Screw drill tool by-pass valve with large displacement flow dividing function and using method thereof

A technology of screw drilling tools and shunt action, which is applied in the valve device of wellbore/well, earth-moving drilling, special data processing applications, etc. It has the problems of low output speed and torque, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

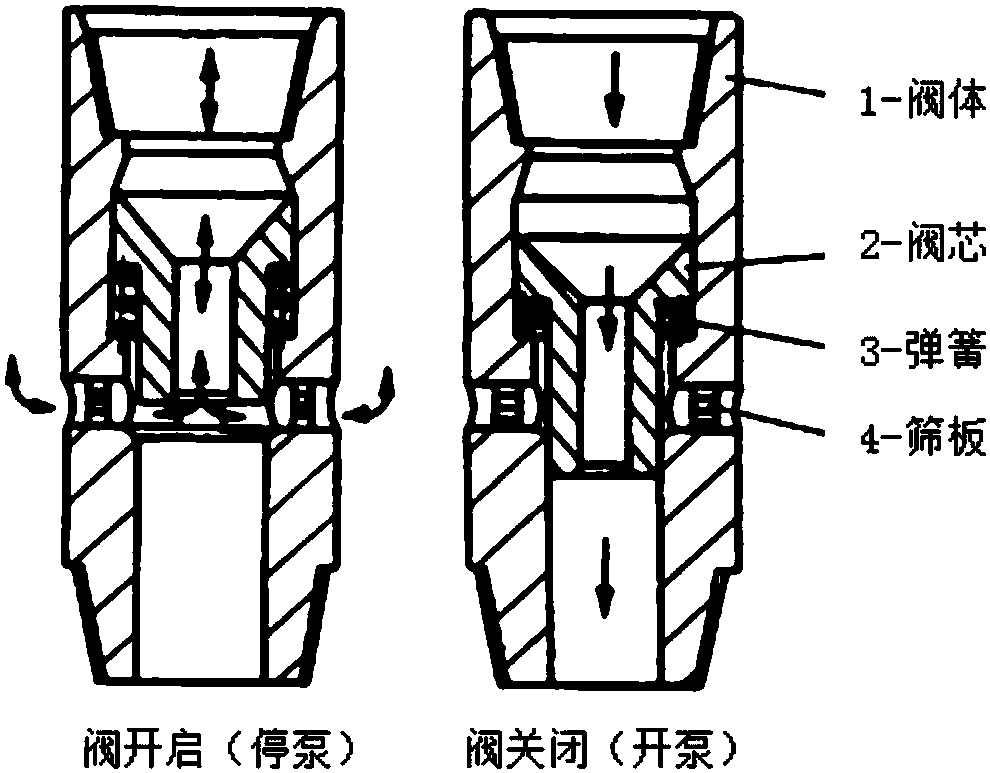

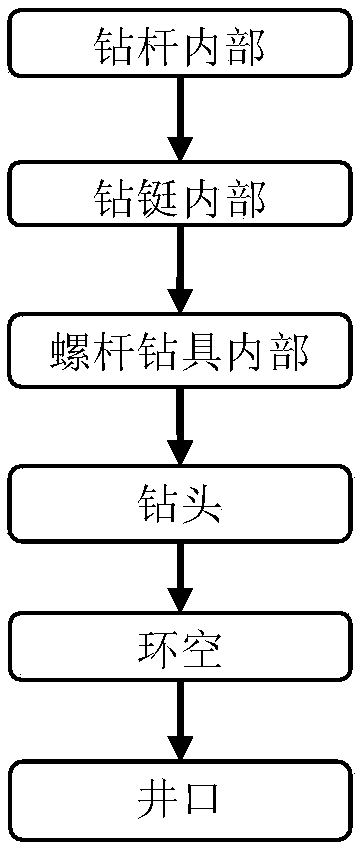

[0072] Aiming at the technical problems that ordinary screw drilling tools are difficult to use for large-displacement circulation drilling, the structure of the hollow rotor screw drilling tool is complex, and the cost is high, the invention provides a design and application of a new screw drilling tool bypass valve with flow diversion function method, large displacement circulation and drilling can be used to replace the existing hollow rotor design, which helps to improve the rock-carrying efficiency of large-scale well sections, highly deviated well sections and horizontal sections, reduce drilling risks and increase drilling speed .

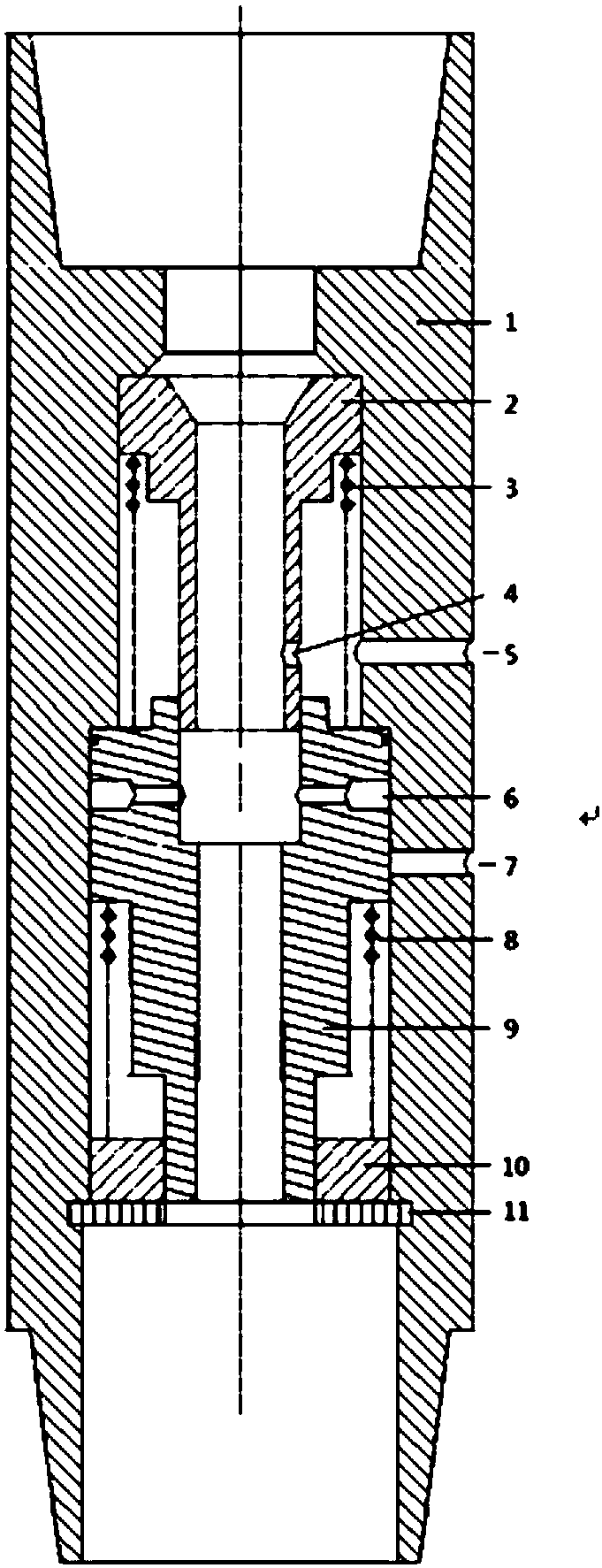

[0073] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0074] Such as figure 2 As shown, a screw drilling tool bypass valve with a large displacement flow diversion function includes a valve body 1, a primary valve core 2 and a secondary valve core 9 are arranged inside the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com