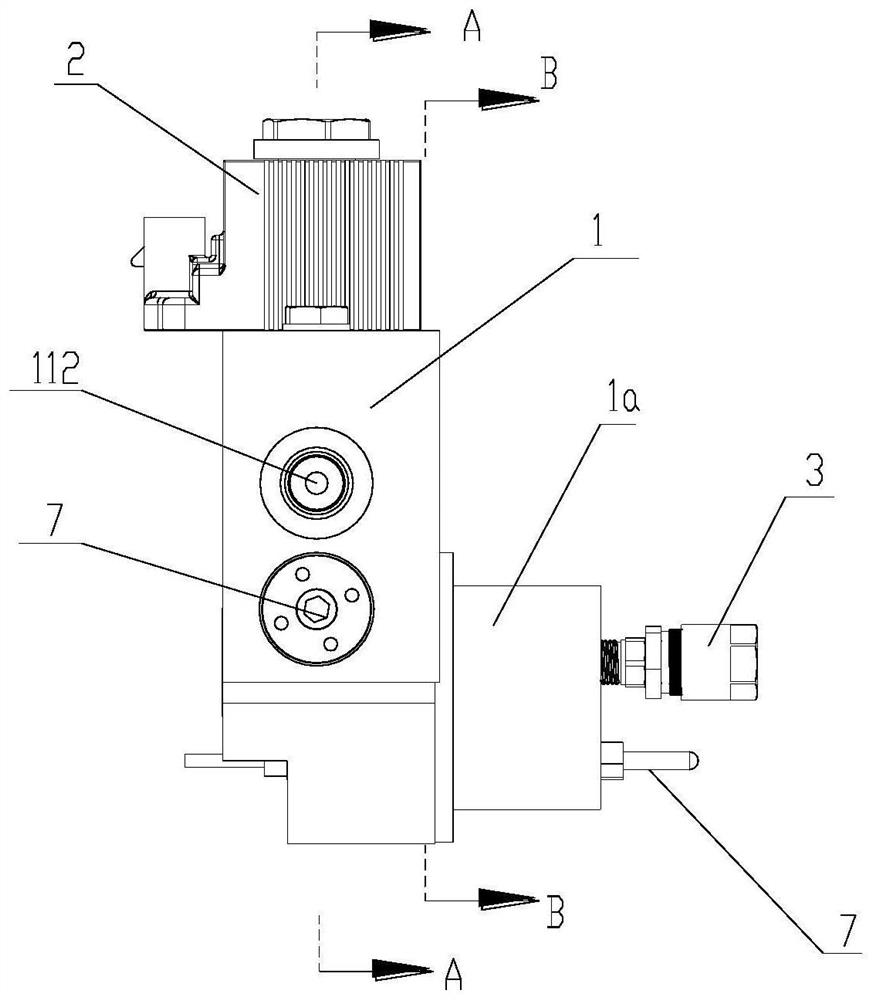

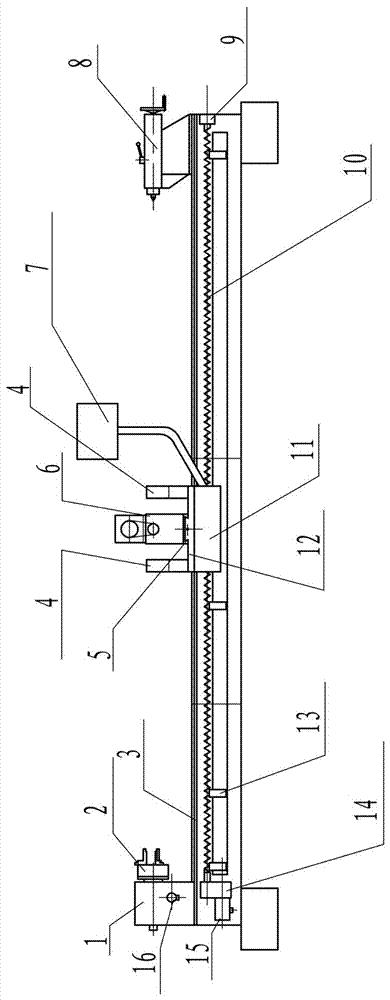

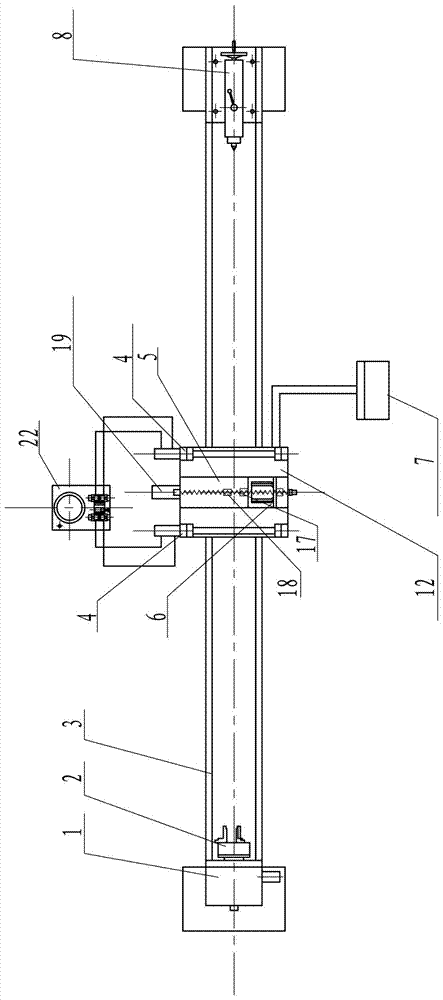

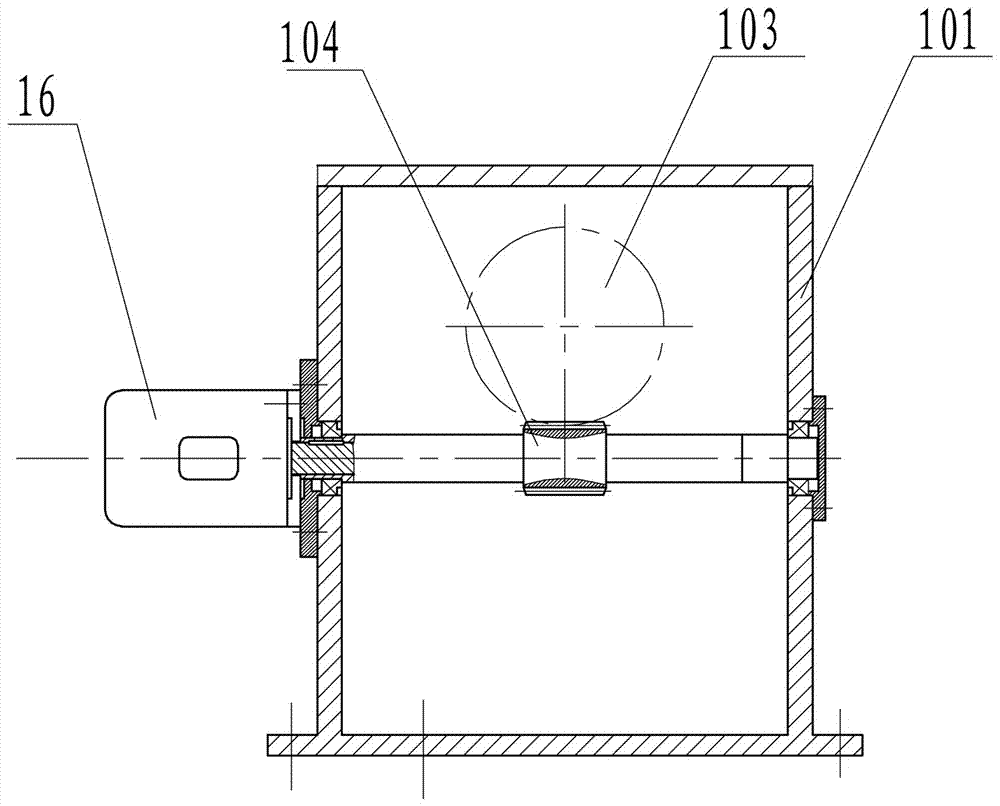

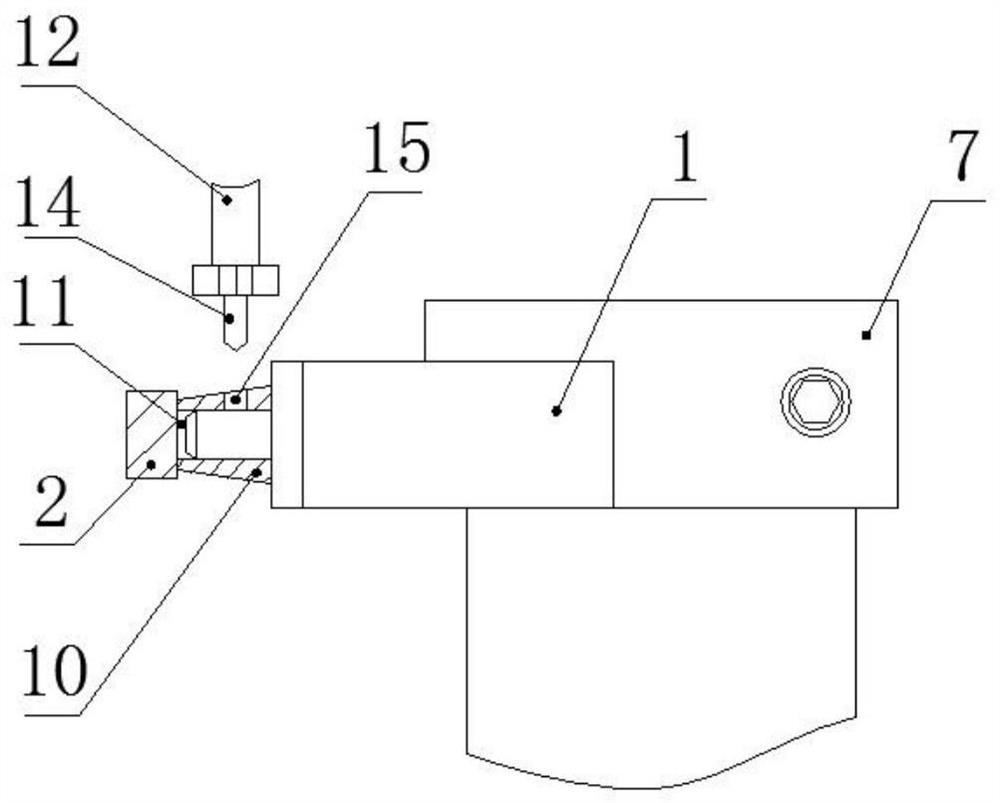

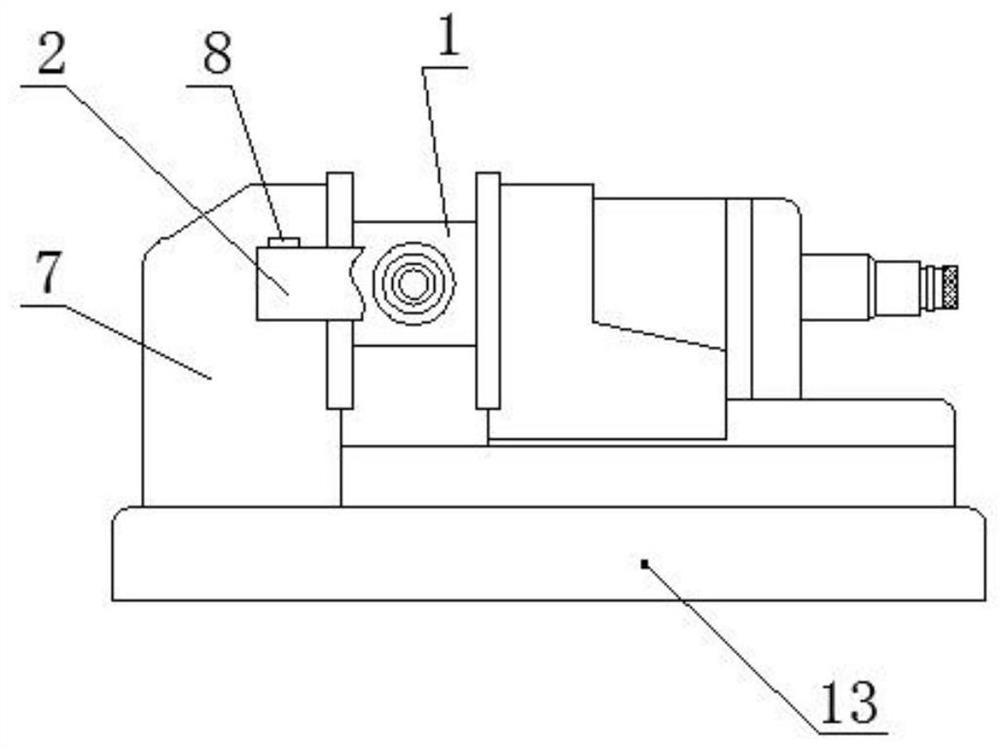

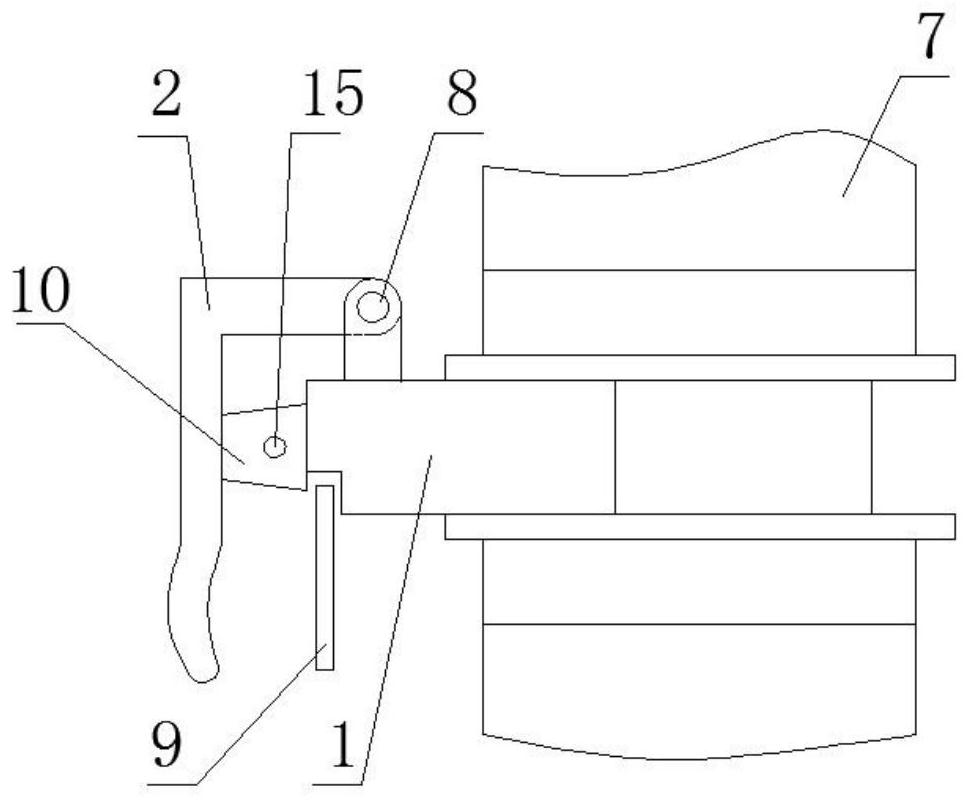

Pipe Drilling Machine

InactiveCN105965058BSimplify the drilling processReduce scribing processPrecision positioning equipmentFeeding apparatusPipe fittingEngineering

The invention provides a pipe fitting drilling machine comprising a machine body, an indexing spindle box disposed at a front end of the machine body to clamp a workpiece, a longitudinal drive system, a carriage disposed above the machine body and capable of sliding along a carriage moving guide rail with a transverse moving guide rail disposed at an upper portion of the carriage, a slide carriage frame located below the carriage and fixedly connected to the carriage, a longitudinal nut in screwing fit with a longitudinal lead screw to form a longitudinal lead screw pair together, a slide plate disposed above the carriage and capable of sliding along the transverse moving guiding rail, a transverse lead screw fixed to the carriage, a transverse nut fixed to the slide plate and in screwing fit with the transverse lead screw to form a transverse lead screw pair together, a transverse servomotor fixed to the carriage and having an output shaft fixedly connected to the transverse lead screw, a drill rod case fixed to the slide plate and used for drilling a pipe fitting, a tailstock assembly disposed at a rear end of the machine body to press against a workpiece, and a workpiece clamping device disposed above the carriage to clamp a workpiece during drilling.

