System for detecting drilling fluids outlet flow

A technology for outlet flow and detection system, which is used in surveying, earthwork drilling, wellbore/well components, etc., can solve the problems of affecting the measurement accuracy, difficult installation and maintenance, low measurement accuracy, etc., so as to improve the measurement accuracy and reduce the drilling risk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

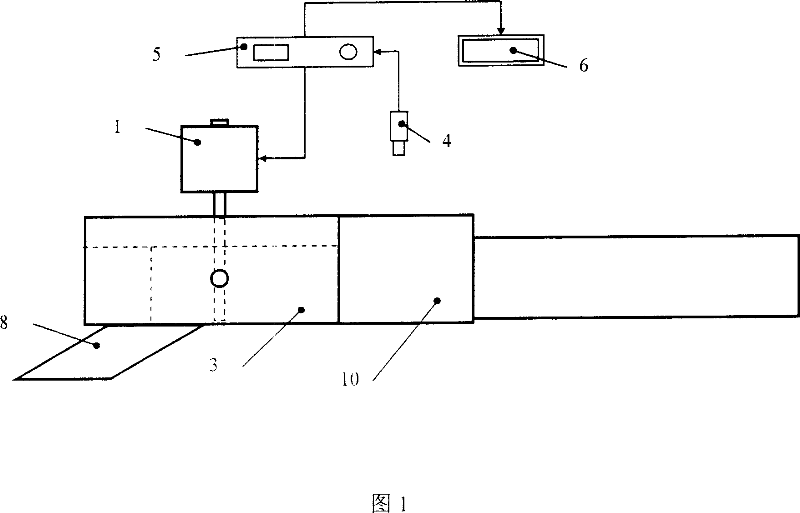

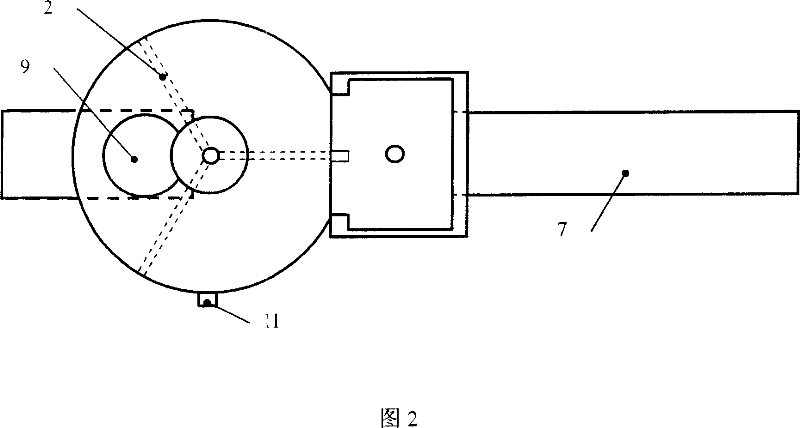

[0015] In the present invention, a multi-blade impeller (2) is installed on the DC servo motor (1). The impeller (2) is installed in the casing (3). A buffer tank (10) is installed downstream of the drilling fluid inlet (7) to buffer the incoming drilling fluid flow so that the liquid level gauge monitors the liquid level. A liquid level gauge (4) is installed above the buffer tank (10). The liquid level gauge (4) is connected with the DC servo motor (1), the controller (5), and the display and alarm unit (6) through a circuit, and is used to complete the measurement, display, and alarm of the drilling fluid flow. The metered fluid flows through the outlet (8) to the vibrating screen. The overflow channel (9) is located on the upper part of (3), and is used for discharging excess fluid in special cases, such as instrument failure or when the flow rate is greater than the upper limit of system measurement.

[0016] The drilling fluid outlet flow detection system of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com