Method for inverting borehole expanding rate based on standpipe pressure change of gas drilling

A technology of gas drilling and diameter expansion rate, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve problems such as well diameter expansion, increased drilling risk, and complex downhole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

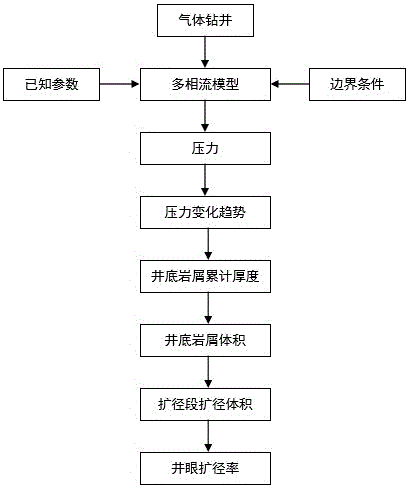

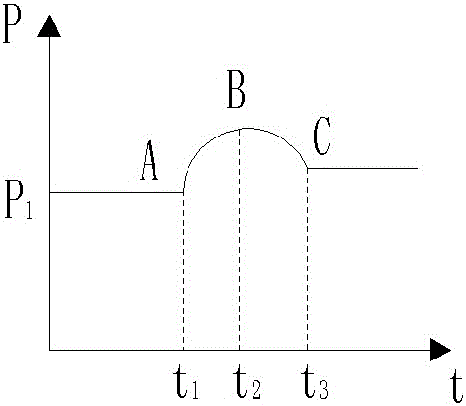

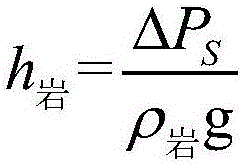

[0042] A method for retrieving the borehole diameter expansion rate based on the change of vertical pressure in gas drilling. The specific steps are as follows: firstly, the vertical pressure value P of the borehole under normal conditions can be obtained by observing the vertical pressure gauge. S1 And the vertical pressure value P after diameter expansion S , so as to obtain the change value of standing pressure ΔP S . Standing pressure change value ΔP S It is equal to the pressure generated by the accumulation of cuttings at the bottom of the well. Density ρ of cuttings obtained by sampling 岩 , the cumulative thickness h of cuttings can be calculated 岩 , so as to obtain the volume V of accumulated cuttings 岩 , the volume of accumulated cuttings V 岩 That is, the expansion volume V of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com