Patents

Literature

93results about How to "Reduce drilling risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

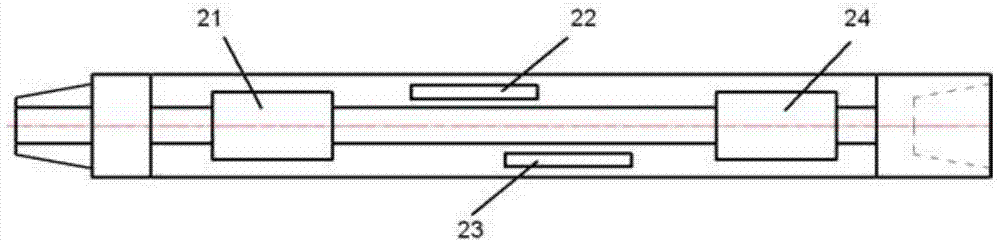

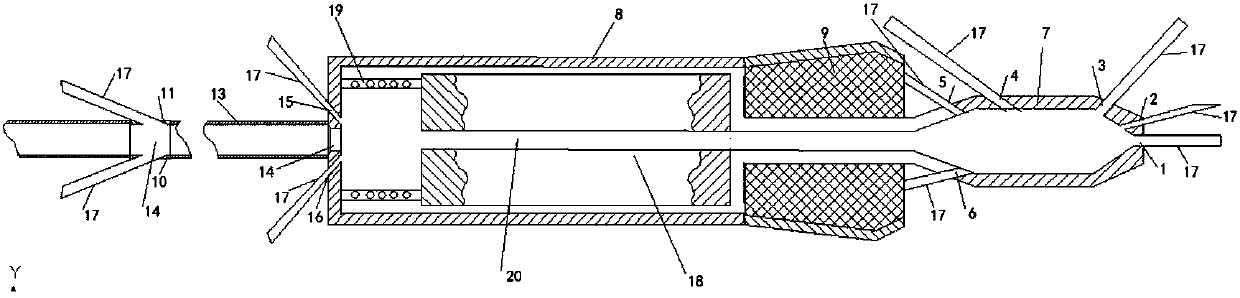

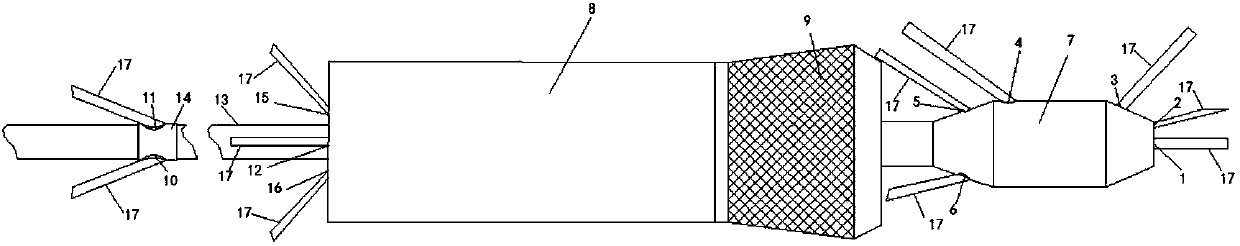

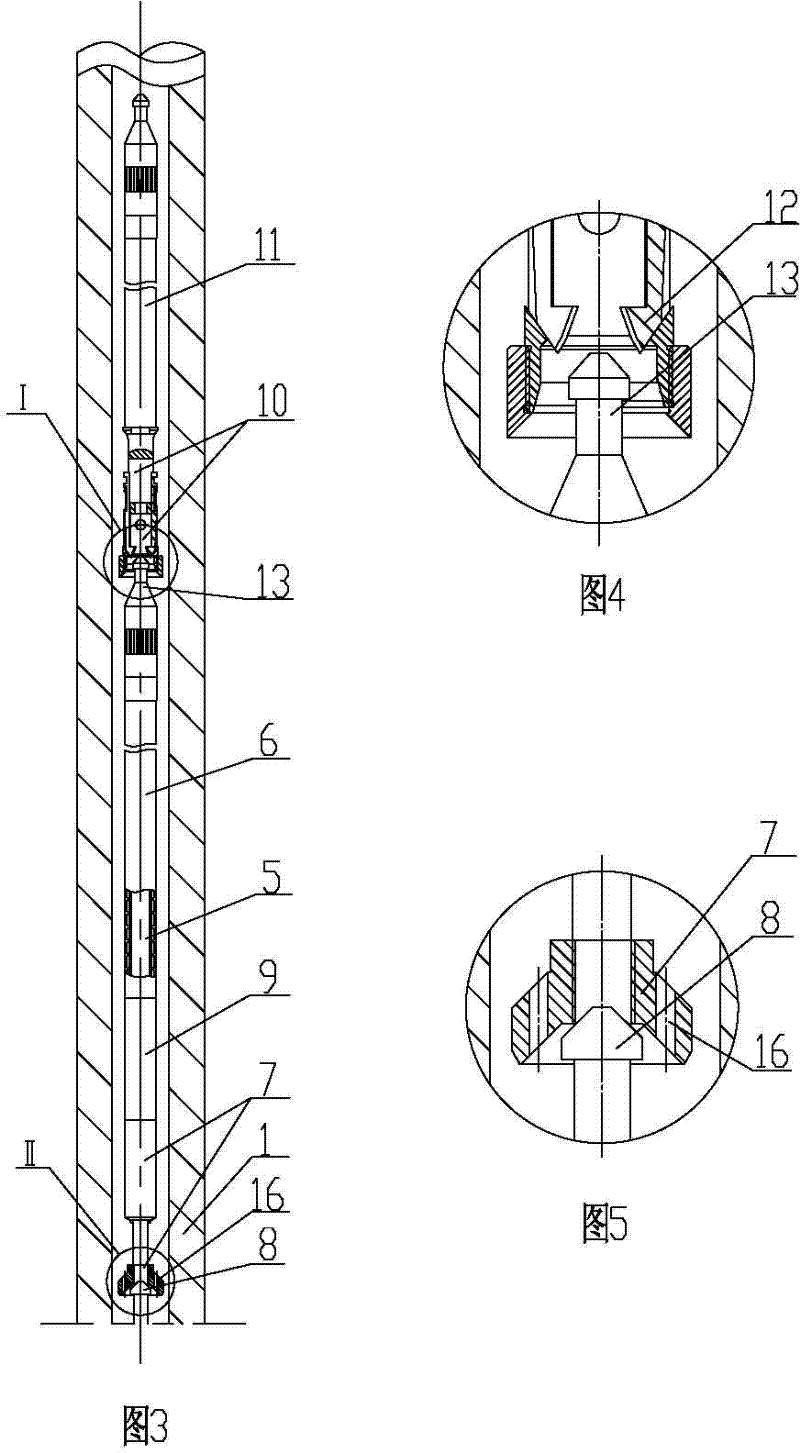

Well drilling information acoustic wave transmission relay device based on drilling string information channel

ActiveCN102733799AReduce distractionsImprove versatilitySurveyWell drillingSurface acoustic wave sensor

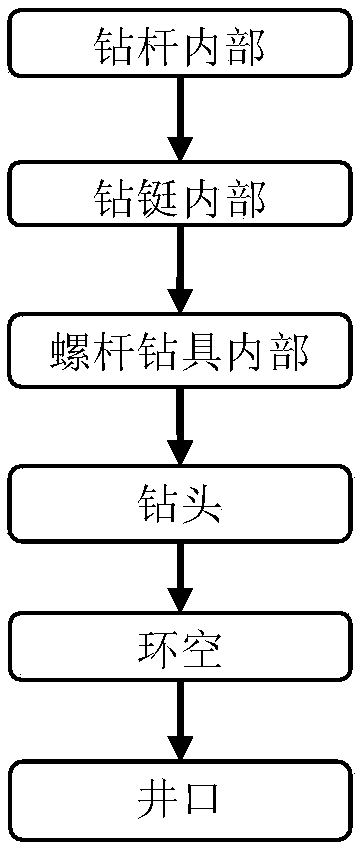

The invention relates to a drilling information transmitting device in the field of petroleum and natural gas drilling engineering, in particular to a well drilling information acoustic wave transmission relay device based on a drilling string information channel. The well drilling information acoustic wave transmission relay device comprises an acoustic wave sensor, a modulator circuit, a power source and a transmitting transducer assembly, wherein the modulator circuit receives electric signals outputted from the acoustic wave sensor; effective data are obtained after the electric signals are processed, and are transmitted to the transmitting transducer assembly; and the power source is used for supplying power for the acoustic wave sensor, the modulator circuit and the acoustic wave transmitting transducer assembly. The well drilling information acoustic wave transmission relay device can effectively work in an underground complex environment for a long time, the transmission distance of acoustic waves in a drilling string is lengthened, effective detection and directional signal transmission are ensured, and interference of a ring is decreased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

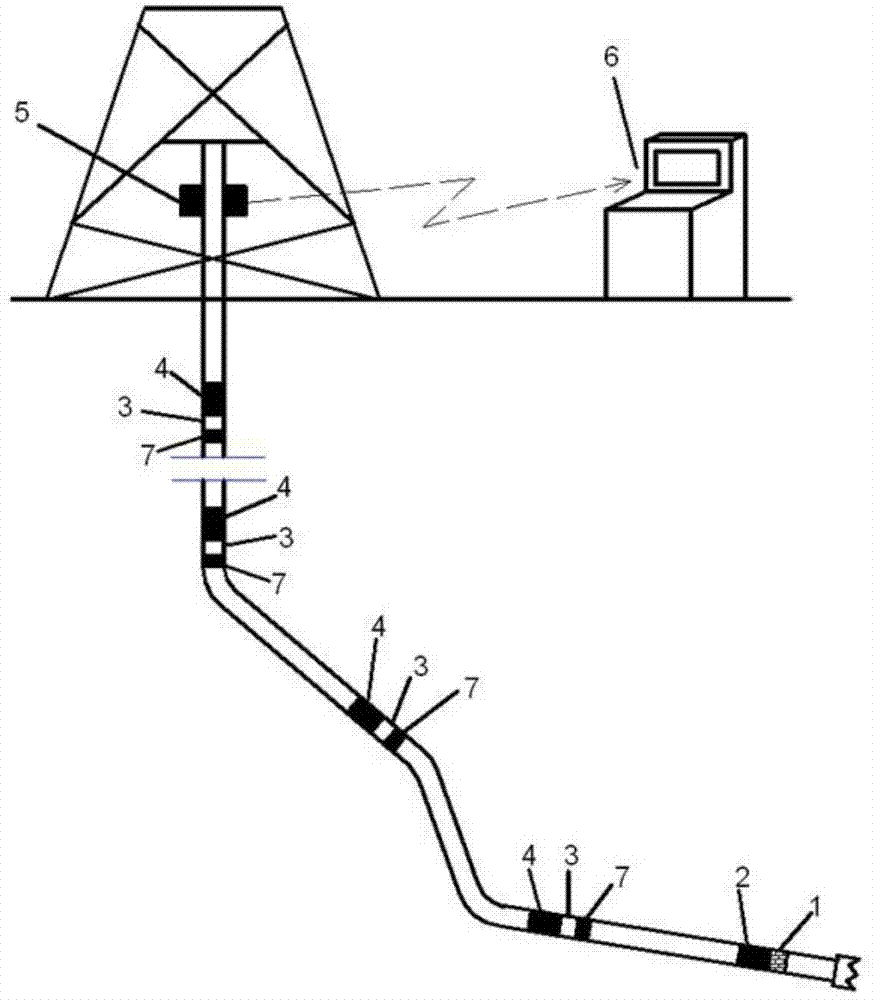

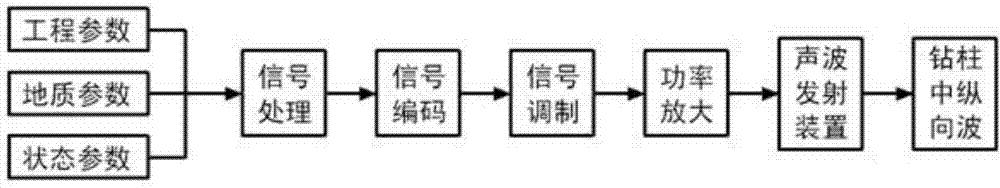

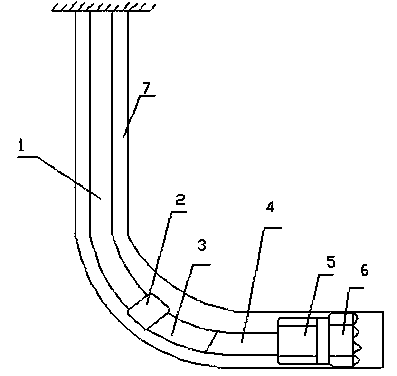

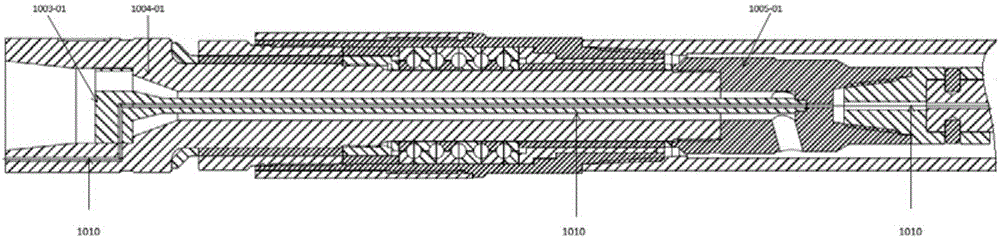

Method and system for real-time multi-parameter measurement and transmission while drilling in all well sections

The invention discloses a method and a system for implementing parameter measurement while drilling and real-time transmission to the ground at a plurality of points in a mineshaft along a drill column based on sound wave information transmission. An underground while-drilling parameter measurement system is used for acquiring underground information, the information is regulated and then transmitted to an underground signal transmitting system and transmitted upwards in a sound wave manner along the drill column; sound wave signal relay systems are used for receiving a signal upwards-transmitted from the underground, decoding the signal, combining the measurement information, and then transmitting the information upwards; afterwards, the signal is upwards-transmitted to the ground, received by a ground receiving system, decoded and then wirelessly transmitted to a ground information display and decision making system, wherein a plurality of relay systems are arranged along the drill column according to the well drilling construction requirements so as to realize real-time acquisition of the parameters of all well sections along a well body. The method and the system provided by the invention can be used for acquiring real-time underground parameters of all well sections so as to effectively reduce the risk of accidents such as underground jamming of a drill and hole-wall collapse, improve the well drilling efficiency and provide support for best well drilling decisions. The method and the system can be used for greatly improving the precise pressure control capability especially during a managed pressure drilling process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

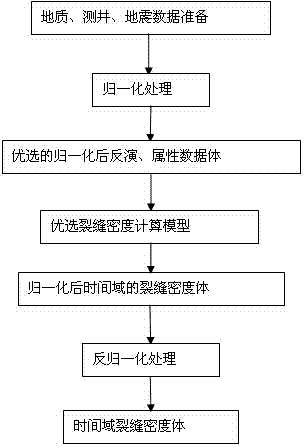

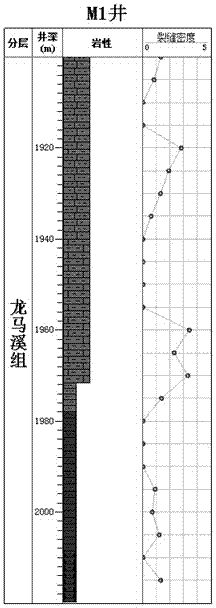

Method for using fracture density curve to forecast fracture density body

ActiveCN104502997AImprove exploration efficiencyReduce drilling riskGeological measurementsDensity curveTime domain

Disclosed is a method for using a fracture density curve to forecast a fracture density body. The method for using the fracture density curve to forecast the fracture density body includes following steps: (1) preparing geology, well logging and earthquake data, performing normalization processing, inversion and attribute data body optimization on the related data, and obtaining the fracture density curve and an optimized data body of all wells after being normalized; (2) building various fracture density calculation models, bringing data on the fracture density curve of all the well after being normalized and curve data of the optimized data body into calculation, and selecting the fracture density calculation model most approximate to an actual fracture density situation according to calculation results; (3) bringing the optimized data body into the selected fracture density calculation model for calculating so as to obtain fracture density bodies after being normalized, and then obtaining the fracture density body of a time domain through reverse normalization processing. The method for using the fracture density curve to forecast the fracture density body can complete detailed description for the fracture density data body of the time domain, and then reduces well drilling risk, and improves shale gas exploration benefit.

Owner:CHINA PETROCHEMICAL CORP +2

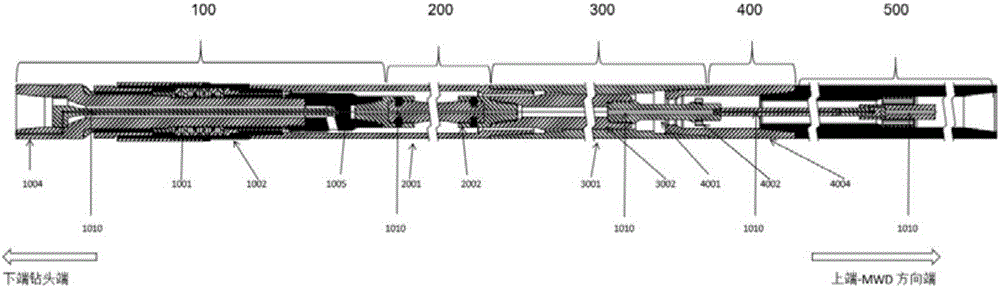

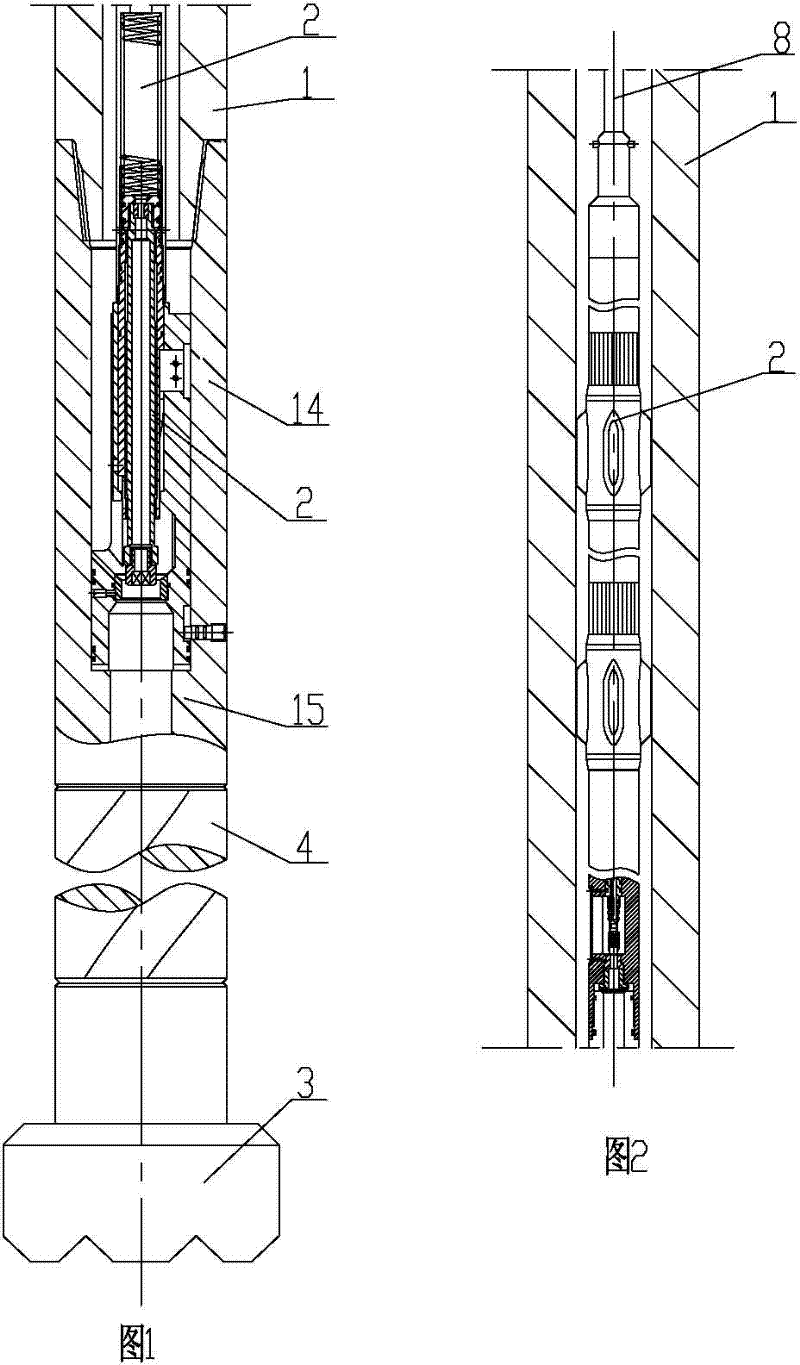

Complex structural well drag-reduction wrenching-reduction compound drilling method

ActiveCN103510871AReduce frictional torqueReduce drilling riskDrilling rodsDirectional drillingPetroleum engineeringDrill bit

