Drilling fluid leakage prediction method for fissured formation

A prediction method and drilling fluid technology, applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of lack of scientific basis and inability to take leak prevention and plugging measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

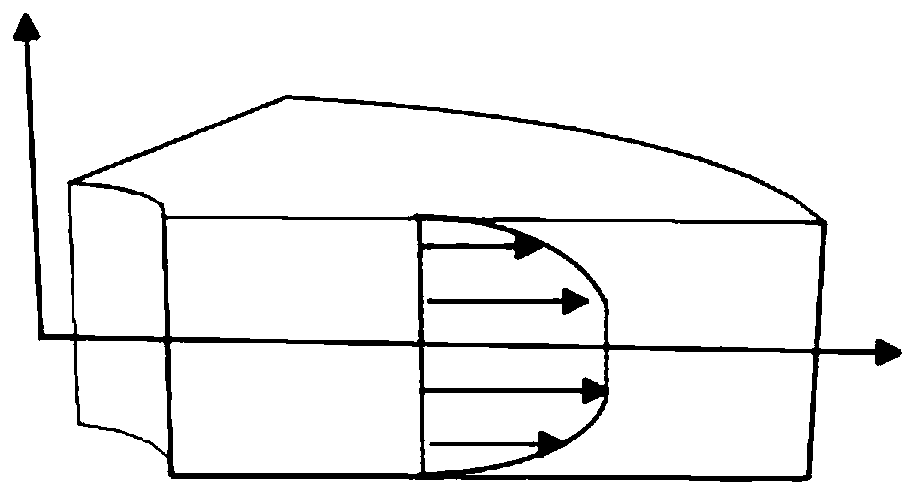

[0083] A method for predicting drilling fluid loss in fractured formations, comprising the following steps:

[0084] A method for predicting drilling fluid loss in fractured formations, comprising the following steps:

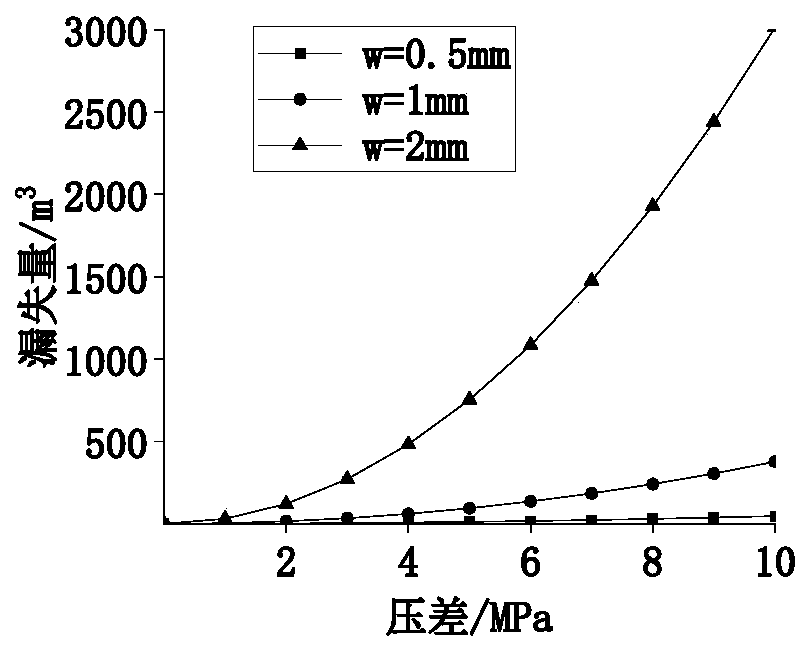

[0085] A. Calculate the width w of various fractures through electrical imaging logging data;