Owner:国网山东省电力公司宁津县供电公司 +1

A processing fixture and processing method for drilling holes on the surface of a conical bush

ActiveCN108098388BReduce manufacturing costPrevent movementPositioning apparatusBoring/drilling componentsMachine toolMachining

The invention relates to a machining fixture and method for drilling a conoid bushing surface. The machining fixture comprises a fixture body and a handle, and one end of the fixture body is a fixed end; the other end of the fixture body is a machining end; the fixed end is fixedly connected to a machine tool workbench, and the machining end face is provided with a boss; the outer side of the machining end is provided with a reaming base, and one end of the handle is rotatably connected to the reaming base; the other end of the handle movably covers the end face of the boss; the machining method comprises the steps of preparing a workpiece and a machine tool separately, installing a cutter and the machining fixture on the machine tool, drilling holes, removing a finished conoid bushing andso forth; according to the technical scheme, the workpiece is located through the boss on the fixture body, and pressed by the handle, while the alignment of the workpiece is not required; the drilling procedures are simplified, and the operation is convenient; the workpiece is prevented from offsetting effectively, and the machining efficiency is improved; and lots of technological auxiliary time is saved, and the production efficiency and capacity are improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Downhole control pressure casing drilling method containing formation injection pressure

PendingCN114763732AReduces accidents where stress gets out of handShorten the drilling cycleSurveyConstructionsWell drillingWell logging

The invention relates to a control pressure casing drilling method for underground containing formation injection pressure. The problems that the yield and the three-production development effect are affected during drilling, closing and updating of an existing three-production casing damage well, and drilling safety is affected when drilling and closing are not conducted are mainly solved. The method is characterized by comprising the steps of drilling a well, cementing the well, installing pressure control drilling equipment and testing pressure; secondly, drilling a well in a non-oil-layer section, testing a hydraulic pressurizing anti-deviation tool, and recording the pressure of a vertical pipe and the pump displacement in the process; drilling in a second-opening casing drilling section, and performing second-opening well cementation; and logging. By the adoption of the drilling method for the control pressure casing pipe containing the formation injection pressure underground, a renewal well can be drilled under the condition that the well is not stopped, the injection-production relation of a casing damage well group can be completed in time, injection of a drilling area is not affected, and the normal block development effect is guaranteed.