The invention discloses a complex structural well drag-reduction wrenching-reduction compound drilling method. An underground drag-reduction wrenching-reduction device is arranged between an upper-portion drilling rig and a measurement-while-drilling drilling assembly combination, and therefore the upper-portion drilling rig can rotate independently relative to the measurement-while-drilling drilling rig; a reaction torque balancing device is arranged between a power drilling rig and a drill bit, and the disturbance of the reaction torque generated by a power drilling rig to a tool face is eliminated. The complex structural well drag-reduction wrenching-reduction compound drilling method has the advantages that the drag-reduction wrenching-reduction device can change the drill string sliding drilling into rotary drilling during the guiding drilling process, the friction resistance and the torque loss are reduced, and the occurrence rate of complex situations that the drill string is stuck and clamped is reduced; the reaction torque balancing device can effectively eliminate the influence of the reaction torque generated by a power drilling rig on the tool face, the tool face is controlled to be stable, the well track control accuracy is improved, the well body quality is improved, and complex structure well efficient drilling is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

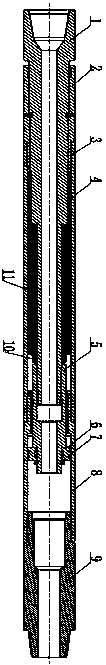

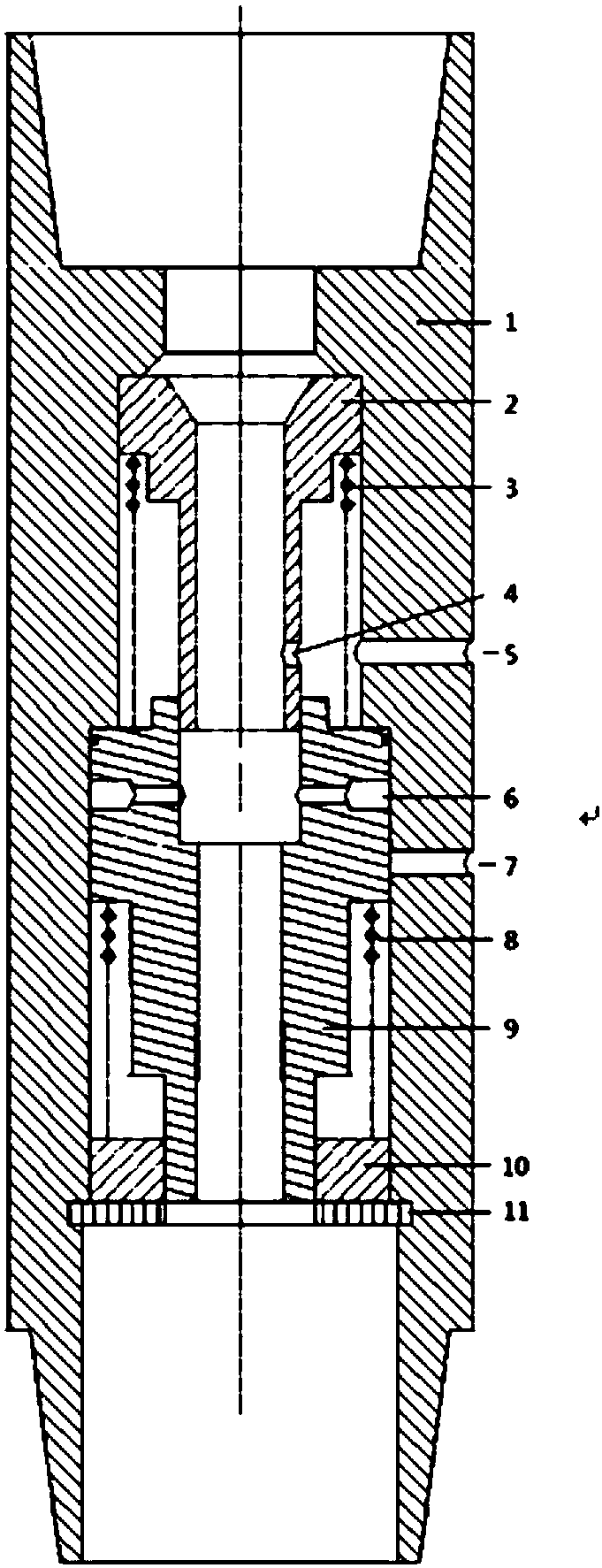

Line-passing screw drilling tool

InactiveCN106639898AAchieve full over-the-wire connectionRealize power supplySurveyDrilling rodsWell drillingWell logging

The invention relates to a line-passing screw drilling tool comprising a driving assembly, a universal shaft assembly, a motor assembly and a falling-proof assembly which are arranged in sequence. The line-passing screw drilling tool has the advantages that (1), a complete line-passing connection of a screw from the upper end to the lower end is achieved; (2), the lower end of the screw can be connected with an independent measuring short section or module / well logging short section or module such as a near-bit geosteering measuring short section or rotating guiding system; (3), the power supply and signal bidirectional communication of instruments of the upper end and the lower end of the screw are achieved; (4), the centralized and uniform power supply through the upper end of the screw can be selected, so that the system structure is simplified; and (5), the measuring short section between a drill and the screw is shortened, and the well drilling risk is reduced.

Owner:北京赛诺凤凰能源科技有限公司

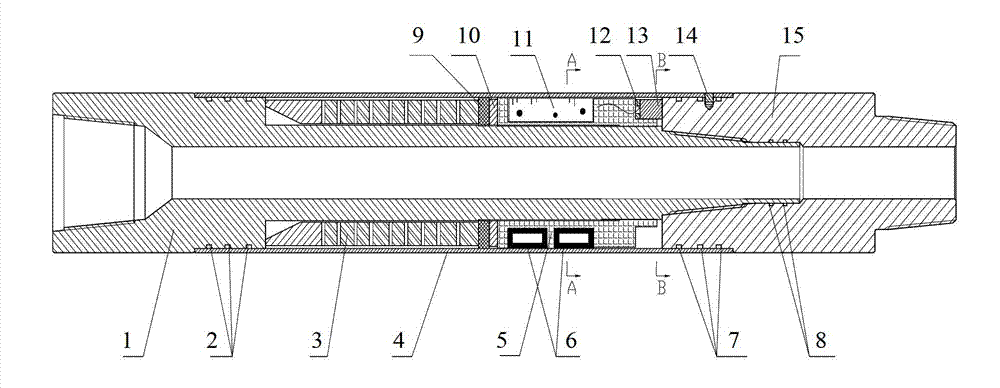

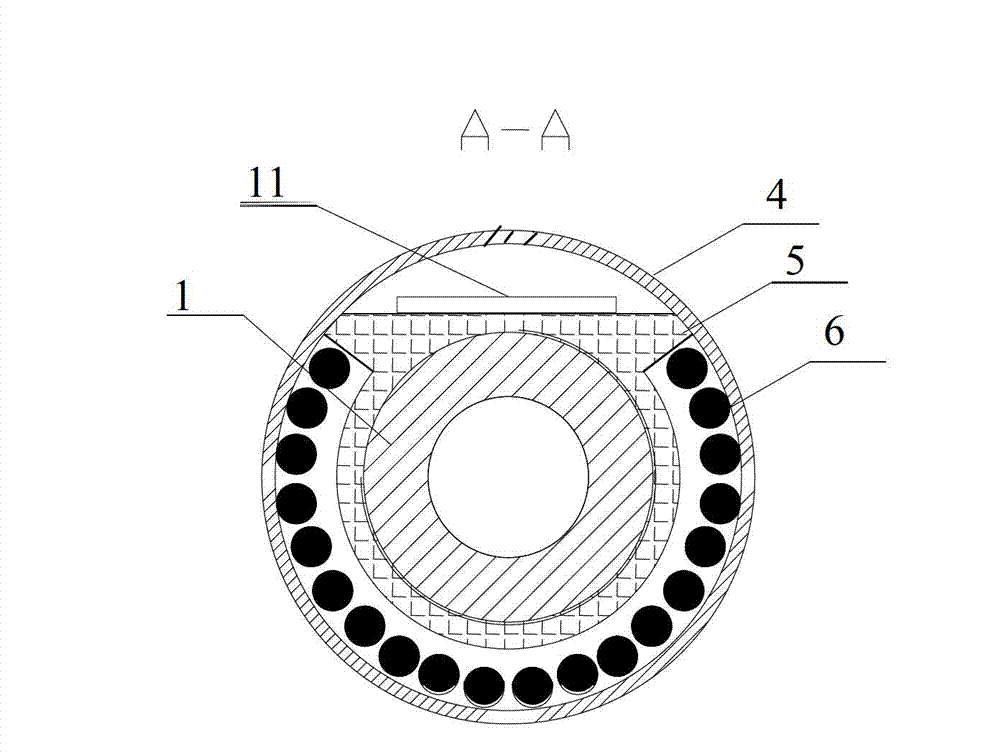

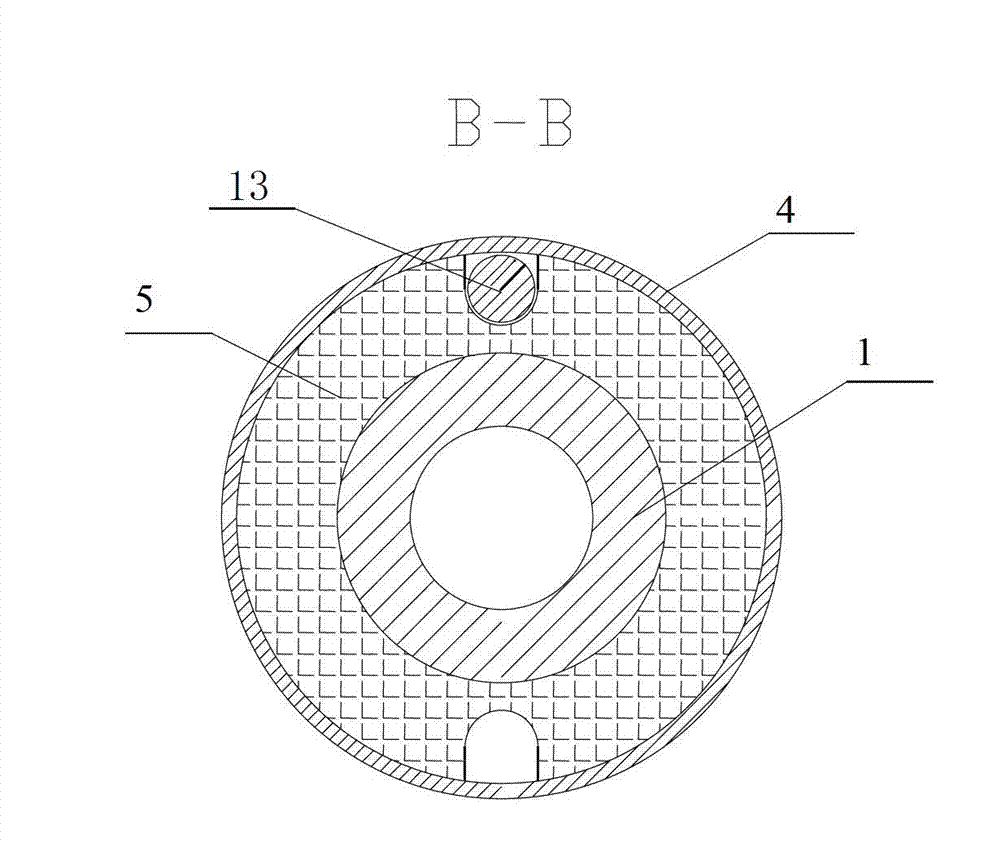

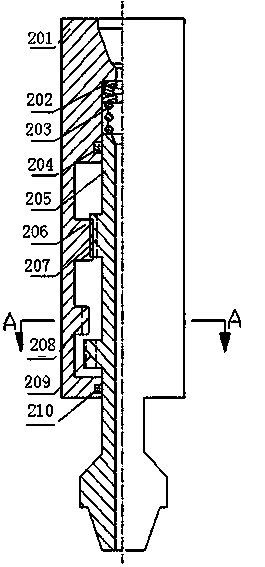

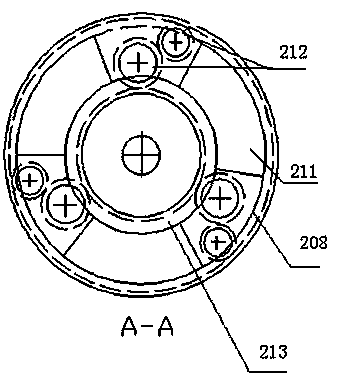

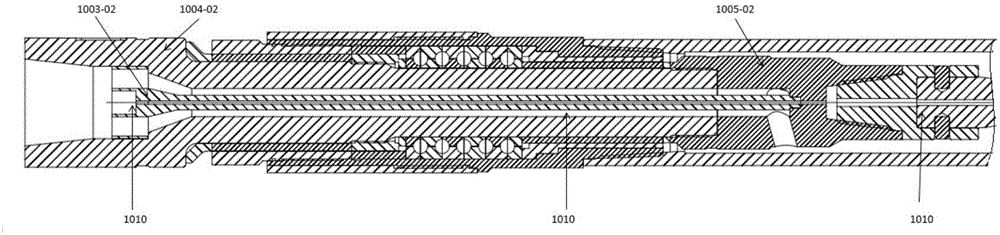

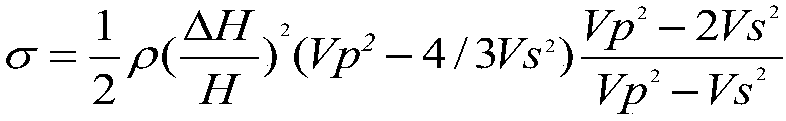

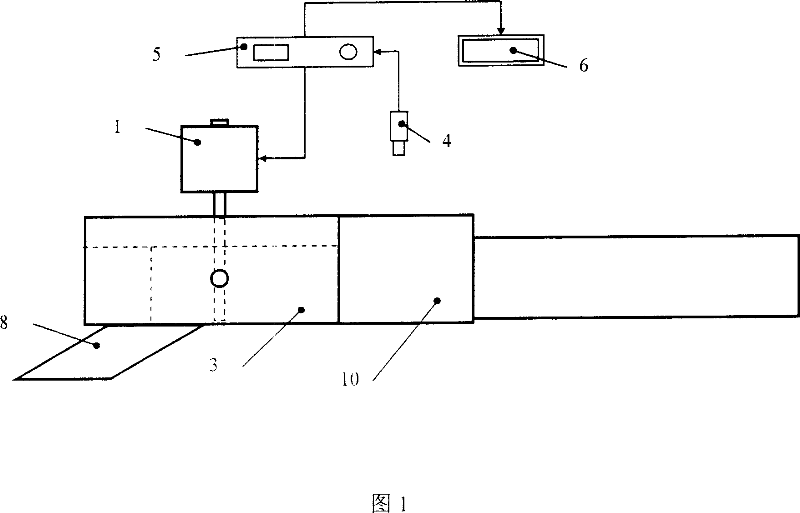

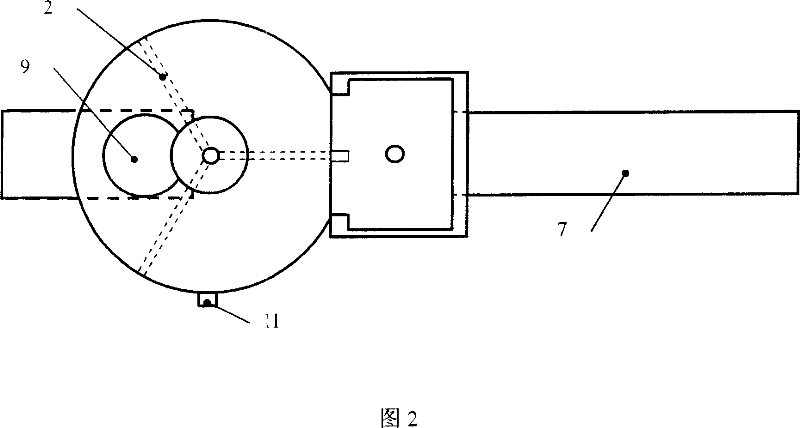

Information while drilling sound wave transmission relay transmitting device

ActiveCN103382837AImprove the effective transmission distanceKeep abreast ofSurveyWell drillingTransducer

The invention relates to the technical field of devices for transmitting information while drilling of petroleum and natural gas drilling engineering, in particular to an information while drilling sound wave transmission relay transmitting device. The information while drilling sound wave transmission relay transmitting device comprises a transducer connector, a sound wave receiving connector, a sound wave receiving sensor, an instrument cabin body, an instrument cabin sealing assembly, an underground power module, an underground circuit module and a sound wave transducer assembly. The sound wave receiving connector is fixedly installed at the lower portion of the transducer connector. The information while drilling sound wave transmission relay transmitting device is reasonable and compact in structure and convenient to use, receives a sound wave signal transmitted by a lower-portion drill column through the sound wave receiving sensor, converts the sound wave signal into an electrical signal and transmits the electrical signal to the underground circuit module, and the electrical signal is disposed by the underground circuit module and then transmitted to the sound wave transducer assembly. The information while drilling sound wave transmission relay transmitting device can greatly increase an effective transmission distance of the sound wave signal, accordingly reduces drilling risk, improves the well drilling benefit and has the advantages of being good in overall strength, flexible in use, good in adaptability and accurate and quick in transmission.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