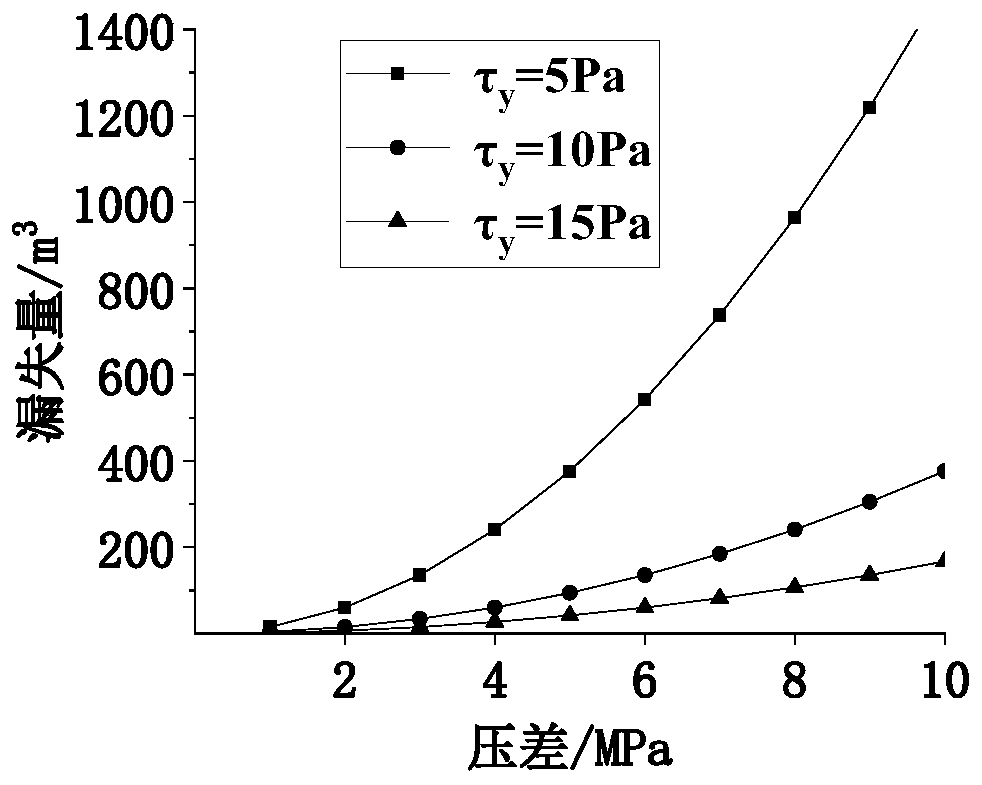

[0086] B. Measure the viscosity coefficient k, flow property index m and yield stress τ of the drilling fluid with a rotational viscometer y ;

[0087] C. Calculate formation pressure p p , specifically, the formation pressure p p ;Select the shale section with shale content greater than 80% on the standard acoustic time difference data, read out the corresponding acoustic time difference value of the well depth at intervals of 5m, and draw points on the semi-logarithmic curve; establish a normal compaction trend line and the normal compaction trend line equation; bring the acoustic time difference on the logging curve into the trend line equation to obtain the e...

Embodiment 2

[0153] A method for predicting the leakage of drilling fluid in fractured formations, the steps are as shown in Example 1, and the parameters required for predicting the leakage of drilling fluid in fractured formations are shown in Table 1

[0154] Table 1: Parameters required to calculate leakage

[0155] parameter parameter value w 0.5mm r w

0.03m r i

1m τ y

10pa·s k 0.1pa·s m

m 0.8 Q 0.1m 3 / s

p w

30MPa P p

20MPa δ 1.8 V lost

235.30m 3

Field practice 221.02m 3

error 6.46%

[0156] Given the parameters in Table 1, the total loss of drilling fluid is calculated according to formula (23), which is 235.30m 3 , the total leakage measured on site is 221.02m 3 , the error is 6.46%, indicating that the drilling fluid loss prediction method of the present invention is not much different from the actual one, and can quantitatively predict the drilling fluid lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com