Measuring head of pneumatic instrument

A technology of measuring head and pneumatic measuring instrument, applied in the field of machinery, can solve problems such as large error and failure to meet the detection standard of pneumatic measuring instrument, and achieve the effect of solving the problem of drilling pressure and simplifying the process of opening holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

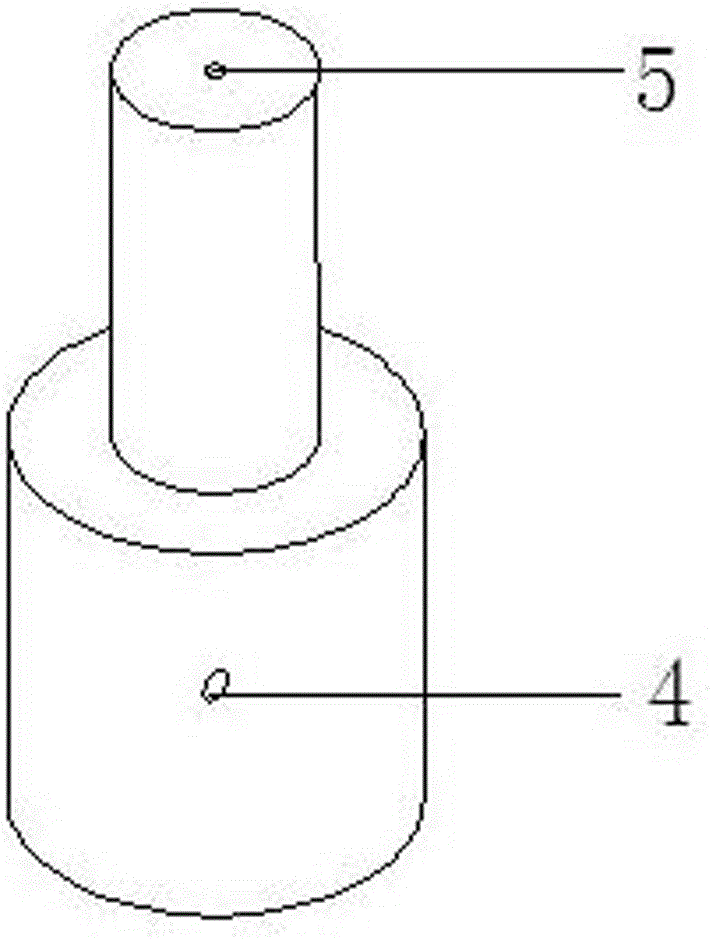

[0019] like figure 1 As shown in the figure, the measuring head of the existing technical pneumatic gauge is an integral inseparable structure, and its vent hole end 5 and vent port 4 must strictly pass through the solid steel member, and must be strictly symmetrical, so when the thickness of the steel member becomes thicker, the machining Accuracy and punch pressure present difficulties.

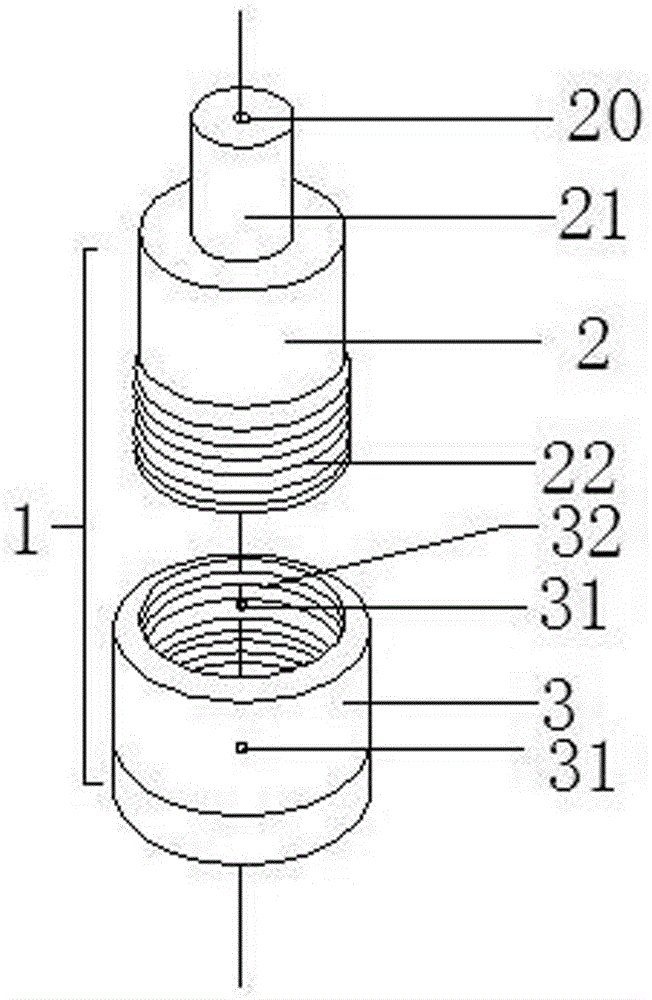

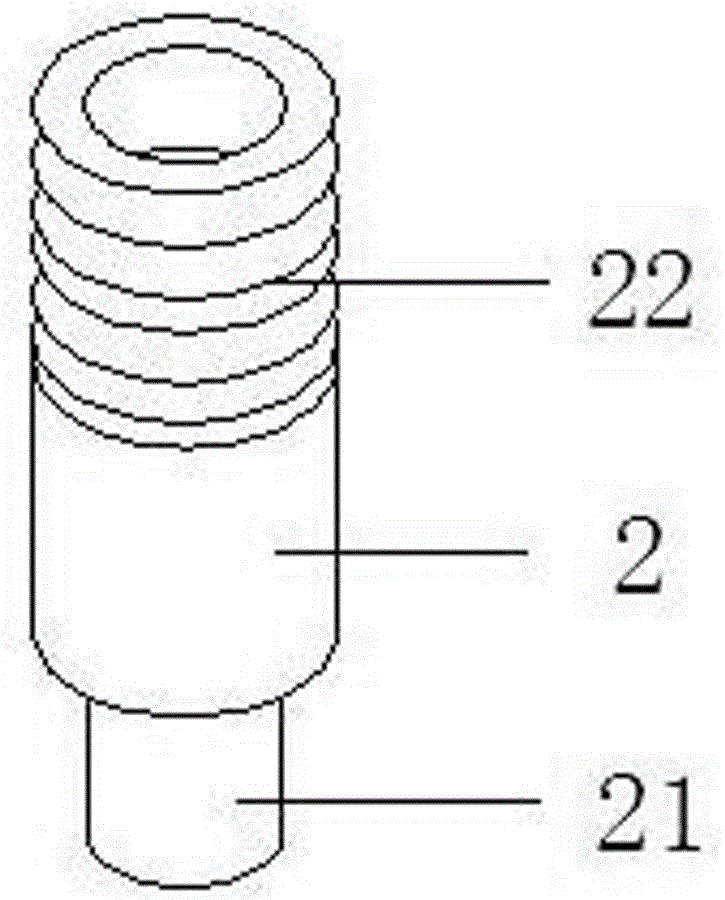

[0020] like figure 2 As shown in -3, a measuring head of a pneumatic measuring instrument of the present invention includes a measuring head body 1, and the measuring head body 1 includes a vent hole end 3 and a vent hole end 2, the vent hole end is slotted, and a pair of symmetrical The ventilation hole 31 is provided with an inner thread 32 in the inner ring of the groove; the ventilation hole end 2 includes an outer thread end 22 and an air inlet end 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com