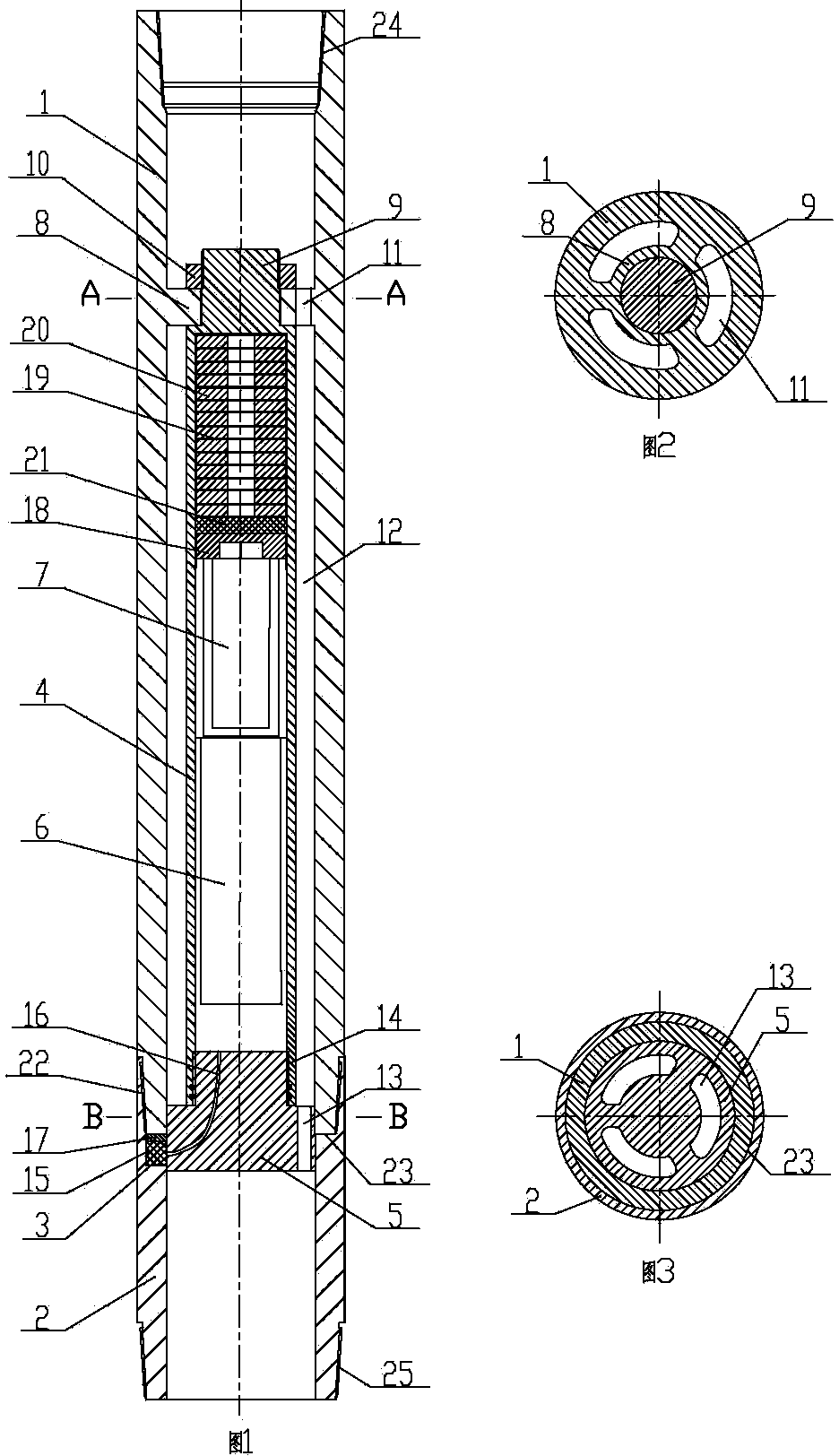

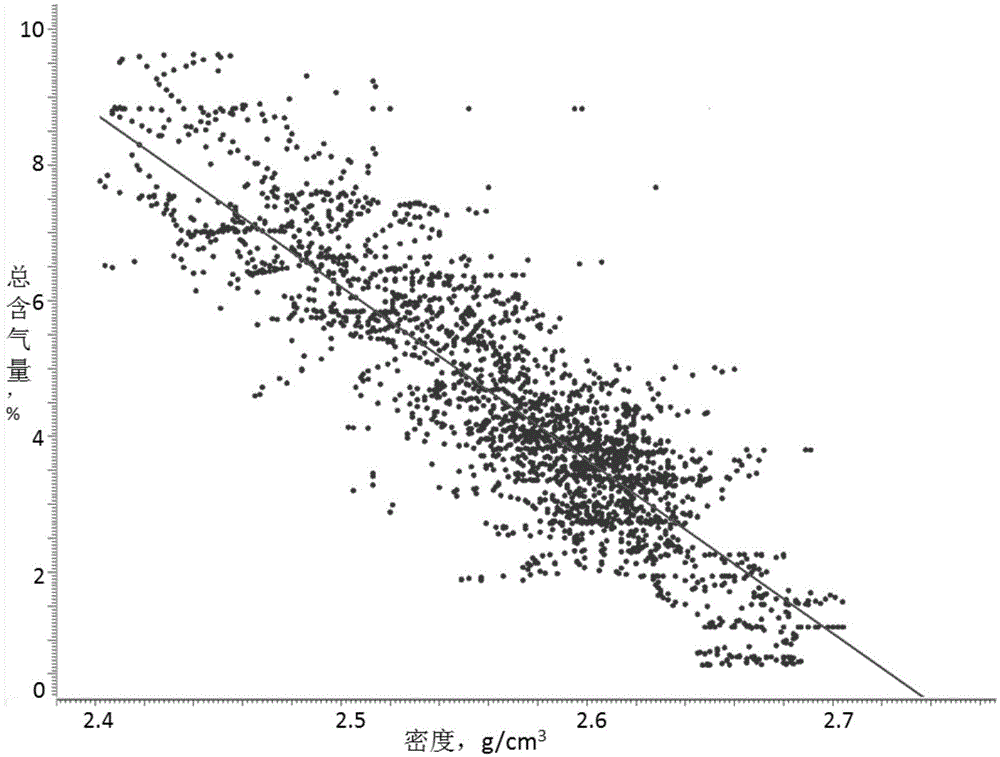

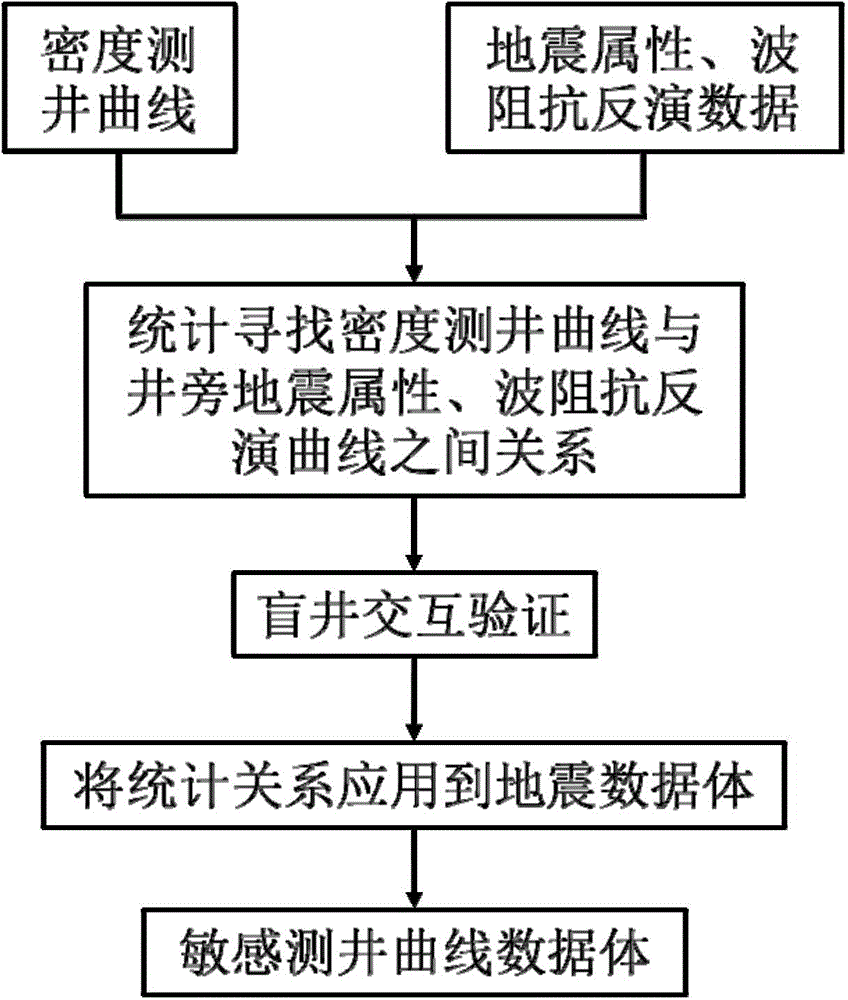

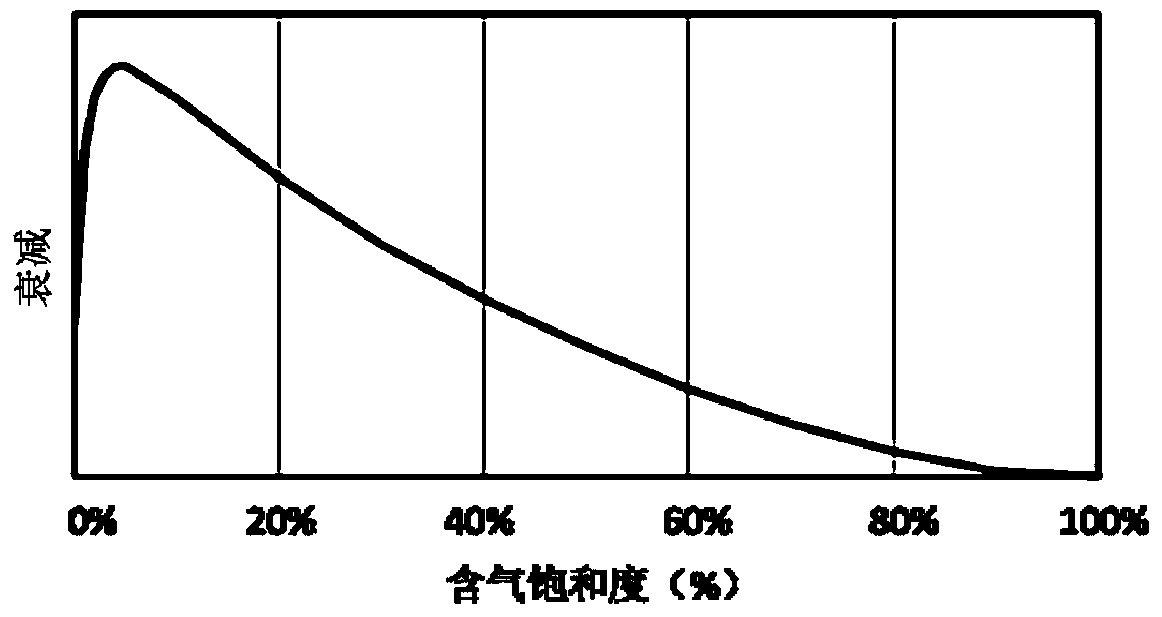

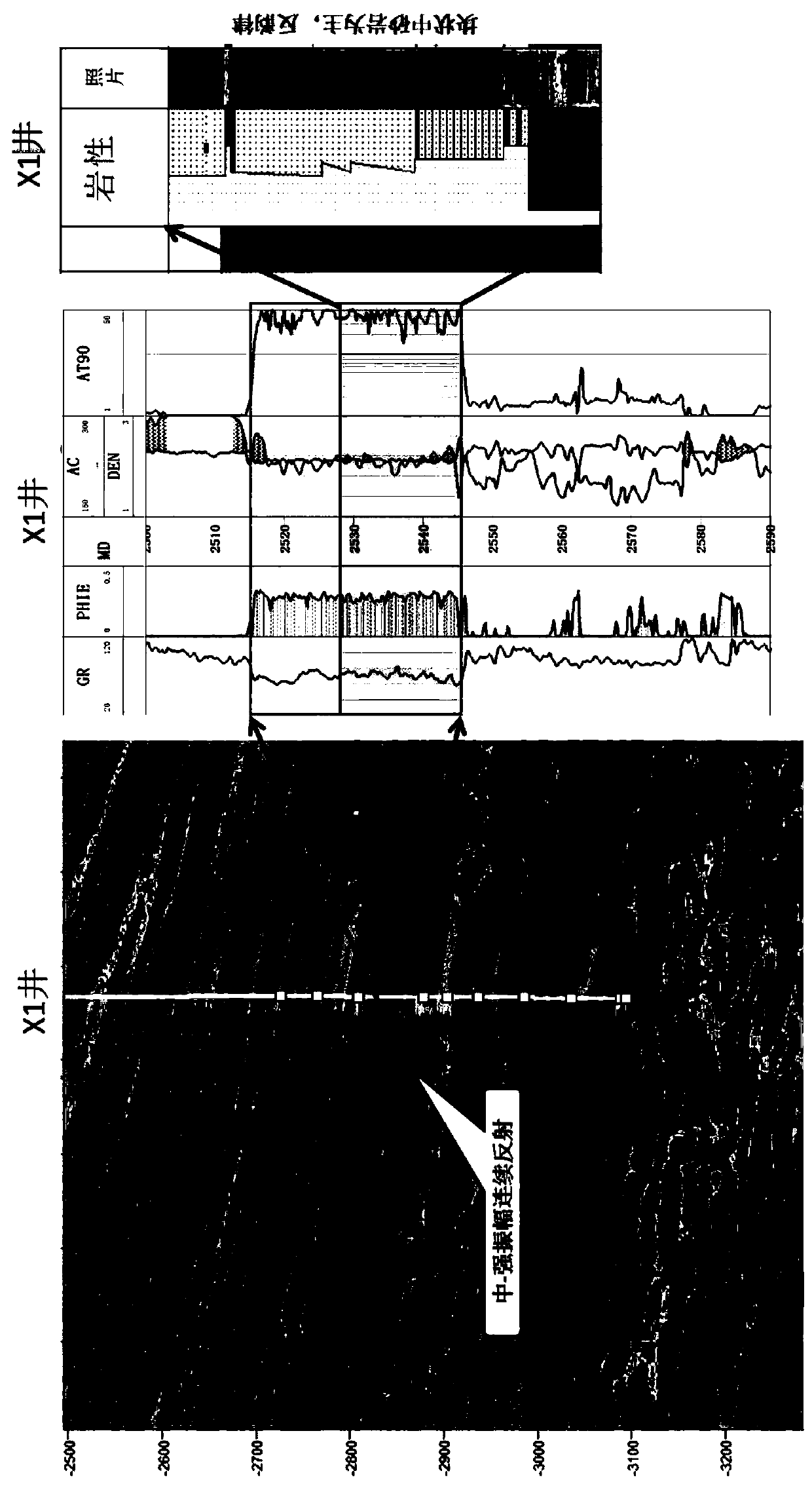

Method for predicting gas content of shale by using seismic data

ActiveCN105319588AImprove exploration efficiencyReduce drilling riskSeismic signal processingDensity curveDensity based

The invention provides a method for predicting gas content of shale by using seismic data and belongs to the petroleum and natural gas exploration field. The method includes the following steps that: (1) geological, logging and seismic data are prepared; (2) a density logging curve-based gas content calculation model, that is VGAS=f(DEN) (1), is established through using high correlation between a density logging curve and shale gas content data, wherein VGAS is gas content, m<3> / t, DEN is a density logging curve, g / cm<3>, and f is a function relational expression between gas content and density; (3) post stack multi-attribute inversion is carried out, so that density curve data required by the gas content calculation model can be obtained; and (4) gas content prediction is carried out: the density curve data obtained in the step (3) are introduced into the formula (1), so that the gas content of the shale can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

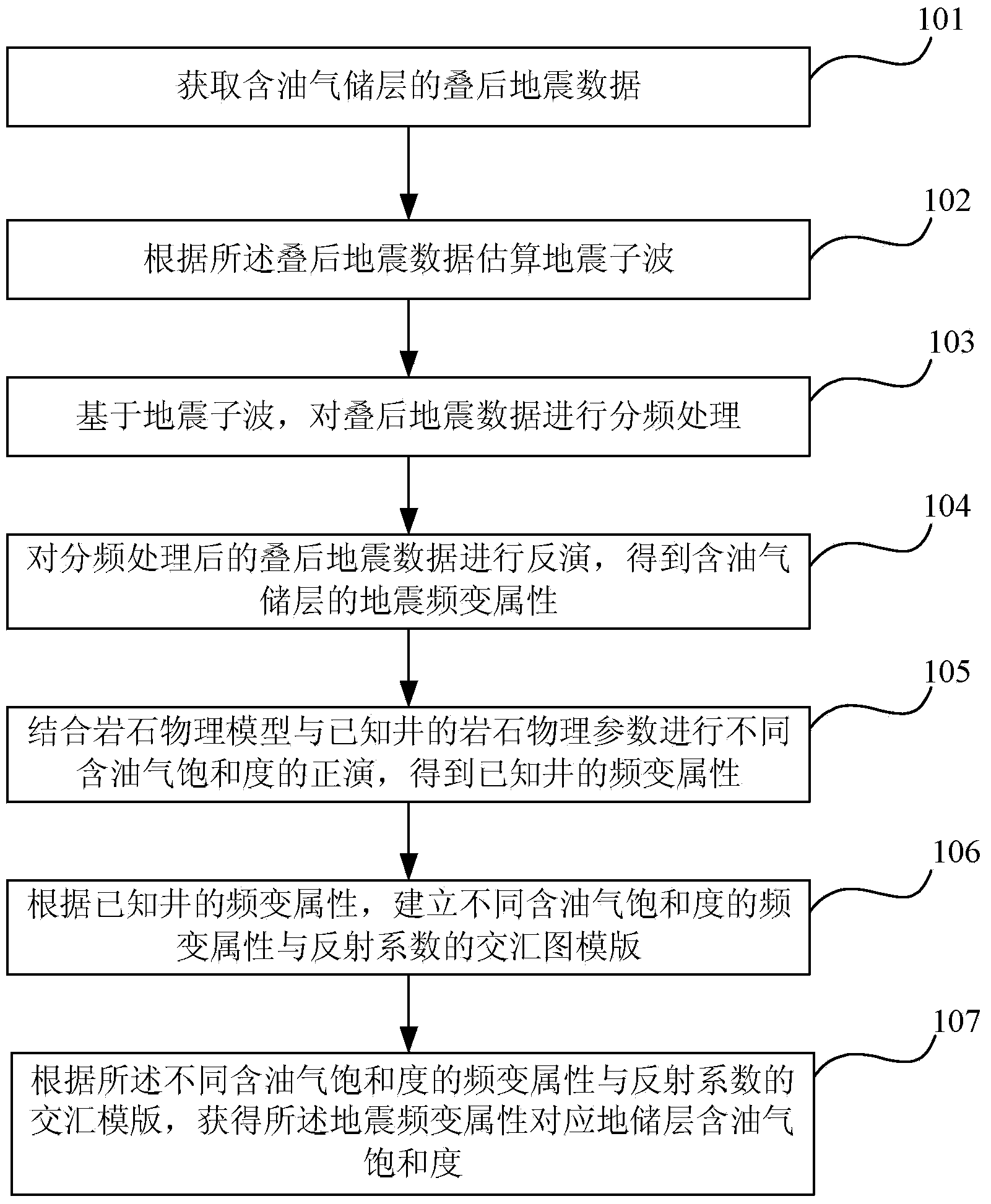

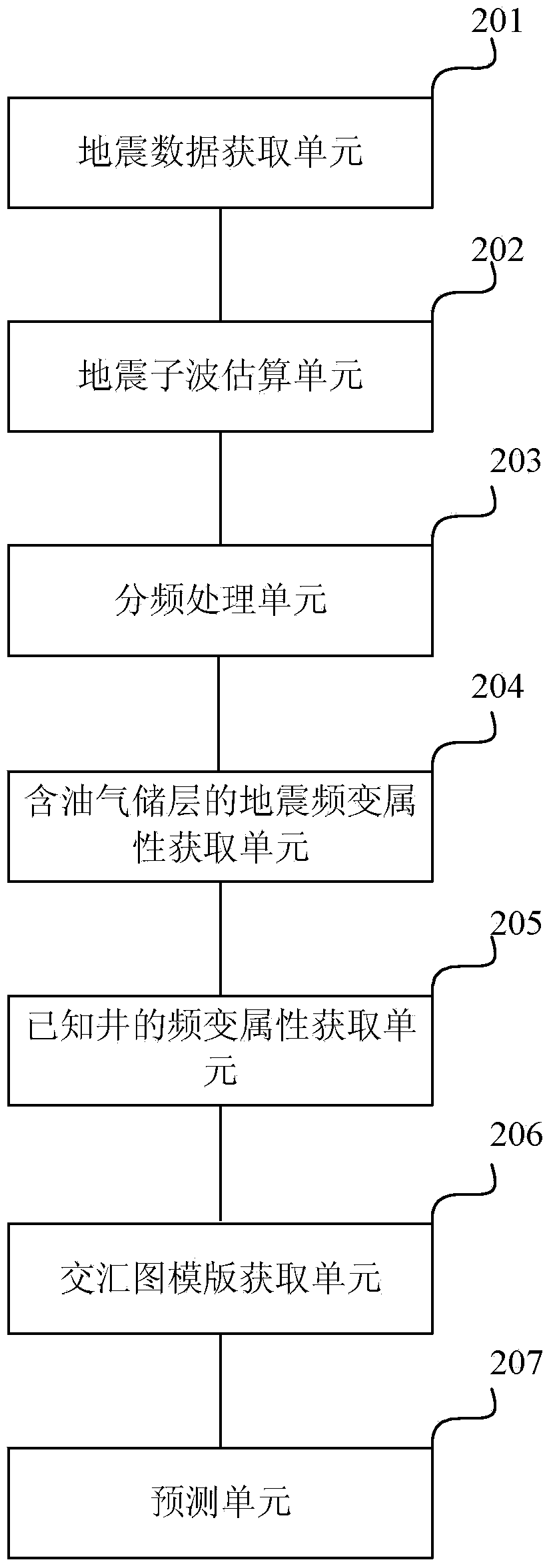

Quantitatively forecasting method and device for oil-gas possibility of reservoirs

ActiveCN103643949AReduce drilling riskImprove exploration efficiencyBorehole/well accessoriesPhysical modelBusiness forecasting

The invention provides a quantitative forecasting method and device for oil-gas possibility of reservoirs. The method comprises the following steps: obtaining post-stack seismic data on the oil-gas reservoirs; estimating seismic wavelets based on the post-stack seismic data; performing frequency division processing on the post-stack seismic data based on the seismic wavelets; performing inversion on the post-stack seismic data subjected to frequency division processing, so as to obtain the seismic frequency variable attributes of the oil-gas reservoirs; performing forward modeling of the different oil-gas saturation degrees based on a rock physical model and rock physical parameters of a known well, so as to obtain the frequency variable attribute of the known well; based on the frequency variable attribute of the known well, building an intersection graph template between the frequency variable attributes of the different oil-gas saturation degrees and reflection coefficients; based on the graph template, obtaining the reservoir oil-gas saturation degrees corresponding to the seismic frequency variable attributes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Axial vibrator

ActiveCN103742076ASolve the pressure problemHigh Efficiency DrillingVibration drillingHorizontal wellsEngineering

The axial vibrator belongs to the field of drilling tools, in particular to an axial vibrator. The axial vibrator can produce an axial vibrating through adopting pressure pulses produced by a circumferential vibrator or a pulser to effectively solve the pulling problem of drill string of high angle extended-reach wells and horizontal wells. The axial vibrator is simple in structure and reliable in vibrating. The pulser can be replaced and pressure oscillation of slurry can be changed; therefore, the vibration power can be adjusted and the adjustability is strong.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