Owner:DAQING PETROLEUM ADMINISTRATION +1

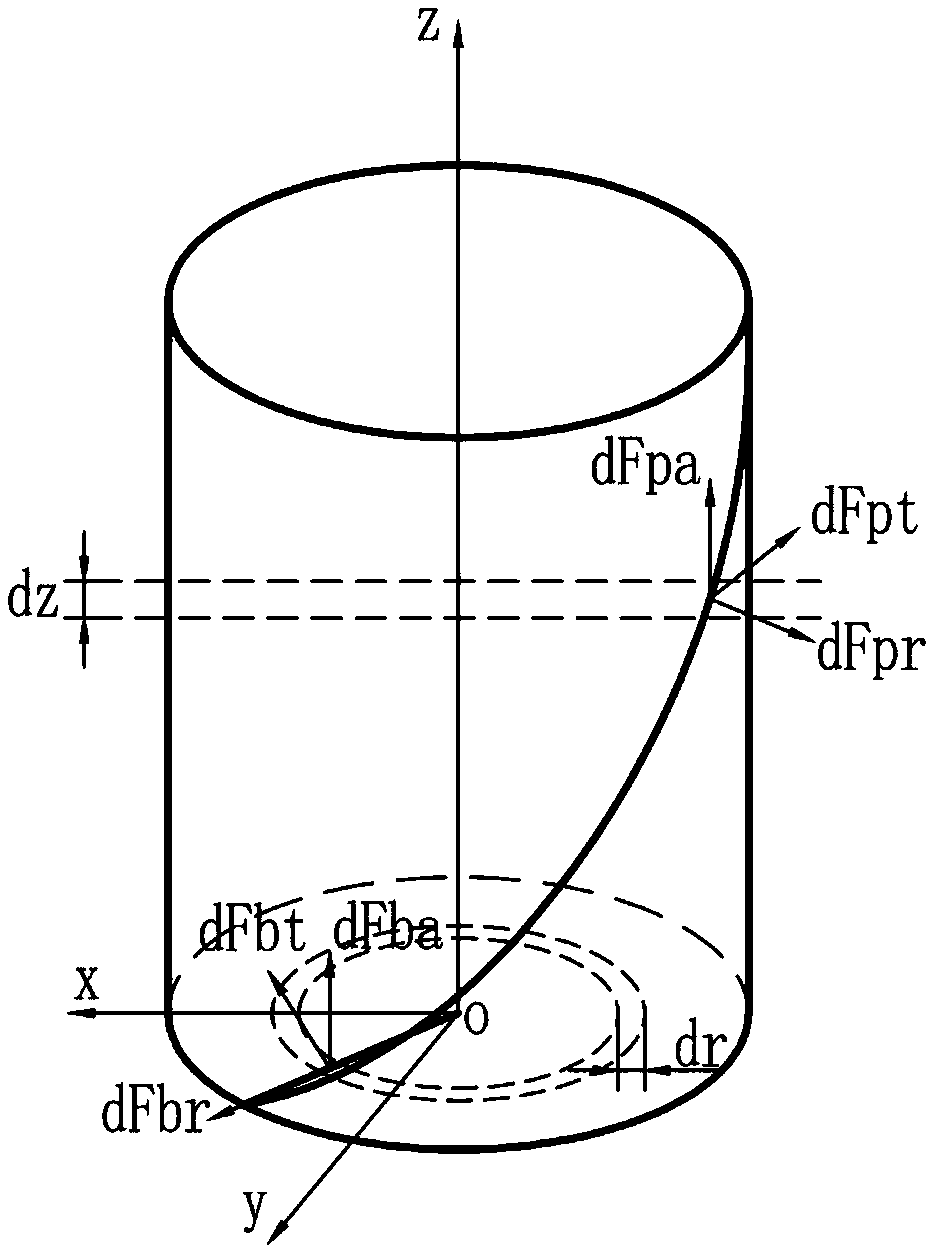

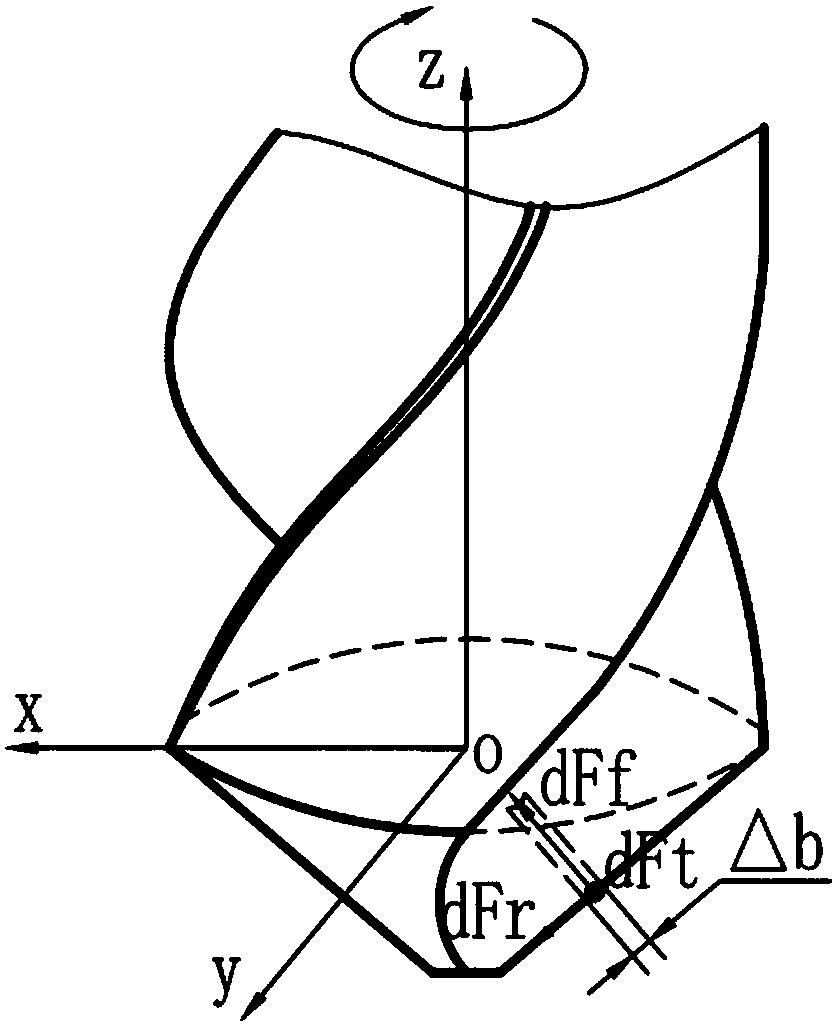

Automatic identification method for laminated interface during laminated structure drilling

