Gas cylinder valve and gas cylinder group

A gas cylinder valve and gas cylinder technology, which is applied to the valve for inflation, lift valve, valve details, etc., can solve the problems of inability to repair, valve seat seal failure, etc., to reduce volume, reduce processing difficulty, and reduce processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

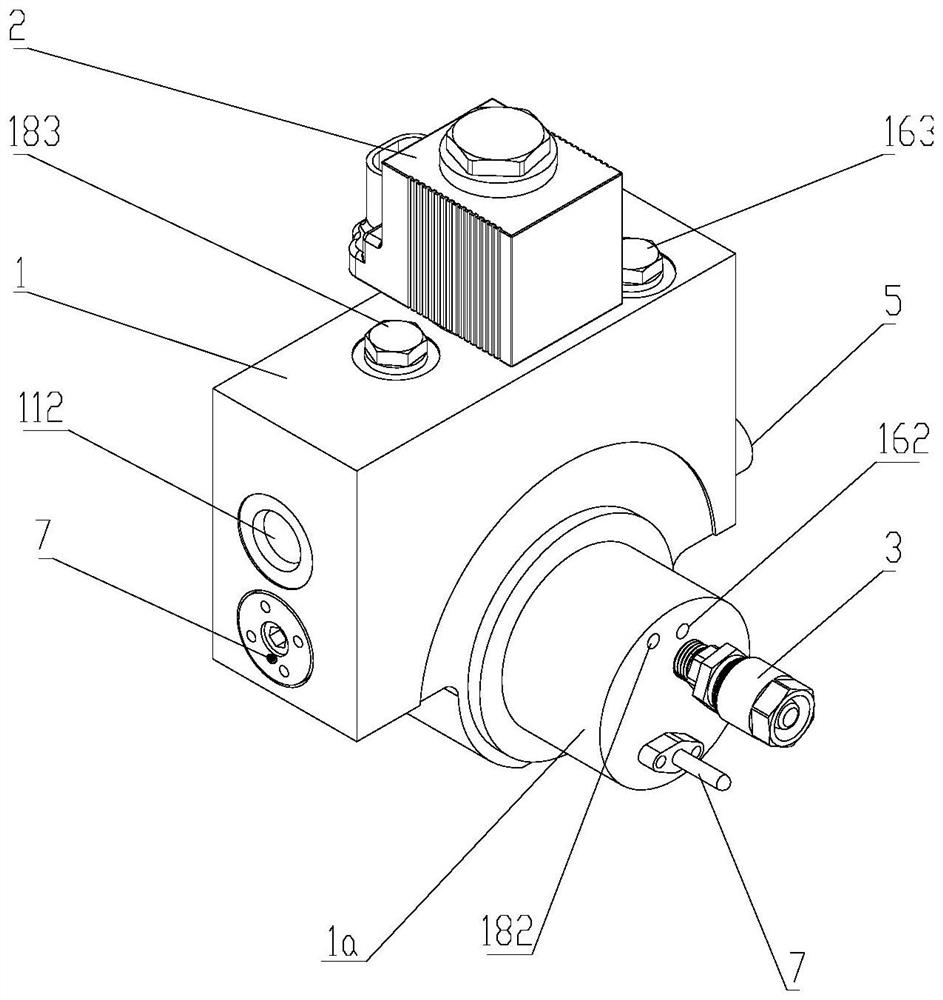

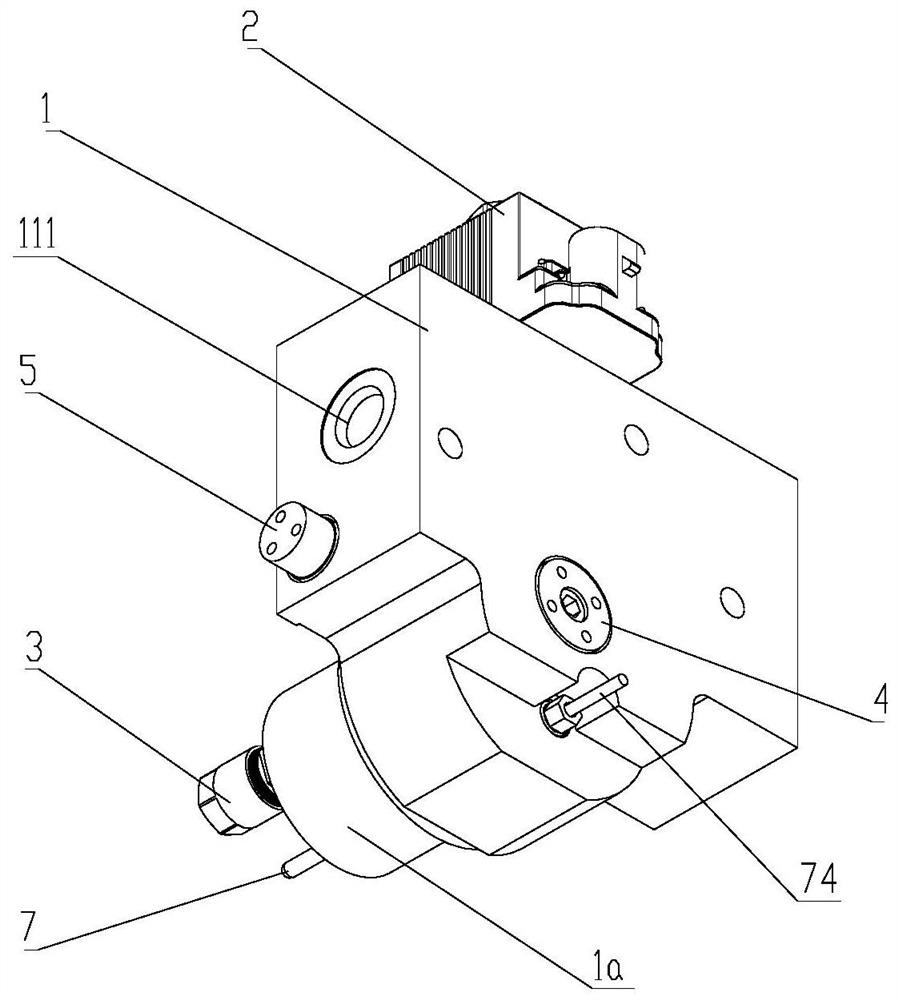

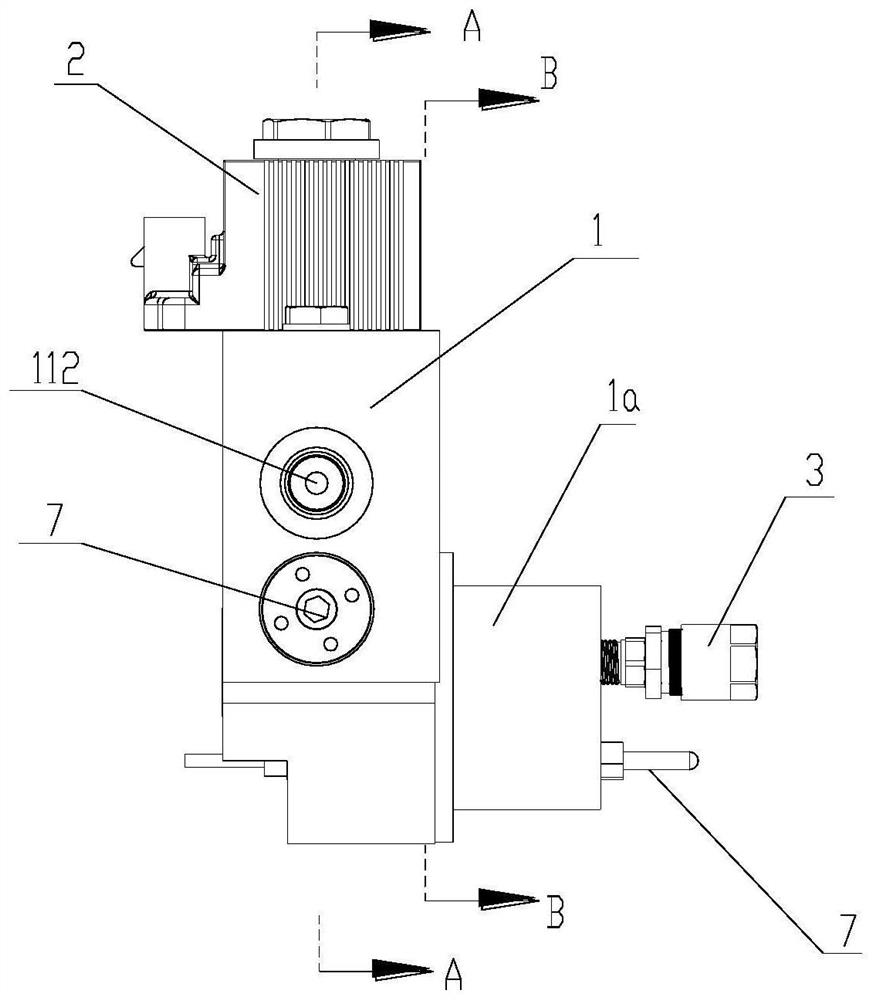

[0044] The invention provides a gas cylinder valve, which is used to be installed at the mouth of the cylinder body of the gas cylinder, such as Figure 1 to Figure 4 As shown, including mounting body 1 and solenoid valve 2.

[0045] The mounting body 1 has a main channel 11 running through both ends thereof, one end of the main channel 11 has an air inlet 111 , and the other end has an air outlet 112 , the air inlet 111 is used to communicate with the upstream of the air inlet 111 The pipeline is provided with a one-way valve (not shown in the figure) that only allows gas to enter the main channel 11, the installation body 1 is also provided with a first valve hole 12, and the first valve hole 12 is connected to the main channel 11. The channels 11 communicate with each other, and the mounting body 1 is further provided with a gas charging and discharging channel 13 for communicating with the inside of the cylinder body of the gas cylinder.

[0046] like Figure 7 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com