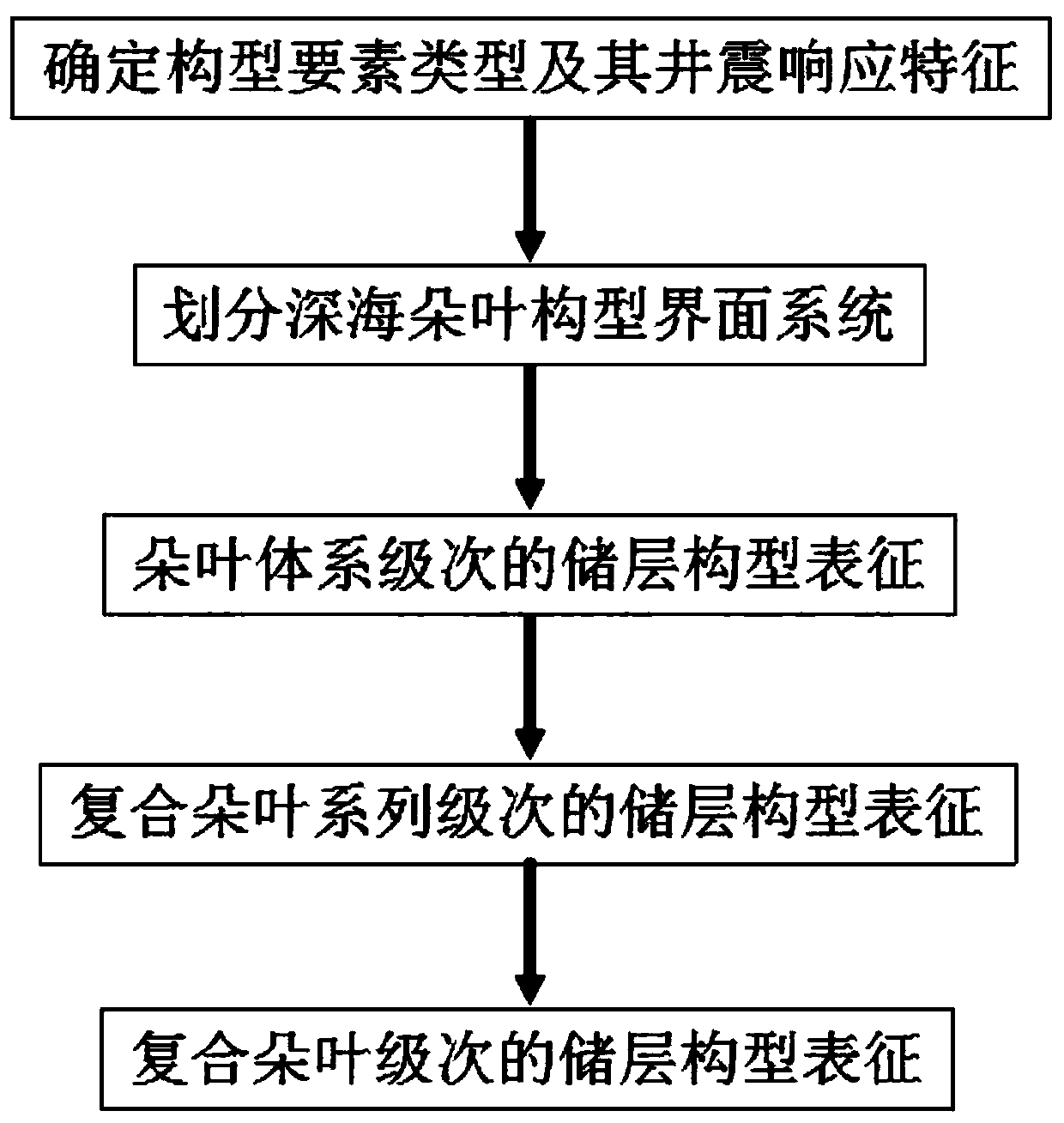

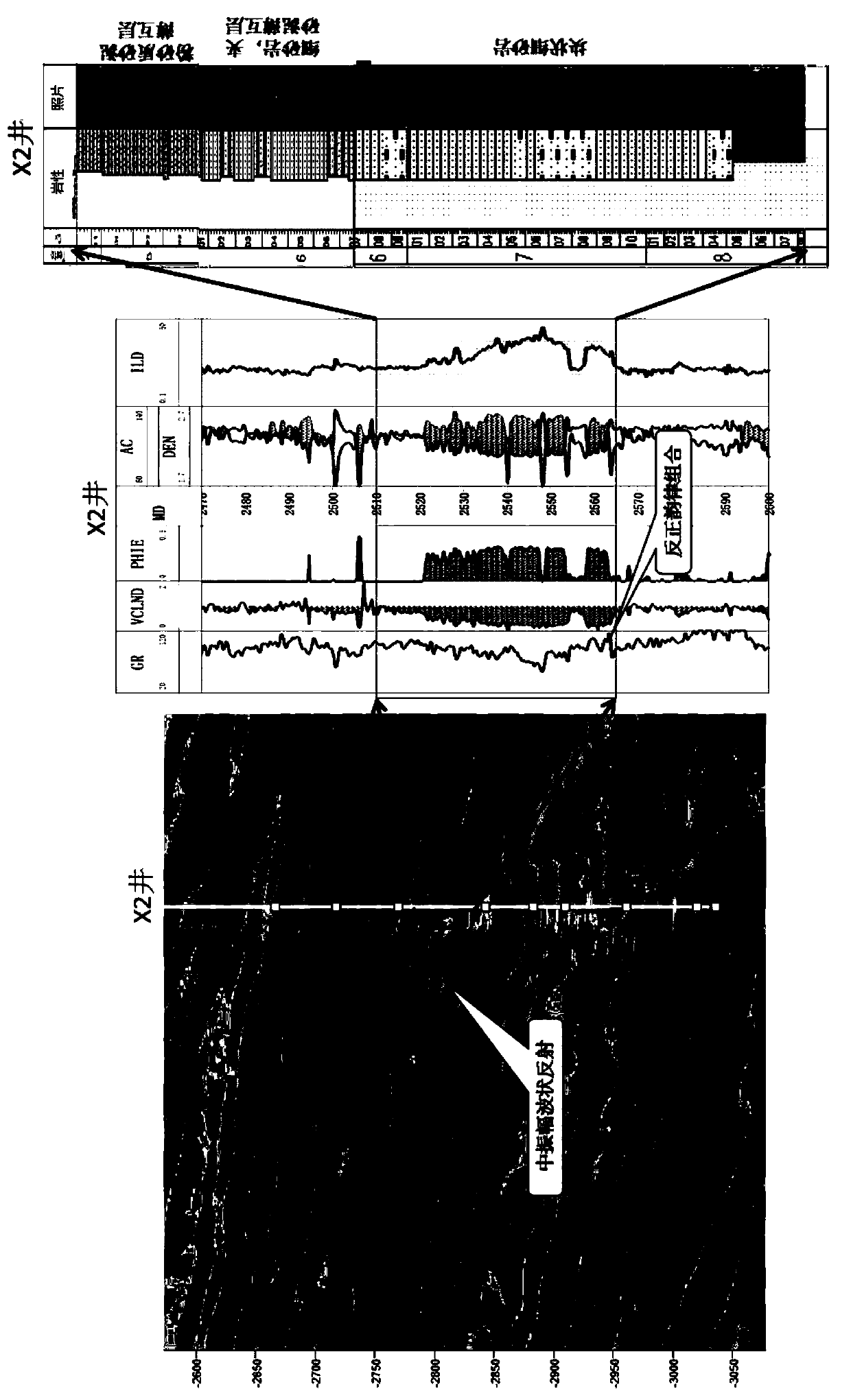

Deep sea lobe reservoir configuration characterization method based on well-to-seismic mode fitting

ActiveCN111239820AAchieve heterogeneityReduce drilling riskSeismic signal processingSeismology for water-loggingSoil scienceWell placement

The invention discloses a deep sea lobe reservoir configuration characterization method based on well-to-seismic mode fitting, which comprises the following steps: determining configuration element types and well-to-seismic response characteristics thereof; dividing a deep sea leaf configuration interface system; representing the reservoir configuration of the leaf system level; representing the reservoir configuration of the composite lobe series level; and characterizing the reservoir configuration of the composite lobe level. An idea is provided for carrying out underground reservoir configuration research by utilizing well-to-earthquake combination; scientific and reasonable prediction of flow paths, geometrical shapes, scale sizes and mutual superposition relations of sand bodies caused by different levels of deposition of deep sea leaves is realized. Effective characterization of reservoir heterogeneity of the deep-sea leaf oil and gas reservoirs is achieved, so that important geological basis and guidance are provided for well position deployment, well pattern design, injection-production correspondence analysis, remaining oil distribution prediction and the like of the deep-sea leaf oil and gas reservoirs, and therefore, the method has important practical engineering significance for reducing drilling risks of the deep-sea leaf oil and gas reservoirs and efficiently developing the deep-sea leaf oil reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

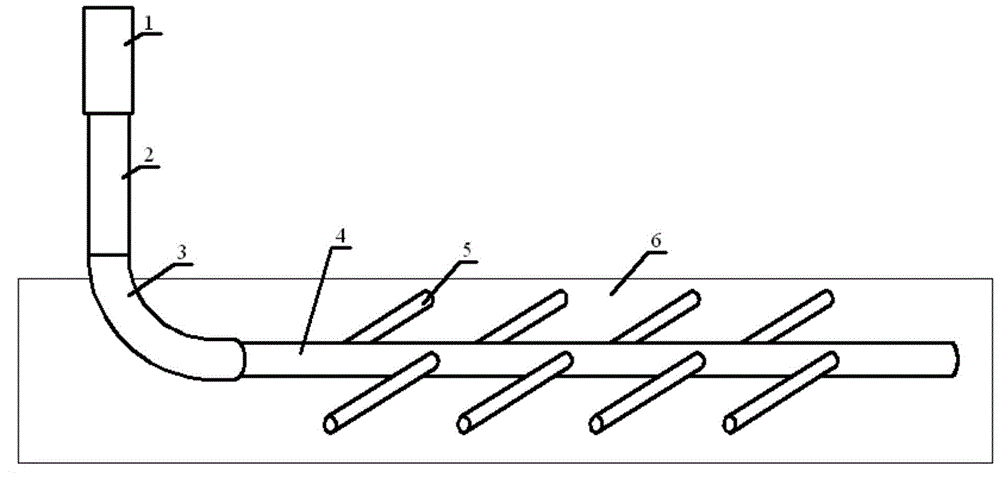

Method for drilling and completion of horizontal branched well for coal bed gas

ActiveCN104912479AStable supportSimplify the drilling processFluid removalDrilling machines and methodsSurface layerWell drilling

The invention discloses a method for drilling and completion of a horizontal branched well for coal bed gas. The method comprises the following steps: step 1: drilling a first-opening surface layer section, a second-opening straight well section and an incline angle buildup section of the horizontal branched well by adopting a conventional drilling tool combination, and after finishing drilling, arranging casing pipes so as to fix the well; step 2: drilling a third-opening coal bed horizontal section by adopting a casing pipe well drilling tool combination until a designed well depth is reached, and pulling out a directional drilling tool combination at the bottom of the well from the casing pipe with a steel wire fishing device; and step 3: adopting a radial lateral well drilling tool with a super-short radius so as to mill the casing pipe and drill the branched well in a coal bed. According to the method disclosed by the invention, pumping termination time can be shortened during drilling a main well hole of the coal bed, the coal bed can be effectively supported, the swabbing effect of well drilling is avoided, and accidents of collapse of a horizontal well and burying of the drilling tools are reduced; a well drilling technology of the branched well is greatly simplified, the well drilling risk of the branched well is reduced, the operation period is shortened, and the cost of drilling the branched well for the coal bed gas is reduced.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

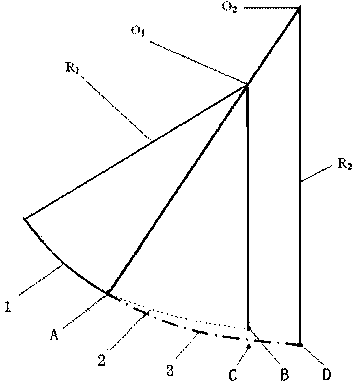

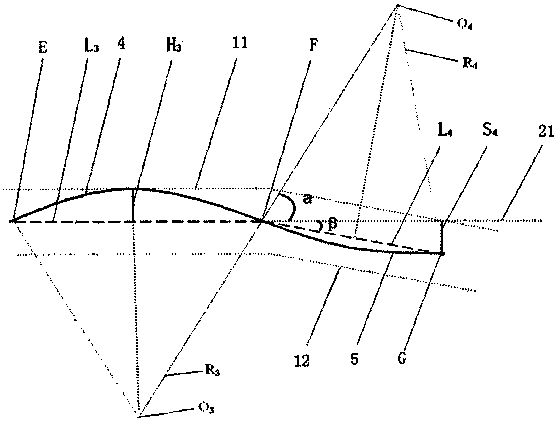

Horizontal well logging guiding track optimization method

InactiveCN103510855AGood for directional controlEnhanced mechanical extensionDirectional drillingWell loggingWell drilling

The invention belongs to the field of horizontal well logging guiding technologies, and discloses a horizontal well logging guiding track optimization method. The method is mainly characterized in that track optimization before landing includes the steps of determining the position of a new target point, calculating the radius of a new track and designing the track of the new target point, track optimization after entering layers includes the steps of setting a peak valley control line, building a track control point and building a first section track, a second section track and each following section track. The horizontal well logging guiding track optimization method achieves smoothness of a whole horizontal well track, effectively controls the frontal distance from the target point, reduces the friction between a drilling tool and the well wall, improves the rate of penetration, shortens the well drilling period and creates good conditions for follow-up construction.

Owner:CNPC BOHAI DRILLING ENG

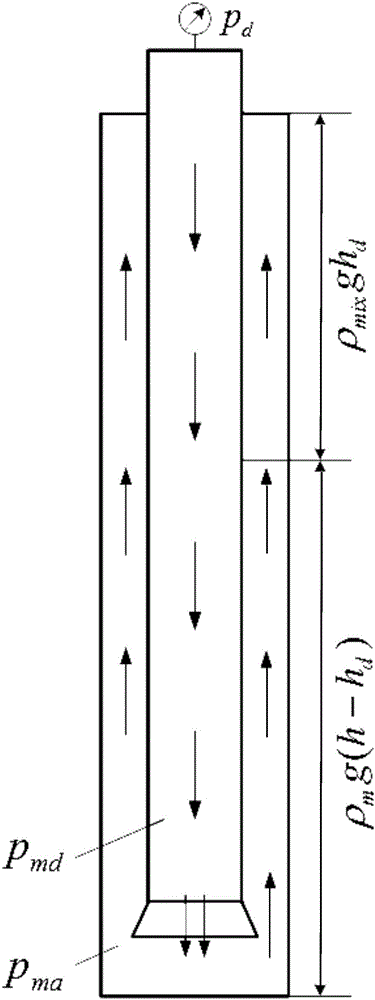

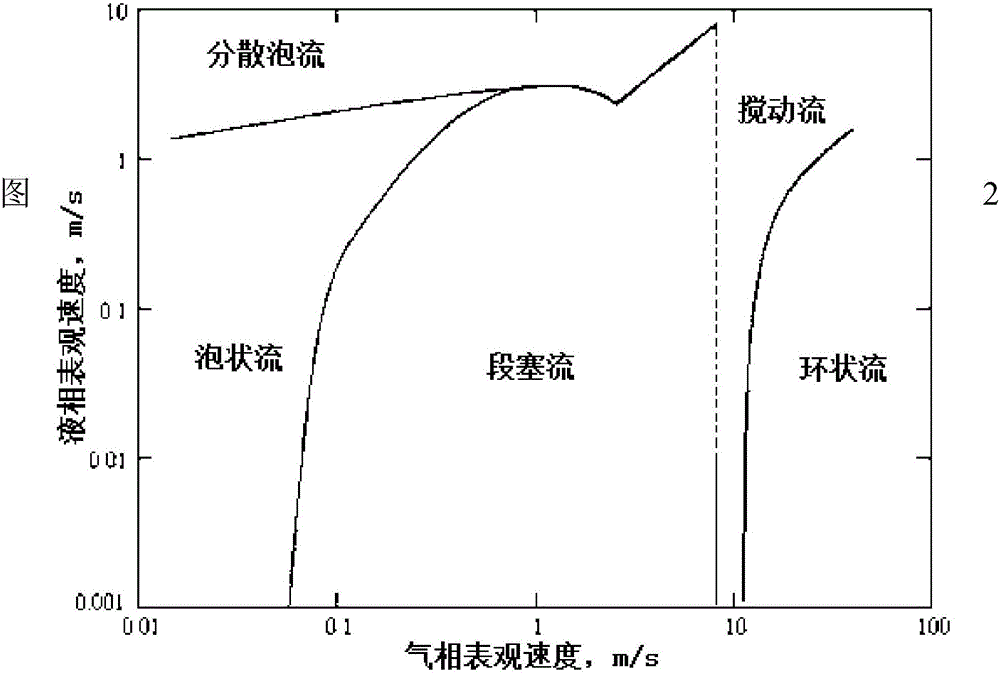

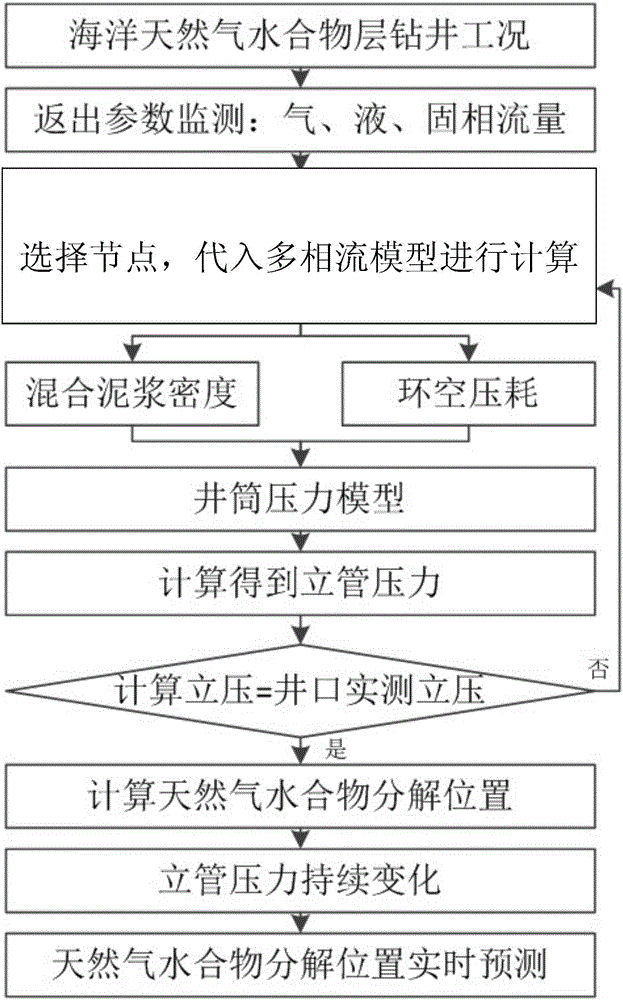

Method for detecting hydrate dynamic decomposition position of natural gas hydrate reservoir drilling well shaft

InactiveCN105822264AReduce drilling riskReduce lossesSurveyConstructionsDensity distributionWell drilling

The invention discloses a method for detecting hydrate dynamic decomposition position of a natural gas hydrate reservoir drilling well shaft, and particularly relates to a method for detecting the hydrate dynamic decomposition position of the natural gas hydrate reservoir drilling well shaft, which belongs to the field of exploration drilling or production drilling of ocean natural gas hydrates. The method for detecting the hydrate dynamic decomposition position of the natural gas hydrate reservoir drilling well shaft has the advantages that the real-time collection of data is realized, the detection accuracy is high, and the dynamic change can be dynamically detected. The method comprises the following steps of A, dividing nodes according to the drilling depth position range; B, substituting parameters into a multi-phase model, and calculating the density distribution of mixed slurry and the annulus pressure loss; C, calculating the pressure of a vertical pipe; D, comparing the calculated pressure of the vertical pipe and the monitored pressure of the vertical pipe. The method has the characteristics that by monitoring the change of vertical pressure on ground, the dynamic decomposition position of the hydrate can be calculated and predicted in real time, the drilling risk of the ocean natural gas hydrate reservoir is effectively decreased, and the loss is reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