ActiveCN109226801ASimplify the drilling processShorten processing timeMilling equipment detailsBoring/drilling machinesMachining timePetroleum engineering

The invention discloses an automatic identification method for a laminated interface during laminated structure drilling. The method has the advantages of measuring and recording an idle rotation speed n0 of a drilling equipment spindle; obtaining a function expression of Td=f(n) of an output torque Td of the drilling equipment spindle with respect to the rotation speed n of the drilling equipmentspindle by experiment and mathematical fitting; deriving a formula of Td=g(n,m,k) for calculating the torque by using the formula; combining two equations to obtain an equation of f(n)=g(n,m,k); determining the corresponding coefficient of mi(i=1,2,3...) for each material, determining other processing parameters except the rotation speed of the drilling equipment spindle, and obtaining the corresponding coefficient ka; solving the rotation speed ni (i = 1, 2, 3...) of the drilling equipment spindle corresponding to different materials; during drilling processing, measuring the real-time rotation speed na of the drilling equipment spindle, comparing na with n0 and ni one by one, and finding a value closest to na, wherein if the value is closest to n0, a cutter does not touch a workpiece orcuts through the workpiece, and if the velue is closest to ni, the drilling equipment processes the workpiece material corresponding to Ni. The method has the advantages of simplifying the drilling operation process, shortening the processing time and the like.

