Line-passing screw drilling tool

A screw drilling tool and line-passing technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of screw drilling tool line-passing, achieve the effects of shortening the length, simplifying the system structure, and reducing drilling risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

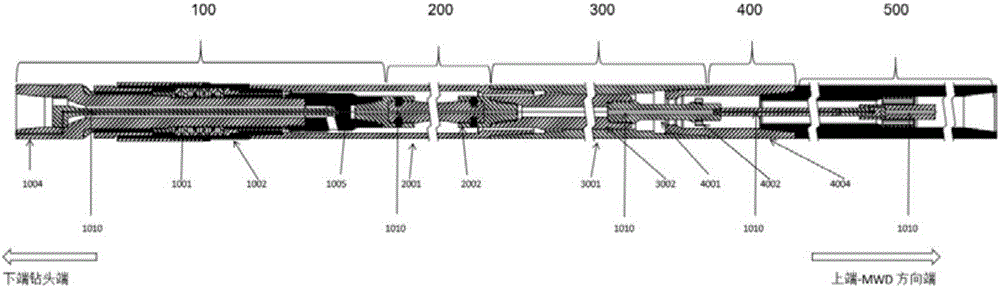

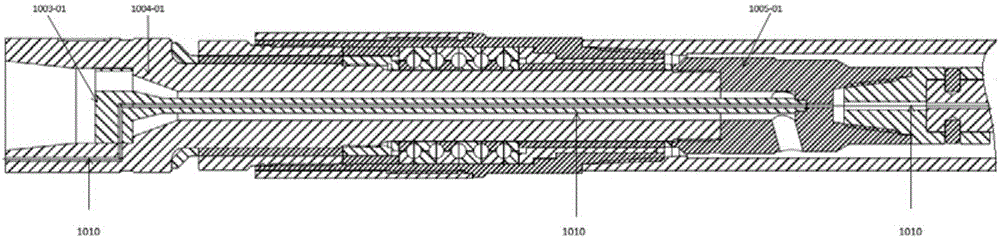

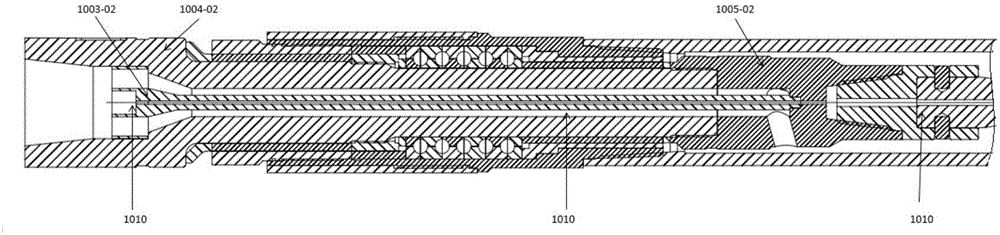

[0049] Such as figure 1 , figure 2 , an over-the-line screw drilling tool, including a transmission assembly 100, a cardan shaft assembly 200, a motor assembly 300, and an anti-drop assembly 400 arranged in sequence:

[0050] Anti-drop assembly 400 includes anti-drop housing 4004, anti-drop shaft 4001 and anti-drop nut 4002, anti-drop housing 4004 is connected with stator housing 3001 of motor assembly 300, and anti-drop nut 4002 is installed on anti-drop shaft 4001 On the top, the anti-drop shaft 4001 is installed inside the anti-drop housing 4004, and the anti-drop shaft 4001 is connected to the rotor 3002 of the motor assembly 300; the anti-drop shaft 4001 is provided with an anti-drop shaft inner hole;

[0051] The motor assembly 300 includes a stator housing 3001 and a rotor 3002. The rotor 3002 is installed in the stator housing 3001. The stator housing 3001 is connected to the housing 2001 of the cardan shaft assembly 200. The rotor 3002 is connected to the cardan sha...

Embodiment 2

[0057] Such as Figure 5 , in this embodiment, on the basis of Embodiment 1, a conversion compensation assembly 500 is also provided, including a wire passing shaft 5001-01, a conductive rotor 5002-01, a conductive stator 5003-01, a centralizer 5004-01, compensation and conductive The device 5005-01 and the conversion compensation housing 5006-01, the compensation and conductive device 5005-01 are installed in the conversion compensation housing 5006-01 through the centralizer 5004-01, the conductive rotor 5002-01 communicates with the conductive stator 5003-01, And installed together in the compensation and conductive device 5005-01, the two ends of the wire shaft 5001-01 are respectively axially connected with the anti-drop shaft 4001 and the conductive rotor 5002-01, and a wire hole is drilled in the middle of the wire shaft 5001-01, and the power supply and After the signal line passes through the line hole, the inside of the compensation and conductive device 5005-01, it ...

Embodiment 3

[0059] Such as Figure 6 , in this embodiment, on the basis of Embodiment 1, a conversion compensation assembly 500 is also provided, including a wire passing shaft 5001-01, a conductive rotor 5002-01, a conductive stator 5003-01, a centralizer 5004-01, compensation and conductive The device 5005-01 and the conversion compensation housing 5006-01, the compensation and conductive device 5005-01 are installed in the conversion compensation housing 5006-01 through the centralizer 5004-01, the conductive rotor 5002-01 communicates with the conductive stator 5003-01, And installed together in the compensation and conductive device 5005-01, the two ends of the wire shaft 5001-01 are respectively axially connected with the anti-drop shaft 4001 and the conductive rotor 5002-01, and a wire hole is drilled in the middle of the wire shaft 5001-01, and the power supply and After the signal line passes through the line hole, compensation and conductive device 5005-01, it is directly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com