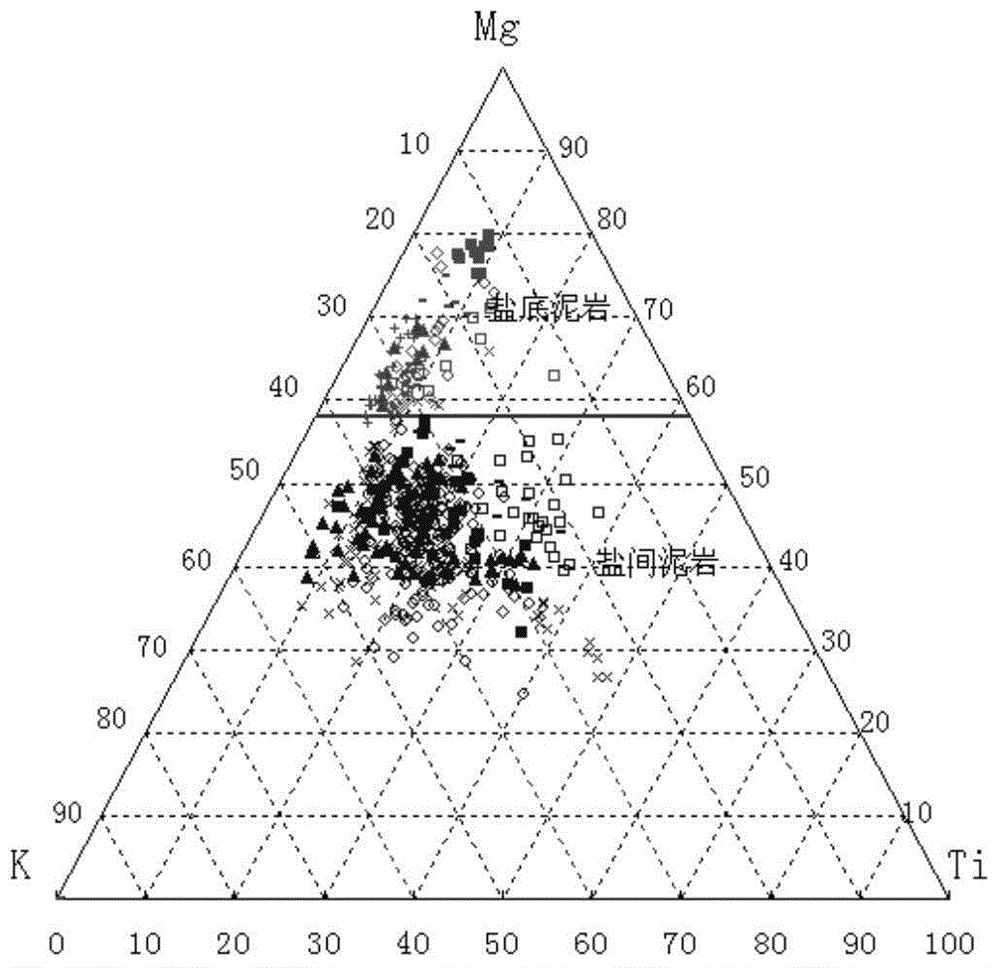

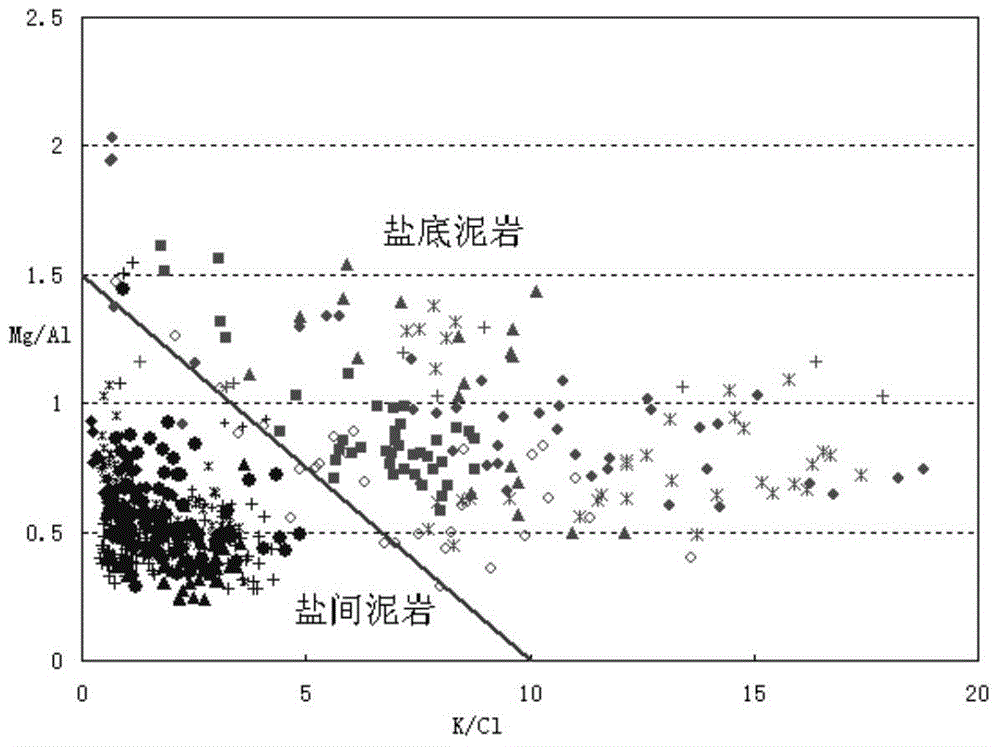

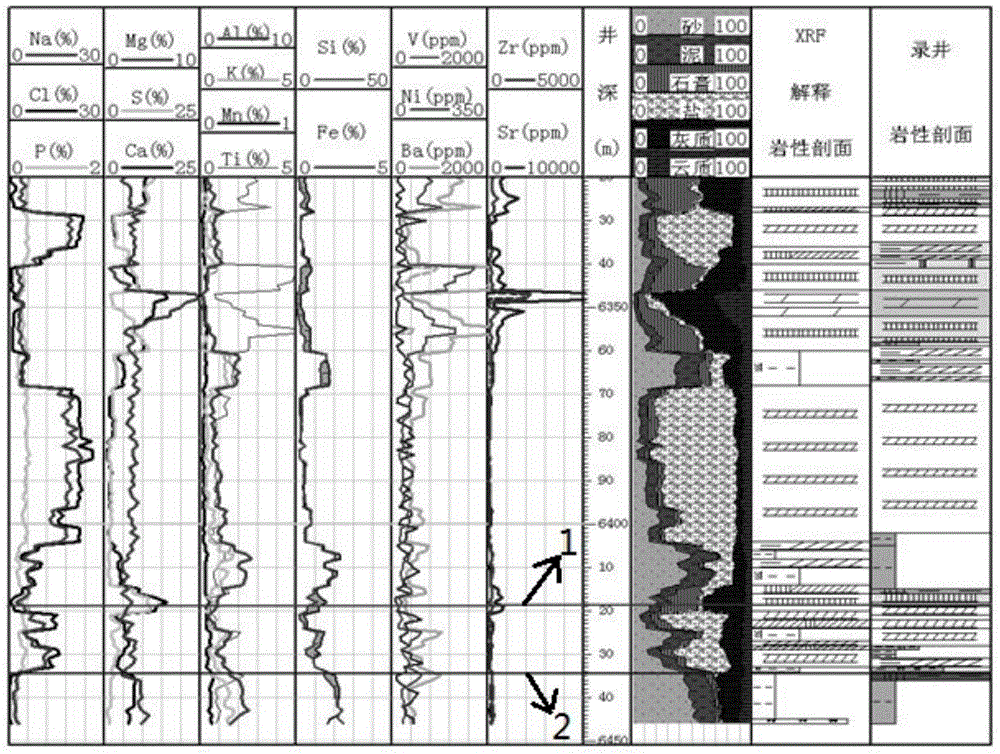

X-ray fluorescence element well logging technology-based salt bottom clamp taking method

ActiveCN105044140AIncrease success rateSafe and fast drillingMaterial analysis using wave/particle radiationLithologyWell logging

The invention discloses an X-ray fluorescence element well logging technology-based salt bottom clamp taking method. The method comprises the following steps: 1, carrying out lithology naming by using a major element; 2, determining an element marker layer by using a trace element; 3, carrying out data analysis on mud rocks above and under the marker layer; 4, discriminating by using a plate. The method is mainly used for clamp taking of the bottom interface of gypsum-salt rocks of Eogene Kumugeliemu Group in Kuqa Depression of Tarim Basin, can reduce the gypsum-salt rock drilling risk, guarantees the safe drilling of the oil gas layer of a drilling well, plays an important role in realization of geologic purposes, and belongs to the field of geology research of petroleum exploration.

Owner:BEIJING AOYIER ENG TECH

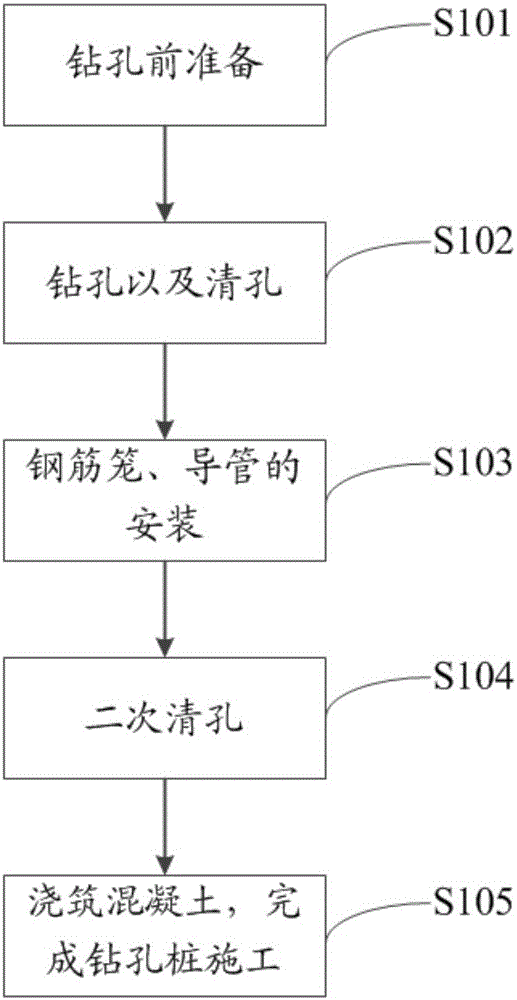

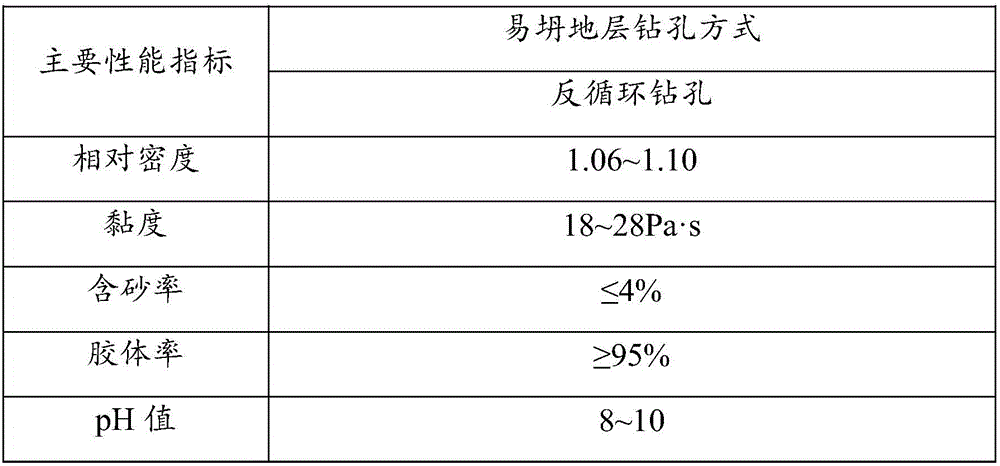

Construction method for drilling pile under bad geological conditions

The invention discloses a construction method for a drilling pile under bad geological conditions. The construction method comprises the following steps of drilling a construction hole in a soil layer at a preset pile position; and arranging a steel reinforcement cage in the construction hole, and pouring concrete in the steel reinforcement cage to finish the construction of the drilling pile. The method for drilling the construction hole is realized by drilling by adopting slurry mainly comprising bentonite and clay in a reverse circulation drilling mode, wherein for the slurry adopted by reverse circulation drilling, the relative density is 1.06 to 1.10, the viscosity is 18 to 28Pa.s, the sand factor is 4 weight percent or below 4 weight percent, the colloid fraction is 95 percent or above 95 percent, and the pH value is 8 to 10. According to the method, drilling operation can be performed under the condition of sandy soil, and hole-diameter shrinkage or hole collapse can be avoided, thereby improving the construction safety and the construction efficiency of the drilling pile.

Owner:江苏燕宁工程科技集团有限公司

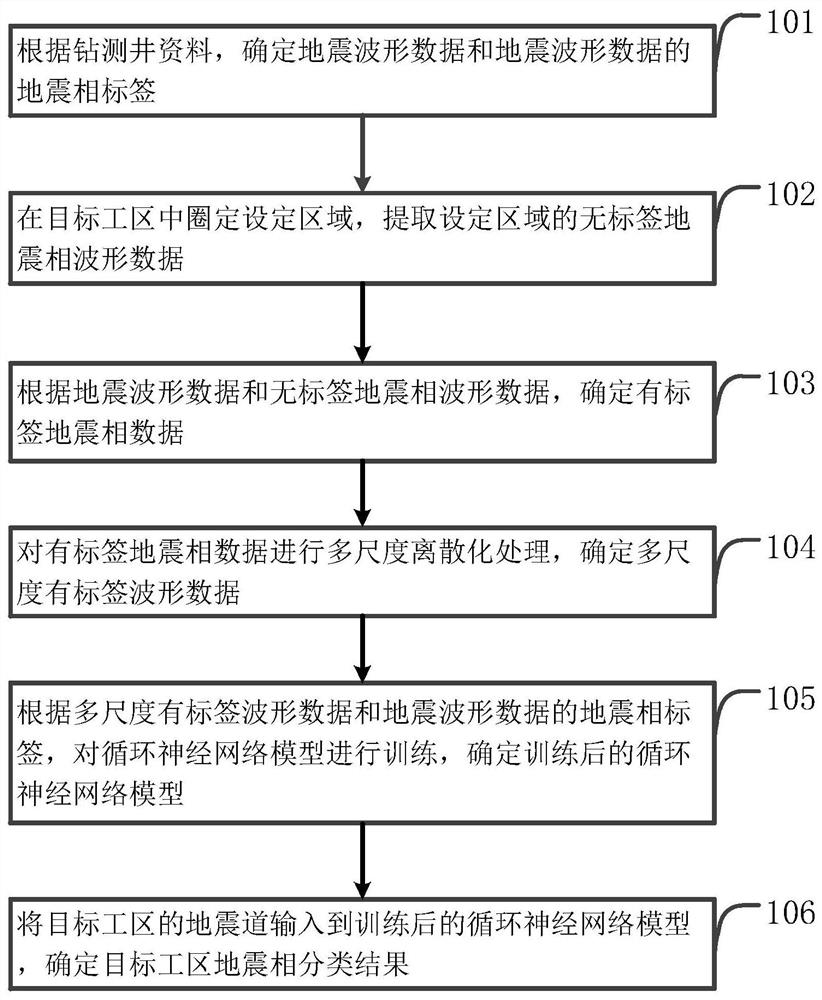

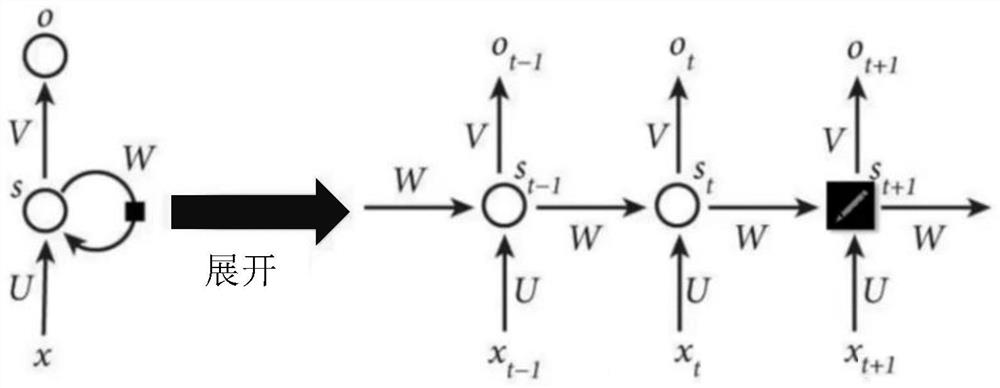

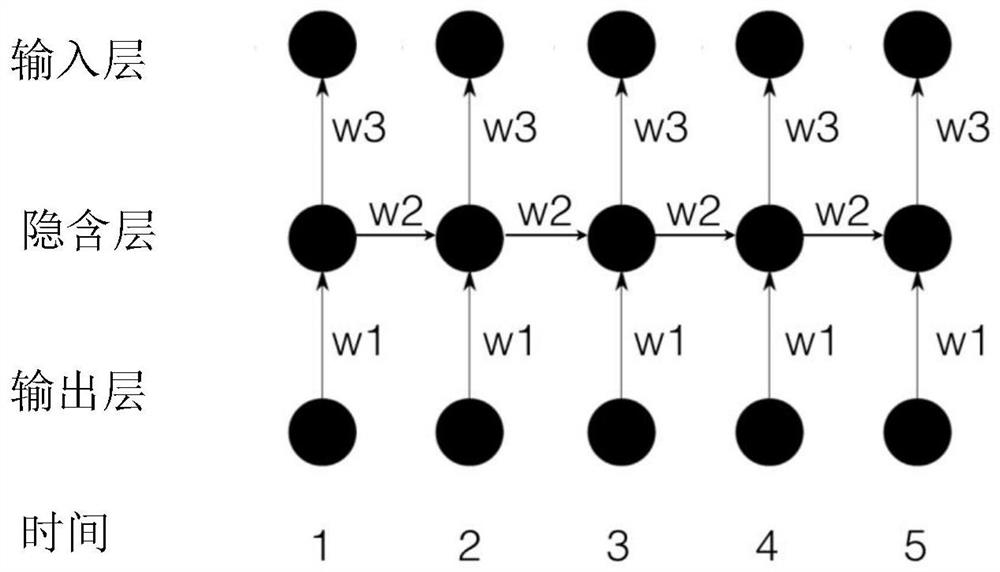

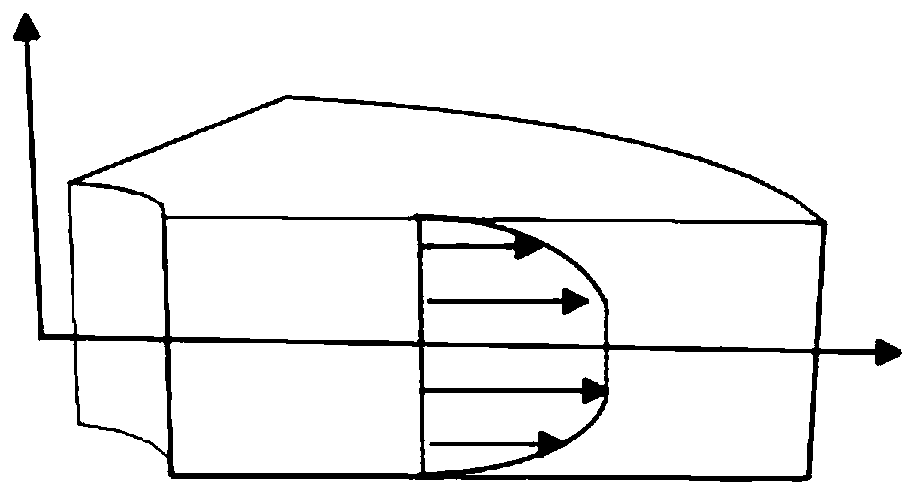

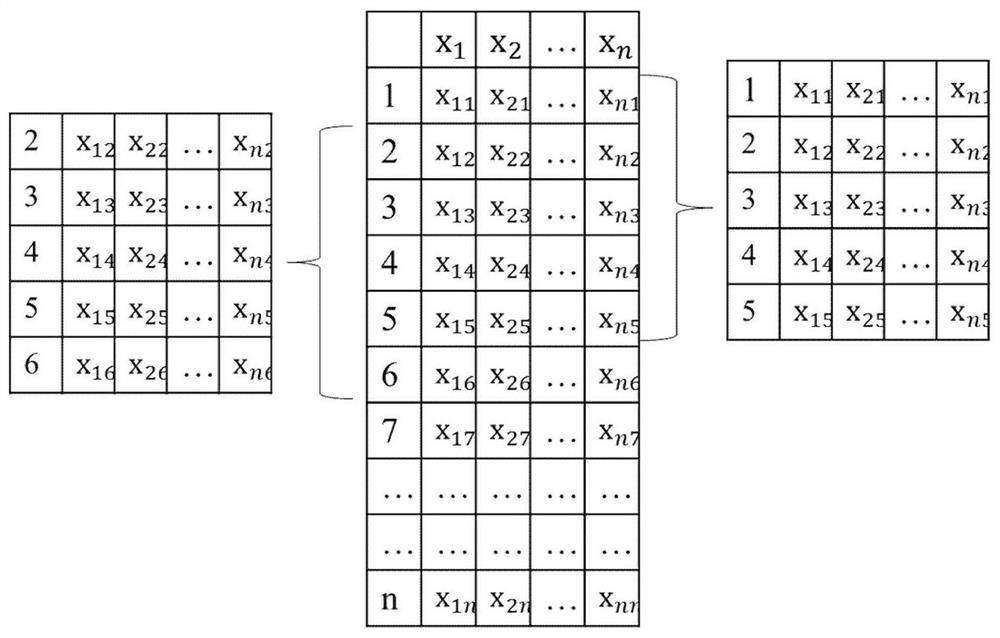

Seismic waveform clustering method and device

PendingCN112684497AClustering is fast and accurateImprove forecast accuracyCharacter and pattern recognitionSeismic signal processingAlgorithmWell logging

The invention provides a seismic waveform clustering method and device, and the method comprises the steps of: determining seismic waveform data and a seismic facies label of the seismic waveform data according to drilling and logging information; delineating a set area in a target work area, and extracting label-free seismic facies waveform data of the set area; determining labeled seismic facies data according to the seismic waveform data and the unlabeled seismic facies waveform data; performing multi-scale discretization processing on the labeled seismic facies data, and determining multi-scale labeled waveform data; training a recurrent neural network model according to the multi-scale labeled waveform data and the seismic facies label of the seismic waveform data, and determining the trained recurrent neural network model; and inputting the seismic trace of a target work area into the trained recurrent neural network model, and determining a seismic facies classification result of the target work area. According to the invention, the semi-supervised learning method of the recurrent neural network model generative adversarial network is used to realize rapid and precise classification of the seismic facies of the target work area.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

