Gas extraction method for protected layer

A technology for protected layer and gas drainage, applied in gas discharge, mining equipment, earth-moving drilling, etc., can solve problems such as hidden safety hazards and low efficiency, save construction costs, simplify drilling construction process, and improve drilling The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

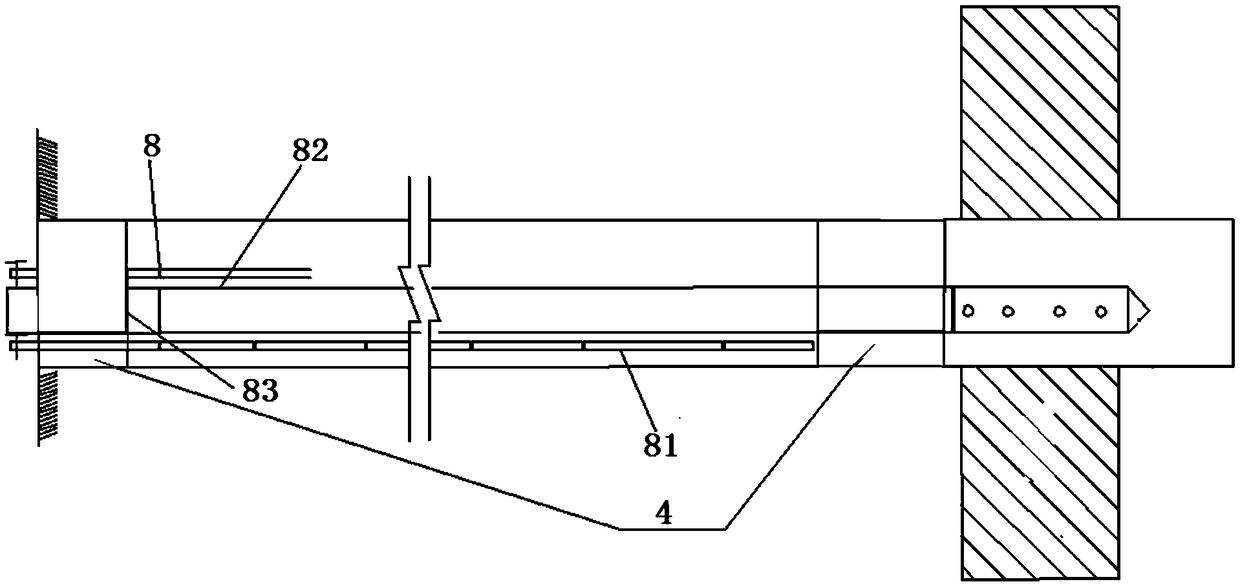

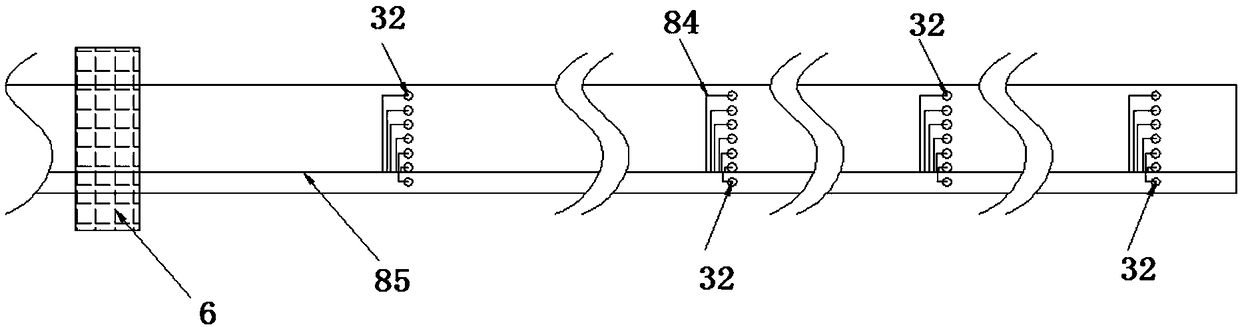

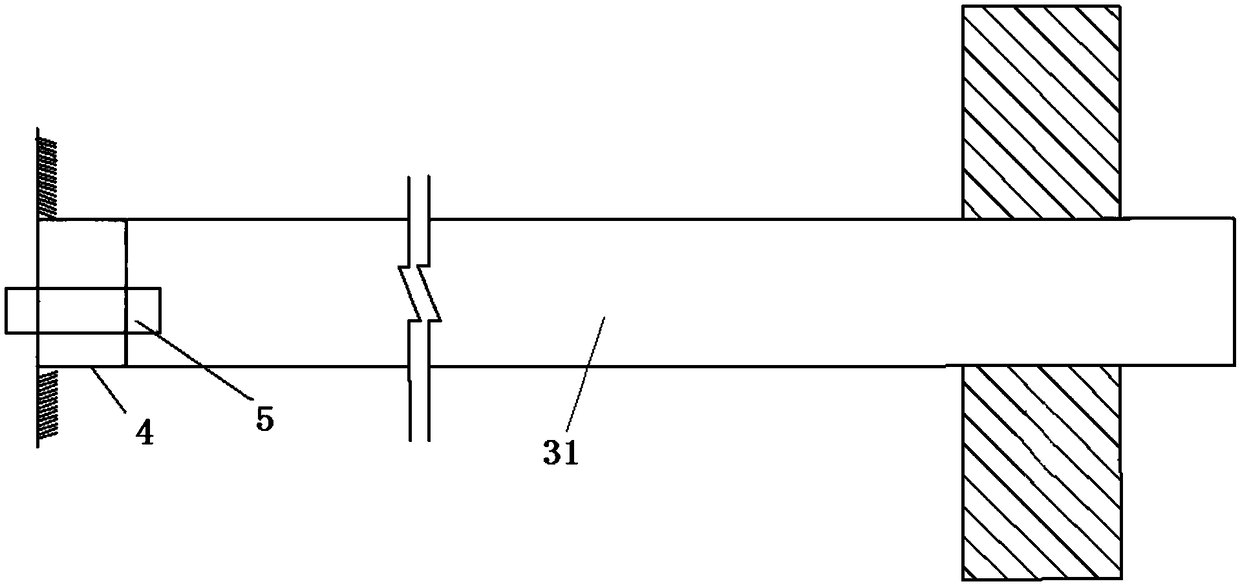

[0031] Such as Figure 2-3 As shown, the present invention discloses a method for gas drainage in the protected layer, which includes the following steps:

[0032] (1) Construct the floor roadway 3 on the bottom plate of the protected layer, and construct the layer-penetrating drilling 31 in the floor roadway 3. The layer-penetrating drilling holes 31 can be multiple groups and multiple, and the layer-penetrating drilling holes 31 pass through the protected layer, and Seal the opening of the layer-penetrating hole 31 and reserve the sealing pipe 5, which connects the layer-penetrating hole 31 and the floor roadway 3, so that the gas in the protected layer can enter the floor roadway along the layer-penetrating hole 31 3. Use polyurethane to fix the sealing pipe 5 at the opening of the layer-penetrating drilling hole. The length of the sealing section is 2-4m, and the sealing pipe 5 is a 2-inch PVC pipe, such as a double-resistant solid pipe. To extract the gas from the protec...

Embodiment 2

[0039] The difference between the second embodiment and the first embodiment is that the distance between the pressure relief boreholes of each group is 30 meters.

Embodiment 3

[0041] The difference between the second embodiment and the first embodiment is that the distance between the pressure relief boreholes of each group is 40 meters.

[0042] The 1122(1) and 1123(1) working faces are located in the Dongyi 11-2(2) mining area of Zhangji Mine (Central District), and the corresponding protected layer working faces belong to Dongyi 13-1(2) ) mining area, and the gas content, gas pressure and coal seam elevation are basically similar.

[0043] (1) Implementation effect:

[0044] The protected layer 1122(3) floor roadway corresponding to the 1122(1) working face adopts the traditional drilling sealing, stubble and extraction mode, and the protected layer 1123(3) floor roadway corresponding to the 1123(1) adopts drilling The new technology of "naked sealing" and "naked pumping" in the roadway is now intercepted and compared with the relevant data during the normal recovery period of the 1122(1) and 1123(1) working faces as follows:

[0045] 1122(3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com