Owner:DALIAN UNIV OF TECH

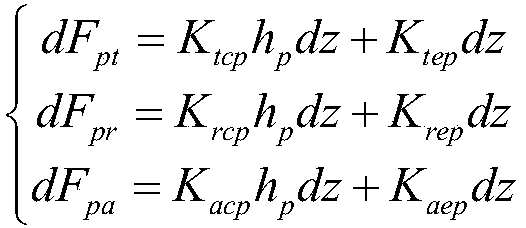

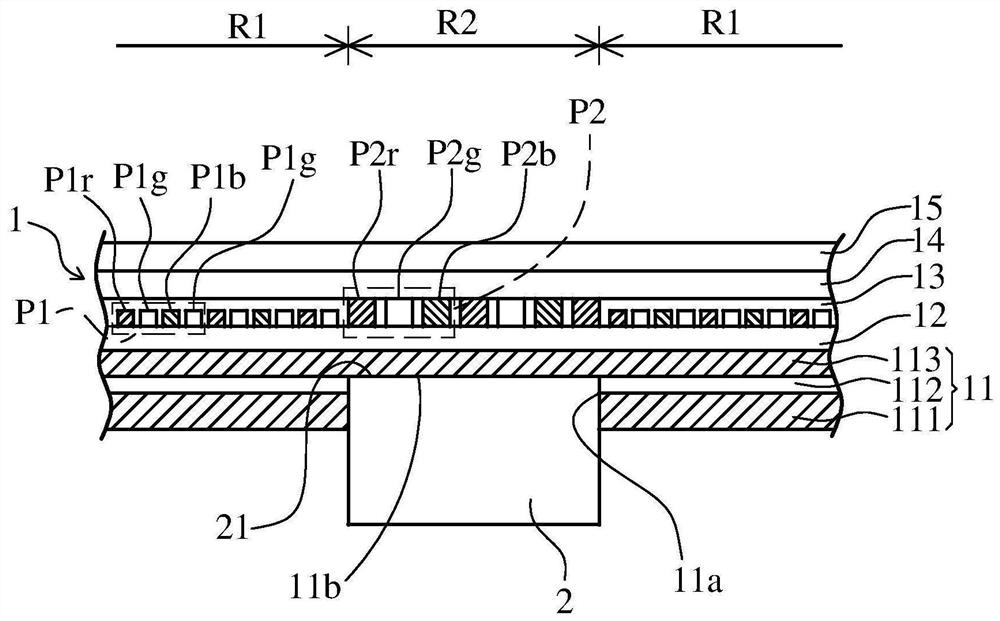

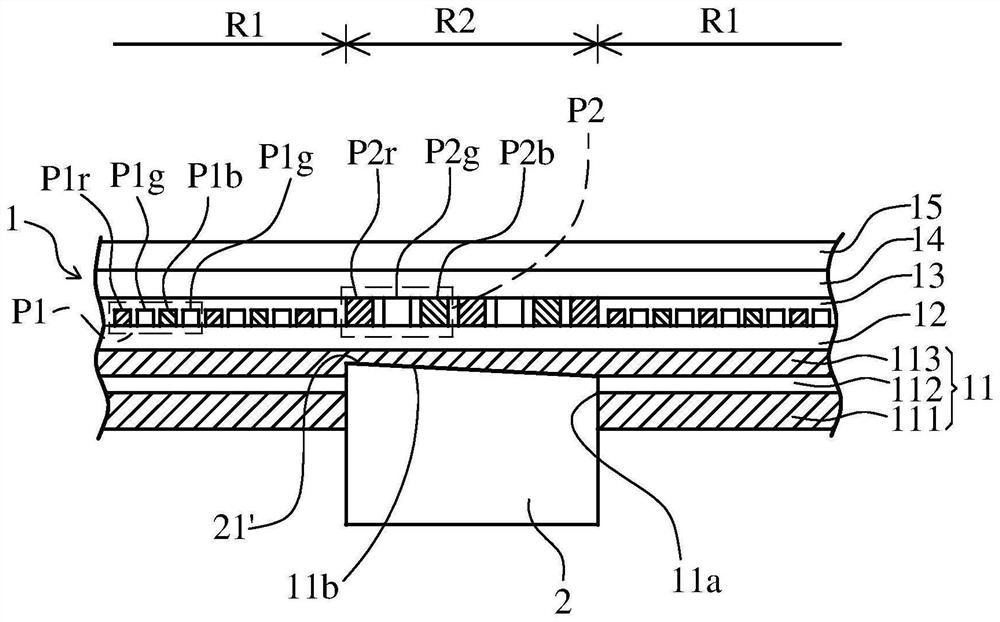

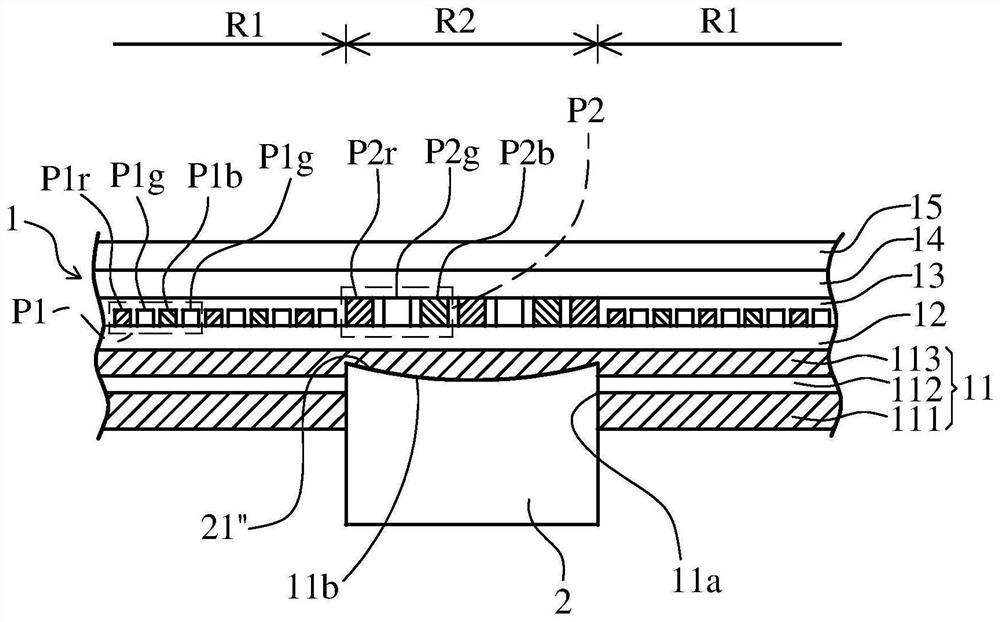

Display device and electronic device

ActiveCN111584582BSimplify the drilling processReduce complexityStatic indicating devicesSolid-state devicesComputer hardwarePixel density

The invention discloses a display device and an electronic device, comprising a display component, having a first display area and a second display area, the first display area is around the second display area, and the second display area The pixel density is less than the pixel density of the first display area, the plurality of first sub-pixels in the first display area are configured as a red, green, blue and green array, and the plurality of second sub-pixels in the second display area The pixels are configured as a red, green and blue array; and a camera component is arranged on one side of the display component at a position corresponding to the second display area. Therefore, the problems of panel opening and complicated assembly in the prior art can be solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com