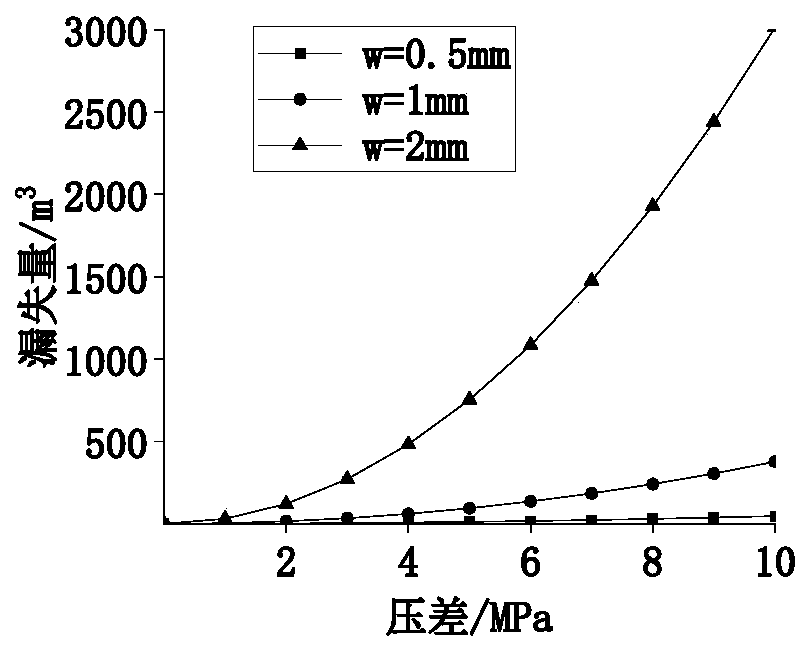

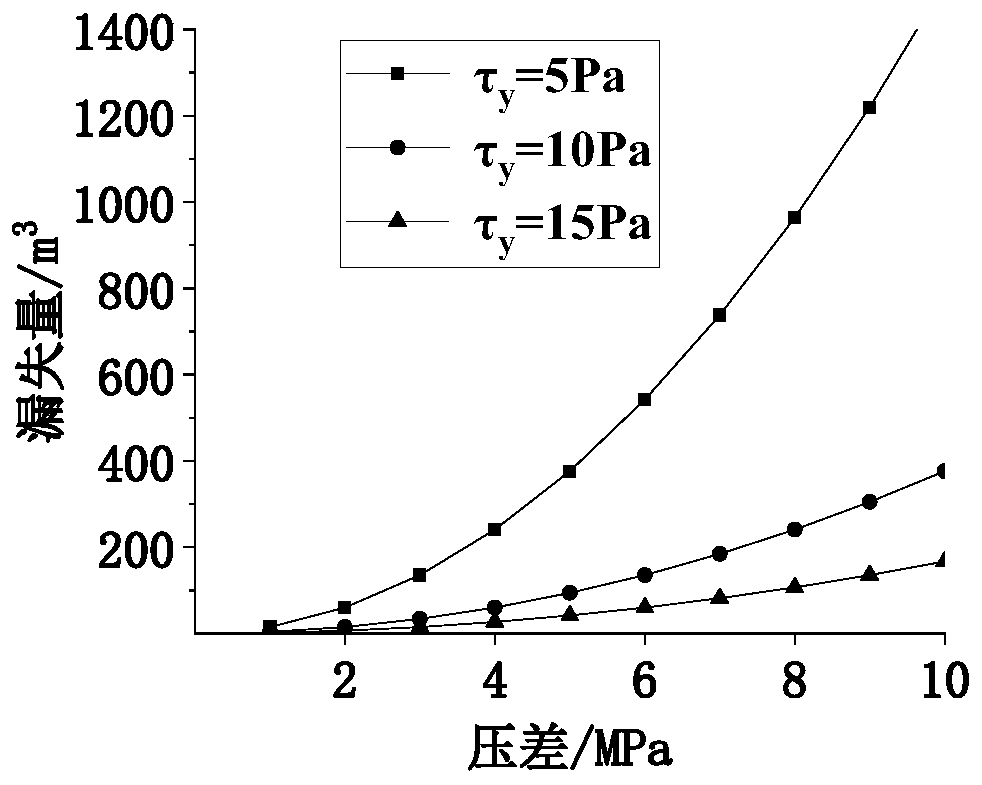

Drilling fluid leakage prediction method for fissured formation

ActiveCN111236925AReduce leakageReduce drilling riskSurveyComplex mathematical operationsPhysicsGeotechnical engineering

The invention relates to a drilling liquid leakage prediction method for fissured formation, and belongs to the field of petroleum and natural gas drilling engineering. The method comprises the following steps that A, the width w of various fissures is calculated; B, the consistency coefficient k of a drilling fluid, the flow behavior index m and the drilling fluid yield stress tau<y> are measured; C, the formation pressure p is calculated; and D, the leakage of the drilling fluid is calculated according to a formula, a drilling fluid leakage model is obtained though the following method that the drilling fluid mass conservation equation, the leakage momentum equation, the rheological equation of a fluid and the tortuosity equation are solved simultaneously to obtain a formula (18) anda formula (23), the formula (18) is the relationship between the differential pressure and the leakage radius, and the formula (23) is the total leakage relationship of the drilling fluid. According to the drilling fluid leakage prediction method for the fissured formation, the leakage of the drilling fluid of the fissured formation can be predicted, so that a field engineer adopts a reasonable and efficient leakage stopping technology in time according to the loss condition of the formation, solves the drilling risk in time, and reduces the loss of the drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

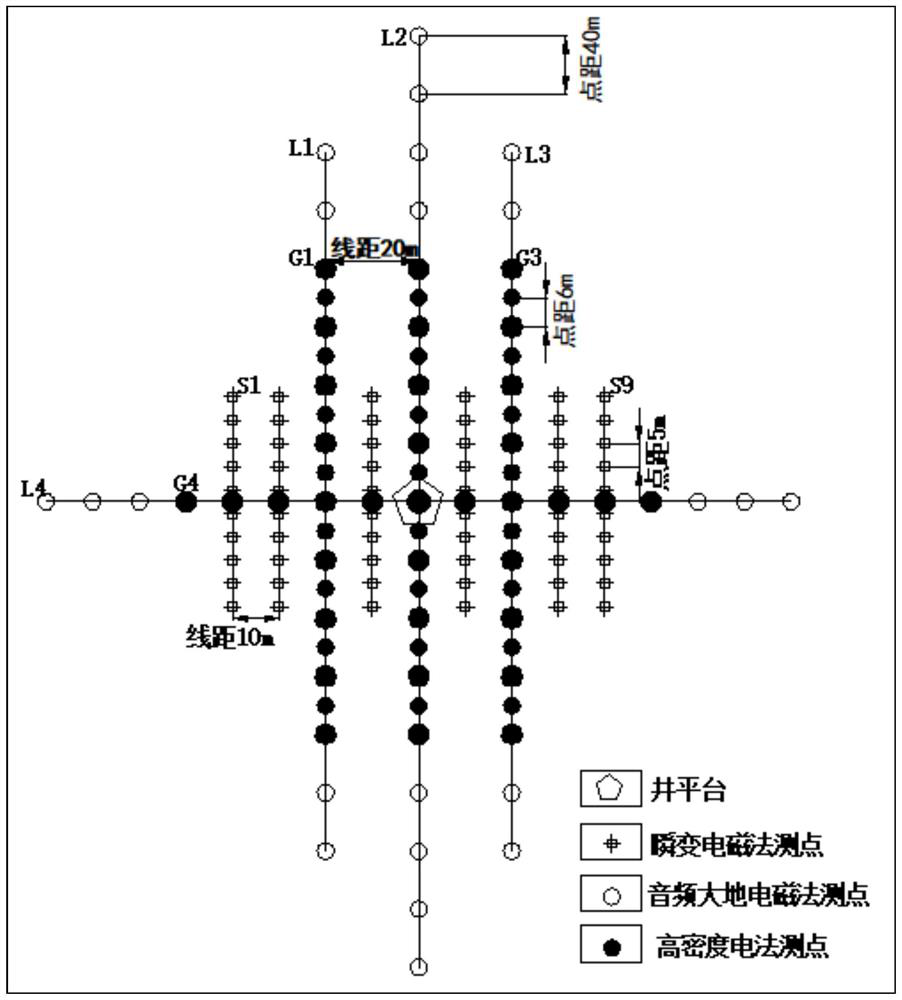

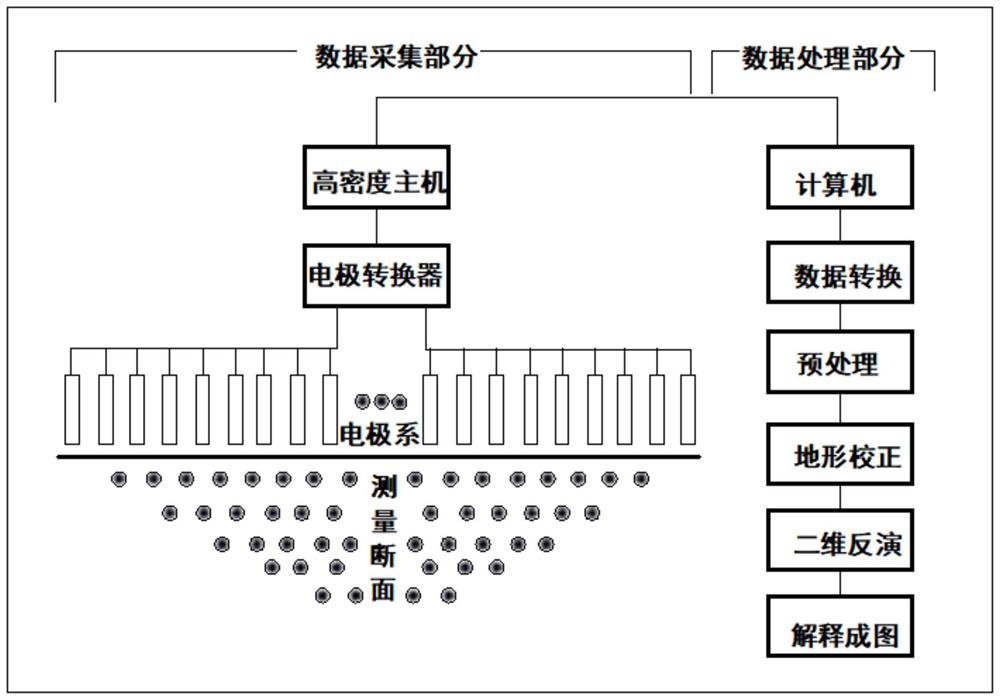

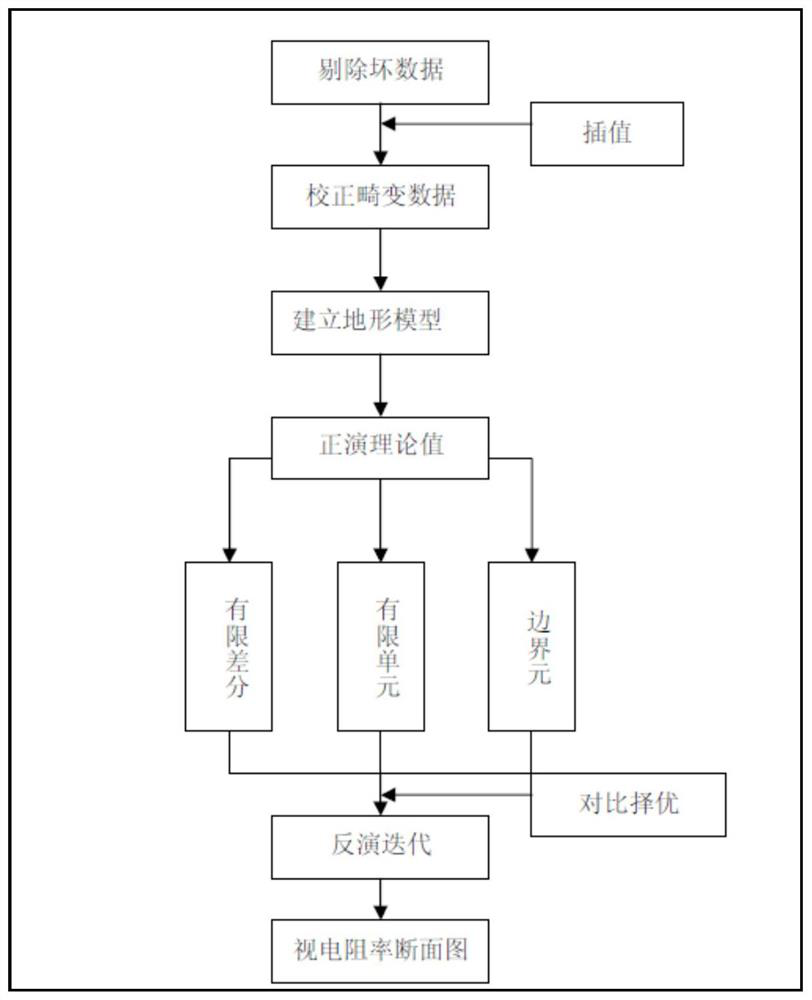

Karst detection method combining three geophysical prospecting methods and two geological methods

ActiveCN111781651AImprove accuracyExpansion of detection depth limitationsElectric/magnetic detection for well-loggingAcoustic wave reradiationKarstEngineering geology

The invention relates to the field of shale gas pre-drilling exploration, in particular to a karst detection method combining three geophysical prospecting methods and two geological methods. The karst detection method comprises the steps that S1, engineering geology and hydrogeology reconnaissance is carried out to obtain comprehensive geological information; S2, the underground space is dividedinto a first burial depth interval, a second burial depth interval and a third burial depth interval from shallow to deep, and a geophysical prospecting data integrated observation system is designed;S3, high-density electrical method, TEM and AMT data acquisition and data processing inversion are respectively performed according to the geophysical prospecting data integrated observation system to obtain a first apparent resistivity profile, a second apparent resistivity profile and a third apparent resistivity profile; 4, karst development ranges in the first burial depth interval, the second burial depth interval and the third burial depth interval are determined; and 5, the shallow karst development range of the third burial depth interval is determined by integrating the karst development ranges in the first, second and third burial depth intervals and the comprehensive geological information. According to the method, the problem that the detection depth is limited by adopting a single geophysical prospecting method is solved, meanwhile, advantage complementation of multiple geophysical prospecting methods is achieved, and the risk identification precision is improved.

Owner:四川省自然资源投资集团物探勘查院有限公司

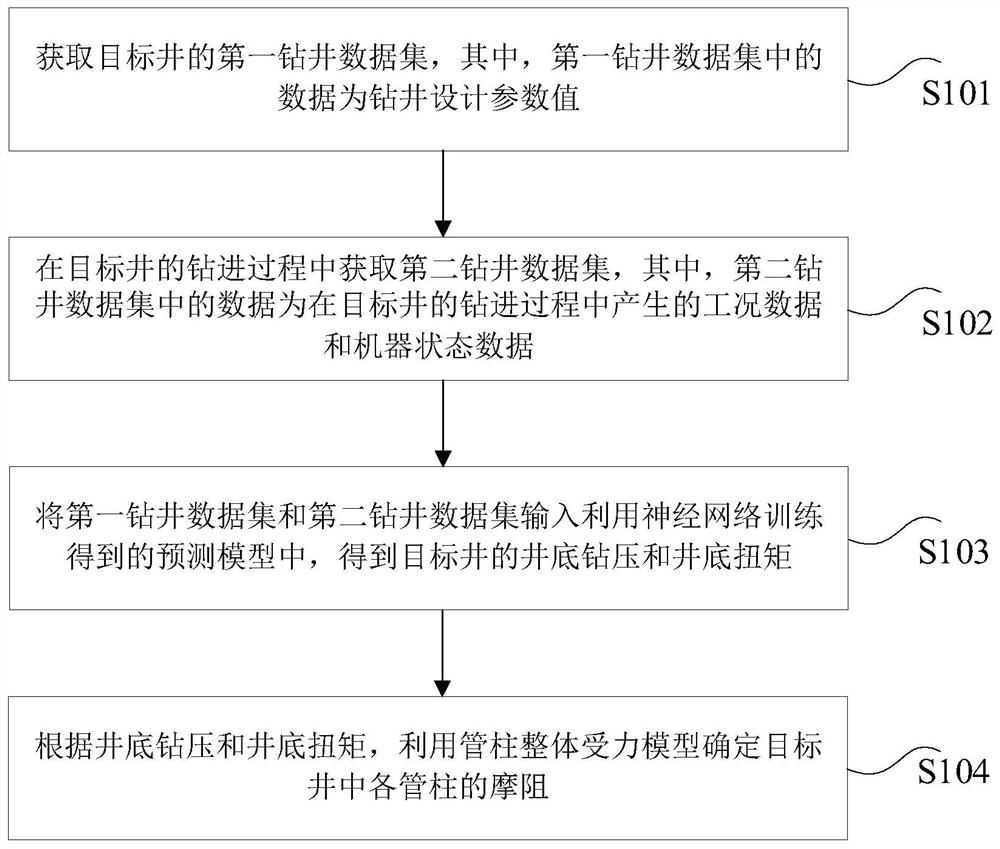

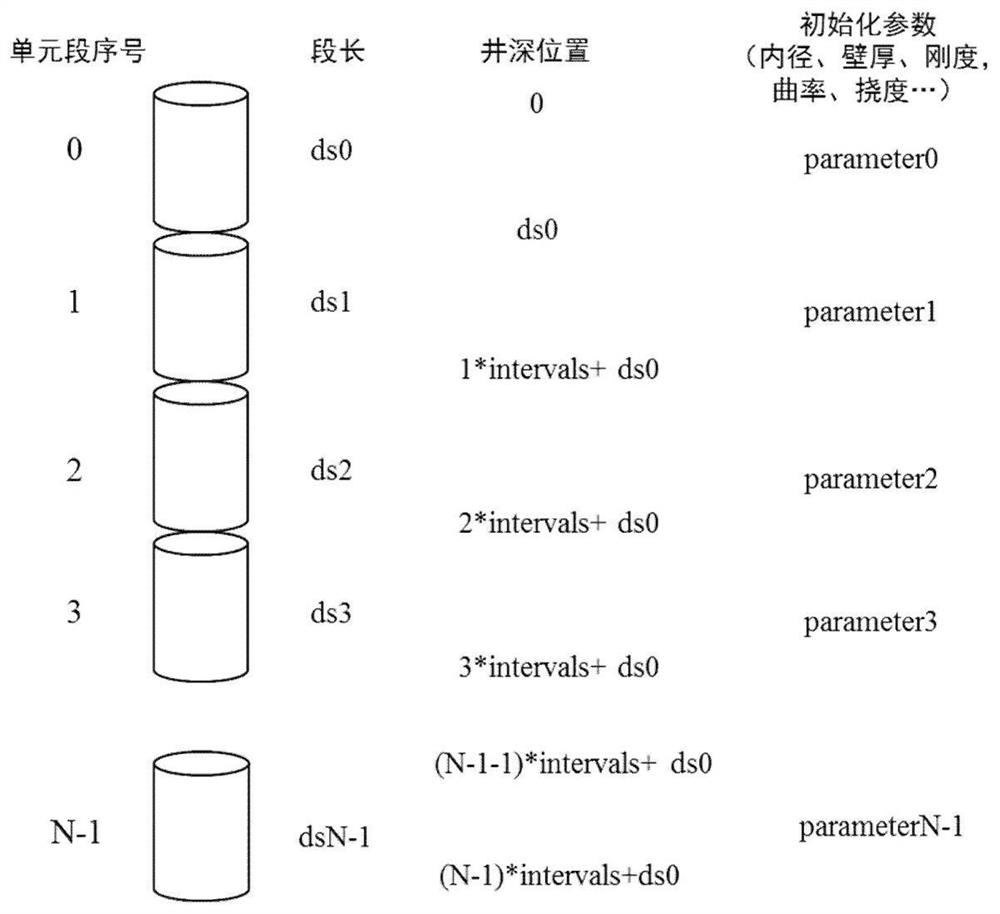

Method, device and equipment for determining friction resistance

PendingCN111734396AEasy to controlReduce drilling riskSurveyDesign optimisation/simulationThermodynamicsData set

The invention provides a method, a device and equipment for determining friction resistance. The method comprises the following steps of obtaining a first drilling data set of a target well, wherein the data in the first drilling data set is a drilling design parameter value; acquiring a second drilling data set in the drilling process of the target well, wherein the data in the second drilling data set are working condition data and machine state data generated in the drilling process of the target well; inputting the first drilling data set and the second drilling data set into a predictionmodel trained through a neural network to obtain well bottom drilling pressure and well bottom torque of the target well; and determining the friction resistance of each tubular column in the target well by utilizing a tubular column integral stress model according to the well bottom drilling pressure and the well bottom torque. In the embodiment of the invention, through the real-time monitoringof the well bottom drilling pressure and the well bottom torque, the drilling process can be more accurately controlled, and the drilling risk is reduced. By means of the prediction model trained through the neural network, the well bottom drilling pressure and the well bottom torque can be more accurately and efficiently predicted.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

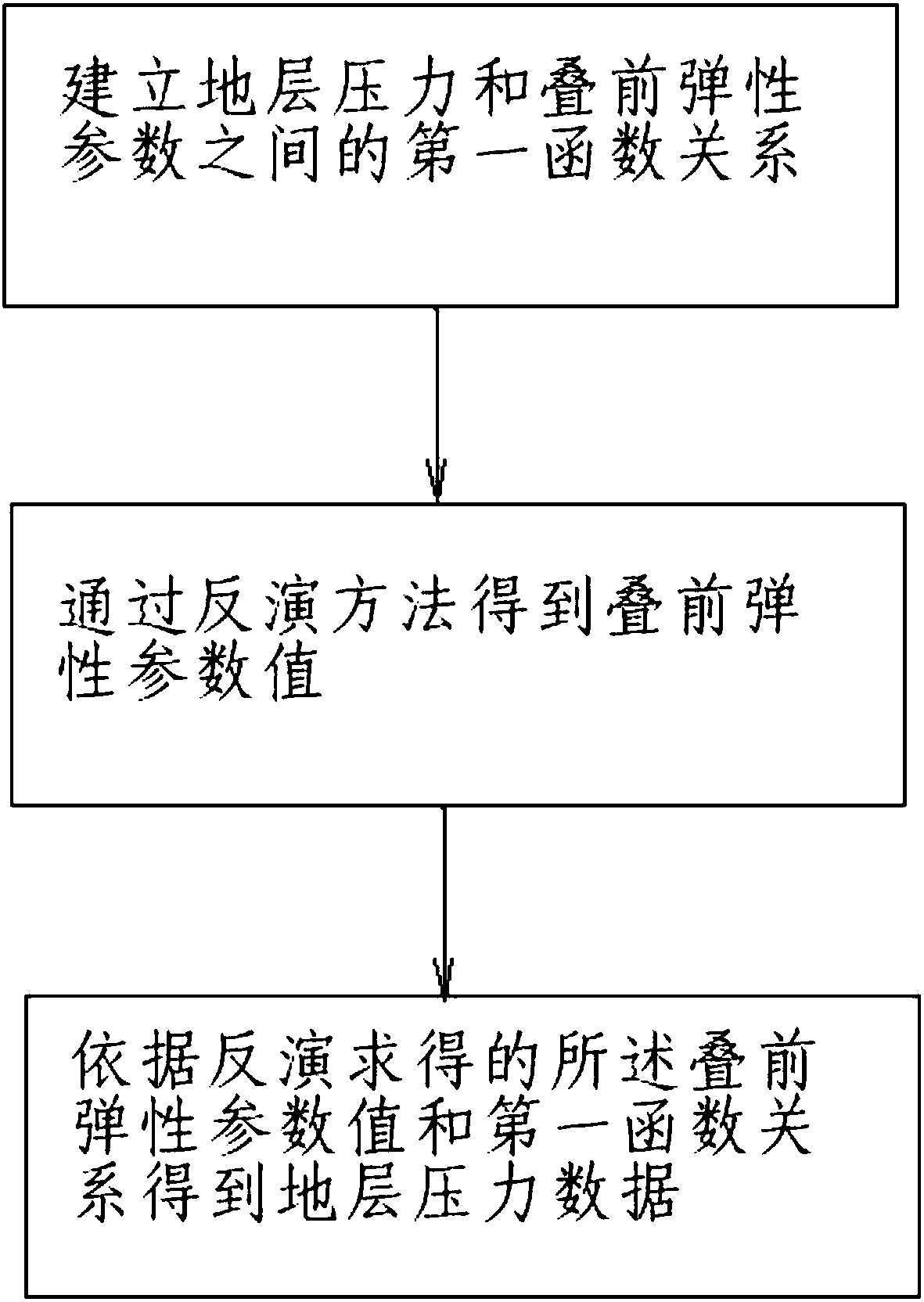

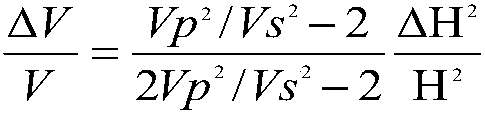

Stratum pressure prediction method

ActiveCN107728205AReduce drilling riskImprove exploration efficiencySeismic signal processingPrediction methodsEnvironmental geology

The invention relates to a stratum pressure prediction method comprising the following steps: building a first function relation between the stratum pressure and a pre-stack elasticity parameter; using an inversion method to obtain the pre-stack elasticity parameter value; obtaining the stratum pressure data according to the pre-stack elasticity parameter value solved by the inversion and the first function relation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-rotating high-pressure water jet adjustable drilling device

ActiveCN107605403AEfficient formationEffective stimulationConstructionsLiquid/gas jet drillingPropellerHigh pressure water

A self-rotating high-pressure water jet adjustable drilling device comprises a high-pressure pipe, a fixed shell, a rotating body and a rotating spraying head. The fixed shell comprises a cylindricalbody, the high-pressure pipe is arranged at the rear end of the cylindrical body, and a first propeller is mounted on the high-pressure pipe. The high-pressure pipe is fixed trough a second propellermounted at the rear end of the fixed shell, the rotating body is rotatably located in the fixed shell, and the rear portion of the rotating body is elastically supported to the fixed shell through a spring. The front portion of the rotating body is connected with the rotating spraying head provided with a breaking cutting nozzle set for front-end breaking operation. A first propulsion nozzle set is mounted on the first propeller, a second propulsion nozzle set is mounted on the second propeller, high-pressure fluid is broken through propulsion nozzle sets at the rotating spraying head, and thepropulsion nozzle sets drive the fixed shell and the rotating spraying head to move forwards, so that automatic propulsion drilling is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

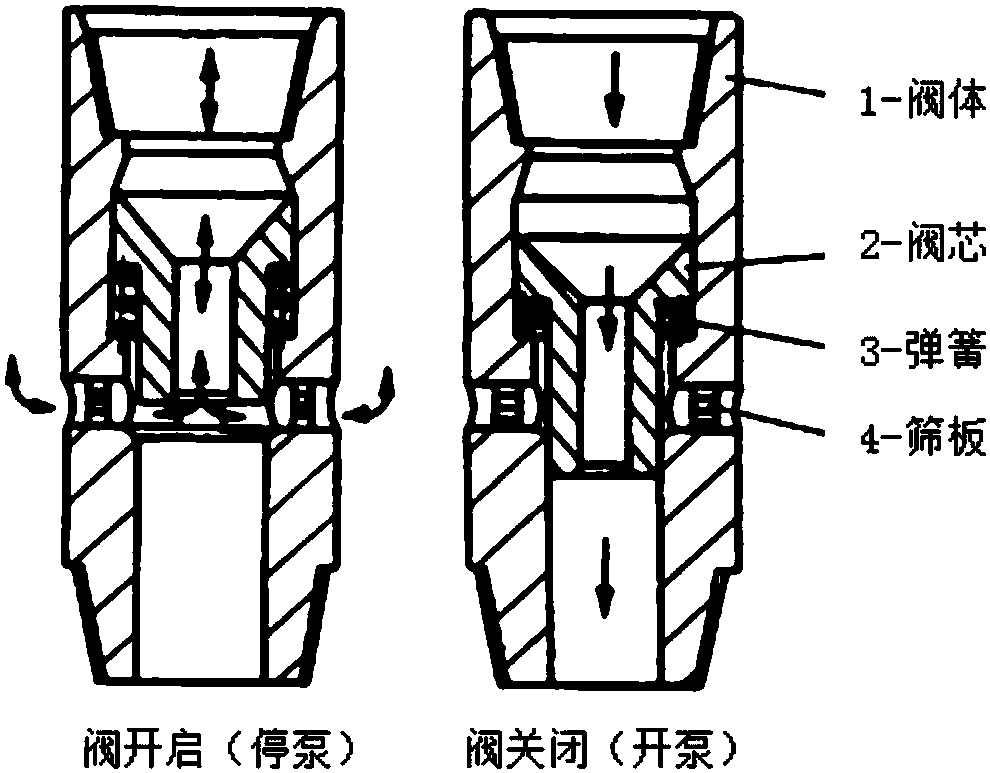

Screw drill tool by-pass valve with large displacement flow dividing function and using method thereof

ActiveCN108166940AReduce manufacturing costImprove rock carrying efficiencyGeometric CADConstructionsBoundary valuesEngineering

The invention discloses a screw drill tool by-pass valve with a large displacement flow dividing function and a using method thereof. The screw drill tool by-pass valve comprises a valve body. The interior of the valve body is provided with a first-level valve core and a second-level valve core. A first-level spring is arranged between the first-level valve core and the second-level valve core. Asecond-level spring is arranged between the second-level valve core and a valve seat. The rigidity of the second-level spring is larger than that of the first-level spring. An inner by-pass hole is formed in the first-level valve core. An outer by-pass hole is formed in the valve body. When the flow pressure in a drilling-fluid fluid channel disappears, the inner by-pass hole communicates with theouter by-pass hole; and an inner flow dividing hole is formed in the second-level valve core, an outer flow dividing hole is formed in the valve body, and when the flow pressure in the drilling-fluidfluid channel is increased to the boundary value, the inner flow dividing hole communicates with the outer flow dividing hole. According to the screw drill tool by-pass valve with the large displacement flow dividing function and the using method thereof, a screw drill tool is allowed to adopt large displacement for circulation and drilling, the rock carrying efficiency at a large size well section, a highly-deviated well section and a horizontal section are improved advantageously, the drilling risk is reduced, and the drilling speed is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

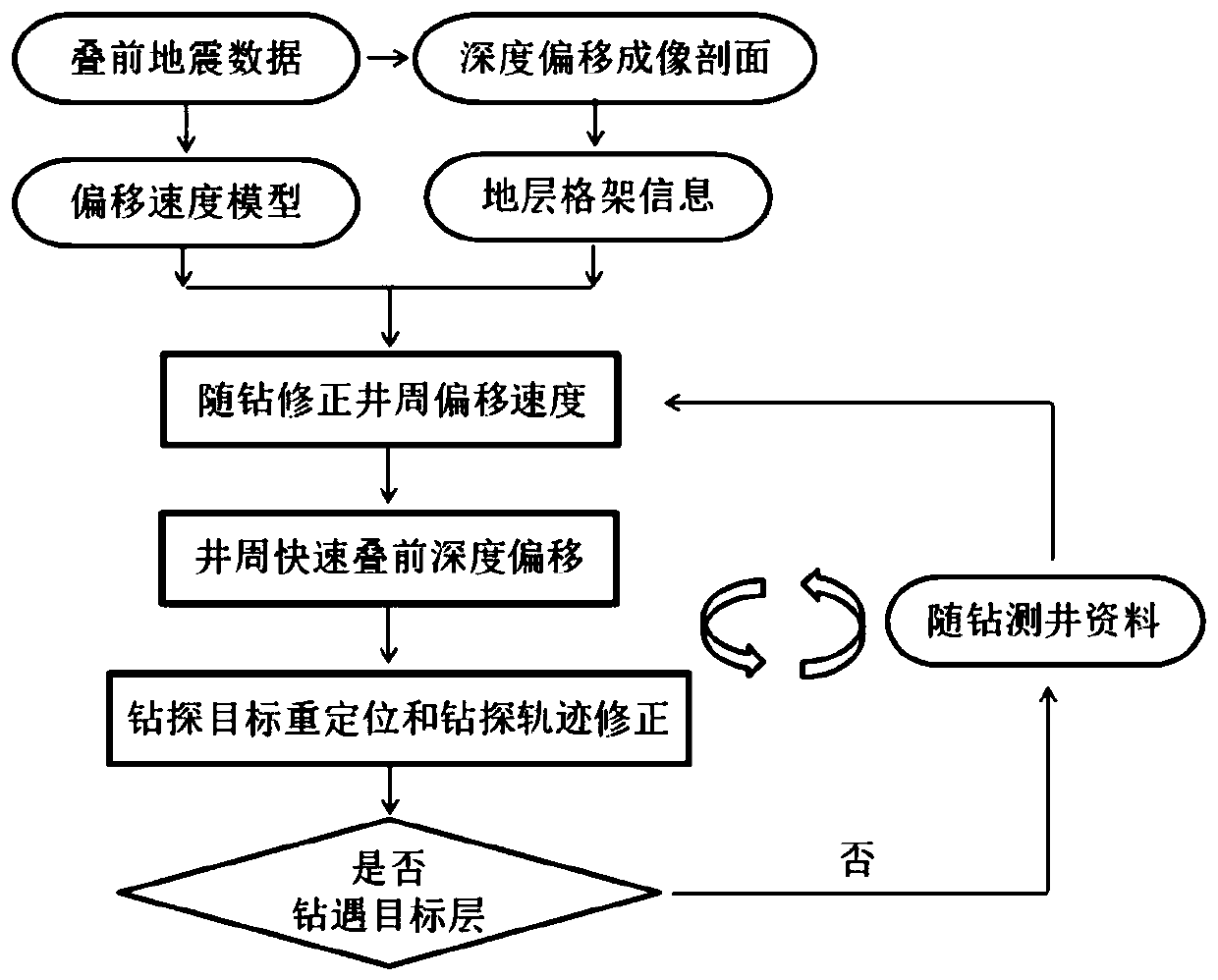

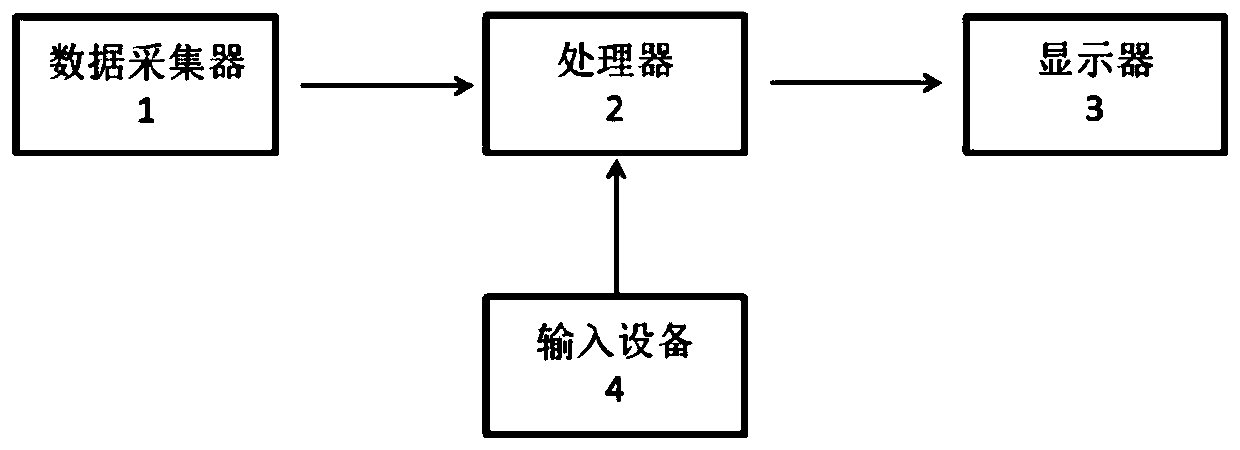

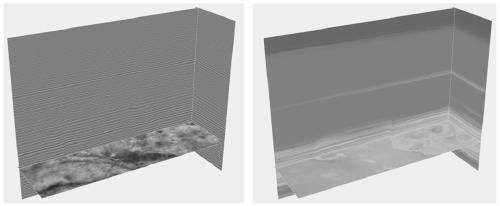

Well periphery seismic imaging detection method and device based on logging while drilling and stratum grillwork constraints

The invention relates to a well periphery seismic imaging detection method and device based on logging while drilling and stratum grillwork constraints. Acoustic velocity data acquired by staged welllogging in the drilling process are utilized, an offset velocity field around a well hole is updated under the constraint of a stratigraphic framework; wave equation datum plane continuation is combined to achieve rapid imaging of depth offset around the well, a drilling target is relocated, and a drilling track is optimized in time. Compared with the prior art, the well periphery seismic imagingdetection method and device has the following advantages: geological reasonability can be achieved when the stratum speed provided by well logging data can be expanded from a borehole to the peripheryof the well, and the drilling success rate is increased.

Owner:TONGJI UNIV

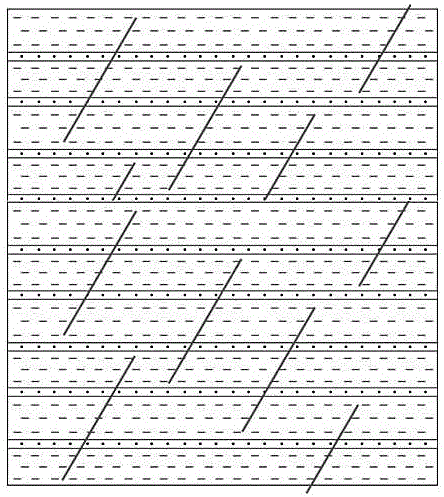

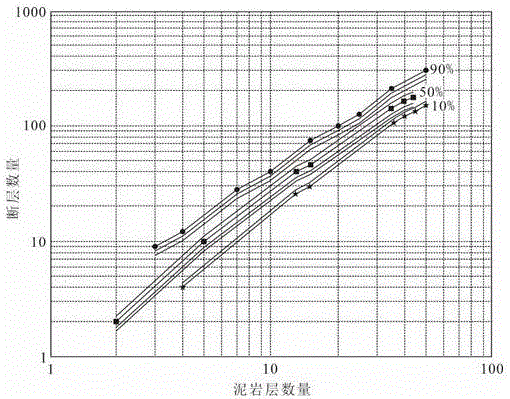

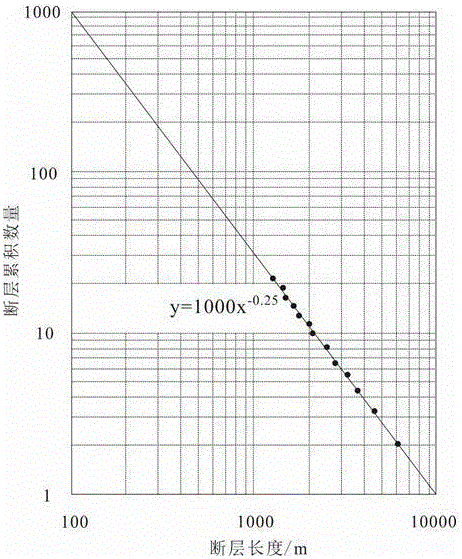

Method for quantitative representation of leakage risk of oil-gas cap rock due to faulting effect

The invention relates to a method for quantitative representation of a leakage risk of oil-gas cap rock due to a faulting effect. The method comprises: establishing a cap rock and fault structure model; drawing a cap rock leakage risk model plate; calculating an effective mudstone layer number; calculating a minimal fault displacement value Tmin needed by an adjacent leakage layer butt joint; predicting the number of faults with the fault displacement value large than the Tmin; and establishing a leakage probability model of a research area and determining a leakage risk. According to the method provided by the invention, because of comprehensive consideration of features of the cap rock and the characteristic of different cap sealing capabilities of different cap rock lithology combined features, the accuracy of the leakage risk determination can be improved and the effectiveness is good. With the method, the probability of the oil-gas cap rock leakage risk resulted from a faulting effect can be calculated in a quantitative mode before drilling, so that the drilling risk can be reduced and the drilling success rate can be improved. Therefore, the method has the great significance in guiding exploitation and development of an oil and gas field.

Owner:NORTHEAST GASOLINEEUM UNIV

Wireless while-drilling compound multipoint instrument

The invention relates to the technical field of a wireless while-drilling testing instrument and in particular relates to a wireless while-drilling compound multipoint instrument comprising a nonmagnetic drill collar, a drill collar joint, a wireless while-drilling instrument, a multipoint probe, a multipoint instrument bin, a pallet buffer and a dropping and fishing self-floating carrier, wherein the outer side of the lower end of the nonmagnetic drill collar is fixedly connected together with the inner side of the upper end of the drill collar joint by virtue of threads; the wireless while-drilling instrument is fixedly arranged in the nonmagnetic drill collar and the drill collar joint; the upper end of the wireless while-drilling instrument is fixedly provided with a wireless while-drilling fishing spear; and the inner side of the lower part of the pallet buffer is in a conical-platform shape with a narrow upper part and a wide lower part. In the wireless while-drilling compound multipoint instrument, the structure is reasonable and compact, and the use is convenient; the drilling-down measurement is carried out by the multipoint instrument of the wireless while-drilling instrument; and after measurement, a fishing device and a buoyancy bin float to a wellhead in a dropping-fishing and self-floating manner; and compared with single-point measurement of the wireless while-drilling instrument, according to the invention, the process drilling up and down is omitted, the drilling efficiency is improved, the drilling risk is reduced, and simultaneously the drilling period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

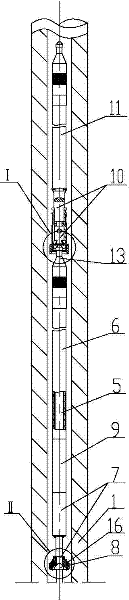

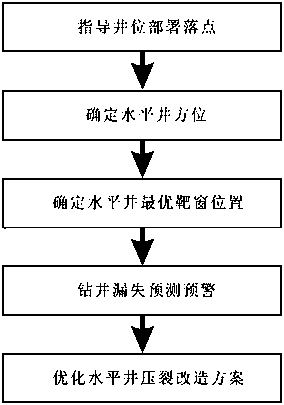

Basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method

InactiveCN110295882AHigh Efficiency DrillingEnsure drilling safetyFluid removalPorosityGeomorphology

The invention relates to a basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method. In the design process, for the characteristics that such as the Southeast Chongqing basin edge transition zone is strong in tectonic deformation, and the geological condition is complex, through superposition evaluation of a structural figure, a burial depth figure, a porosity figure, a gas content figure, a pressure coefficient figure and a curvature figure, geology and engineering optimal dessert areas are optimized, well sites are deployed, the seismic attribute isused for predicting stratum seam hole development situation, interval intvl losing is avoided, the well drilling aging is improved, and through target window and horizontal well orientation optimization and curvature prediction, the reservoir stratum fracturing effect is improved, the reservoir stratum capacity is sufficiently released, the single well economic benefits are improved, the technical support is provided for efficient exploration and development of the basin edge transition zone shale gas, operation is high, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

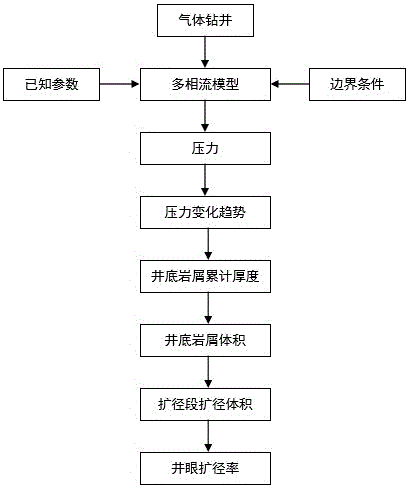

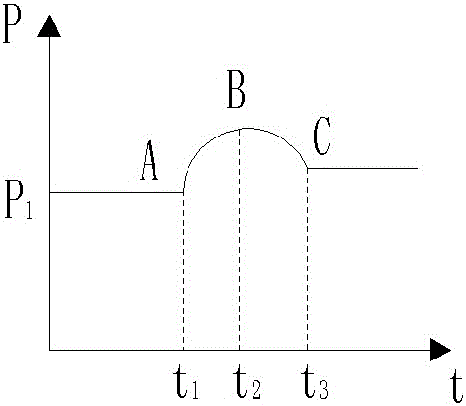

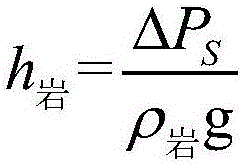

Method for inverting borehole expanding rate based on standpipe pressure change of gas drilling

The invention discloses a method for inverting a borehole expanding rate based on standpipe pressure change of gas drilling. The method comprises the following steps: (1) in a normal drilling process, acquiring a standpipe pressure value of a borehole under a normal condition through a standpipe pressure meter, and reading a standpipe pressure value of an expanded borehole according to the standpipe pressure meter after the borehole is expanded in order to calculate a change value of the standpipe pressure before and after expanding; (2) calculating the accumulation thickness of rock debris at the bottom of a well through the change value of the standpipe pressure before and after expanding; (3) measuring the inner diameter of a casing and the outer diameter of a drilling rod through the known accumulation thickness of the rock debris to obtain the volume of the rock debris at the bottom of the well, namely, the expanding volume of an expanding segment; (4) calculating the volume of an original borehole according to the known mechanical drilling speed, drilling time and borehole radius of a drilling bit in a drilling process; (5) calculating the expanding rate of the borehole. By adopting the method, when the borehole of gas drilling is expanded, relevant information can be acquired immediately, so that specific measures can be taken, the drilling risk is lowered effectively, and loss is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

System for detecting drilling fluids outlet flow

A drilling fluid discharge amount detecting system for oil-gas drilling machine, comprised of a blade wheel, direct current dynamo, casing, buffer port, level gage, controller, display alarm unit and purge valve etc. Drilling fluid discharge amount detecting is realized by controlling speed of the direct current dynamo. The invention is provided with drilling fluid discharge amount measuring and abnormal alarming functions. The purge valve is used for keeping clean of the blade wheel. The drilling fluid discharge amount detecting system of the invention is provided with simple structure, high measurement accuracy and wide detection range, which is specially suitable for small flow detection, It is a new type of instrument for detecting lost circulation and overflow, which reduces well drilling risk.

Owner:刘志国 +1

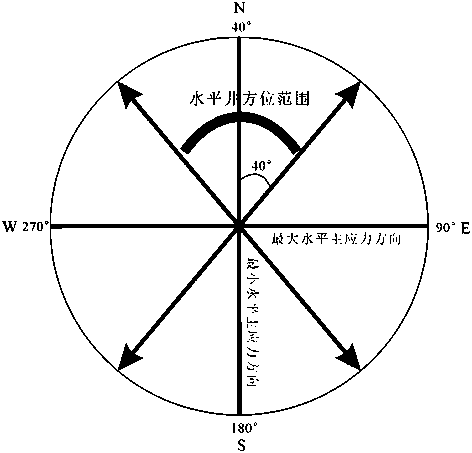

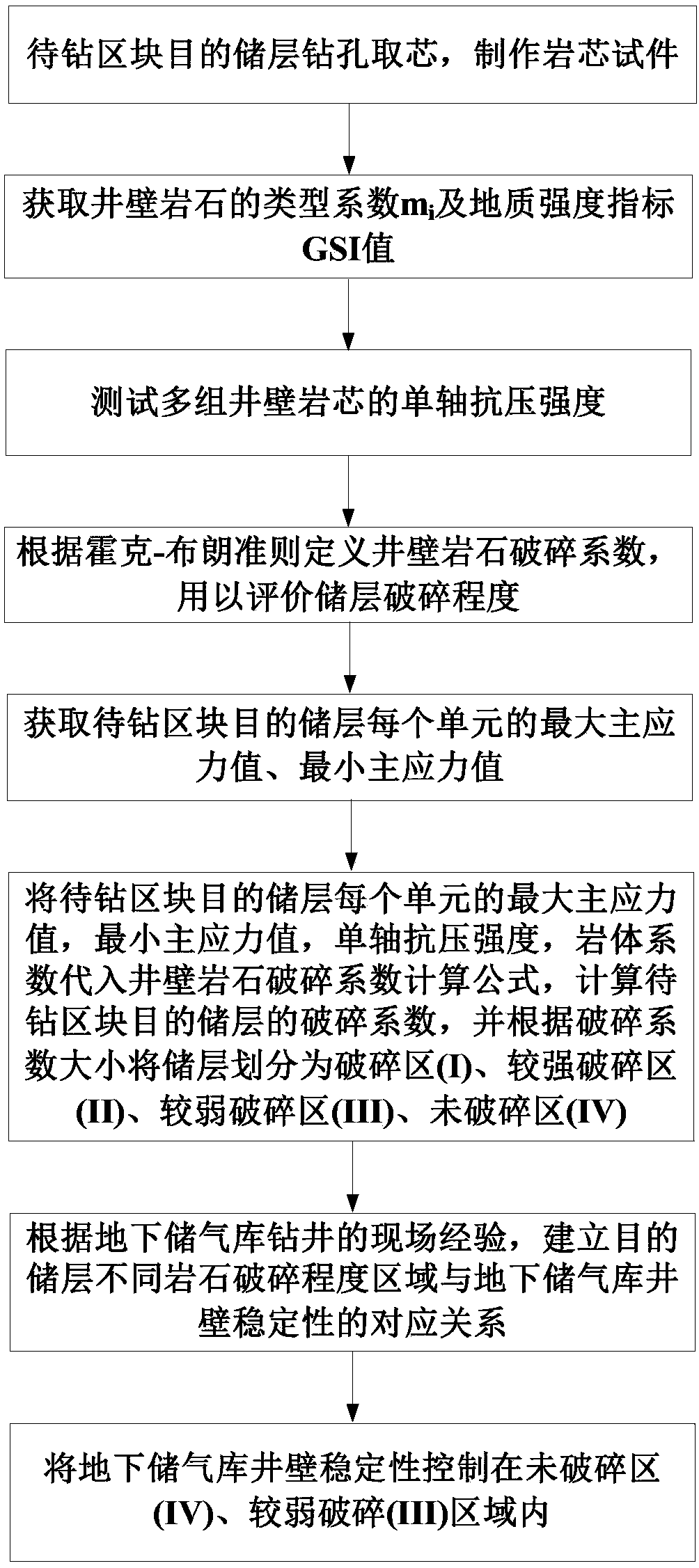

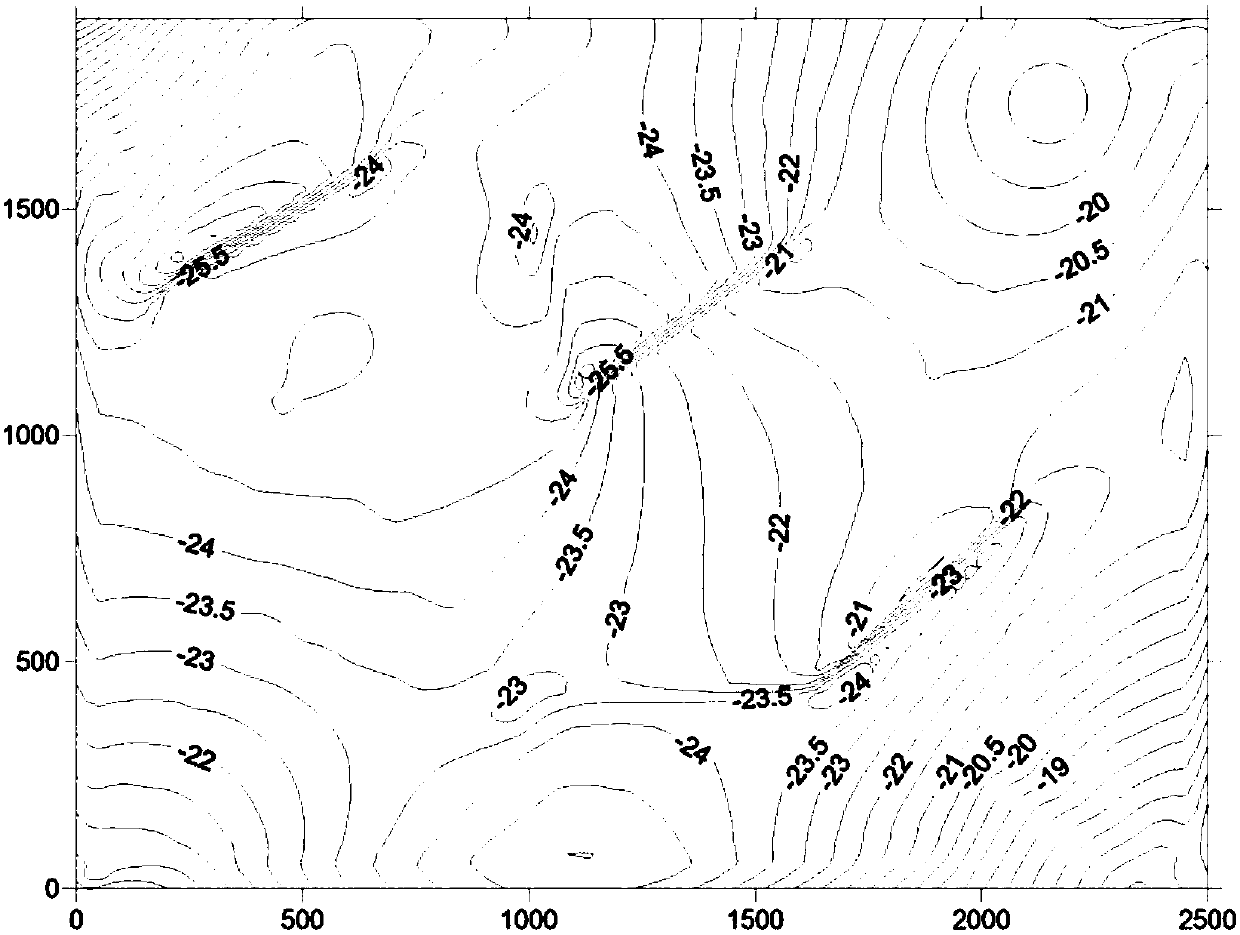

Underground gas storage well wall stability analysis method

InactiveCN107066660APrevention of borehole collapseReduce drilling riskGeometric CADDesign optimisation/simulationPetrologyCore test

The invention discloses an underground gas storage well wall stability analysis method. According to the method, drilling is performed on a destination reservoir in a to-be-drilled block to acquire a rock core, and a type coefficient and a geological strength index of well wall rock are determined; multiple groups of standard cylinder well wall rock core test pieces are made; the mean value of multiple groups of test values is used as well wall rock uniaxial compressive strength of the to-be-drilled block; a well wall rock breaking coefficient formula is defined according to the Hoek-Brown criterion and used for evaluating the reservoir breaking degree; a maximum principal stress value and a minimum principal stress value of each unit of the destination reservoir in the to-be-drilled block are acquired; and the underground gas storage well wall stability is judged according to divided areas with different breaking degrees of the destination reservoir in the to-be-drilled block. When the method is adopted to analyze the underground gas storage well wall stability, the area with a high well wall rock breaking degree can be effectively avoided, and the effects of preventing well wall collapse and lowering the drilling risk can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

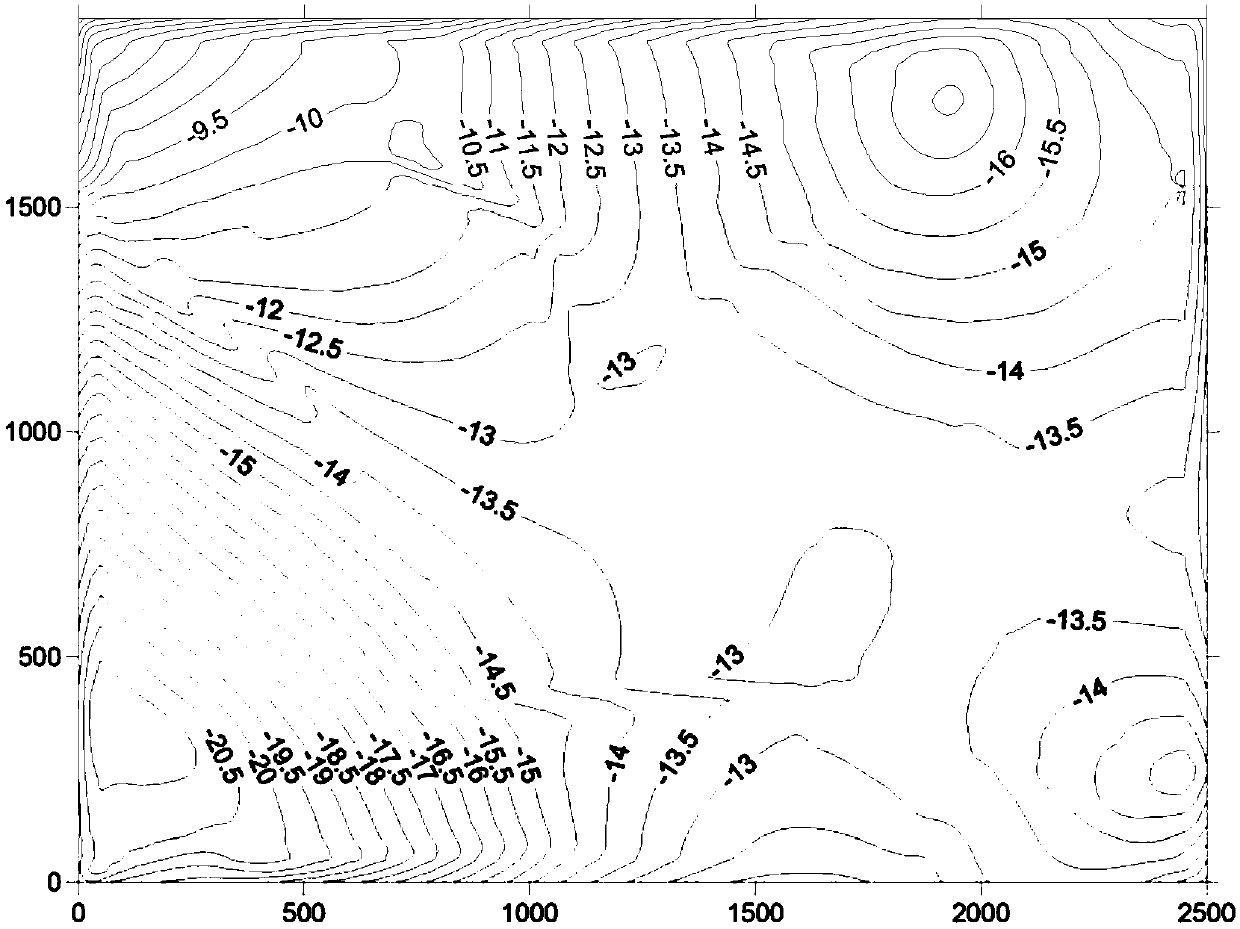

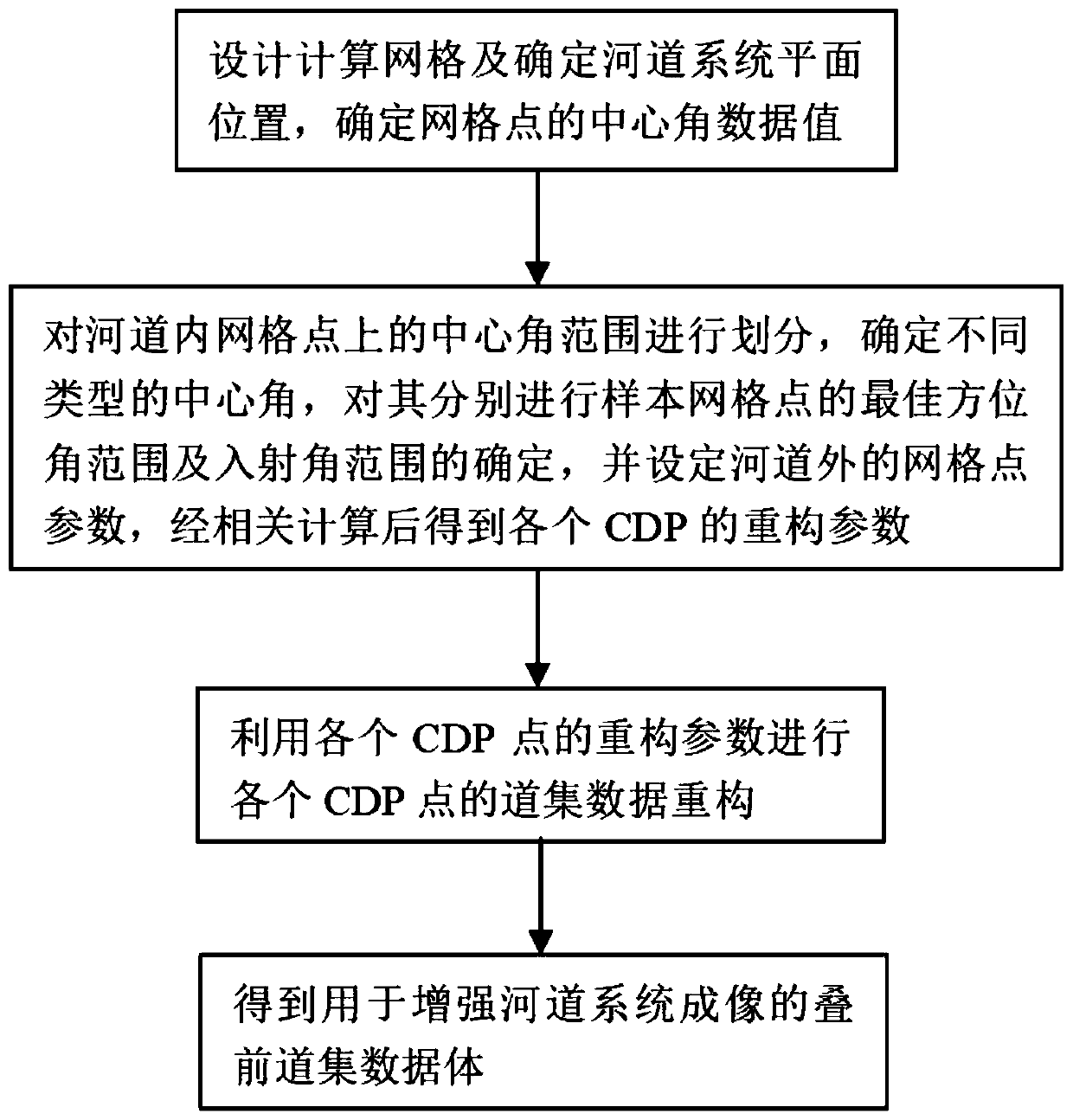

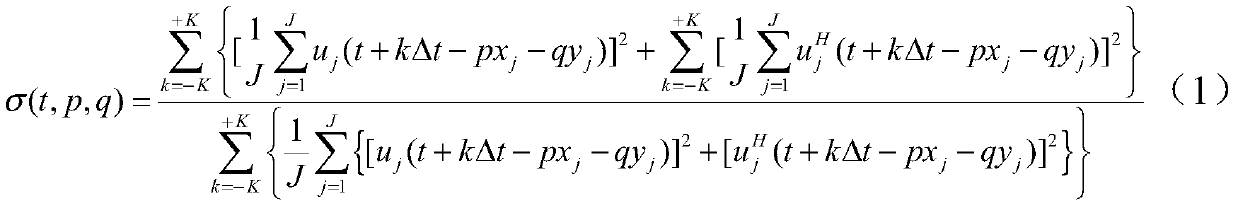

Method for enhancing riverway geological anomalous body imaging based on gather data reconstruction

ActiveCN111399047AImprove exploration efficiencyReduce drilling riskSeismic signal processingEngineeringData reconstruction

The invention provides a method for enhancing riverway geological anomalous body imaging based on gather data reconstruction, and relates to the field of petroleum and natural gas exploration. The method comprises the following steps: (1) designing a calculation grid, determining a riverway plane position, and calculating central angle data values of inner and outer grid points of a riverway; (2)classifying the central angle data on the grid points in the riverway, and calculating the optimal azimuth angle and the incident angle parameters of each type of central angle to obtain gather reconstruction parameters corresponding to each data point; and (3) carrying out data reconstruction on each trace gather data by utilizing the trace gather reconstruction parameters of each data point to obtain the pre-stack gather data volume. Accurate imaging work of the riverway system and the like in a research area is achieved, the position prediction precision of the geological anomalous body ina related exploration area is improved, then the drilling risk is reduced, and the economic benefits of oil and gas exploration of the riverway system are improved.

Owner:四川杰瑞泰克科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com